In this section, we cover how to select and care for the cassette—the collection of cogs on the rear hub. What we don’t cover: freewheels, the old-fashioned setup that uses thread-on cogs. Most bikes built since about 1980 use cassettes. They’re easier to remove and install, and they allow for stiffer, stronger hub construction. Win!

• CASSETTE BASICS

• CASSETTE MAINTENANCE

• COMPATIBILITY

• CASSETTE REMOVAL AND DISASSEMBLY

• TROUBLESHOOTING CASSETTES

1. This is all about cleaning and lubrication. We recommend that this be done at least monthly. If you ride in a heavy rainstorm, clean and lubricate both your chain and cassette.

Want to do a thorough cleaning job? Remove the wheel, then lay it down on a workbench or other flat surface to free both your hands for cleaning.

2. Make sure to also clean the troughs between teeth. If you have difficulty getting the cogs clean with a rag alone, use a stiff brush (like a toothbrush) to loosen the grime, and use the rag to wipe it away.

Clean the teeth of the cogs as well as you can. When the chain pulls against those teeth, any leftover grit.

Step 2

Use a rag to wipe the grime off the surface of the cogs. Moisten the rag with solvent if necessary. After cleaning the outer surface of the first cog, hold the rag with both hands. Pull it taut and slide it between successive cogs, cleaning both sides of each with a shoeshine motion.

3. Once the cogs are clean, attend to the inner parts. Spin the cassette a few times. If you hear only the familiar sound of the ratcheting mechanism, proceed with lubrication. If you hear grinding sounds, as though there are little particles of sand partying inside, you should try to clean out the grit. It’s usually possible to flush out foreign matter by dripping oil or some type of solvent through the mechanism. (Don’t try to disassemble a cassette body. They aren’t meant to be serviced.)

Look for a crack between the outer and inner cassette bodies by spinning the cassette and watching for where they are separated. Usually, you can find this without removing the cassette from the hub.

Drip bicycle oil or medium-weight motor oil into the mechanism, spinning the cassette to help the oil work its way around. Put a rag underneath to catch any excess that drains through. There’s a handy tool available called the Morningstar Tools Freehub Buddy that allows you to flush and lubricate cassette bodies.

4. If your cassette still feels gritty, try a penetrating oil-and-solvent mixture such as WD-40. Rotate the cassette while you spray the solvent mixture into it (see photo). Wipe away any excess, and lubricate the cassette once again with oil.

Some people use a more potent solvent, such as kerosene. If you do, you may have to oil your cassette several times before the lubricant is adequately replaced. A penetrating oil should be able to do the job.

Step 4

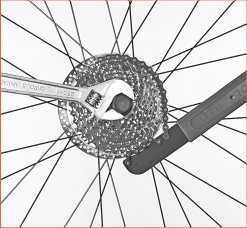

1. To replace a broken spoke, change gear ratios, or replace worn cogs, it’s necessary to remove the cassette from the hub. This is easy to do with the correct tools. For Shimano, SRAM, and Campagnolo cassettes, it requires one chainwhip, the appropriate cassette lockring remover, and a large adjustable wrench. For old cassettes (ones without lockrings), two chainwhips will do the trick.

Start disassembly by removing the rear wheel from the bike. If it’s a modern cassette, you’ll see a spline pattern at the center of the small cog; this accepts a special lockring remover.

2. Unscrew the quick-release mechanism, and insert the cassette lockring remover into the spline. For extra stability, reinstall the quick-release (remove the springs first) to hold the remover in place. This will prevent the tool from rocking and getting damaged when you apply force.

Step 2

3. Stand the wheel up (hold it or lean it against something), and wrap the chain section of a chainwhip around the largest cog, placing the handle forward (in the drive direction). Then place a large adjustable wrench on the flats of the lockring remover with the handle facing the other direction (see photo). Hold the chainwhip handle and push down on the adjustable wrench to loosen the lockring.

Step 3

4. Once it’s loose, remove the quick-release and, still holding the chainwhip, unscrew the lockring completely, turning the remover by hand. Once the lockring is removed, the cogs will slide off the hub.

Step 4

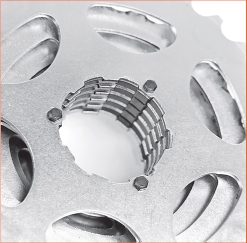

5. Some cassette gear clusters are assembled with bolts or screws (see photo) or are attached to a carrier, which you’ll see when you remove the gear cluster. In order to separate the cogs on these, it’s necessary to remove the hardware. Just be sure to keep everything in order as you remove it so you can reassemble the cassette correctly.

Step 5

WATCH THIS FIX:

FIND A STEP-BY-STEP VIDEO OF HOW TO REPLACE A CASSETTE AT