CHAPTER 9

Crushing the Malt

Barley malt should be milled so that the husk is not shredded; ideally it should be split along its length. In this manner, the contents of the crushed kernel is released, and the maximum surface area of starch grits is exposed to enzyme activity without tearing the hulls. Only reasonably intact husks will form a suitably porous filter bed in the lauter-tun. Shredded hulls also contribute to a rough, harsh palate in the finished beer.

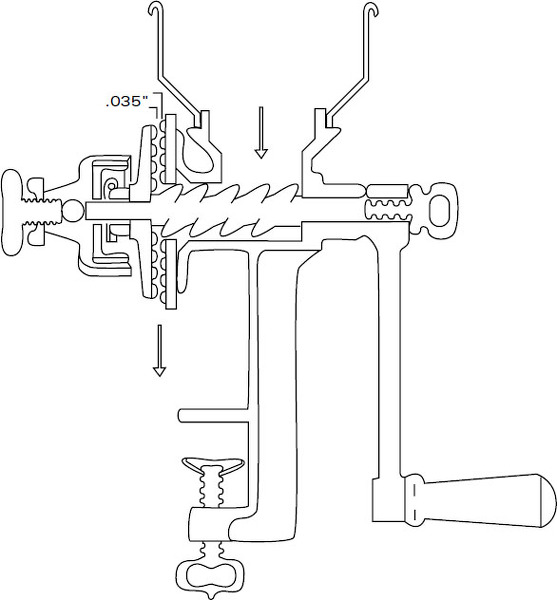

The best grist is obtained from six-roll malt mills, which crush the malt by running it between three successive pairs of rolls ten to twelve inches in diameter, each pair being set closer together and turning faster than the previous pair. Screens are placed between each set of rolls to allow the fine grits to fall through, so they are not pulverized into flour by further crushing. More than 75 percent of the malt may be reduced to grits in this manner — the remaining part being hulls and flour. More than 10 percent flour is undesirable because it balls or cakes readily. Balled flour is inaccessible to enzymes and results in unconverted starch, some of which washes into the wort during sparging, causing an irreversible haze in the beer.

Milling equipment other than a six-roll mill is employed, but none yields as good a grind. Only mills equipped with blades that cut the grain are entirely unsuitable, however. Hammer mills and the more commonplace grain mills that employ radially grooved, opposing-face grinding wheels are used, although they tend either to grind grain too finely and shred the husks, or to leave large chunks of the kernel intact.

Coarsely ground malt also does not yield the extract that it should. Heavy, gummy, insufficiently modified starch particles interfere with mash filtering. The hard ends of poorly malted grain are particularly subject to being left uncrushed. In general, it is better to crush the malt too finely (at the risk of a set mash), taking extra care doughing-in, and sparge very slowly than not to mill it finely enough. Only well-modified malts give up their extract when very coarsely ground; poorly modified malts especially require adequate milling. If the iodine test after a sufficient mash saccharification rest shows significant blue-black starch particles and grain ends (not husk fragments, which always deeply discolor iodine), and the spent malt gives any sweet taste, then crushing was probably insufficient.

Milling for lauter-tun brewing should yield predominantly fine grits.

| Lauter-Tun Grist Profile | |||

|---|---|---|---|

|

U.S. Standard Mesh |

Mesh Width |

Characteristics |

Lauter-Tun Grist Composition |

|

10 |

.0787 inches |

husks held |

15% |

|

14 |

.05512 |

husks held |

15% |

|

18 |

.03937 |

husks held |

15% |

|

30 |

.02323 |

coarse grits held |

25% |

|

60 |

.00984 |

fine grits held |

30% |

|

100 |

.00587 |

flour held |

20% |

|

100 |

.00587 |

fine flour falls through |

10% |