CHAPTER 10

Mashing

During mashing, the reduction of complex sugars and of insoluble proteins to simpler amino acid chains is entirely an enzymatic process. Before mashing, the malt is only 15 to 25 percent soluble (CWE). Mashing should yield an extract equal to 65 to 80 percent of the weight of the dry malt. Not all of this extract is fermentable; in fact, the varying percentages of unfermented “rest extract,” i.e., dextrins, proteins, and peptides, give each beer its malt character. The part of any extract that is unfermentable dextrins (sweetness and flavor) and proteins and peptides (body) is controlled by manipulation of the times and temperatures of the mash.

Doughing-In

Enzymes act on the malt only in an aqueous solution; water induces the enzymes, encased in the aleurone layer of the malt kernel, to go into extracellular solution with soluble starch and hemicellulose. Because crushed malt, and especially floury malt, tends to “ball” into a dry mass that isolates it from enzyme activity, it is essential to mix the grains with liquor in a way that does not saturate any part of the mash while another part is still dry. The intention is to create conditions conducive to dissolving all of the endosperm, including the enzyme-rich particles of the aleurone layer, and not to induce enzymatic activity just yet. Even moistening prevents the starch from balling and entirely solubilizes the enzymes.

A successful mixture is most readily accomplished by the gradual addition of liquid to the grain. Small amounts of liquor are sprinkled onto and then kneaded into the whole of the grain mass until the crushed malt can absorb no more. When a mash is doughed-in cold, only a small amount of liquor should be standing free at the bottom of the well-kneaded mash.

Using the least possible amount of liquor to form a very thick mash improves enzyme effectiveness early in the mash and simplifies rest-temperature maintenance later on. Liberal infusions of boiling-hot liquor may then be made to hold the saccharification temperature without overly thinning the mash. In decoction mashing, this is best accomplished by doughing-in the malt with twenty-four to forty fluid ounces of cold liquor at a deep-well water temperature of about 58 degrees F (14 degrees C) per pound of crushed grain, the higher end of the range being for larger brew lengths and mechanized systems.

The doughed-in mash is allowed to stand for fifteen to thirty minutes, the longer time being for malts that are dark, weakly enzymatic, hard tipped, or poorly malted. At the same time, roughly half the volume of liquor used to dough-in the malt is brought to boiling. It is infused into the mash to raise the temperature of the whole from 60 degrees F (16 degrees C) or so up to 95 to 105 degrees F (35 to 41 degrees C).

Where the grist is not doughed-in cold, even more attention needs to be paid to evenly hydrating it. Even with well-modified British malts, balling is a problem as the temperature at doughing-in increases.

Mash pH

The correct initial pH of any mash depends on the type and color of the malts employed and the planned mashing technique. It must never be begun at above pH 6.2, or below 4.7. When the mash is from enzyme-poor malt that will be fully decoction mashed, the mash cycle may begin at a pH as high as 5.5 to 5.8 (as measured at the reference temperature, usually 68 degrees F (20 degrees C).

“Acid” sourmalt is used to lower the alkalinity of the mash. Sourmalt has been treated with lactic acid or lactic-acid bacteria to a percentage-lactic-acid of 3.5 to 4.0 percent, giving a wort pH of 4.0 to 5.0. It is employed as 5 to 10 percent of the grist to give an initial mash pH of 5.2 to 5.8. Colored malts also have a significant effect on wort pH; the darker-roasted the malt, the greater its effect on wort acidity. While lager malts generally give a wort pH of 5.7 to 6.0 in a laboratory mash from distilled water, more highly kilned Vienna and Munich give pH 5.5 to 5.7, better-modified pale pH 5.3 to 5.7, the darker brown and caramel/crystal-50 pH 4.5 to 4.8, chocolate 4.3 to 4.5, and black malt 4.0 to 4.2.

Depending on their proportion in the grist and the alkalinity of the liquor, colored malts may be enough to give proper mash acidity. Until the proper initial mash acidity is approximated (within pH 0.2), however, the mash cycle should not be begun.

Acid Rest

The pH of calcium-bearing liquor always drops as it is mashed with malt because phosphates in the malt react with calcium and carbonate, precipitating alkaline calcium phosphate and lowering the mash pH. Where malt color and calcium content of the liquor are low, however, this reaction is insufficient to give an acceptable mash acidity.

The acid rest is made solely to correct the initial mash pH. Significant phytase activity in conjunction with very limited bacterial fermentation of glucose to lactic acid acidifies the mash without imparting a harsh flavor to its extract. The rest is most successfully employed when mashing with reasonably soft or sulfate water; it cannot overcome the alkalinity of strongly carbonate waters. Excessive carbonate salts present in the brewing water must first be precipitated by boiling or adding slaked lime, or overcome by the inherent acidity of dark-roasted malt, or by adding lactic, phosphoric, sulfuric, or citric acid to the brewing liquor or sourmalt or lactic-acid mash to the mash itself.

Acidulation of the mash is primarily by the enzyme phytase, active at 86 to 128 degrees F (30 to 53 degrees C), which dismantles insoluble phytin, a salt in which most of the malt phosphate is bound up, to significantly acidic phytic acid. Generally referred to as an enzyme of malting, reactivation of phytase by the acidic hydrolysis at 95 degrees F (35 degrees C) accounts for a twofold or threefold increase in the phytic acid in a decoction mash from lager malt. It benefits the mash not only by lowering its pH but by increasing the mineral content of its liquid extract and producing a rich and accessible source of yeast nutrients, especially myoinositol, a B-vitamin necessary for yeast growth.

Phytase activity is most dramatic when mashing undermodified malt, since less of the malt phosphate has been inverted during malting. Mashes made from highly kilned malts show little pH reduction during an acid rest because phytase is destroyed by the high kiln temperatures. The natural acidity of these malts, however, can be sufficient for establishing a proper mash pH.

During the rest, the pH of a mash from low-modified lager malt generally drops from 5.5 to 5.8 to pH 5.2 to 5.3. A mash sequence employing an acid rest thus needs to rely less on the brewing water being naturally acidic or calcium rich, or on using colored malts, or acid malt, mash, or treatment, and begins at a higher pH than an infusion mash.

The rest is not usually held for longer than it takes to boil the first decoction. When the acidulation occurring within this period is inadequate, some manner of acidifying treatment must be made.

Traditionally, where at mashing-in the pH would be above 5.8, a separate “lactic-acid mash” is made prior to the main mashing. A 5 to 15 percent fraction of the mash volume is doughed-in and saccharified, cooled to below 130 degrees F (55 degrees C), inoculated with crushed malt, and then rested, closely covered, at 95 to 122 degrees F (35 to 50 degrees C) for up to several days. The saccharified mash at 95 to 122 degrees F (35 to 50 degrees C) creates an ideal environment for the fermentation of glucose to lactic acid by Lactobacillus delbruckii (temperature range 86 to 131 degrees F [30 to 55 degrees C], most active at 107 to 111 degrees F [41 to 44 degrees C]; pH optimum 5.6 to 5.8). The closely covered lactic acid mash is held until its pH drops below 4.0. It is then intermixed into the main mash to correct its pH.

If the lactic-acid mash begins to smell the least bit solventy or rancid, if turbulence or ropiness develops on its surface, or if it is “off” in any way, it should be skimmed and its temperature raised to above 122 degrees F (50 degrees C) to destroy the spoiling mold, aerobic butyric or acetic-acid bacteria. Where thermophilic anaerobes (L. bulgaris, L. brevis, or any of the thermophilic strains of Bacillus) are the source of the spoilage, temperatures may have to go above 140 degrees F (60 degrees C) to terminate the activity. The most common contaminant is the putrefying Clostridium butyricum, which turns the mash rancid and renders it unusable. Anaerobic conditions prevent the growth of most organisms that might otherwise spoil a lactic-acid mash, so elimination of air space between the mash and its cover is of primary importance.

Why Decoction Mash?

Although decoction mashing serves to raise the temperature of the mash to the protein, saccharification, and lauter-rest temperatures, its more important function is to cause several significant changes in the boiled portions.

Not even the most thorough infusion mash can eke out the quantity or quality of extract that is obtained by decoction mashing. There are several reasons for this. During decoction mashing, the thick part of the mash passes through the diastatic-enzyme temperature range two to three times. Boiling also reduces the size and complexity of malt starch and protein — a process that is absolutely essential when mashing-in difficult malts. Malts such as dark Munich, having only one-third the enzyme strength of pale malt, cannot otherwise be satisfactorily mashed.

Since boiling destroys enzymes, the enzymes in the unboiled mash portion must be preserved. In a mash that is satisfactorily solubilized during doughing-in, the enzymes are washed into the free liquid when the mash is flooded to raise its temperature to 95 degrees F (35 degrees C). The thickest part of the mash — containing the heaviest and least accessible concentration of native starch and protein — can then be boiled without decimating the enzyme population.

The heavy decoction is quickly heated to 150 to 158 degrees F (65 to 70 degrees C), without resting at 122 degrees F (50 degrees C), so that no further enzymatic acidulation of the mash occurs.

There are two good reasons for passing by this rest, and both are based on the pH sensitivity of the diastatic enzymes. First, the dextrinization of native starch by alpha-amylase (pH optimum 5.7) is far more effective at the higher pH of this first decoction than later when the whole mash comes into the saccharification/dextrinization range at a far lower pH. Second, the same high pH that stimulates alpha-amylase activity retards beta-amylase activity (pH optimum 4.7). Because native starch is far too complex to be successfully reduced by beta-amylase until alpha-amylase has reduced it to shorter amylose chains and smaller amylopectin fragments, resting the decoction at saccharifying temperatures is not productive. It is quite enough that the manageable small dextrins replace the native starch, even when mashing for a high-maltose extract.

Regardless of the diastatic power of the malt, unconverted starch is invariably entrapped within poorly solubilized malt particles. As the decoction is heated above 167 degrees F (75 degrees C), the particles burst, and their contents are absorbed into the liquid extract. This makes them accessible to alpha-amylase activity during the diastatic-enzyme rest of the main mash. This otherwise lost extract increases both the quality and the quantity of the extract yield.

The acidity of worts generally decrease after mashing, as they are heated to boiling (the more so with rising liquor alkalinity), because heat disassociates carbonic acid in solution to H2O and CO2, causing the pH to rise. This phenomenon is of less concern to the decoction-mash brewer because the mash is stirred and portions of the mash are boiled, both of which actions decompose HCO3, and because the acid and protein rests lower the mash acidity. Boiling the decotions also precipitates more inorganic calcium phosphate than is otherwise achieved.

Boiling also dissolves protein gum. At lower temperatures, protein gum is unaffected by enzyme activity and passes through mashing largely unconverted. Only when thick mash is boiled can the proteolytic enzymes successfully degrade dissolved gum to albuminous fractions; instead of clouding the beer, the smaller proteins enhance its body and head. Protein trub precipitated during wort cooling is also dramatically decreased.

Boiling also deoxygenates the mash, reducing hot-side aeration and allowing it to settle in well-defined layers in the lauter-tun. Only the absence of residual protein gum makes this effective filter bed possible; when an infusion mash is employed, such a dense filter bed likely results in a set mash.

In mashing techniques that do not use a decoction sequence, the proteolytic and diastatic enzymes are destroyed before the mash achieves optimum temperatures for the dissolution of starch particles and protein gum. The extract content, clarity, character, fullness, maltiness, and body of the finished beer are negatively affected. Where the malt is reasonably well modified and evenly crushed, however, the traditional three decoctions may not be necessary; even a single-decoction (or step) mash is never advisable with British ale or brewers’ malts that have been thoroughly modified during malting and would be “overmodified” by exposure to low temperature rests.

Doughing-in with boiling water to 95 degrees F (35 degrees C), followed by a second infusion to 122 or 131 degrees F (50 or 55 degrees C), only a limited protein rest, and a single, thick decoction before saccharification is sufficient for all but the most undermodified malts, and doughing-in at 122 or 131 degrees F (50 or 55 degrees C) is sufficient for most modern lager malts.

During decoction mashing, the brewer is at his busiest, because two mashes must be handled at the same time, with great care. The brewer must be thoroughly organized before plunging into the sometimes hectic decoction mash cycle.

Decoction mashing is often met with open skepticism by brewers who have no experience with it. The fact remains that the beguiling maltiness of European lagers is only achieved by boiling undermodified malt. Extract yield is increased. Moreover, hot-side aeration is reduced, because the boiling and mixing of the mash deaerates it. Boiling of the mash does not lead to astringent harshness in the brew, probably because the density and pH of the decoction prevents phenols from being leached out of the husks.

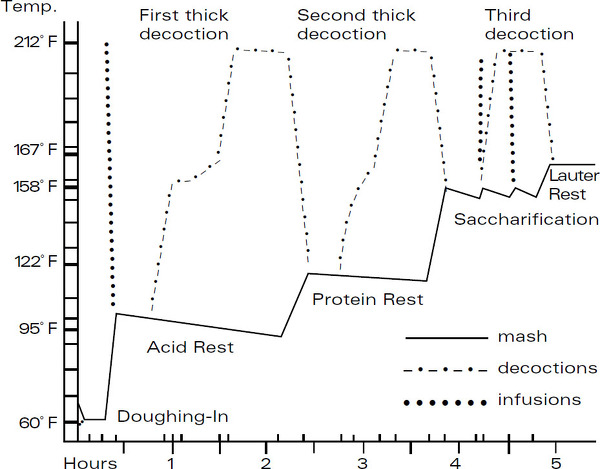

There are two widely accepted programs for decoction mashing. The first, described here, employs a protein rest at 122 degrees F (50 degrees C) and saccharification/dextrinizing at 149 to 158 degrees F (65 to 70 degrees C). It is best suited to malts of below 37 percent soluble nitrogen.

The second program is better suited to higher-protein modern malts with a soluble nitrogen ratio of 37 to 40 percent. A combined proteolysis/saccharification rest is made at 131 degrees F (55 degrees C), allowing proteases to reduce large proteins to body- and head-building polypeptides and beta-amylase (temperature optimum 126 to 149 degrees F [52 to 65 degrees C], pH 5.4) to reduce amylose to maltose and glucose, and amylopectin to ß-limit dextrins. Dextrinization is then accomplished separately, usually at 158 to 162 degrees F (70 to 72 degrees C).

Three-Decoction Mash

First Decoction

The volume of thick mash to be boiled, relative to the volume of the whole mash, is dependent upon mash thickness. A very thick mash requires that only its heaviest one-third part (mostly grain mass, with only enough liquid to fill the spaces between the grain particles) be boiled, along with very little of the mash liquid. Thinner mashes require that proportionally more of the mash be boiled, along with more liquid, because even if most of the malt is removed and boiled, in a thin mash it would not contribute enough heat to the resting mash to sufficiently raise its temperature to the next rest. One pound of crushed malt contributes about the same amount of heat to the mash as does one pint of water, yet displaces only as much volume as six fluid ounces of water. In a thick mash, the favorable heat-to-volume ratio of the malt is such that the heaviest one-third part can raise the temperature of the whole mash to the next rest. In a thin mash, however, the heat value of the malt is not enough to overcome the far greater amount of water. A greater percentage of the mash must therefore be boiled — but usually not more than 40 percent.

After the decoction has been pulled, the rest mash (cold settlement) is closely covered and held undisturbed, except for occasional mixing to disperse temperature and enzyme activity. At the end of each decoction cycle, the mashes are remixed to raise the temperature of the whole to the next rest.

Protein Rest (First Thick Mash)

With traditional lager malts, the character of the finished beer — its body, clarity, lack of chill haze, stability, and resistance to spoilage — is largely established during the protein or “albumin” rest. This “softens” poorly modified malt and improves mash runoff by decomposing heavy, gummy, insufficiently modified malt particles. During the rest, complex protein globules are decomposed by proteolytic enzymes to less troublesome fractions. With relatively unmodified lager malts, proteases, peptases, and proteinases progressively dissolve the peptide links within the protein coils to liberate coagulable albuminous fractions, peptides, and amino acids. It is albumin (proteoses, peptones, and polypeptides), not protein, that gives beer its body and enables it to raise and support a frothy foam head.

The protein-rest temperature should be 122 to 131 degrees F (50 to 55 degrees C), although temperatures from 113 to 140 degrees F (45 to 60 degrees C) support proteolytic enzyme activity. It should be kept in mind, however, that at the lower end of the temperature range, head-and-body polypeptides may be denatured to peptides and amino acids, reducing the body of the beer. Proteinase (temperature range 104 to 140 degrees F (40 to 60 degrees C), optimum 122 to 140 degrees F (50 to 60 degrees C), pH 4.6 to 5.0, solubilizes and breaks down simple proteins to peptones, polypeptides, and peptides. Peptidase (optimum range 113 to 122 degrees F [45 to 50 degrees C] pH below 5.3) dissolves polypeptides and peptides to individual amino acids, which fuel yeast growth in the early stages of fermentation. In any all-malt beer, however, there are generally sufficient amino acids to support fermentation.

Extract efficiency is also enhanced by the protein rest. Extract is exposed by the dissolution of membranous proteins, and complex amylopectin may to some extent be dismantled by debranching enzymes (maltase, dextrinase).

Phytase continues its activity during the rest, reducing phytin from the aleurone layer and embryo of the malt to phytic acid. Other acids also rapidly form during the rest, further lowering the pH toward the optimum values for saccharification, the clarification of the wort during boiling, and subsequent yeast fermentation. During this rest, the pH should drop again to below 5.4.

Other nonproteolytic enzymes (most notably cytase, temperature range 113 to 131 degrees F [45 to 55 degrees C], pH 5.0, and beta-glucanase, range 95 to 131 degrees F [35 to 55 degrees C]) actively dissolve pectins and other constituents of the malt hemicellulose during the protein rest.

A thick mash improves enzyme performance. In a thin mash, proteolytic and other heat-labile enzymes are destroyed in the course of the rest; in a thick mash, they may survive into the saccharification range.

The protein digestion can be overdone, however. Devoid of proteoses and peptides, the beer would lack body and a froth head. It would be very stable, but very empty-tasting. Without any coagulable proteins to adhere to, hop tannin would not precipitate from the boil, and the beer would taste “rough.” Reducing nitrogen complexes too far would result in the presence of an excessive amount of simple nutrients in early fermentation, which would encourage bacterial contamination.

The degree of protein degradation achieved during this rest may be fairly judged later on by the thickness and slickness of the protein sludge covering the settled grist in the lauter-tun. It should be moderately thick and powdery rather than gummy.

The rest temperature must be reached by effective mixing, accomplished by lifting the mash from the bottom of the tun. It is essential that the return of the decoction be competently handled so that temperature dispersal is absolutely even. Attempting to correct wide temperature fluctuations within the remixed mash is never easy.

In the event that the strike temperature is reached before all the decoction has been returned, the remainder of the boiled mash is force-cooled to 122 degrees F (50 degrees C) before it is returned to the main mash.

The objectives of the albumin rest should be accomplished in less than two hours, or the malt is entirely unsuitable for use in brewing. Usually after five to twenty minutes at 122 to 131 degrees F (50 to 55 degrees C), the heaviest part of the mash is again drawn off, to begin the second decoction. Up to 30 percent of the malt nitrogen can be expected to have gone into solution at its conclusion.

Saccharification Rest

Malt starch occurs as long straight or complex-branched chains of linked glucose, C6H10O5. During the saccharification rest, alpha- and beta-amylase reduce that starch to simpler fractions. This yields flavorful dextrins and fermentable sugars.

Alpha-amylase very rapidly reduces insoluble native starch to smaller polysaccharide fractions (a mix of some glucose, maltose, maltotriose, and straight-chain dextrins with a predominance of branched “a-limit” dextrins). Given long enough, the alpha-amylase continues to sever 1-4 glucose links, producing more glucose, maltose, and maltotriose, but starch-chain fragments are more effectively saccharified to fermentable sugars by the faster-acting beta-amylase. Beta-amylase has no effect on native starch, but in hydrolytic solution, it reduces soluble starch by cleaving glucose molecules from one end of starch chain fragments and rejoining them in pairs with a water molecule to create maltose, C12H22O11.

It is inadvisable to reduce all starch to fully fermentable maltose. Significant quantities of more complex polysaccharides must be carried over into the ferment for the beer to have a sweet flavor and sense of fullness. Partially fermentable dextrins, oligosaccharides, and especially maltotriose support the yeast during the long, cold aging period.

The temperature of the rest may be from 149 to 160 degrees F (65 to 71 degrees C), depending on the nature of the beer being brewed. Precisely hitting the appropriate rest temperature is essential, as a variation of two or three degrees for even five minutes will dramatically alter the maltose/dextrin ratio of the extract.

Mash thickness also affects the fermentability of the wort. A thick mash (less than three-tenths of a gallon of water per pound of malt) induces the greatest overall extraction. A much thinner mash increases the proportion of maltose, and thus wort attenuation.

The reduction of the large starch chains in a thick mash at 155 to 158 degrees F (68 to 70 degrees C), almost excludes any maltose formation whatsoever. The richly dextrinous wort produces a fullness and sweetness complementary to Munich-style lagers and darker beer with a contrasting burnt-malt bitterness. It is seldom suitable for light-colored beers.

Above 160 degrees F (71 degrees C), strong enzyme action ceases; temperatures below 149 degrees F (65 degrees C), on the other hand, seriously limit dextrin formation (by alpha-amylase, temperature optimum 149 to 158 degrees F [65 to 70 degrees C], pH 5.1 to 5.9) while favoring the formation of maltose by beta-amylase. Because starch granules are not gelatinized or dispersed below 149 degrees F (65 degrees C), beta-amylase activity at lower temperatures serves only to eliminate the straight-chain dextrins formed in the decoction, without further significant starch reduction.

For very light beers, the release of ungelatinized starch into solution at 149 degrees F (65 degrees C) is capitalized upon by raising the temperature of the mash from 131 to 149 degrees F (55 to 65 degrees C) over fifteen to thirty minutes; this largely eliminates the amylose liberated during the decoction. The mash is brought to rest at 149 to 151 degrees F (65 to 66 degrees C) to gelatinize and further dextrinize the starch, and to produce a maltose/dextrin ratio that favors lightness on the palate and rapid maturation.

For rather more usual palate fullness and fermentability, the recombination of the mashes requires even more careful handling. The decoction must be returned to the rest mash as quickly as possible, but without creating wide temperature variations within it. The rest temperature should be evenly attained within less than ten minutes.

Most of the amber and gold lagers, and even the pale Pilsener/Dortmunder types, rely on the heavier, richer dextrin complement formed at 152 to 155 degrees F (67 to 68 degrees C). This is the strike temperature of most “character” beers brewed with undermodified malts and a protein rest at 122 degrees F (50 degrees C). Saccharification in this temperature range encourages an alpha-/beta-amylase activity ratio greater than five to one; as a result, the dextrin content of the wort is 25 percent or greater, and the alcohol content by weight of the finished beer is roughly one-third the value of the wort density (°Plato). Where a combined protein/saccharification rest at 131 degrees F (55 degrees C) has been made, similar results are acheived by a dextrinizing rest at 158 to 160 degrees F (70 to 71 degrees C).

As the mash saccharifies, it becomes thicker, brighter, and browner. The brewer may decide to add brewing liquor to thin an overly thick mash and to speed up saccharification (beta-amylase is more effective in the looser mash). Caution must be used, however; as mash temperatures rise above 149 degrees F (65 degrees C), enzymes are rapidly destroyed in a thin mash. Even in a thick mash, beta-amylase is destroyed in less than an hour at above 149 degrees F (65 degrees C), and alpha-amylase is destroyed within two hours at above 154 degrees F (68 degrees C) in a mash below pH 5.5. This fact must be remembered when mashing to yield a dextrinous wort; a satisfactory dextrinous wort cannot be formed at below 153 degrees F (67 degrees C).

As opposed to British infusion mashes, which are entrained with air and “float,” a decoction mash is stirred regularly, in a nonaerating fashion, to break up any pockets of unmodified starch and ensure uniform conversion. After fifteen minutes at the rest temperature, testing for saccharification with iodine should begin.

Iodine Starch-Conversion Test

Place a small sample of the extract in a porcelain dish. Float common iodine (.02N solution; 1.27 grams iodine and 2.5 grams potassium iodide in 500 milliliters water) onto the extract, drop by drop, until a distinct layer of iodine is formed. Note any color change in the iodine at its interface with the mash liquid. Also observe the intensity of the color: is it trace, faint, or strong? Blue-black indicates the presence of native starch (amylose); deep mahogany/red-brown evidences gelatinized starch (amylose fragments and large a-limit dextrins), faint red simple a-limit dextrins. A faint mahogany to violet-reddish reaction denotes a mix of small dextrins. Total mash saccharification (a solution of some small a-limit dextrins with maltotriose, maltose, and simple sugars) causes no change in the yellow color of iodine.

Iodine is a poison. DISCARD ALL TESTS. Ensure that there is no iodine contamination by washing any article that comes into contact with it. Conduct iodine tests some distance from the mash so that no iodine will inadvertently contaminate the mash.

Most of the starch should be reduced to at least small a-limit dextrins by alpha-amylase. Even for sweet, less-fermented beers, the reaction with iodine should be no more than faintly mahogany-to-red. There should never be a strong color reaction with the iodine; neither, however, should rich beers be saccharified to the point that a negative iodine reaction occurs. A faint mahogany-to-reddish reaction indicates an acceptable extract composition for these beers.

The mash should be held at the strike temperature until saccharification is complete. Infusions of boiling water may be made with less regard to enzyme viability as conversion nears completion. The looser mash improves filter bed formation.

(Note: Koji or other diastatic enzyme preparations should not be used to increase enzyme activity. Although they convert hundreds of times their weight in soluble starch to simple sugar, they do not form dextrins.)

If the mash does not saccharify within one hour, it should be stirred, restored to temperature, verified for proper pH (5.2 to 5.5), and held for thirty minutes more. If the iodine color is not further reduced, addition of diastatic malt or extract may be required.

The efficiency of the malt crushing can be gauged by pressing a sample of the goods until all of the kernel ends and malt particles have been crushed, then separating the liquid from the particulate matter. Repeat the iodine test on the liquid, as above. If the color at the iodine-mash interface is intensely black or blue, then crushing was insufficient or the malt was poorly doughed-in. (Some isolated color from insignificant amounts of exposed starch is to be expected; husk particles themselves will always turn intensely black). Suspicions regarding the efficiency of milling may be verified either by a wort density that is less than predicted or by tasting the dried spent mash. If extract efficiency is below 65 percent or the spent grains taste sweet, the malt has probably been insufficiently crushed.

Final Decoction

When the starch end point has been verified, the very thinnest part of the mash is removed to be boiled. The decoction is usually 40 percent of the volume, although a very thin mash may require boiling half of the mash. Because there are fewer starch and albuminous particles in the thinner portion, there is less risk of these being decomposed during the boiling of the runoff. These remain with the rest mash. On the other hand, enzymatic reduction of the dextrins in the thin part of the mash is more quickly terminated, preventing oversimplification of the extract.

The lauter decoction is brought to boiling, while being stirred, in ten to fifteen minutes and may be held at a strong boil for a further fifteen to forty-five minutes, although in modern practice it is uncommon to boil the mash for more than five or ten minutes. The temperature of the rest mash is held at or slightly above the strike temperature during boiler-mash processing.

The boiled extract must be well mixed with the rest mash. Care should be taken that the strike temperature of the final rest, 167 to 170 degrees F (75 to 77 degrees C), is not exceeded. Temperature adjustments may be made by the infusion of either cold or boiling brewing liquor, as required.

Exact temperature maintenance is, as before, critically important. Lower temperatures do not terminate enzyme activity or expand particles of intermediate starch degradation enough to keep them in temporary suspension, up and away from the bottom of the mash filter bed. At higher temperatures, the starch granules burst, and insufficiently modified carbohydrate and albuminous matter becomes dissolved and unfilterable. Because the diastatic and proteolytic enzymes have been destroyed by the high temperatures, the starch and protein gum have no opportunity to be reduced to manageable fractions. High temperatures also induce the extraction of tannins from the husk.

The mash-out temperature may be maintained for up to one-half hour while the mash is roused up. Thorough mixing allows the mash to settle very slowly and form a well-delineated filter bed.

The lauter mash should be very thin and thoroughly intermixed to encourage the absorption of the malt extract into solution and to temporarily force small starches and proteins into suspension, allowing the husks to freely settle.

Wort Separation

The purpose of sparging/filtering is to rinse the soluble extract free from the malt husks and to trap insoluble, poorly modified starch, protein, lipids, and silicates within the husks. Without adequate filtering, extract is lost, while the mash runoff is clouded by starch, proteins, tannins, and husk particles. This produces beer likely to be cloudy, astringent, and unstable.

The mash may be transferred to a lauter-tun for filtering. The diameter of the vessel should allow the filter bed to form to a depth of twelve to eighteen inches. A filter bed of six-row barley, however, may need to be only six inches thick; the greater percentage of husks in six-row barley increases its filtering efficiency. The mash filter bed when brewing with infusion-mashed British ale malts is more commonly twenty-four inches deep at the start of the runoff.

The husks accumulate on a false bottom, or filter plate, that fits one-eighth to two inches above the real bottom of the lauter-tun. Slots or perforations in the plate allow the sparge water to slowly and evenly filter through the husks. The lauter-tun itself is equipped with a spigot located below the level of the false bottom to draw the extract-rich sweet wort off from below the grain mass.

Setting the Lauter Bed

The lauter-tun should be filled to one-half inch above the false bottom with water of 175 to 212 degrees F (80 to 100 degrees C). This preheats the lauter-tun and reduces the amount of debris that is otherwise carried into the space below the false bottom. This practice largely eliminates the need for flushing the space prior to filtering and improves the clarity of the runoff. The thin lauter mash is quickly transferred to the tun, given a last thorough stirring, and allowed to settle.

An infusion mash, on the other hand, is handled gently. Stirring is avoided. An unstirred infusion mash does not settle in as well-defined stratification as does a decoction mash, and tends to “float.” The suspended particulate matter somewhat offsets the lack of a clearly defined filter bed, as it entraps less extract. However, it never yields so clear a runoff as does a decoction-mash filter bed. Commercially, false bottoms for infusion mashes generally have larger slots than those used for decoction mashes.

Within ten to twenty minutes, the liquid displaced by the settling mash should show clear and “black” above a nebulous cloud of trub. If it doesn’t clear, then filtering efficiency can be expected to be poor. The temperature of the mash is likely to drop during the setting of the filter bed; every effort, however, should be made to limit its heat loss.

In an ideal stirred-mash filter bed, the heavy hulls that settle onto the false bottom are covered by a deeper layer of lighter hull fragments and endosperm particles. Until this porous filter-mass has formed, tiny, gelatinized particles of starch and protein remain suspended in the liquid; after it has formed, they should settle out, creating the pasty “protein-sludge” or upper dough.

If this trub precipitates too early and settles within the hulls in any appreciable quantity, some will wash into the sweet wort runoff. It may also cake within the filter bed and cause a set mash that blocks the flow of liquid down through the filter bed; either a set mash or a runoff that doesn’t clear may be due to ineffective crushing and mashing.

Sparge Liquor

A volume of liquor roughly 25 percent greater than the liquor used for mashing-in is heated to 170 to 176 degrees F (77 to 80 degrees C) in preparation for sparging. The temperature of the sparge liquor is critical because sugars flow more freely in hot solution than in cold. Its temperature must be maintained throughout the sparging to dissolve and rinse free the extract cupped in the hulls or adhered to the malt particles.

Excessive temperatures in the mash itself, however (above 170 degrees F [77 degrees C]), rupture balled native-starch particles and decompose the protein sludge, causing them to be carried away in the runoff. Because only very simple protein and carbohydrate fractions can be managed by culture yeast, none of these more complex fragments should be allowed in the wort. Runoff temperatures above 170 degrees F (77 degrees C) also cause extraction of husk polyphenols and marked astringency in the beer.

If necessary, the salt content or acidity of the sparge liquor should be adjusted, preferably with calcium salts or lactic or phosphoric acid, to limit extraction of harsh-tasting malt fractions and improve clarity. The pH of the runoff should never rise above pH 6; better results are achieved when the runoff pH does not rise above 5.8.

Carbonate waters are not useful for sparging, because they induce haze fractions and silicates into solution and may induce renewed enzyme activity. These waters become even more alkaline upon heating. Carbonate ions must be precipitated or disassociated before the liquor is used for sparging.

Preparing to Sparge

The space below the false bottom can be purged of particulate matter by flushing it with clear, 170 degree F (77 degrees C) liquor, either through an inlet below the false bottom, opposite the spigot, or through a tube thrust down through the mash. The inlet and runoff rates must be carefully matched to avoid disturbing the filter bed above. Flushing can be eliminated if the cloudy runoff is refiltered through the mash until it runs clear (vorlauf vehrfahren), or the runoff is starch free.

The degree of clarity that should be obtained in the runoff is a matter of debate. A lot of draff carried into the kettle is a recipe for astringent beer, but a small amount may improve trub coagulation. The majority of brewers recycle until the runoff is no longer heavily clouded; this is generally accomplished in less than ten minutes. Excessive recycling may lead to greater lipid levels in the wort and ought to be avoided.

To set the filter bed and settle the protein sludge, the lauter-tun spigot is opened once the liquid above the grains clears. The liquid is run off very slowly until it stands one-half to one inch deep above the surface of the mash. This liquid level must be maintained throughout sparging. Draining below the mash surface level causes the mash to settle too tightly and the protein sludge to cake. Extract efficiency is reduced and the potential for developing a set mash increases. Too great a liquid depth, on the other hand, acts as weight on the grains and leads to stuck mashes. The mash surface should be periodically leveled and smoothed to fill in all the depressions and vertical channels.

Sparging

The liquid level above the filter bed is maintained by the introduction of sparge liquor. Sparge liquor should be gently and evenly dispersed over the top of the mash so it will evenly percolate through the mash and diffuse all the extract from it. The sparging rate should be free from surges and matched to the runoff rate so that the liquid level in the lauter-tun is not changed.

The sparging/runoff rate may be gradually increased, but not so much so that turbidity is caused in the runoff. Set mashes also result from too rapid a flow rate.

High-husk, six-row barley may be run off in less than an hour (a six-inch-deep bed may be filtered in as little as one-half hour). Maximum extraction, however, is achieved with a very slow runoff rate, a deeper filter bed, and raking the mash to within six inches of the false bottom. Raking restructures the filter bed, ensuring even percolation of the sparge liquor through the grain and complete extraction of the sugars. A mash that is raked, or that is from finely ground malt, or shows a tendency to set, must be run off slowly. Set mashes that don’t respond to being stirred must be cut repeatedly during sparging in order to reopen channels of extract flow.

Within 1 ½ hours, the greater part of the extract will have been leached from the malt. Although the maximum yield is obtained by restricting the runoff rate so that it takes two to four hours to collect the sweet wort, the small percentage of extract gained is not worth the time and effort.

The temperature within the mash should be carefully maintained during sparging and filtering, although the early runoff will usually be well below 168 degrees F (75 degrees C). In the interest of preventing further enzyme activity, the wort collecting in the copper should be heated to above 170 degrees F (77 degrees C) as it accumulates. Where a large amount of evaporation is required, the sweet wort is brought to boiling and partially hopped as soon as it has covered the bottom of the kettle.

As the color of the runoff pales, its extract content is periodically checked with a hydrometer; when the reading drops to below 3 °Plato (SG 1012, corrected to 68/60 degrees F [20/15.56 degrees C]), the runoff is diverted from the wort kettle.

Below this density, the runoff pH is likely to rise above pH 6, increasing the likelihood that malt tannins, lipids, and silicates will be leached into it. Malt tannins give an astringent taste and are harsher flavored than hop tannins. They are more soluble and are not as readily precipitated in the kettle. Lipids interfere with foam stability, increase ester formation, and are precursors to cardboardy, stale flavors in beer.