And so, in January 1938, here I was seated in my Spartan little office in Nightingale Road, Derby. After a few days, I resolved that I must end my isolation and go forth to explore the surroundings. I discovered that just across the corridor was a door marked ‘Library’, so in I went and found the Librarian very friendly and helpful. He explained the surrounding geography, and who was who.

The overall Chief Engineer was A. G. Elliott, who was primarily a design engineer, and had been Royce’s right-hand man for many years. Under him were Barrington as Chief Designer, and Jimmy Ellor as Chief Experimental Engineer. All people who designed and made drawings were responsible to Barrington, and all people who tested engines and components or did other experimental work were responsible to Ellor. The information that Ellor’s department produced was fed to the Design department, who incorporated it into modified designs to improve the engines.

Since I knew nothing of design, it was clear that I must direct my attention to the work being done in the Experimental Department. So, one afternoon after lunch, I took my courage in both hands, and wandered diffidently into the next office, which I knew housed the engineers responsible for testing the single-cylinder research engines. In it were about half-a-dozen highly efficient-looking young men, all busy at reports or examining blueprints. Over in the corner sat a quiet grey-haired man gazing into space, and since he looked the most innocuous, I went over and asked him what he did. He replied, ‘I am in charge of testing superchargers’.

‘What does that mean?’, I asked.

‘Well, we have a rig back there in the test area, driven by two electric motors each of 250 horsepower, on which we can drive a test supercharger, and measure its performance independently of the engine. In fact, this is a typical set of curves that we get’.

He picked up a bunch of sheets from his desk, and showed them to me. Plotted on them was the amount of air that the supercharger pumped, the pressure it produced, and the temperature rise of the air due to its compression.

I asked, ‘Could I borrow one of these curves?’ ‘Certainly’, he replied, ‘take a complete set’.

I bore them back in triumph to my office. By the grace of God I had stumbled on the one man whose job it was to produce test results which were right up my street, namely, the flow and compression of air.

I was not to know that Hs, under advice from Llewellyn Smith, had given instructions that I was to be left to soak in the atmosphere of Rolls-Royce for the time being, in the hope that I would find my own feet in an area to which I could contribute. His attitude was that I was not to be deviated into any routine task until I had had a chance to settle down, and get some idea of what went on. And, although I felt neglected, it happened in just the way he had hoped.

I had never even seen a supercharger, and had no idea how it managed to compress air by centrifugal action. I rushed to the Library and borrowed two books, The Internal Combustion Engine, by D. R. Pye and Stodola’s great work on Steam Turbines. Both contained chapters on the elementary theory of centrifugal compression, and I was soon able to compare the theory with the experimental results which Frank Allen had given me. There were wide disagreements.

In both Stodola and Pye the theory was very sketchy, and I was soon able to extend it to include the separate efficiencies of the rotor and the diffuser. Briefly, a centrifugal supercharger consists of a rotor carrying a number of equally spaced radial vanes. In the case of the Merlin supercharger, which I was examining, the rotor was 10.25 in (260 mm) in diameter and had 16 vanes. It was driven by the engine through a step-up gear, and revolved at 28,000 rpm. The air entered at the centre of the rotor, moved out radially under the centrifugal force, and was flung off the rim into a stationary 12-vaned diffuser, the object of which was to convert the velocity of the air into the pressure which forced greater masses of air into the cylinders of the engine.

If one thinks of the cylinders and pistons of an engine as the heart which converts the force of the burning air and petrol mixture into mechanical power by the downward motion of the piston, then the supercharger is the lungs of the engine, and by its efficiency controls the power output.

Clearly, the efficiency of the supercharger depends upon the efficiency of its component parts — the rotor and the diffuser — and to get the best results the maximum efficiency of the rotor must be made to coincide with the maximum efficiency of the diffuser. I found, by mathematical analysis and much to my surprise, that this happy coincidence did not occur on the Merlin supercharger, and that changes to both the rotor and diffuser were necessary. I even computed that the efficiency of the supercharger would improve from the existing 65 per cent to a new level of 75 per cent by such changes, but could it be true? How could the great Rolls-Royce firm have missed this?

I checked and rechecked my calculations over the following weeks, and became very fluent in the aerodynamics of the supercharger. I could find no flaw in my deductions. So I took my courage in both hands and persuaded A. G. Elliott’s secretary to type the report for me. With great diffidence I appeared in Elliott’s office and handed it to him. He casually glanced through it, and said,

‘This looks very interesting, I must send a copy to Mr Ellor’.

I learned later that Ellor’s speciality was superchargers, and that he had come to Rolls-Royce from the Royal Aircraft Establishment at Farnborough, some ten years previously. He had been responsible for the giant supercharger on the famous ‘R’ engines which won the Schneider Trophy in Mitchell’s Supermarine S.6 and S.6B seaplanes.

I returned to my office wondering what would happen next. Interminable days went by. Then suddenly, one evening just as I was leaving my office, the door burst open and in came the great Ellor himself. He had in his hand my report, and my heart came to my mouth.

‘Did you write this?’, he asked abruptly. I admitted to being the culprit, and then smiling broadly he said,

‘Well done, jolly good stuff. From now on you are in charge of supercharger development’, and he shook me warmly by the hand and departed!

The bleak depression of the preceeding weeks lifted like magic, and I drove home elated. I had no idea what it all meant, but doubtless in good time all would be revealed to me. The casual way Ellor had informed me could only be a preliminary before a proper ceremony of appointment at which my duties would be explained to me, and amidst the applause of the assembled company, I would descend to take up my office — or so I imagined!

But not a bit of it. Life went on unchanged. Then a couple of days later a fine upstanding young man with red hair called on me and said,

‘My name is Doug Nelson. I hear that you are my new boss’.

I smiled at him warily, and replied,

‘That must have been as big a surprise to you as it is to me’.

‘Not really’, he said, ‘you see I have just read your report and I wish that I could have written it’.

There wasn’t a trace of jealousy, rancour or disdain in him as we warmly shook hands. I invited him to sit on my empty desk and describe the set-up to me. I remember thinking of W. S. Gilbert’s attractive line, ‘Tell me, pretty maiden, are there any more at home like you’? He said there were a few, including ‘Prof’ Allen who sat in the office next door, and who had given me the original set of curves.

Frank Allen was really an electrical expert, and had been chosen because the governing arrangement on the electric motors which drove the supercharger test rig was the Ward-Leonard system, which only he understood. It was his duty, also, to compare successive tests to see if, by chance, any improvement in performance had been effected. But Doug Nelson told me that the supercharger for the Merlin III, which was the current production engine for the Hurricane and Spitfire fighters, had not been changed since its original design in 1934.

Let me hasten to add that the Merlin III supercharger was easily the best in the world at that time, as I was to discover later when I became more knowledgeable about the performance of contemporary superchargers in Germany and the USA.

The other members of the team, Nelson went on, were Frank Barnes and Frank Nicholls who operated the test rig and produced the experimental data. Any modification to the supercharger was designed by ‘Flap’ Fletcher’s section, but they belonged to the Main Engine Design Department, and it was Nelson’s responsibility to act as the link between the Design Office and the Experimental Workshop to ensure that the superchargers were built to the specified test standard.

At this stage I had to admit to Nelson that I had never seen a supercharger in the flesh. He immediately offered to take me on a tour of inspection, a suggestion I welcomed with open arms. We left the office block by the back door which led along a short corridor into the Experimental Workshop, which was the kingdom of one Horace Percival Smith, or HPS. He was a complete autocrat. He allowed no one into his shop except on a ‘need to be there’ basis. We made a courtesy call on him, and found him seated at a table covered with blueprints. By his side was the longest array of pushbuttons I had ever seen.

He looked up. ‘Yes, yes, yes, what do you want, what do you want?’, he barked abruptly in his repetitive style. Nelson explained that I was the new man in charge of supercharger development, whereupon he pressed a couple of buttons, and almost instantaneously two men in overalls burst into the office. ‘This is Roy Speed, who is in charge of the supercharger assembly, and his assistant’. He then turned to them and said ‘You now take your instructions from this man, and he is to be allowed into the Shop at all times’. Then he smiled and we all shook hands.

The informality of the whole thing astounded me. I had yet to learn of the tremendous esprit-de-corps that existed between the engineers and the Experimental Workshop, and the single-minded purpose of all to work together with energy and harmony to improve Rolls-Royce engines. It was enough for them to know that I had been appointed for me to be accepted.

HPS was an impressive character. He was well dressed, with his hair parted exactly in the middle and well smoothed with hair-cream. He wore thick horn-rimmed glasses and oozed authority and efficiency. The whole workshop stood in ‘awesome’ respect for him, and men were prepared to work day and night at his command. Little did I know that the time was to come when HPS on passing my office would open the door, put his head in and bark rapidly,

‘What do you want me to make. What do you want me to make?’, and leave.

The greatest privilege that one could enjoy in Rolls-Royce was the right — which had to be earned — of entry direct to HPS with a request for something to be made. Woe betide you if you wasted the great man’s time on something trivial.

The four of us backed rapidly out of his office, like schoolboys leaving the Headmaster’s study after clemency. Roy Speed laughed and said,

‘Thank God it was only to meet you. I thought I must have put my foot in it somewhere. What do you want, anyway’.

I threw caution to the winds and said could I please see a supercharger.

‘Which supercharger’, he replied, ‘I’ve got half-a-dozen over there that I’m building’.

I said, ‘Any one will do, because I’ve never seen one before’.

The two shop-men gazed at one another in amazement. They then led the way into the largest workshop that I had ever been in. On the right were the machine tools in rows upon rows, each with its busy operator. On the left was a fenced-off area equipped with large benches on which were laid out components of stripped down aero engines, each bench labelled with its engine number, while inspectors equipped with micrometers, clock-gauges and magnifying glasses pored over the component parts looking for cracks and measuring wear or other deficiences arising from the last test of the engine. The whole place hummed with activity.

We passed through the shop to the further end where the engines were built for experimental test. Roy Speed went up to one and laid a hand on it. ‘This here’, he said ‘is a Merlin engine. This is the front end where the propeller is bolted on, and this contraption on the back end is the supercharger with the gears that drive it’.

My mind boggled as I looked at my end, with, as I could read, its SU carburettor, and rods and levers operating the throttles. I felt I ought to say something intelligent, and stuttered,

‘What is the power of the Merlin’?

He lapsed automatically into the lilt of Eskimo Nell:

‘It has the driving force of a thousand horse … and it’s your job to make it do better. Nobody has managed to do that yet, so the best of British luck to you’.

We both laughed, he confidently and I nervously.

An apprehensive Nelson said, ‘Come on, don’t let’s hang about here or Horace will jump down our necks for holding up the work. I am going to take you now to see the test rig’.

We left by the side doors and turned left down the wide driveway between two rows of workshops. I suppose it was about a quarter of a mile before we turned right and came to the experimental test beds, where engines were roaring away, belching flames and fumes from their short exhaust pipes.

The test beds were of the simplest and crudest form, open at each end, with a small cubby-hole for the driver and his instruments. The noise was absolutely tremendous and everything seemed to vibrate — even one’s chest. And yet testers were leaning over each engine while it was running at full power, making sundry adjustments with no protection other than small ear plugs. I watched one take a short piece of steel between his teeth and put the other end on the cylinder block of an engine running at full throttle. In this way he could detect the onset of ‘detonation’ in the cylinders. A detonating engine could be self-destructive by literally hammering small holes in the cylinder head and pistons.

The main object of experimental testing was to run the engine to the point of destruction, and thus determine the weakest and most vulnerable components, which would then, subsequently, be strengthened by design action. Testers were so skilled that they could detect the slightest change in an engine’s note - even when dozing in the tester’s cabin. In this way they would save many engines from ‘blowing up’, and thus preserve valuable evidence from being destroyed. Their simple philosophy was ‘We will test the engine as soon as you give it to us, be it morning, noon or night, weekends or holidays’. They were the tough-guys of the factory.

That morning we passed them by, and entered a small building where, in its polished pristine glory, was the Supercharger Test Rig. It consisted of two electric motors in line, each of 250 horsepower. Between the two motors was the control panel, which enabled each to be run at any desired speed, or the motors could be coupled together as one unit of 500 horsepower. The extreme ends of the two motors were arranged to accommodate a supercharger, so that two tests could be made simultaneously if desired. All around were the manometers and pressure gauges for recording the performance.

I was received with great respect by the Chief Tester, Frank Barnes, and his assistant, Frank Nicholls, who had already heard of my appointment. I felt at home immediately in these surroundings. This was not a factory but a laboratory, and I could recognise the measuring apparatus and soon grasped the set-up. My spirits rose, and with them my confidence. This was my laboratory, and although I knew nothing as yet of the mechanical arrangement of the supercharger, I could easily understand the test apparatus. The data it produced in terms of airflow, air pressure and temperature were something I could handle with ease.

I returned to my office well satisfied, and indeed thrilled, by the morning’s tour. I was very happy at the co-operation I had received all round.

Doug Nelson said, ‘Do you want me to get you some drawings of the Merlin blower?’

I took the plunge, ‘Certainly, which can I have?’

He returned with a cross-sectional general arrangement, and drawings of the rotor, diffuser and other components. I spread them out on my desk, and found to my surprise that I had little difficulty in interpreting them. I put this down to Professor Levy’s insistence that the mathematical students at Imperial College should take a course in projective geometry, and thereby learn the elements of drawing and of projecting sections.

And thus it was, as a Junior Section Leader, that I put my foot on the first rung of the engineering ladder in Rolls-Royce. This step was to take me some 30 years later, through many vicissitudes and trials, to the ‘plum’ job in Engineering, that of being the Chief Engineer and Technical Director.

When I had travelled to Derby for the interview with Hs, I had gone by car. On the return journey, about 10 miles south of Derby I noticed a sign off to the right which said ‘Donington Hall Residential Hotel’. I was committed to Rolls-Royce, so decided to make a detour and explore this place. Donington Hall proved to be a magnificent country mansion situated just outside the attractive village of Castle Donington, by today’s East Midlands Airport. The Hall had a large park around it, which included the famous Castle Donington motor-racing circuit, and one could walk for miles through the splendid grounds of this country estate. There was even a nine-hole golf course which I enjoyed very much. The Hall itself was only sparsely furnished, and the space available to the few residents was enormous. The bedrooms were very large, and one had been converted to four or five bathrooms.

Since the weekly charge covering bed, breakfast and dinner was only £3, it seemed an ideal place, particularly as the works was on the south side of Derby, and so I booked in as from January 1938. I discovered that there were three other members from Rolls-Royce in residence; Cyril Lovesey, who was a small dapper man about 40 years old; Christopher Ainsworth-Davis; and Francis Tudor Wayne, who was an efficiency consultant seconded to Rolls-Royce at the time. There were three other residents, an Army captain who was in charge of the Army Depot nearby, the local bank manager, and an ex-Naval commander. Altogether, they made an interesting and amusing bunch.

For some time I had no idea what Lovesey and Ainsworth-Davis did in Rolls-Royce, but eventually I discovered that Lovesey was a real king-pin: Deputy Chief Experimental Engineer under Ellor. He had been in the RAF at the end of World War I, had taken a degree in Engineering at Bristol University, and then joined Rolls-Royce. He had been the man in charge of the ‘R’ engines which won the Schneider Trophy in 1929 and 1931, and then held the world air speed record at 408 mph (657 km/h). He was a man of great experience in mechanical engineeering, and was affectionately known in the firm as Lov.

Ainsworth-Davis was a junior engine designer at the time, and was being trained in Rubbra’s office to the special standards required by Rolls-Royce, and which had been inherited from the natural genius of Royce himself, who seemed to have known instinctively what constituted good sound design. Sir Henry Royce had died in 1933, but his methods and principles lived on through his protégés Elliott and Rubbra.

The friendship and partnership between the Hon Charles S. Rolls and the self-made engineer Henry Royce which began at the beginning of the century was, indeed, an event of great portent.

Rolls, the young sporting aristocrat, hailed from Monmouth, and was educated at Eton and Cambridge where, in 1898, he took a degree in Mechanics and Applied Sciences. All things mechanical interested him, and he was certainly the first undergraduate at Cambridge to own a motor car, at that time a French Peugeot. On leaving Cambridge, he spent some time learning to be a mechanic at the LNWR locomotive works at Crewe in order to be able to cope with the various failures and breakdowns that the unreliable motor cars of the day were susceptible to. Of his motor journeys he said:

‘In those days, your passage through the districts was recorded in every local newspaper, and if ever you dared to stop in a town for a moment to take in benzoline or anything, you had to fight your way back to the car. Out in the country, on the other hand, every other man climbed up a tree or telegraph pole to get out of your way; every woman ran away across the fields; every horse jumped over the garden wall as a matter of course; and the horse in every butcher’s cart that was left at the side of the road with the tailboard open, bolted scattering various spare parts of animals about the road’.

He was fascinated by motor cars, always searching for the best car, and taking a leading part in the sporting-car events of the day. Thus he gravitated to Manchester, where Royce had made his first few cars. It is recorded that Rolls made a prophetic statement that it was his ambition that there should be a car made which would be connected with his name and would become as well known as a Broadwood or Steinway grand piano.

Thus, Rolls and Royce met at Manchester, and Rolls had his first run in a car designed and made by Royce. The two men took to each other immediately, and both recognised the mutual benefits of a partnership. For Royce here was the very man, with his great motoring record, who could introduce his car to London Society. Rolls knew he had found the greatest car designer in the world.

The third element of administration and organisation was supplied by Rolls’ friend Claude Johnson, Secretary of the Automobile Club. He became Secretary of the new Rolls-Royce firm, in which post he stayed until he died.

Henry Royce’s background could scarcely have been more different from those of his two partners. He wrote of his early days:

‘Owing to the want of success (through unsteadiness) and early death of my clever father, who was of a well-known milling family, my mother was left unprovided for, and I became a newspaper boy from ten to eleven years of age. Then one more year at school, from eleven to twelve years of age, and then a telegraph boy from thirteen to fourteen, when I went as an apprentice on locomotive engine work under the Great Northern Railway from fourteen to seventeen years of age when I acquired some skill as a mechanic but lacked technical, commercial and clerical experience’.

He was born in 1863 at Alwalton near Peterborough, where his father was a flour miller, and was only nine when his father died. His apprenticeship at the GNR was paid for by his aunt, but the little money she had ran out before he completed his indentures, and he had to leave at the age of 17 to find other work. He found it in Leeds with a firm of toolmakers, where he worked long hours each week, from 6.00 am to 10.00 pm and all Friday night, for the princely sum of eleven shillings (55p) a week.

Recalling this period of his life he wrote: ‘I was offered employment at the newly formed Electric Light and Power Generating Company at Bankside, London, at 22 shillings a week, which I accepted, and for maximum economy lived in a ‘third floor back’ in the Old Kent Road’.

He was transferred to Liverpool, and then the company failed. However, in association with A. E. Claremont, they decided to set up business together, Claremont having a capital of £50 and Royce £20. Thus in 1884, the firm of F. H. Royce and Co was born in Cooke Street, Manchester, where they manufactured first bell sets and later lampholders and dynamos. By 1899, things had progressed sufficiently for them to raise £30,000 to build a new works, and to extend their scope to cranes. These were much superior to the imported ones, but more expensive because of Royce’s insistence on quality and reliability.

In 1903, against the wishes of his partner, Royce began to indulge in his great desire — to build a motor car, and to repair and modify the various makes of cars belonging to his friends. From this small beginning came the great firm of Rolls-Royce, which was to stand throughout the world as the pre-eminent engineering company.

Royce had added to his practical training by attending night classes at technical schools, but, above all things, he was one of those rare people who are natural-born engineers and designers. He had an instinct for excellence of design, and would spend great time and patience in the consideration of engineering drawings before allowing the parts to be manufactured. On the other hand, he constantly appealed to experiment, and would examine with great care every part after it had been run. No wear, frettage or indication of malfunctioning was too trivial for him to notice, and make efforts to correct.

After Rolls was killed flying at Bournemouth in 1910, and Royce had his severe illness in the years following, the firm was kept together by Claude Johnson. He regarded Royce as his precious jewel, and insisted that he lived in milder climes than grey Derby. Accordingly, Royce spent the winters in the south of France at Le Canadel and, later, the summers at West Wittering in Sussex. In both places, he had his senior designers with him. When I joined Rolls-Royce, official drawings still bore the nomenclature LeC., while most of those made at Derby were kept from Royce and known as D.E.S. (Derby Experimental Schemes).

From what one reads, Royce appears as a cold, austere martinet who would not tolerate any opposition. His early marriage had failed, and for the last 20 years of his life he was cared for by Nurse Aubyn who never left his side, and appeared to exert authority over him. Whether she was more than a nurse we shall never know but, if so, good for Henry for it would be one of the few humane attributes in his character.

Before World War I, Royce’s great passion had been the design and manufacture of motor cars. He was a perfectionist, and with his natural skill and capacity to gather around and to lead firmly men of similar objectives, the Rolls-Royce car soon became the finest in the world. Perhaps it was because of Rolls’ death as a pilot that Royce took no interest in aviation prior to World War I, but when the cataclysm broke on the world, it was clear that the great factory at Derby would have to give up luxury motor cars and devote its skill and capacity to the war effort.

Just prior to the outbreak of war in 1914, Royce was approached by the War Office, who wished him to make an aero engine of French design. He took one look at it and refused point-blank. However, the Admiralty encouraged him to design his own engine, and in August/September 1914, he began the design of the 200 hp engine, as it was then known, and which subsequently became the famous Eagle, later developed to 375 hp.

At the time, for reasons of health, Royce was living at Ramsgate in Kent, and had with him his usual bureau of designers. After the outbreak of war, he never once visited the factory at Derby, and this was regarded as a blessing in disguise by the inhabitants thereof. Royce’s presence in the shops was very obstructive, since he would stop work and sack people on the instant if they were not doing the job exactly as he thought it ought to be done. I was told that they left by the front door, and were immediately re-engaged at the back door.

And so, from 200 miles away, he controlled the design and manufacture of the 200 hp engine, and nothing was allowed to be done unless it had his thumbprint upon it. A constant stream of drawings and instructions flowed from Ramsgate to Derby, and in December 1915, these were bound into a volume of a limited edition of 100, entitled The First Aero Engines made by Rolls-Royce Ltd. The preface to this volume states ‘In the opinion of the Board of Directors, the Memoranda and letters written by Mr F. H. Royce, the Engineer-in-Chief, in connection with the design, testing and manufacture of these engines are so admirable as evidence of extreme care, foresight, and analytical thought, that the Directors decided to have them printed and bound in order that copies may be available for study and as an example to all grades of Rolls-Royce Engineers, present and future’.

The book is headed ‘Confidential, not to be shown to anyone without the authority of the Directors’. I am happy to say that Copy No 72 is in my possession today, almost 70 years later.

The first note on the 200 hp engine is dated 26 August 1914, and states ‘We are working at the new 200 hp engine to find out the space required. We propose to fit it with wrought steel cylinders and steel jackets. Each cylinder is to be separate’. Royce had already made up his mind that the engine should have 12 cylinders in two banks of six, inclined to each other in a 60° Vee format. This became the standard arrangement for Rolls-Royce aero-engines for the next 30 years.

A typical note was the one dated 24 October 1914 to Wormald, who was then Works Manager at Derby. Royce stated ‘I am very surprised to hear there was any difficulty about finding machines to work on the aero-engine cylinders. I am afraid the position is that we must find machines. We have worried the RFC and the Admiralty. We have also worried and worked continually on the design of this, and there must be no delays put in the way of the progress of the engine, because we must either do the work promptly or abandon the idea of doing it altogether. We cannot possibly have it hanging about, otherwise it will be only a disgrace to us’.

His admonition was heeded and by February 1915 the engine was running on the test bed. A note from Royce dated 4 March 1915 records his satisfaction at the engine having given 225 hp at 1,600 rpm — already more than its design power. Thus in six months Royce had designed and the Derby Works had made the most powerful aero-engine in the world. Weighing 700 lb, it was destined to play a great part in the war effort, and Royce would allow no other firm to make it.

One sees references to E. W. Hives as being in charge of the testing programme. Hives had joined Rolls-Royce at the beginning of the century as a car mechanic for Rolls, and had graduated to being the chief rally driver. He it was who drove a 40/50 Silver Ghost on the famous trip from London to Edinburgh and back, in top gear all the way, in 1911. Hives retained his enthusiasm all his life for driving Rolls-Royce cars, which he did with great élan.

I remember driving to London with him in 1946 in the first straight-eight Rolls-Royce. This car had been ready just as war broke out, and had been shipped to Canada for safety during the war. It was very fast indeed, with a top speed in the order of 120 mph. We were en route to London, long before motorways, and were doing a steady 100 mph (161 km/h) when he started to feel for his cigarette case. He tried all his pockets, changing hands on the steering wheel meanwhile. He then extracted a cigarette and went through the same process finding his lighter. Meanwhile we were streaking past other traffic on what today would be regarded as a second-class road. My hair stood on end, but I dared not say a word.

He very occasionally hit things. On one occasion, while travelling with his colleague Bill Lappin, they ran into a car full of bookmakers and racing touts. Hs stopped and Lappin went back. The victims were very belligerent and were threatening to knock the block off the lunatic who had hit them. Lappin said ‘You mustn’t do that. Do you know he is the Manager of Rolls-Royce’.

‘The Manager of Rolls-Royce, eh’, was the reply. ‘In that case we won’t hit him, we’ll sue him?’

The excitement of testing the Eagle engine and its successors in World War I changed Hives’ allegiance from cars to aero engines. The Eagle was the powerplant for the Handley Page and Vickers heavy bombers, and a scaled-down version called the Falcon became the main engine fitted to the Bristol Fighter, which ended the war as the supreme two-seater fighter.

It was Hs’ experience, gained in World War I, which fitted him so admirably to lead Rolls-Royce in World War II. He alone amongst us knew the power of the aeroplane in warfare, and the enormous efforts that would be required from Rolls-Royce to satisfy the demands for the engines. We in Britain have cause to be thankful that this strong, sagacious man, at the height of his powers, was in the right place at the right time to co-ordinate the effort that was necessary to bring our country to victory in the air.

After World War I, Hives became Chief Experimental Engineer, covering both cars and aero engines, and three young graduates from Bristol — A. C. Lovesey, R. N. Dorey and A. A. Rubbra — joined the firm. All three were destined for top positions — Lovesey in Engineering, Rubbra in Design, and Dorey in Management.

Lovesey was a keen amateur aviator and owned his own Gipsy Moth, which he flew all over Europe in his spare time. At the time when I met him at Donington Hall, he was still a batchelor and worked very long hours, seldom leaving the factory before 7.00 pm, just in time for dinner.

Being Deputy Chief Experimental Engineer, he had a large staff because all engine test, performance and build came under his command. The pattern for developing an engine had been set by Royce himself. We find him writing on 22 March 1915: ‘Re. 200 hp Aero Engine — Short Duration Tests, etc. We presume that you are continuing the test at high compression and increased speed, first finding out how fast you can run for one or two hour spells with the lubrication as in the 20 hour test, and then whether the big-end will bear an increase of speed with (1) “Castrol”, (2) cooler oil, or (3) higher pressure’.

In other words, Royce laid down the principle of gradually increasing the speed and power of the engine in steps in order to find the weakest link. Thereafter, the engine would be pulled back slightly, and long-endurance runs made to demonstrate the mechanical integrity. All this philosophy, and much more, is now embodied in the Type Test which all engines must undergo before going into full production.

It was Lovesey’s main task to get the Merlin through its Type Test, and to join with Rubbra in the design of modified parts to overcome any mechanical failure that occurred during testing. He had great powers of concentration, and it was his custom to deal with the many problems individually, one at a time, and not spread himself over the whole gamut of difficulties facing him.

He would arrive in his office, and gather around him the appropriate specialists, and together they would begin to examine the evidence of a particular failure. Day after day the same people would gather with him, and gradually they would piece together the mechanism of the failure, and decide upon the appropriate action. He never made a snap decision, and when his investigation was complete he would give a masterly summary and exposition of the problem. Hives described him as the finest development engineer in the world.

Although his methods were first-class for solving problems, they were no way to run a large department, because the rest of his staff did not exist while he was concentrating with the few. This was temporarily very frustrating for many of his engineers who felt they were not getting their fair share of his attention.

It came to pass that I shared an office with him as his assistant, and thereby had a daily tutorial on how to become a mechanical engineer. I remember a man bursting into his office during the war in a state of high dudgeon. He advanced on Lov, and banged his desk shouting:

‘When the hell am I going to be allowed to get on with my job’.

Lovesey leaned back and smiled at him: ‘Now let me see, what is it that you want to do?’

‘You know damned well, I have got to measure the oil flows in all the lubricating pipes on the engine, and yet I cannot get on any engine test’.

‘But it’s absolutely vital that we have that information’, Lovesey replied, ‘How do you propose to measure it?’

The man sat back and gave a lengthy exposition, with Lovesey interjecting, ‘Yes, yes, what a good idea’.

The man calmed down, with Lov thanking him for drawing the matter to his attention and assuring him of his great interest.

The man left completely mollified and happy. Since I knew that he had little hope of getting this routine information, because all the engines were heavily committed, I asked Lovesey,

‘What are you going to do about that?’

‘Bugger all’, he replied, and turned back to his papers.

Almost daily the Chief Tester, Stan Orme, and his assistant, Alf Arnold, would appear first thing to report on the state of the engine tests. Both were well over six feet tall, whereas Lovesey was a slight man of about 5 ft 6 in. They knew there would be only one test Lov would be interested in, and they spent a good deal of effort making sure they knew which one that was. Sometimes they slipped up, and got their priorities wrong. Lovesey would rise in his wrath and demand,

‘Can’t I rely on you to test the right engine, or must I come on to the test beds and do it myself?’ He would start to take off his jacket and would have to be forcibly restrained in his chair, while they promised that he would have his test done immediately. He was held in great respect and affection by all, and was really kindness and good nature itself.

Both he and Rubbra gave their whole life to Rolls-Royce, and their outstanding talents were an inspiration to all. When, in March 1971, I was asked to return to Derby to take responsibility for the RB211 engine, whose problems had just caused the world-shaking crash of the company, I telephoned them both, asking them to help me. Although well over 70 years old, and retired, they both joined me in my office, and towers of strength they were too, readily accepting the junior man of 1938 as their Chief.

Back in 1938 I soon became very familiar with the construction of the Merlin supercharger and carburettor. The engine had been designed to fit the Spitfire and Hurricane fighters, and its length had been compressed as much as possible to match the fore-and-aft balance on these aircraft. Since the supercharger was at the rear of the engine it had come in for pretty severe design treatment, and the air intake duct to the impeller looked very squashed, with a shape that seemed peculiar to my eye.

I tried to calculate the pressure losses which the air flowing through this intake would experience before entering the impeller, and the answer looked bad. Since it is the function of the supercharger to compress the air, it was obviously a bad thing to have a pressure loss in the intake.

I wished to determine the magnitude of this loss. After consulting with my new staff, we went to see Albert Rigg, an old boy who inhabited his own little corner of the Experimental Shop, surrounded by the tools of his trade. Albert was a very highly skilled craftsman who specialised in sheet metal work. He could make anything in sheet metal from a sketch on the back of an envelope. Not only could he beat metal to make it thinner, but he could operate on a metal sheet with a hammer to make it thicker in places.

We told him that we wished to cut away the heavy aluminium intake casing from the blower, and asked him to replace it with a sheet metal intake so that the air could go directly into the impeller without having to pass through carburettors or turn awkward corners. This was, of course, for test purposes only, so that we could determine, by experiment, the price that was being paid for the standard configuration on the engine. In a short time the parts were made, and the supercharger put on test. The effect was most enlightening, because the blower pumped a higher pressure and increased airflow, from which the losses in the carburettor and air intake could be calculated.

But engines must have a carburettor, so there was nothing to be done about that. They must also have an air intake leading the air from the carburettor to the eye of the supercharger, but this part could be reshaped to reduce the loss. So back we went to Albert and concocted a new shape for him to make. This was a much more difficult task than his original flare. The principle was that air velocities should be kept as low as possible, by making the cross-sectional area of the duct as large as possible, with the air directed into the eye of the blower in a very gentle curve. At the same time, the overall length had to be unchanged, so that the Merlin could still be fitted into the Hurricane and Spitfire.

With Albert’s sheet-metal intake a great improvement was effected over the standard Merlin design, and combining this with the original prediction of the improvement to be obtained from the modifications to the rotor and the diffuser, I was confident that a vastly improved supercharger would result.

At this stage, I had no idea what effect this would have on the power produced by the Merlin engine, or on the performance of the two fighters. Nor could I find anybody in Rolls-Royce who could tell me. The subject had simply not been studied. Was it worth while changing the whole design of the supercharger, with all the drawing work, experimental manufacture, testing, and disruption to production? The judgement of the magnitude of this task was quite outside my experience. Fortunately, at that stage, I did not feel it was necessary for me even to suggest it. I was treating the supercharger as my personal toy, and got my satisfaction from improving its efficiency. What was done with it after that was someone else’s affair.

But at this stage Hs took a hand. I was sitting in my office one afternoon when he walked in and sat down on the extra chair I had acquired. On my desk was a Merlin rotor, which he picked up and said, ‘I have looked at the reports on your work, and I am interested in the proposal to make the vanes on this thing narrower, because that will take some of the stress out of it’.

As the rotor went round at about 28,000 rpm, cutting down the width of the vanes to about two-thirds would make a substantial reduction in the stress. Hs went on, ‘As for the intake, I like the look of that too, so we are going to make it all for an engine test’.

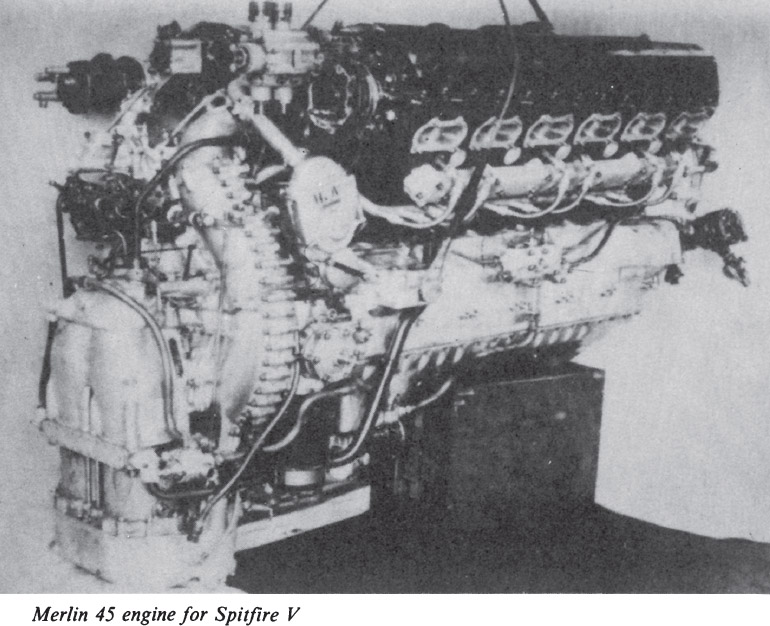

Things then began to happen. Rubbra and Lovesey came to see me to get the dimensions of the rotor and diffuser, and the shape of the intake. The Main Engine Design Office went into gear to produce the definitive drawings for the revised engine. Thus were born the Merlin 45 engine used in Spitfires, and the Merlin XX used in Hurricanes and many other aircraft, and for me the impossible had come to pass. I had changed a Rolls-Royce engine designed by the great Henry Royce himself.

About this time, I was visited by the two senior testers, Orme and Arnold, who always seemed to operate as a pair. Both were horny-handed sons of toil, but they came to tell me that they had working for them a young man, G. L. Wilde — inevitably known as Oscar — who was a mathematical wizard, and a good tester to boot. Would I have a talk with him? Although they would be loath to lose him, they felt that better use could be made of him.

I saw him and was much impressed, and longed to have him on my staff. But how did one do this? I consulted Frank Allen who said there was no problem — if Orme and Arnold were willing to part, and I was willing to have him, then it could be fixed immediately. And so it was that Oscar joined me and became a valued and loyal colleague. He was a man of great enthusiasm and imagination, who was eventually to rise to the very top in the hierarchy of Rolls-Royce engineers.

About this time, I began to realise that it was not sufficient to consider the supercharger by itself. The important thing was the engine-supercharger combination, and it was essential to match the output of the supercharger to the demands of the engine. But what were the demands of the engine? Surprisingly, I could find little information about this, and so decided that we must measure the air consumption of the Merlin on test. Oscar said there wasn’t a hope of doing this on the experimental beds because the schedule of testing was very strictly laid down; but why didn’t we talk to the chaps on production test?

At that time, in early 1939, the production of the Merlin was just getting into top gear, and the rule was that each engine had to do a 2-hour endurance test before despatch. There were plenty of engines doing this routine test, and when we went along to see the chief tester he welcomed us with open arms. We could take what measurements we liked, provided it did not interfere with the passing-off tests. My own men went and made the measurements, and in a few days we had complete sets of air consumption curves for a considerable number of engines, running over the full gamut of varying power outputs.

In the case of the Merlin, the air was first sucked through the carburettor, where the petrol was sprayed in to give the correct mixture of fuel and air. It went on to the supercharger, where the mixure was compressed and, of course, heated by the compression, and delivered into the induction pipe which lay between the two banks of six cylinders with symmetrical off-takes on each side to each of the 12 cylinders. The pressure in the induction pipe was known as the boost pressure and was measured in pounds per square inch. The higher the boost pressure the higher the engine power, because more of the mixture of air and fuel would be forced into each cylinder.

The principle on which all four-stroke engines work is very straightforward. On the first downward stroke, the appropriate mixture of air and fuel — about 15 to 1 by mass, 9,000 to 1 by volume — is drawn into the cylinder through the open inlet valve(s). These valves then shut, and in the following upward stroke the piston compresses the charge. At the top of this stroke, the sparking plug ignites the compressed mixture, and the rapid rise in pressure which results forces the piston down again to give the power stroke. Before the bottom of this stroke the exhaust valves open, and on the next upward stroke the piston forces the burnt gases out through the exhaust pipe. The cycle then repeats itself. Thus there is one power stroke for every two revolutions of the crankshaft; in the case of the 12-cylinder Merlin there would be six power strokes to each revolution of the crankshaft.

In the theoretical examination I made of the relationship between the power output on the Merlin and the quantity of air/fuel mixture which it consumed, I started from the premise that the internal power generated in the cylinder must be proportional to the quantity of air/fuel mixture consumed. But not all the power generated in the cylinder appears as useful power at the propeller shaft. Some of it is used to drive the supercharger at the back of the engine, and some is absorbed by the friction of driving the pistons up and down, the crankshaft round and round, the valve gear and other parts.

The final answer, which was obtained by a combination of theory and experiment, showed that the Merlin generated an internal power in the cylinder of 10.5 horsepower for every pound of fuel/air mixture it inhaled per minute. This figure was independent of the rpm, or of the boost pressure from the supercharger.

On the theoretical side, I deduced a formula which accurately gave the quantity of charge which the engine would inhale under any condition, either on the ground or in the air. Now at last it was that, armed with the various formulae, we could calculate the power that the Merlin would give in any condition of flight.

Prior to this, we had calculated the horsepower from some very suspect and empirical formulae which had emanated from the Royal Aircraft Establishment. These formulae overestimated the power, and caused a constant argument between Mitchell, who designed the Spitfire, and Camm who designed the Hurricane. Both designers claimed that, from the measured speeds of their aircraft, the Rolls engines could not possibly be giving the power that was claimed for it. In fact, both aircraft were 20 - 30 mph slower than expected at about 20,000 feet, a fact that was kept very secret at the time since the war was imminent. Fortunately, the Germans were equally bad at estimating the power of their engines, and their aircraft were also slower than both the calculated and published figures.

The Americans took their usual line, and decided to build a special test bed at Wright Field in Ohio where their engines could be tested on the ground in conditions which simulated those at altitude, and in this way they were able actually to measure the power output of their engines. By the standards of the day this was a huge installation, with refrigerating plant to reproduce the cold air temperatures at altitude, and large exhausters to reduce the air pressure and take away the exhaust gases.

In comparison with this massive attack by the Americans, we had only a few simple formulae which enabled us to calculate the power of the Merlin while sitting at our desks. When, late in the War, a Merlin was actually tested in the Wright Field installation, the measured powers agreed exactly with those we had calculated several years before. From then on we adopted as our motto “The Pen is mightier than the Spanner”.

What was far more important, we were now able to reconcile the performance of the Spitfire and Hurricane with the power output of the engine, and were then able to predict accurately what would happen if we changed the power of the engine by changes to the supercharger.

It is seldom economical or desirable to use a supercharged piston engine at full throttle at sea level, because the resulting power would overstress the engine and its cooling system. In the case of the Merlin, the power at sea level was initially limited to about 1,000 hp, and to obtain this power the throttle would only need to be partially opened. As an aircraft climbs to higher and higher altitudes, the atmospheric pressure decreases, and the density of the air inhaled by the engine diminishes. If nothing is done, the power of the engine would fall off proportionately. But by starting at sea level with the throttle partially closed, as the aircraft climbs the throttle can be gradually opened so as to maintain the power output of the engine. Eventually, an altitude is reached at which the throttle is fully open, and this is known as the “full-throttle height” of the engine.

The function of the supercharger is to force a heavier charge of air/fuel mixture into the engine’s cylinders. The extent to which it does this is measured by the boost pressure. To give its 1,000 hp, the original Merlin required a boost pressure of between 6 and 9 lb/sq in. The engine was fitted with an automatic boost control which kept the boost pressure constant as the aircraft climbed. It did this by a servo system which automatically opened the throttle as the altitude increased. Thus, the engine automatically maintained its 1,000 hp up to the full-throttle height, which in 1939 was about 16,000 ft (4877 m).

There was another vital reason for keeping the boost pressure constant at a predetermined value, and this was the need to prevent the engine detonating. The ideal situation is that the charge of fuel and air should burn smoothly in the cylinders. If too much charge is forced in by too high a boost pressure from the supercharger, then detonation can begin and, instead of burning smoothly, the charge literally explodes, and causes shockwaves, like those at the nose of bullets, to bounce around inside the cylinders. These waves are of such intensity that serious mechanical damage can be caused to the cylinder head and pistons, which for lightness are made of aluminium, and thus can be relatively easily damaged.

The onset of detonation can be controlled by the octane value of the fuel, which in 1939 was limited to 87. Just before the Battle of Britain, small amounts of 100-octane fuel became available from the USA and this enabled us to open the throttle further on the Merlin and, in fact, to obtain nearly 2,000 hp without detonation. Thus, the 100-octane fuel made a crucial contribution to the performance of the Spitfire and Hurricane in that battle, as did the work of Lovesey, Rubbra, and their teams, which enabled the Merlin to withstand double its design power for short periods without mechanical failure.

To obtain the increased power, the pilot had to override the boost control which was normally limiting him to 1,000 hp. To do this, he had to pull a knob in the cockpit, and break the seal on it. So we always knew when he had done it! But in the Battle of Britain, 1,000 ft of extra altitude or 5 mph in speed could mean the difference between shooting down the enemy or being shot down by him, such was the equality between the performances of the Bf 109 and our fighters.

Thus, with the advent of 100-octane fuel, we were for the time being released from the nightmares of detonation. We could concentrate on improving the mechanical integrity of the Merlin to withstand higher power, which was Lovesey’s job, and improving the performance of the supercharger so that the power could be increased and also maintained to higher and higher altitudes, which was my job.

Unfortunately, the results of the work of my team, which I have so far recounted, did not come into fruition in the RAF squadrons in time for the Battle of Britain. In that epic encounter all the Hurricanes and Spitfires were fitted with the original Merlin III, as designed by Royce. Moreover, all the engines that fought in the battle were made at Derby, because the great factories at Crewe, Glasgow and Manchester, which were subsequently to produce more than 100,000 Merlins, were not even built.

We did not discuss it, but I must say that I expected Derby to be flattened by the Luftwaffe in the first weeks of the war. Thank God, Hitler made one of his several crucial mistakes, and Derby was spared to equip the fighters of the RAF.

I still remember the relentless pressure exerted by Hs in those critical months, and the response he got from the workers in the factory, who willingly worked 18 hours a day, seven days a week to produce the engines. Hs would regularly tour all parts of the factory before some of us were even out of bed, and since everybody knew him, and he knew everybody, the effect on morale was great.

It was Hs’ custom to hold a technical review with the senior engineers every Monday afternoon starting at 2.00 pm. On his right hand would sit Elliott as Chief Engineer, and on his left Swift as Chief Production Engineer. Directly opposite him would sit Lovesey, Rubbra and myself, and gathered around would be liaison engineers with the RAF to report troubles in service, material experts from the laboratories, HPS speaking for the Experimental Shop, and Dorey for the Installation and Flight Testing establishment at Hucknall airfield near Nottingham.

Hs was a great chairman. He had the happy knack of being able to carve away the undergrowth and immediately get to the nub of the question. He never allowed time to be wasted by individuals arguing together, because he knew his man, and would turn to the appropriate expert.

‘Well, what have we got to do, so-and-so?’

He would accept ‘I don’t know yet’, but woe betide anyone who tried to dissemble or cloak his manifold sins and wickednesses.

Once he had an answer, HPS would hold up his hands ‘Give me the drawings, give me the drawings’, and Swift would be put on notice that a modification was coming on production.

Of course, on occasions we were all nonplussed. Hs would look around. ‘I don’t know how you can sleep in your beds’, he would say, ‘Get your jackets off, and bring me the answer’.

The Merlin was a water-cooled engine, and we were always troubled by minor leaks at the various joints between the engine and the radiator situated under the wing of the Spitfire. This was Dorey’s province, and these leaks used to exasperate Hs, who would taunt Dorey by saying he had only to make the plumbing as good as his lavatory!

On one occasion in the early days of the war, someone in the RAF had filled a Merlin cooling system with water which had been fetched in carboys originally containing nitric acid, and which still had traces thereof. Even though the acid concentration must have been very small, the mixture played havoc with the aluminium cylinder blocks. The Aeronautical Inspection Directorate of the Air Ministry decided that, to avoid any possible contamination, there must in future be an official specification for the water used. This specification was the first item on Hs’ Monday meeting, and the AID were there in force. Hs sat in his usual place with his head in his hands listening to the prolonged discussion on how to write the specification. Suddenly he looked up exasperated and said,

“I’ll write your bloody specification for you. You have got to be able to drink it’.

These simple anecdotes, out of context as they are, now sound trite and elementary. But in the grim atmosphere of the war, they were just sufficiently humorous to give all enough lift to go away and get on with our jobs with zest and energy.

The initial work that I had done on the supercharger and its air intake appeared on production in 1940 in the form of the Merlin 45 for the Spitfire and the Merlin XX for the Hurricane, Mosquito and Lancaster. The effect was to increase the full-throttle altitude of the engine from 16,000 ft with the Merlin III to over 19,000 ft with the Merlin 45. I knew that this particular blower had now reached the limit of its development. Any further improvement would be much more difficult, and could give only a small gain, unlikely to justify a change to production. Where did we go from here?

At that very time, Lovesey and I were called to a meeting at the Air Ministry in London. We were told that Rex Pierson, Chief Designer at Vickers, had designed a capsule which fitted in the nose of the Wellington bomber and in which the pilot and bombaimer could sit. The idea was to pressurize this capsule, so that the aircraft could fly at very high altitudes in excess of 30,000 ft (9144 m), with the crew comfortably seated with an air pressure corresponding to 10,000 ft in the capsule. It was one of the first pressure cabins.

The standard engine for the Wellington was the aircooled Bristol Hercules sleeve-valve radial. To boost the power of the Hercules to get the Wellington above 30,000 ft, Bristol had decided to fit an exhaust-driven turbosupercharger, similar to those fitted by the Americans to their aircooled engines.

The high-altitude Wellington project was considered of sufficient importance to justify asking Rolls-Royce to provide an insurance policy by turbocharging a Merlin. This proposal was not as straightforward as it sounded. At Hucknall, under Ray Dorey and Harry Pearson, a great deal of work had been done on the Spitfire and Hurricane by taking the exhaust from the Merlin and ejecting it rearwards through very short exhaust pipes, where it acted as a means of jet propulsion equivalent to about 150 extra horsepower. With an exhaust-driven turbocharger we would lose that effect, and were loath to do so. I argued that, to obtain the necessary power, all we had to do was to raise the full-throttle height of the Merlin from 16,000 to 30,000 ft, and that to do this we needed two superchargers in series at the back of the engine, driven by the same gears that existed on the standard Merlin.

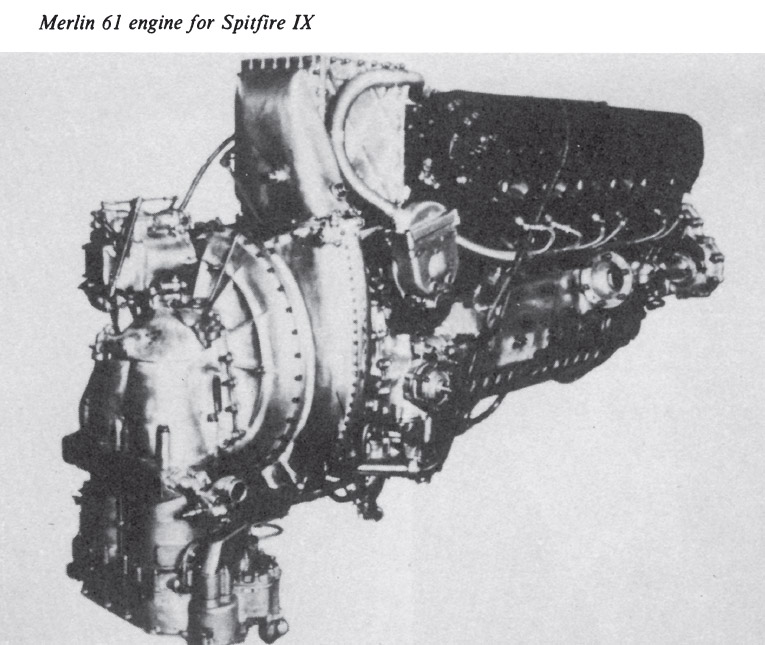

There was one obvious snag. Due to the high compression of the charge, its temperature would become very high, and the old bogey of detonation would rear its ugly head again. Also, the engine power formula indicated that the high charge temperature would actually reduce the power of the engine. The solution was obvious. We had a water-cooled engine, so we would add an extra water-cooled ‘intercooler’ after the two superchargers which would cool the charge to 100°C before it entered the cylinders. Calculations showed that in these ways we could double the power of the Merlin at 30,000 ft from 500 hp to 1,000 hp. Now the task was to determine the dimensions of the two superchargers.

At this point, a happy thought occurred to me. The Rolls-Royce Vulture engine, which had 24 cylinders and was much larger and heavier than the Merlin, gave, by virtue of its size and capacity, 1,000 hp at 30,000 ft. Since the power of an engine depends approximately on the amount of air and fuel it consumes, obviously the Vulture supercharger had the right capacity to supply the necessary air as the first stage of the proposed two-stage blower for the Merlin. No design effort on this component was necessary.

It was now that the advantage of the two independent ends of the supercharger test-rig paid off. On the one end we fitted the Vulture supercharger, and on the other the Merlin blower. A long sheet-metal pipe connected the outlet of the Vulture with the inlet of the Merlin, and thus we were able to run the two blowers in series, and measure their combined performance. The result was so good that no further calculation or testing was necessary, and we were able to go to Rubbra and start the Main Engine Design Office on the task of combining the two superchargers together as a single compact unit suitable for fitment on the rear of the Merlin.

There remained the design of the intercooler between the blowers and the induction pipe necessary to cool the air/fuel charge before it entered the cylinders. Here the Chief Engineer took a major part, and it was most impressive to stand with him and others at a drawing board while he sketched in the principle of the construction and mounting of this new component. In fact, to go with Elliott into the Main Design Office was a great treat for us all. He was like the Specialist in a hospital, examining each drawing as he passed, criticising points and adding deft touches to solve any design problem. It was all highly educational to me to follow in the wake of such a great designer. The trouble was that he did so infrequently, but spent the major part of his time in his office trying to get abreast of yesterday’s problem.

I would add that he was the No 1 gentleman in Rolls-Royce, calm, serene and kind. The rest of us were roughnecks in comparison. I frequently travelled with him to visit the aircraft companies, and it was a pleasure to see him handle such tough and irate designers as Sydney Camm of Hawker Hurricane fame, and Roy Chadwick, the designer of the Lancaster bomber.

The first time I met Camm was with Elliott in the early days of 1940. Camm and his design office had been evacuated from the Hawker factory at Kingston to Claremont House, which Queen Victoria stayed at and loved. Camm occupied the drawing-room — I mean the drawing-room of a past age — which was still beautifully furnished and had a large, comforting fire going. Sydney greeted us in his usual way — which, I found later, was pure fun:

‘What the hell are you lot doing here, wasting my time, telling me how to put your rotten engines into my beautiful aeroplanes!’

I shivered in my shoes, for this was lèse majesté indeed, talking to the Chief Engineer of Rolls-Royce in such a manner. Elliott, smiling, replied, ‘What a splendid office to work in, Sydney. Such an elegant fireplace. So convenient for burning those mistakes in’.

Sydney grunted, and turned to me.

‘Who is this chap. I’ve not seen him before’.

Elliott introduced me. Sydney looked squarely at me and said,

‘I just want to get one thing clear with you, young Hooker. The only time I am wrong is when I am persuaded against my better judgement’.

Then he laughed, and we all sat down amicably to get on with the business of the day in the most constructive fashion.

To return to the intercooler, the internal matrix, through which the charge passed in one direction and the cooling water through in another, as it does in a motor-car radiator, posed a problem. There was no heat-exchanger matrix available in the country of high enough efficiency to do the job in the small space that was available. So we enlisted the help of the Engine Department of the Royal Aircraft Establishment.

Very soon, Farnborough’s Dr Remfrey appeared in my office at Derby with a small sample of a matrix made in copper sheet, which tests had shown would do the job. I examined it. The thing that worried me was its mechanical strength.

‘Oh, it’s strong enough to jump on’, said Remfrey.

Instinctively, I said ‘Show me’. Equally instinctively, Remfrey put the small sample block on the floor and jumped on it. It went as flat as a pancake, to the howls of nervous merriment from the assembled company. Remfrey was very crestfallen, and, since it was the only sample in existence, feared the wrath of his superiors. I said, ‘Never mind, tell them that clumsy idiot Hooker did it’.

In fact, the construction and efficiency of the matrix was excellent, and it was duly adopted for the intercooler. In a matter of months, a Merlin was made with the new design of the two-stage supercharger and intercooler. The test results fulfilled our highest hopes, and the engine worked beautifully on the test-bed first pop.

But the proof of the pudding was really in flying the engine. Although we could predict the power at 30,000 ft, we would only know the real answer in the air. In due course, two engines were installed in a Wellington and the first flight was made from Hucknall.

That day Hs sent for me. I went to his office and he asked ‘What do you say the full-throttle height of the two-stage Merlin is?’

Nervously, I replied, ‘I calculate it to be 30,000 ft, approximately’.

He passed me a piece of paper, and on it was written just 29,750. He said, ‘I have just had that figure from Dorey taken on the first flight of the Wellington’. He never indulged in compliments, but was obviously delighted.

At the next Monday meeting, he referred to the new Mk 60 engine, and then said something that had never occurred to us,

‘What would happen if we put this engine into a Spitfire?’

It was blindingly obvious that the Spitfire was the true home for the engine, and it had been left to Hs to suggest it. We all sat back aghast and silent.

Dorey said, ‘I don’t know, but we will damned soon find out. I will start work on putting one into the Spit immediately’.

This was a considerable task, because the engine was 9 inches longer than the standard Merlin, and thus the whole of the nose of the aircraft, with the engine mounting and controls, had to be redesigned. A new four-blade propeller was needed to convert the power into thrust. An extra radiator had to be provided under the wing to dissipate the heat in the water that cooled the charge (and this helped to balance the extra weight at the front). But the job was done in double-quick time, and in 1941 the first Spitfire with the Merlin 61 engine flew at Hucknall and soared to over 40,000 ft (over 12 km).

This was the prototype of the famous Spitfire IX. The new engine increased its fighting altitude by 10,000 ft, and added 70 mph to its top speed. The Spitfire IX was in the hands of the RAF just in time to counter the formidable Focke-Wulf 190, which owed its performance to an aircooled BMW engine, much heavier and larger than the Merlin. The swept volume of the German engine was 2,560 cu in (41.8 litres); our new two-stage Merlin beat it with 1,647 cu in (27.0 litres). Years later Air Marshal Sir Harry Broadhurst, who had been one of our great fighter pilots at this time, told me of his first operational flight in a Mk IX, and of the look of astonishment on a German pilot’s face as he climbed up past him with much greater performance.

The new engine went into mass-production. Many thousands were made for Spitfires, P-51 Mustangs, Mosquitos and special Pathfinder Lancasters. Conceived for the Wellington bomber with a pressurized cabin — which never went into service — it became the principal fighter engine in the RAF. It had a major application in the outstanding North American P-51 Mustang fighter, which was the only aircraft that really challenged the supreme performance of the Spitfire.

After the War began, and after a major false start with the US Ford Motor Co, the Government placed a large contract for the manufacture of the Merlin engine with the Packard Motor Co, in Detroit. Full manufacturing details and drawings were sent to them from Derby. Ellor and Barrington were seconded to Packard to assist them in interpreting the English drawings, and to act as liaison engineers with the rest of us at Derby. They bore such a crushing load that Barrington died in the USA and Ellor soon after his return.

The departure of Ellor and Barrington in 1940 left a hole in the staff at Derby. Rubbra was appointed Chief Designer in Barrington’s place, and Lovesey was promoted to Chief Experimental Engineer to replace Ellor. To my great satisfaction, I was invited by Lovesey to become his chief assistant, and moved into his office. Now my engineering education really began. His remit to me was: ‘You look after the performance of the engine, and I will deal with the mechanical side’.

And so I had the opportunity of sitting in at many sessions with his staff. I learned the diagnostic way he examined the mechanical problems, and propounded the tests and solutions to overcome them. At the appropriate time, he would say to me,

‘Come along, today we will go and see Rubbra and clean this job up’.

Then would follow a session with the main engine designers. At these I learned of the constant interplay between design and development as Lovesey, in his very skilful way, would illuminate the problems, and the equally skilful designers would sketch the modifications to the drawings in such a way as to cause the minimum disruption to production — and yet maintain the high standards set out in the Manuals of Design Standards which had accumulated since the days of Henry Royce. So I learned about designing from them, although I could never hope to become an accepted designer, because it takes 20 years of dedicated application to become that.

The word ‘engineer’ covers a variety of expertises and people of very varying backgrounds. In my experience, the crème de la crème of these are the designers and, if it be true that the status of engineers is too low in Britain, then the charge applies first and foremost to designers.

They are enthusiasts who seek after something more than wealth and power. They lead a tiring and exacting life, standing long hours at their boards drawing in two dimensions engine parts that they visualise in their minds in three dimensions. Not only must they create the drawings which can be explicitly interpreted into instructions, which can be made by the many manufacturing processes available in the shops, but they must liaise with the designers on each side to ensure that their parts will match exactly with those of their colleagues, and that the whole can be manufactured and assembled as an engine with convenient access for inspection of the vulnerable parts.

They are fed (often to the teeth) with information and advice from experts in specialized fields such as performance and gas dynamics, mechanical integrity and material properties, and they must work within the limits of stress imposed by the experts.

They are the ‘keepers of the Trade’, which embodies all the details of past experience so hardly learned. They are indeed an elite body, yet they are almost always quiet and modest, capable of defending their creation with lucid arguments. At the end of the day, they have the most satisfying and rewarding job of all. They can look at an engine and say, ‘I created those parts, and they are exactly as I saw them in my mind when I took my pencil and began to draw on a blank sheet of paper, and they work!’

For myself, I frequently look at an engine and think, ‘That is how I visualised it’, but, however much one might have influenced the design and laid down the general arrangement, the men who created it were the designers. This does not mean that designers necessarily make the best Chief Engineers, although in the case of Royce this was so. An analogy might be that Yehudi Menuhin, with his superb interpretations, would not necessarily make the best conductor of the orchestra, with its many lesser, but still important, ‘prima donnas’.

In my enthusiasm, I considered that Rolls-Royce designs were the ne plus ultra, until the Ford Motor Co in Britain was invited to manufacture the Merlin in the early days of the War. A number of Ford engineers arrived at Derby, and spent some months examining and familiarizing themselves with the drawings and manufacturing methods. One day their Chief Engineer appeared in Lovesey’s office, which I was then sharing, and said, ‘You know, we can’t make the Merlin to these drawings’.

I replied loftily, ‘I suppose that is because the drawing tolerances are too difficult for you, and you can’t achieve the accuracy’.

‘On the contrary’, he replied, ‘the tolerances are far too wide for us. We make motor cars far more accurately than this. Every part on our car engines has to be interchangeable with the same part on any other engine, and hence all parts have to be made with extreme accuracy, far closer than you use. That is the only way we can achieve mass production’.

Lovesey joined in, ‘Well, what do you propose now?’

The reply was that Ford would have to redraw all of the Merlin drawings to their own standards, and this they did. It took a year or so, but was an enormous success, because, once the great Ford factory at Manchester started production, Merlins came out like shelling peas at a rate of 400 per week. And very good engines they were too, yet never have I seen mention of this massive contribution which the British Ford company made to the buildup of our air forces.

The demand for Merlins seemed insatiable. Starting as the ‘hot rod’ engine for the Spitfire and Hurricane, it rapidly found homes in other aircraft types, one of the most famous, of course, being the Lancaster bomber.

Roy Chadwick, the great designer of the Avro company, had originally designed the aircraft as a twin-engined bomber called the Manchester which had two 1,800 hp Rolls-Royce Vulture engines. For various reasons, the Manchester was very unsuccessful with two Vulture engines. In late 1940, therefore, in double-quick time, Chadwick redesigned the wings and installed four Merlin engines, rated at that time at 1,250 hp each. The result was the Lancaster, the supreme RAF bomber of the war. Over 7,000 were made and Air Chief Marshal ‘Bertie’ Harris described it as ‘a shining sword in the hands of Bomber Command’.

Another Merlin aircraft was the versatile twin-engined Mosquito, designed by Bishop and Clarkson of de Havilland Aircraft. The airframe was made of wood, and thus the wood constructing industry was harnessed to the war effort. Although originally a bomber, the Mosquito had the performance of a fighter, and flew at high altitudes and speeds. It was thus almost invulnerable to anti-aircraft gunfire, and was very difficult to intercept. It was a most popular aircraft in the Royal Air Force.

A third, and perhaps the most outstanding, adaptation of the Merlin was to the North American Mustang fighter. This aircraft was originally fitted with an American Allison engine, but its performance at high altitude was so improved by the Merlin that this became its standard powerplant. Such was its efficiency that, despite having larger wings and three times the fuel capacity, it was faster than any Merlin-Spitfire at all altitudes. It was most successful in shooting down or ‘tipping over’ the V-1 flying bombs, when Hitler launched that devastating weapon against London and south-east England in the summer of 1944.

At the outbreak of war, the Merlin had lately been substituted for a less-powerful engine in the Armstrong Whitworth Whitley bomber. This machine had two engines and was slow and ponderous by later Lancaster and Mosquito standards. Nonetheless, it was at the time the only bomber that could reach Italy with a useful bombload, and was used by the Bomber Group commanded by Alec (later Air Chief Marshal Sir Alec) Coryton for that purpose. En route, it had to climb over the Alps, and at that speed and altitude the Merlin had to be used at maximum power, and the cooling was found to be inadequate. A number of engine failures occurred, and Coryton, who was an enthusiastic amateur engineer, waxed very wrathful with Rolls-Royce, as he thought that insufficient attention was being paid to his aircraft and the safety of his crews. He wrote to Hs inviting any of us to go on one of the raids and to see for ourselves what the problems were. Hs read the letter to us at one of his Monday afternoon meetings, and then surveyed us all.

‘Are there any takers?’, he demanded. There was no scramble, but Coryton certainly got a better service from us.

Throughout the war, the power of the Merlin was continuously increased by Lovesey and Rubbra from 1,000 hp to 2,000 hp. I have described earlier how its power at 30,000 ft was doubled from 500 hp to 1,000 hp by the two-stage supercharger and intercooler. At the maximum engine speed of 3,000 rpm the power developed in the cylinders was divided between the frictional horsepower required to rotate the engine, the power to drive the supercharger and the useful power at the propeller in the rough proportions of 20 per cent, 10 per cent and 70 per cent.