Smith & Wesson M&P

| Data: | Smith & Wesson M&P |

| Origin: | United States |

| Manufacturer: | Smith & Wesson, |

| Springfield, Massachusetts | |

| Cartridge: | 40S&W, 357SIG, 9x19mm |

| Magazine capacity: | 15 rounds (40S&W) |

| Overall length: | 7½ inches |

| Height: | 5½ inches |

| Barrel length: | 4¼ inches |

| Weight: | 24.25 ounces |

The “M&P” designation translates to “Military & Police,” a name long associated with a classic Smith & Wesson revolver. Introduced in 2006, the M&P is the S&W entry in the field of “duty” sidearms for professionals. It has numerous innovative design touches, and it should do well in that role.

Field Strip:

1. Remove the magazine. At lower rear of the grip frame there is a takedown tool that is removed by giving it a quarter-turn, then pulling it out. In some pistols, this may be difficult. Removal of the tool will also release the backstrap piece.

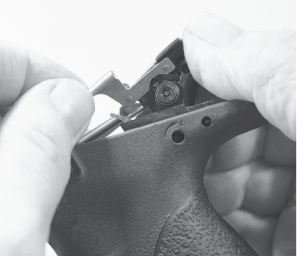

2. Pull the slide back and operate the slide latch to lock it open. With the tool provided, or any tool, tip the sear deactivation lever over into the magazine well. The lever is inside, just to the left of the magazine safety lever, and it has two angle bends. If the pistol is fairly new, the lever will be painted yellow.

3. Turn the takedown lever down to the position shown.

4. Restrain the slide, release the slide latch, and move the slide and barrel assembly off the frame toward the front.

5. Detach the recoil spring unit from the barrel lug, and remove it. Disassembly of the spring unit is not advisable.

6. Remove the barrel from the slide.

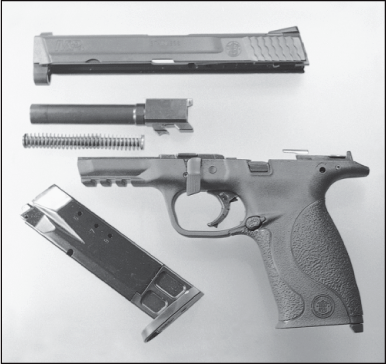

Smith & Wesson M&P field-stripped

Detail Strip:

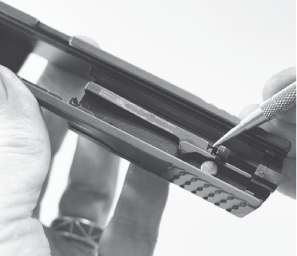

7. To release the slide backplate for removal, insert a tool to push the white polymer lockpiece forward.

8. While holding the lockpiece in forward position, move the backplate downward for removal.

9. Depress the striker block, and remove the striker assembly toward the rear.

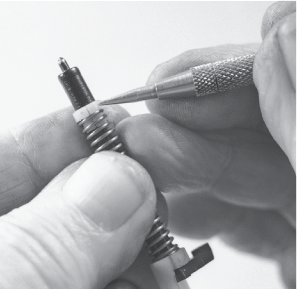

10. The striker assembly can be taken apart by drawing back the spring and removing the two halves of the spring collar at the front. CAUTION: Control the spring. This should be done only for repair.

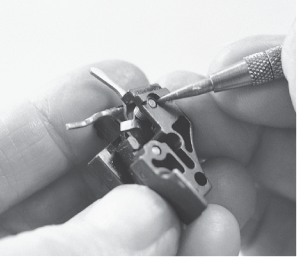

11. The striker block and its coil spring are accessed only by removal of the rear sight. If the striker block is taken out, there is a polymer sleeve in the striker tunnel that can be nudged out rearward.

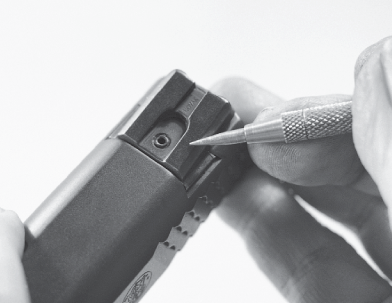

12. Both sights are dovetail-mounted. The rear sight is secured by an Allen screw. Except for repair, removal is not advisable.

13. Drifting out the vertical pin will allow removal of the extractor and its coil spring.

14. With a proper roll-pin drift punch, drive out the cross-pin at the upper rear of the grip frame.

15. After the pin is removed, gently pry the rear sub-frame upward. As it clears the frame, the ejector can be detached from the left side.

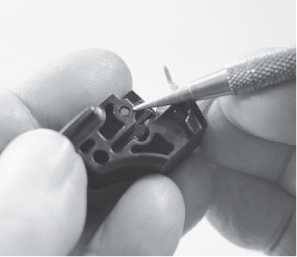

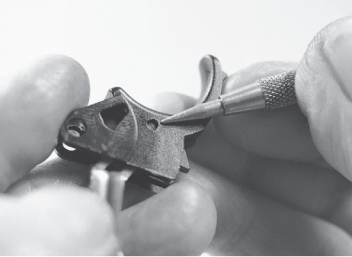

16. Pushing out this cross-pin will allow removal of the sear and its plunger and spring. CAUTION: The plunger and spring are very small and easily lost.

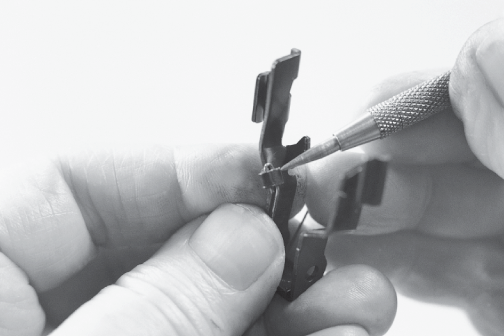

17. Pushing out the cross-pin at lower front will free the magazine safety and the sear deactivation lever, and the attendant torsion spring. CAUTION: The torsion spring will be released, so control it. The key-lock in this unit should not be disturbed.

18. Nudge the takedown lever outward toward the left, and turn it for removal.

19. Drift out the front roll-cross-pin.

20. Drift out the trigger pin toward the left.

21. Gently pry the front sub-frame out upward. As it clears on the left side, remove the takedown lever tension spring. It is very small, and easily lost.

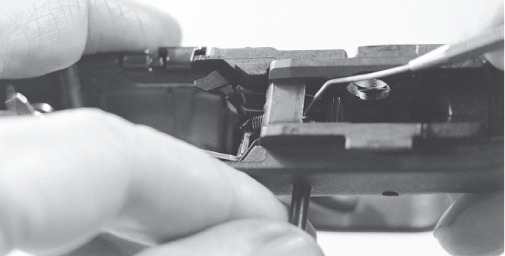

22. Lift out the trigger assembly. The slide latch is easily detached toward the front.

23. The slide latch spring is crimped in place, and removal should be done only for repair.

24. The trigger spring can be taken off by turning it over to the rear and unhooking it from its tab on the trigger bar.

25. The trigger bar can be removed by drifting out this pin. The smaller pin, below, retains the trigger safety and its spring.

26. It’s not possible to photograph this, inside the magazine well. Use slim pliers to move the torsion spring out of its notch in the magazine catch, and remove the catch. This is also the procedure if the catch is to be reversed.

Reassembly Tips:

1. As the trigger assembly is re-installed, it will be necessary to insert a hooked tool to re-engage the loop of the trigger spring with the cross-pin.

2. Note that the takedown lever has a step on its right end to allow compression of the tension spring by turning the lever. Also note that the left tip of the front roll-pin should be even with the frame surface, as shown.

3 As the rear sub-frame is installed, be sure the rear tip of the trigger bar is in its recess.