The Woodside Cheese Wrights use batch pasteurisation (carried out in small batches) by which the milk is heated to 63°C and maintained for 30 minutes, to eliminate any pathogens. ‘Our way is slow, but it creates a better product,’ claims Kris Lloyd. Higher pasteurisation temperatures speed up the process but can adversely affect the milk integrity.

Once pasteurised, the milk is cooled and a starter culture added, followed by rennet. The starter culture is allowed to ripen, putting back into the mix the good bacteria stripped by the pasteurisation. These bacteria multiply and acidify, which is a vital part of the cheese-making process. Rennet is an enzyme that coagulates the mixture.

Next the curds (solids) and whey (liquid) are separated. A large cutter called a cheese harp cuts the curd first one way, then the other. The whey is partially drained off and the curd is poured into cheese hoops. This is called ‘moulding’, and creates the cheese’s shape.

Once in the cheese hoop, the whey keeps draining slowly. The following morning, the drained cheese shapes (which at this point have a mild, subtle flavour) are immersed in a bath of brine or hand salted, as is the case with a large cheese wheel that may be susceptible to breaking in the brine bath. This salting process enhances flavour in the developing cheeses.

After salting, the cheeses are drained again, before having white mould spores added to them. The mould works quickly to envelop the cheese and creates a colony of protective white mould on the outside, while on the inside the bacteria continues to modify the taste and texture of the cheese. The cheeses are placed in one of several controlled-environment ‘caves’. The temperature and humidity of the caves are maintained (at 12°C and 96 per cent respectively) to ensure maximum proliferation of the mould on the outside of the cheese. Colder temperatures would stunt the growth of the white mould and less humidity would extract moisture from the cheese. Depending on the type, the cheeses remain in the cave anywhere from ten days to four weeks.

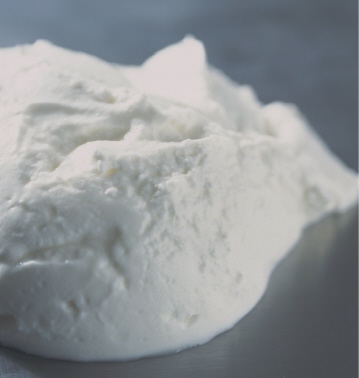

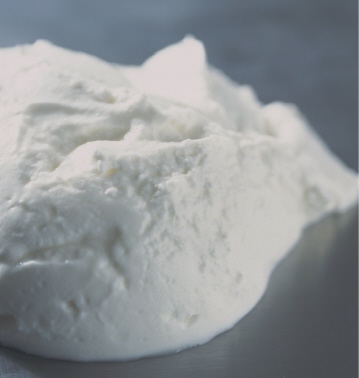

GOAT’S CURD

There is no way to disguise faults in a curd cheese the way you can, to some extent, with other cheeses that are salted, treated or ashed, so it requires precise, disciplined handling. To make the goat’s curd, the same procedure as for all Woodside Cheeses is followed: the milk is pasteurised and treated with starter culture and rennet. After the whey is drained off in cheesecloth bags overnight it is lightly salted and packaged for sale immediately.

Its flavour is light and tangy, with an almost fluffy finish. The versatility of goat’s curd means it is suitable for both sweet and savoury recipes. This is a fresh, young cheese, smelling of grass and milk.

EDITH’S ASH

This traditional French-style goat’s cheese is named after its creator, a woman named Edith from a small town near Burgundy in France. After two weeks’ culturing, it is rolled in fern ash, which alters the acid balance of the cheese. This modification introduces a distinct savoury flavour to the cheese as it continues to mature in the weeks following. After eight weeks, the bacteria will have almost entirely softened the interior of the cheese. That is why soft-rinded cheeses are best consumed within one week of their expiry date, and kept at room temperature, because the flavour and bacteria have developed fully. A fully mature Edith’s Ash will have a ball of thick cheese in the middle, surrounded by a cheese of finer, runnier consistency closer to the rind. Edith is recognised for its strong yet refined flavour and texture.

CABECOU

Cabecou was developed in the Quercy, Rouergue and Perigord regions of France. Its origins are believed to date back to the Arab invasions that brought goats to these areas. The name ‘Cabecou’ means ‘little goat’ in French and refers to the size of the cheese rather than its source. Cabecou attracts strict specifications: 4–5 centimetres in diameter, 15 millimetres in height and not exceeding 40 grams in weight. Its fat content is 45 per cent. Woodside makes Cabecou in 20-gram discs. Due to its small size the cheese matures very quickly and its shelf life is only about two weeks. The flavour is tender and delicate, and the cheese is versatile in cooking.

CAPRICORN

Capricorn is Woodside’s version of a camembert, made with goat’s milk. The cheese is made in the same style as a camembert: salted and matured in a cave. A special bacteria is added to enhance flavour, which can turn patches of the rind a reddish colour. Lloyd carefully pares back the mould so as to avoid a thick rind around what is a delicate, velvety cheese.

The French insist that it is best eaten moitié affiné – half and half – mould having penetrated the interior somewhat, but with the heart still white and not yet creamy. Ripening from the outside in, this cheese can be eaten from two weeks after the make date (the date the milk it is made from is pasteurised), however at this early stage the full flavour and texture potential will not be reached. Four weeks after being made, Capricorn is fully ripe and oozing a subtly flavoured cheese: tangy and salty, the middle (less ripened) section with a definite bite.