Three

HEAVY EQUIPMENT

Horse-drawn equipment made up the early machines of road building until the introduction of steam power. By the time the Blue Ridge Parkway was being built in the 1930s, gasoline-, electric-, and diesel-powered machines were in use.

This chapter will highlight some of the equipment used to build the Blue Ridge Parkway.

Benjamin Holt of Stockton, California, perfected the first successful crawler tractor in 1904. The Caterpillar trade name was first applied to such a machine the following year. Holt’s company photographer thought of a giant caterpillar when he saw the machine moving on its continuous steel crawlers equipped with cleats, or shoes, for traction.

In 1925, the Caterpillar Tractor Company was formed through a merger of Holt’s firm and bitter competitor C. L. Best Tractor Company of San Leandro, California. Caterpillar eventually consolidated its operations at the former Holt plant at Peoria, Illinois, and Peoria has been Caterpillar’s world headquarters ever since. The Caterpillar Thirty, so designated because of its 30-horsepower engine, was introduced by Best in 1921.

The term dozer or bulldozer is often applied to a crawler tractor. More accurately, dozer refers to the blade on the front of the tractor that is used to gather, push, and spread material. Faster self-propelled, rubber-tired machinery rendered them largely obsolete for this work starting in the 1940s and 1950s.

By the 1960s, self-propelled motor scrapers rendered the much slower tractor-drawn scrapers obsolete for nearly all construction applications because of their speed and maneuverability. Many continued to be used for their original purpose of agricultural land leveling, as well as occasional use in construction work where severe conditions made motor scrapers impractical.

The earliest known dump trucks date to 1904. Early dump truck capacities were only a couple of cubic yards, and today tandem-axle trucks like these carry 10 to 12 cubic yards.

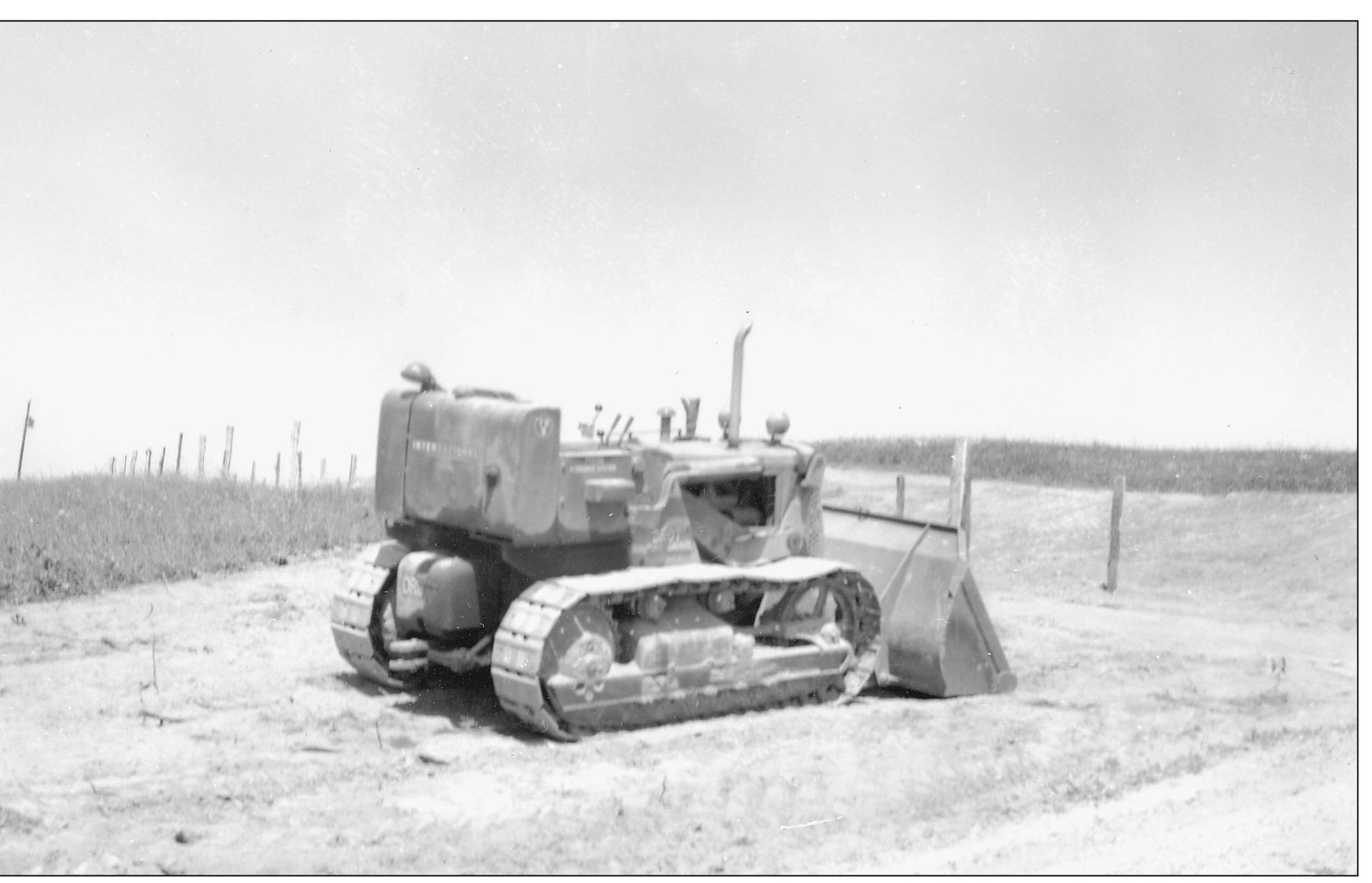

SHOVEL DOZER AT BORROW PIT. A bulldozer is a very powerful crawler (caterpillar-tracked tractor) equipped with a large blade. The first dozers were equipped from farm Holt tractors that were used to plough fields. The blade peels layers of soil and pushes it forward as the tractor advances. Notice this one does not have a cabin to shield the driver from the elements. The borrow pit literally contains excavated material that has been taken from or borrowed from one area to be used as fill at another location. At each stage of the construction where fill dirt was needed, these borrow pits were established to help stage the construction. Projects the size of the Blue Ridge Parkway have to be done in sections. It took over 52 years to complete 45 sections of the Blue Ridge Parkway. (Courtesy of the Blue Ridge Parkway Archives.)

MOWING EQUIPMENT IN 1973. Tractors with bush hogs and grass blades are essential to the upkeep and grooming of the Blue Ridge Parkway. During the warm months of the year, mowing is a constant job for the maintenance crews. This crew is getting ready to mow at Gillespie Gap in North Carolina. (Courtesy of the Blue Ridge Parkway Archives.)

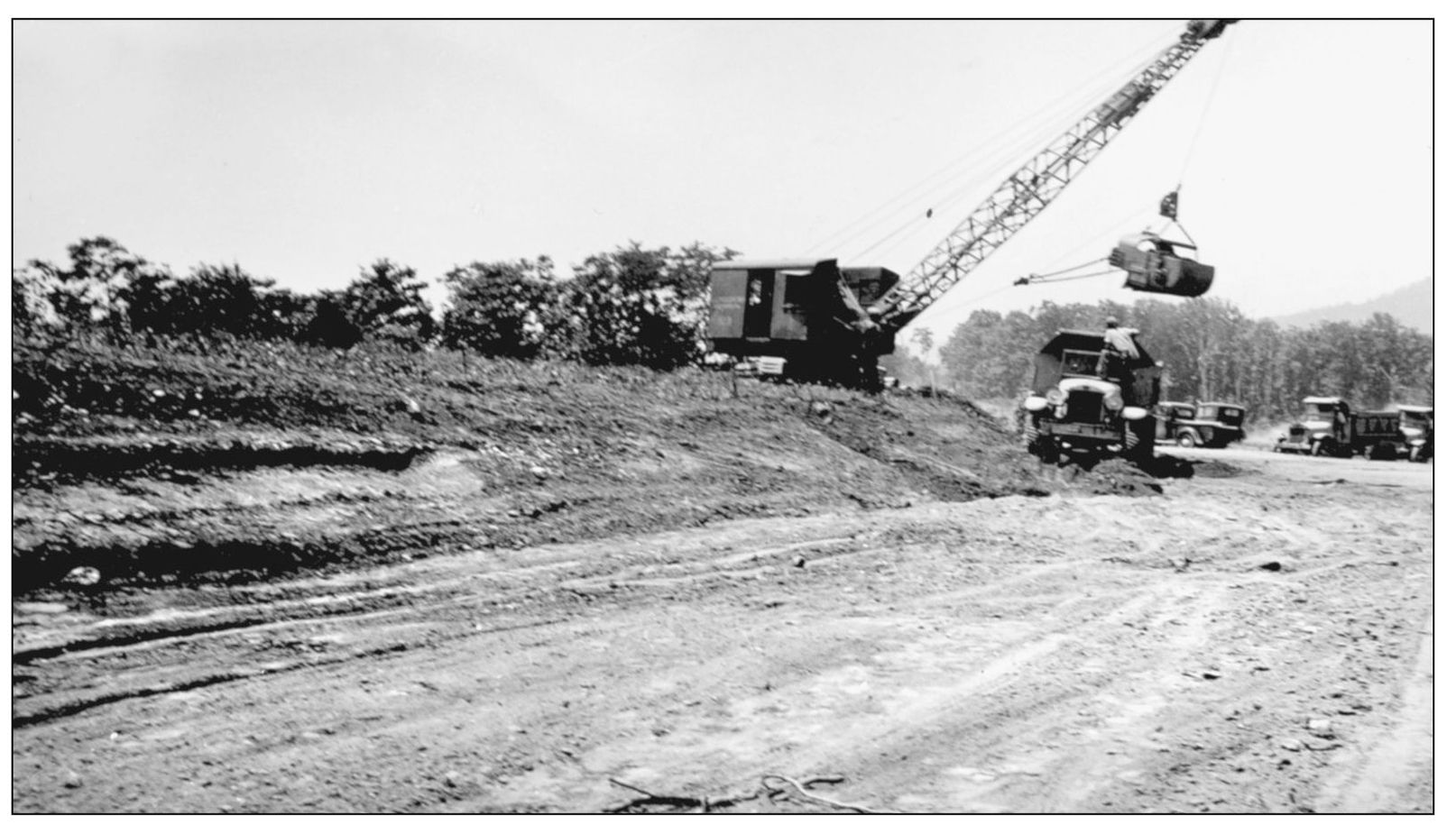

SHOVEL AND TRUCK IN THE LATE 1930S. Shovels became a mainstay of road construction. The cab sits on a swivel so that the driver can turn 360 degrees to access rock that has to be hauled away once blasted. Heavy-duty army trucks were used to haul the large loads to other locations or to crushers for recycling. (Courtesy of the Blue Ridge Parkway Archives.)

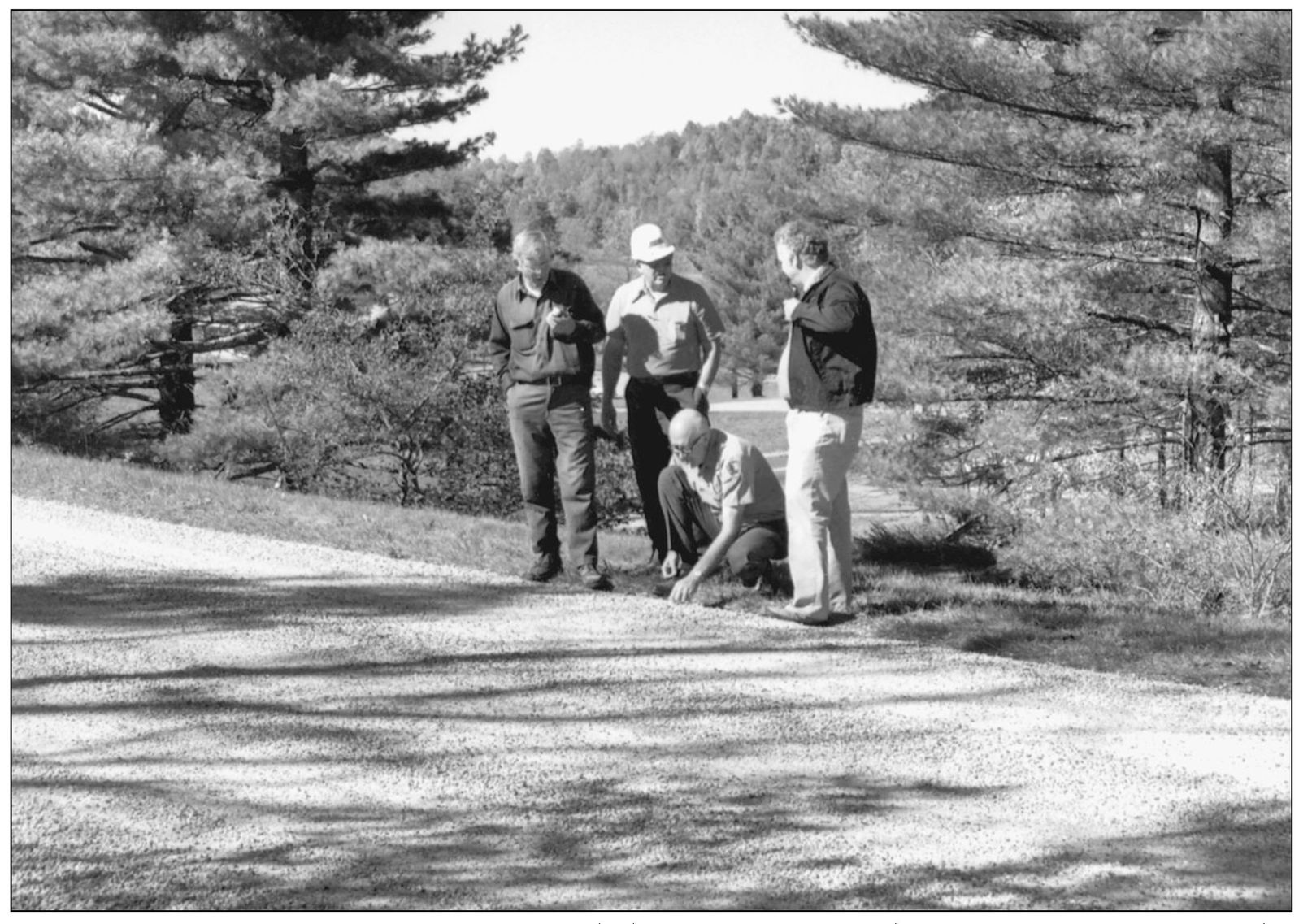

QUALITY CONTROL CREWS IN 1973. Asphalt repair requires a lot of preparation. Before the process begins, the determination has to be made as to the type of materials that will be used and as to the degree of thickness the materials will be covering. Surveys have to be conducted to determine the width of the road. (Courtesy of the Blue Ridge Parkway Archives.)

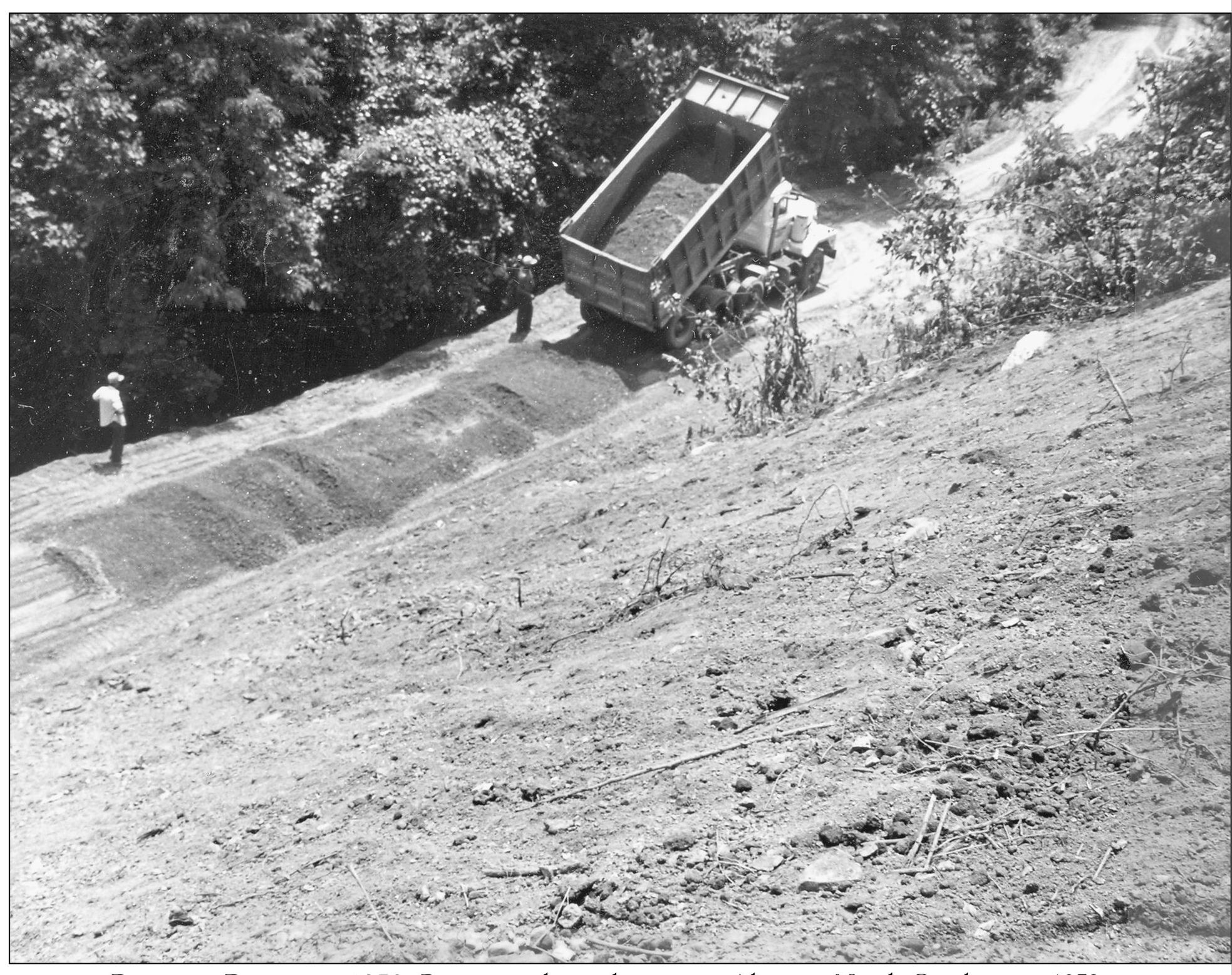

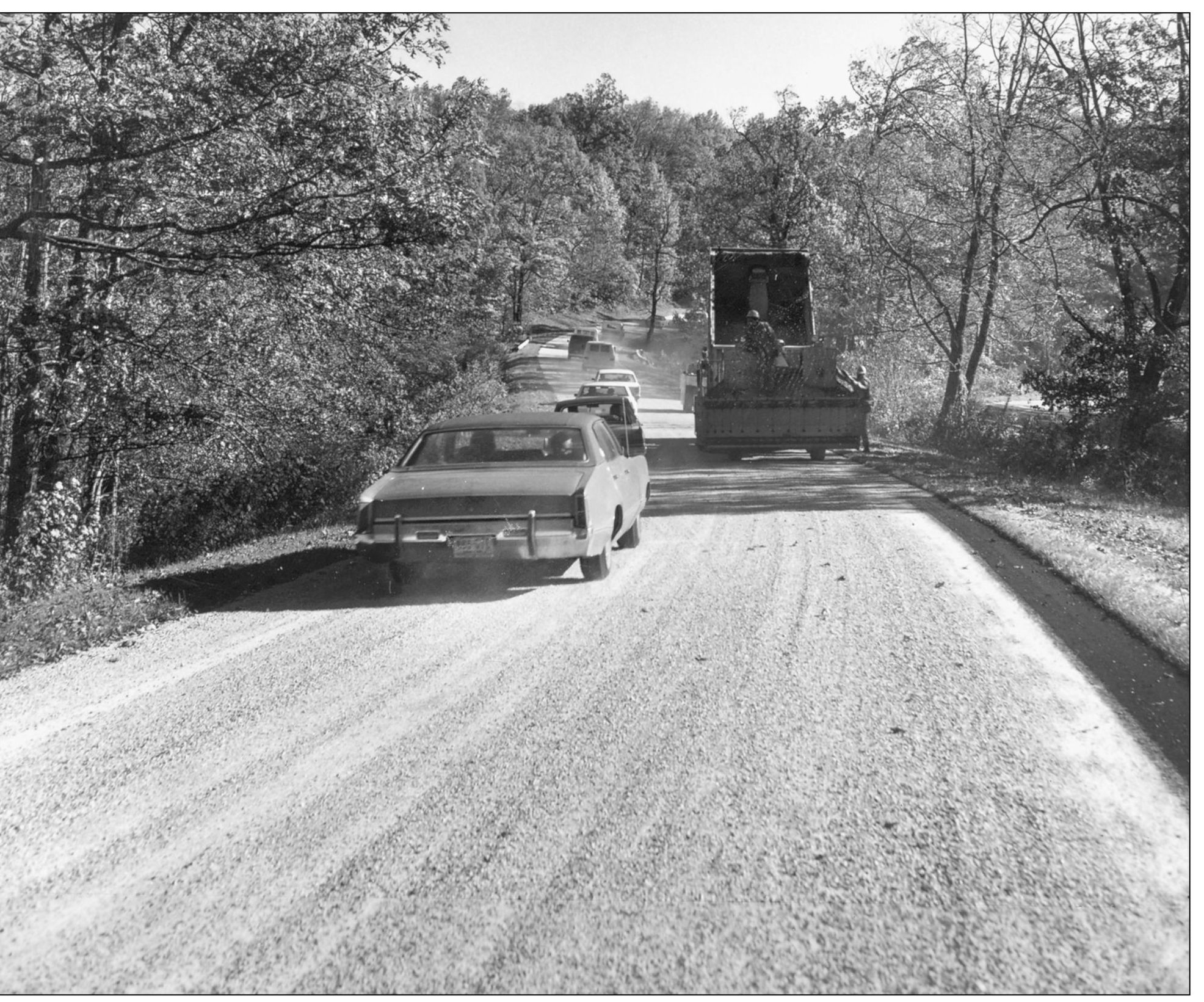

PARKWAY REPAIR IN 1978. Repairing the parkway near Altapass, North Carolina, in 1978 required a large dump truck with a load of gravel. Gravel provides a firm foundation for the buildup of the roadbed. Once it is packed and leveled, asphalt will be added. (Courtesy of the Blue Ridge Parkway Archives.)

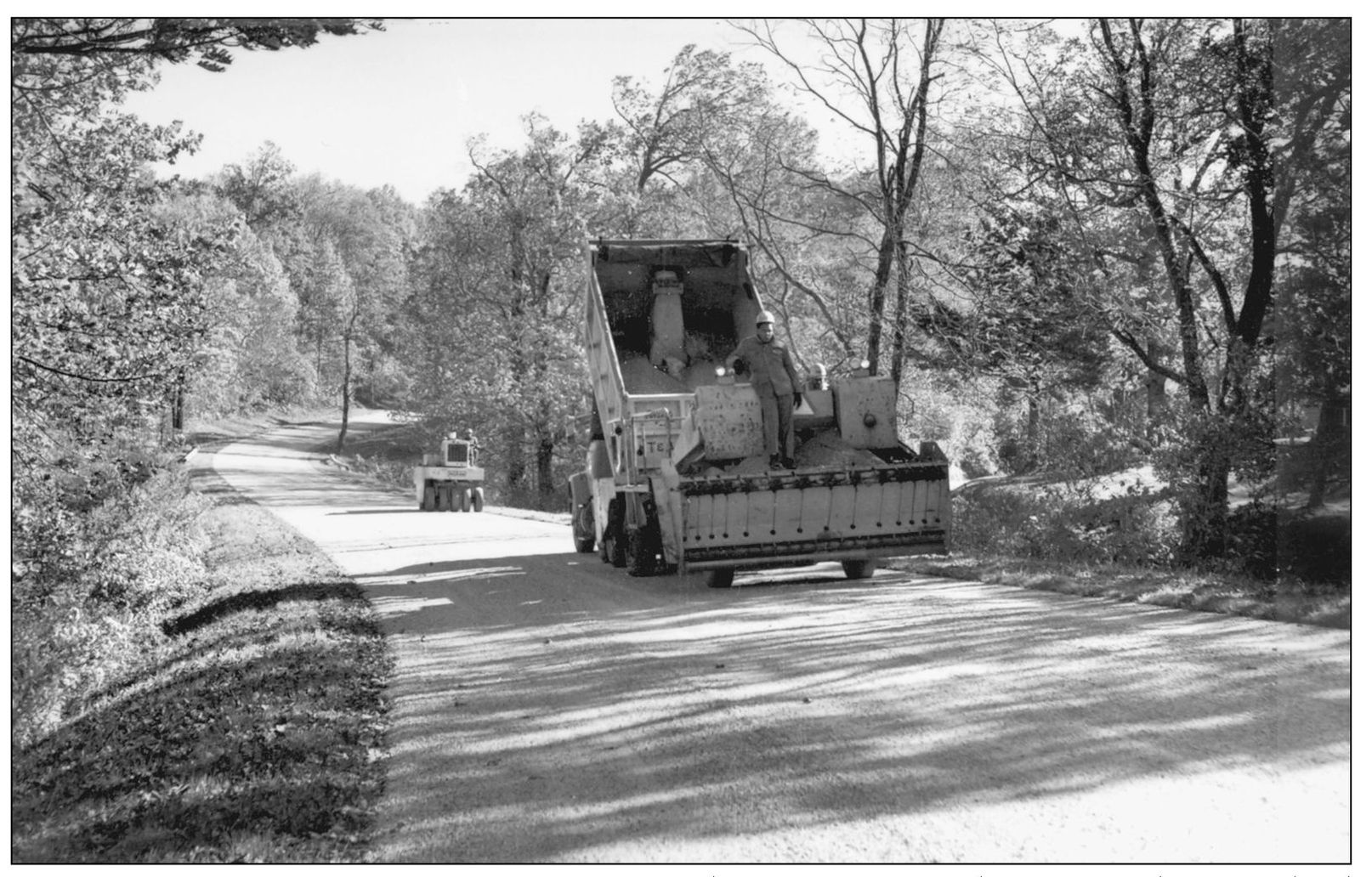

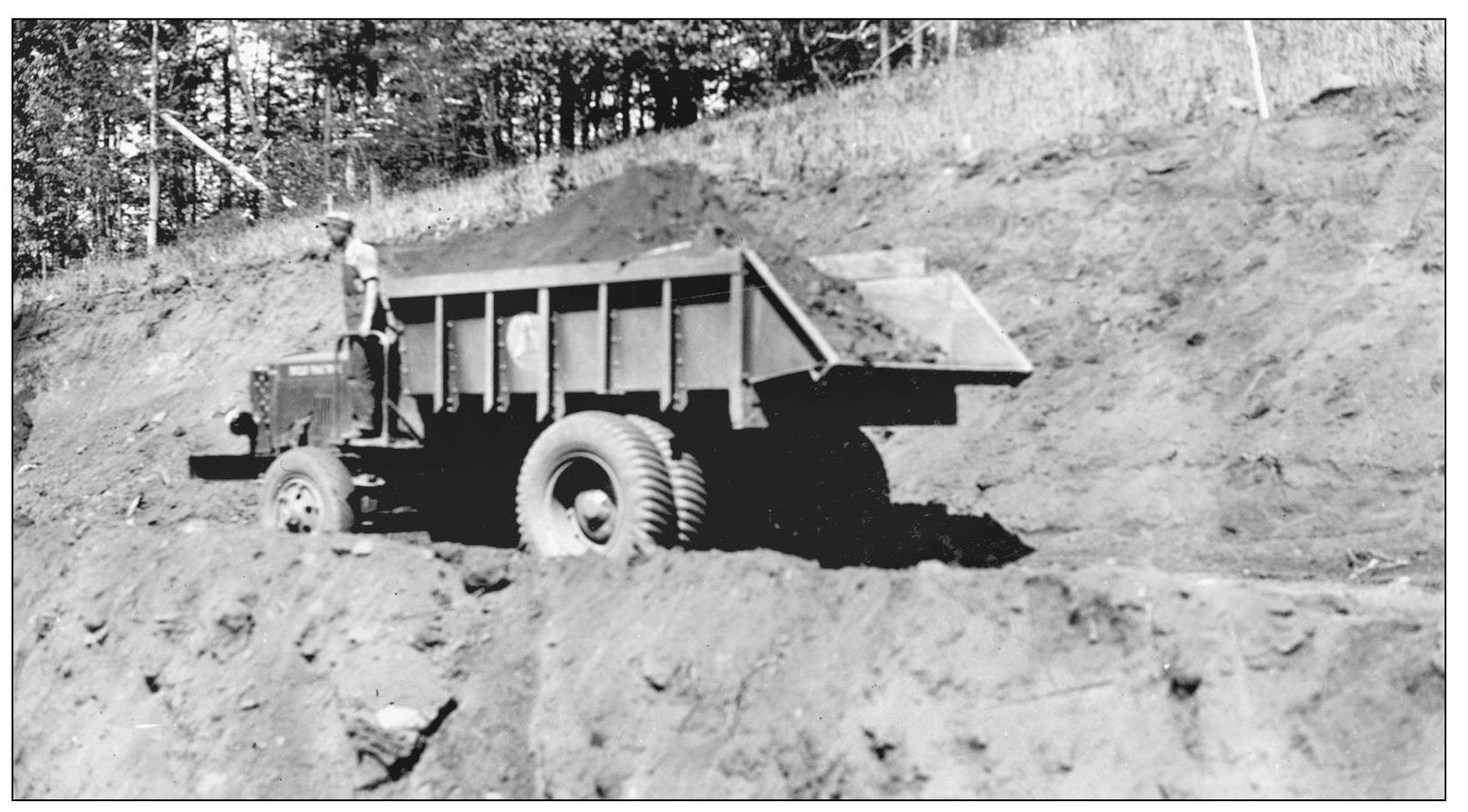

DUMP TRUCK WITH GRAVEL SPREADER. In October 1976, a section between Little Switzerland and Gillespie Gap of the Blue Ridge Parkway had to be paved. This dump truck is pulling a gravel spreader with an operator standing over the spreader to move the levers, allowing gravel to spill smoothly. (Courtesy of the Blue Ridge Parkway Archives.)

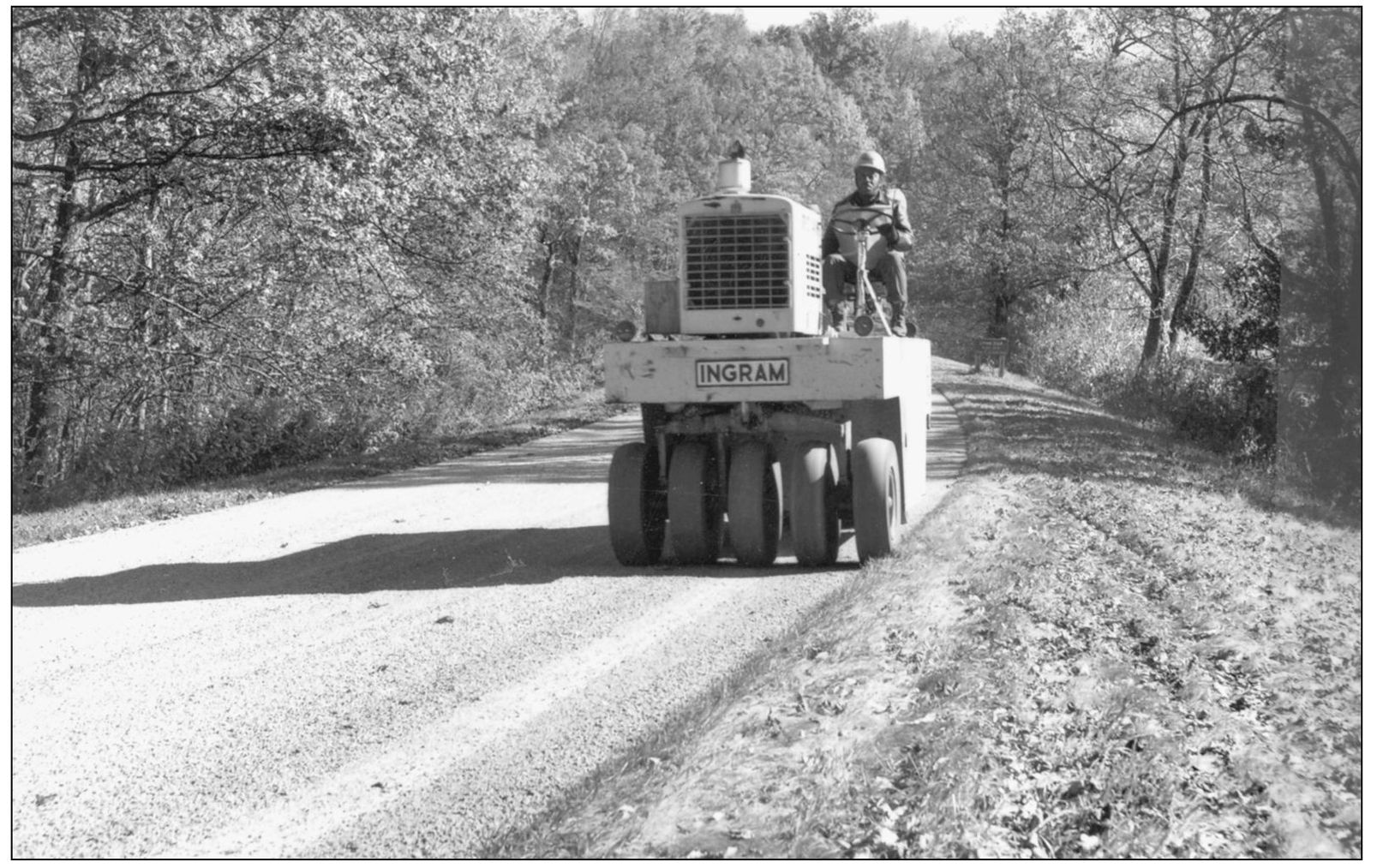

THREE-WHEEL ROAD ROLLER. Once gravel is spread, it must be compacted to a certain thickness and smoothness. Here an operator sits atop a compactor without a hood for shelter from the elements. The first rollers were horse drawn on dirt roads. The wheels were pneumatic. (Courtesy of the Blue Ridge Parkway Archives.)

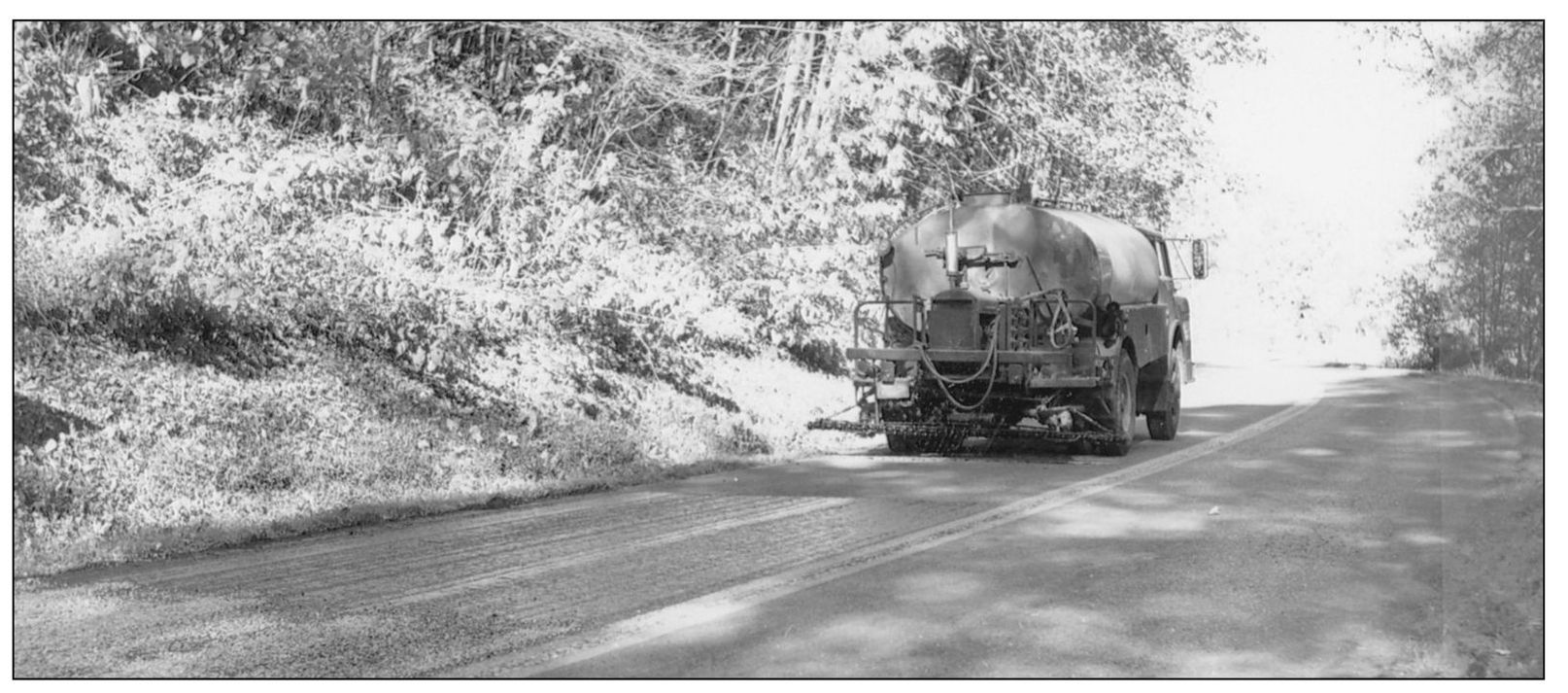

SEAL COATING. Asphalt sealer has to be sprayed over the layer of asphalt to seal any cracks from the elements. Here is a one-half-ton truck with a large tank of sealer spraying a section of the Blue Ridge Parkway between Little Switzerland and Gillespie Gap in North Carolina in October 1976. (Courtesy of the Blue Ridge Parkway Archives.)

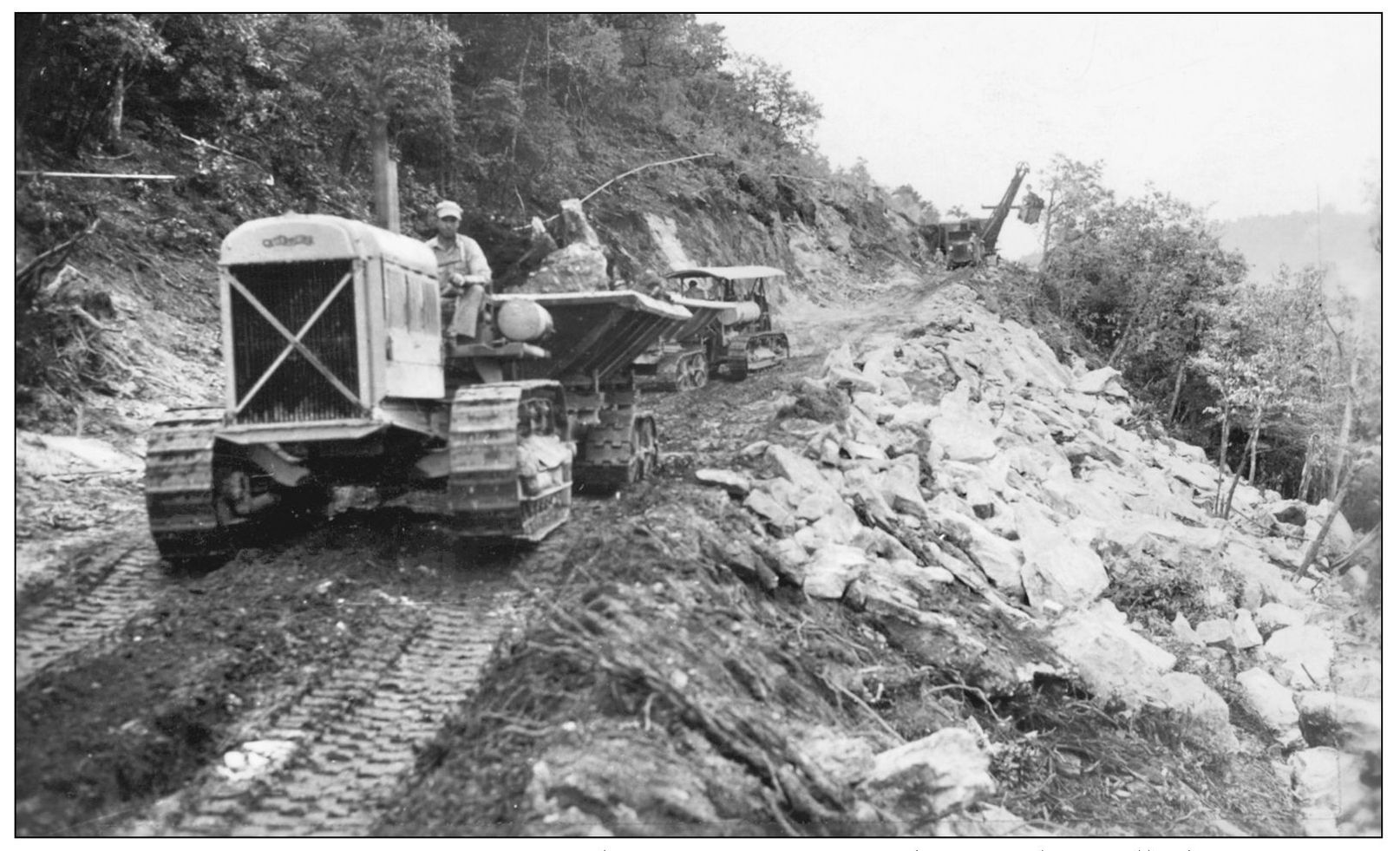

TRACK TRACTOR HAULING IN 1936. This project near Doughton Park in Alleghany County, North Carolina, covered rocky ground. Dynamite had to be used to blast the rock to pieces small enough to be picked up by the shovel in the foreground and loaded onto this track tractor. Track tractors grew bigger and more powerful over the years; they also acquired raised cabins to protect the driver. Experienced miners lived in the mountain regions of Virginia and North Carolina. It’s more than likely that some of the explosive handlers were experienced in the mining industry. By the late 1900s, nitroglycerine had replaced basic gunpowder for explosions. During the early 20th century, the first experiments were done with charges. In 1930, the U.S. Bureau of Mines was formed to upgrade safety. In 1935, DuPont introduced the first commercially successful non-nitroglycerin ammonium nitrate (AN) blasting agent. Thus during the early construction period of the Blue Ridge Parkway, blasting technology was expanding. This greatly increased the accuracy of carving the roadbed out of the mountainsides. (Courtesy of the Blue Ridge Parkway Archives.)

PAVING TRAFFIC JAM IN 1976. During peak season, traffic jams develop easily, especially when road construction is in process. Although inconvenient, paving has to be completed when the weather is just right. When temperatures drop below 50 degrees, asphalt will not cure properly. Rationing of gasoline during this time period interfered with the routine maintenance of the parkway. (Courtesy of the Blue Ridge Parkway Archives.)

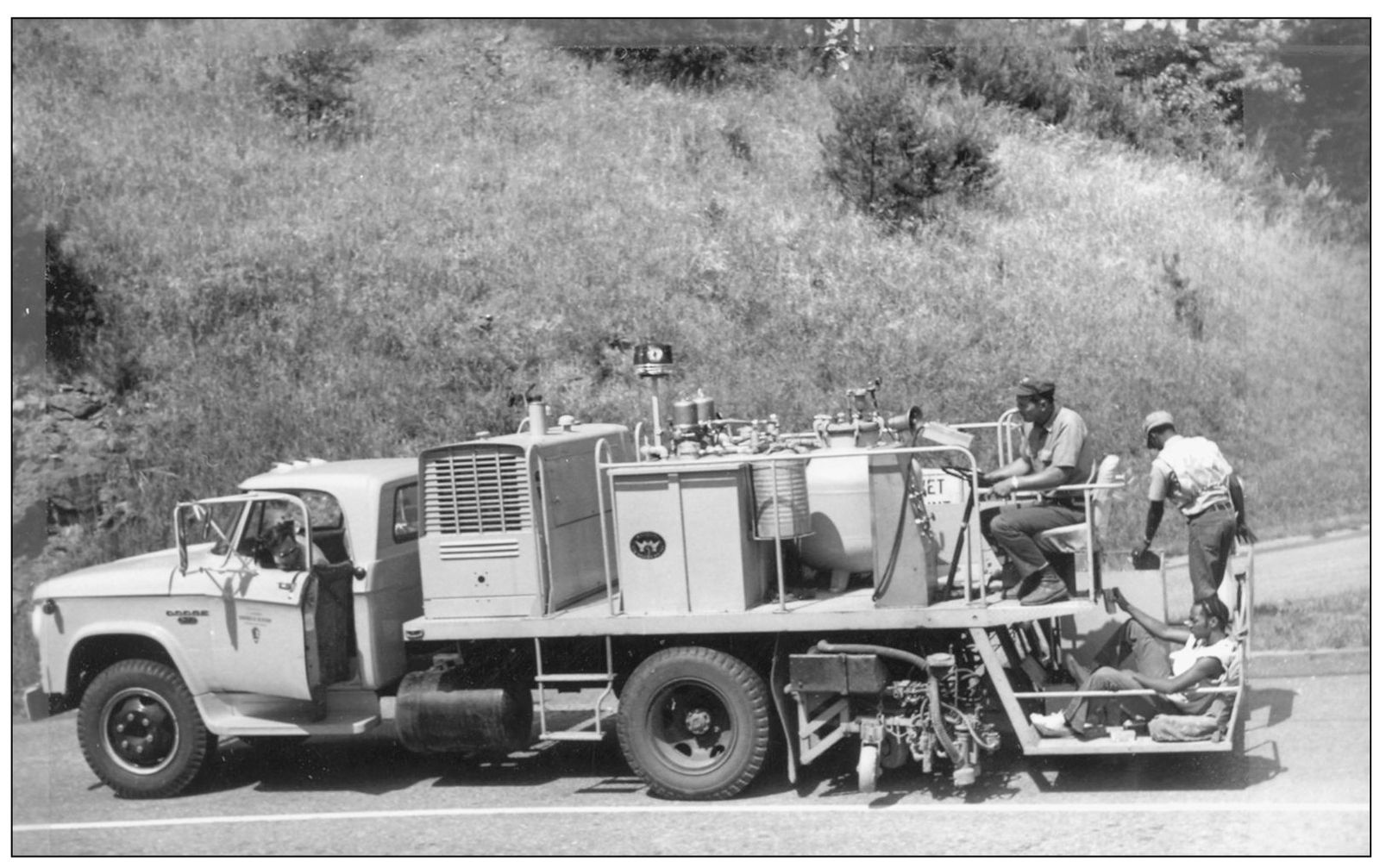

ROAD-STRIPING EQUIPMENT. This three-man crew operates a yellow striping truck in June 1973. A double yellow line is placed down the center of the parkway. Earlier years of the parkway indicate that only a single white line was placed in the center of the road. As traffic increased and road laws changed, a double yellow line was adopted. (Courtesy of the Blue Ridge Parkway Archives.)

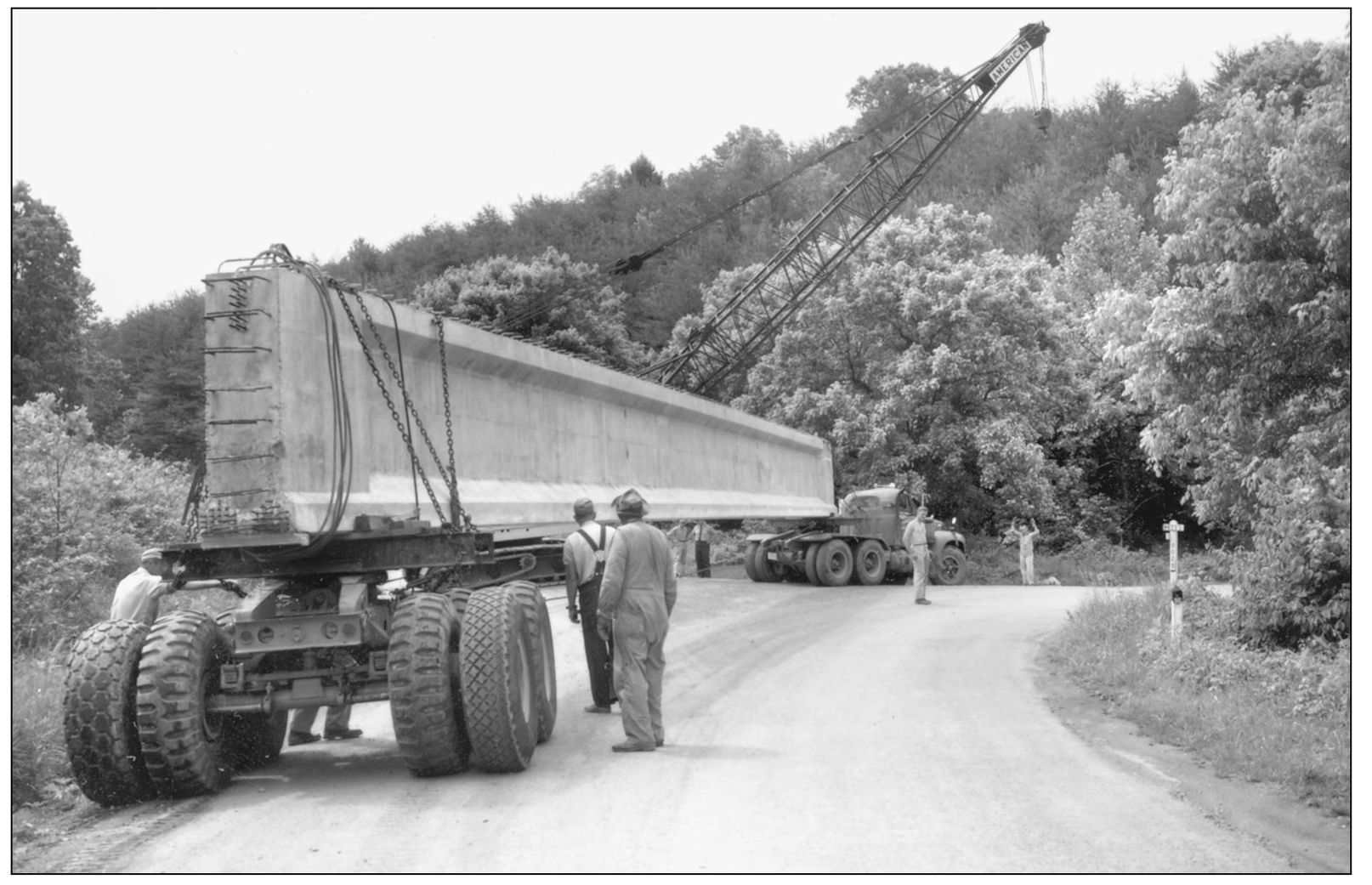

MOVING A BRIDGE GIRDER. This prestressed concrete bridge girder took a lot of maneuvering along the parkway in June 1959. The construction crew had to handle this monster around curves and over hills to get it in place. A crane can be seen over the treetops waiting to position the girder over cement pillars. (Courtesy of the Blue Ridge Parkway Archives.)

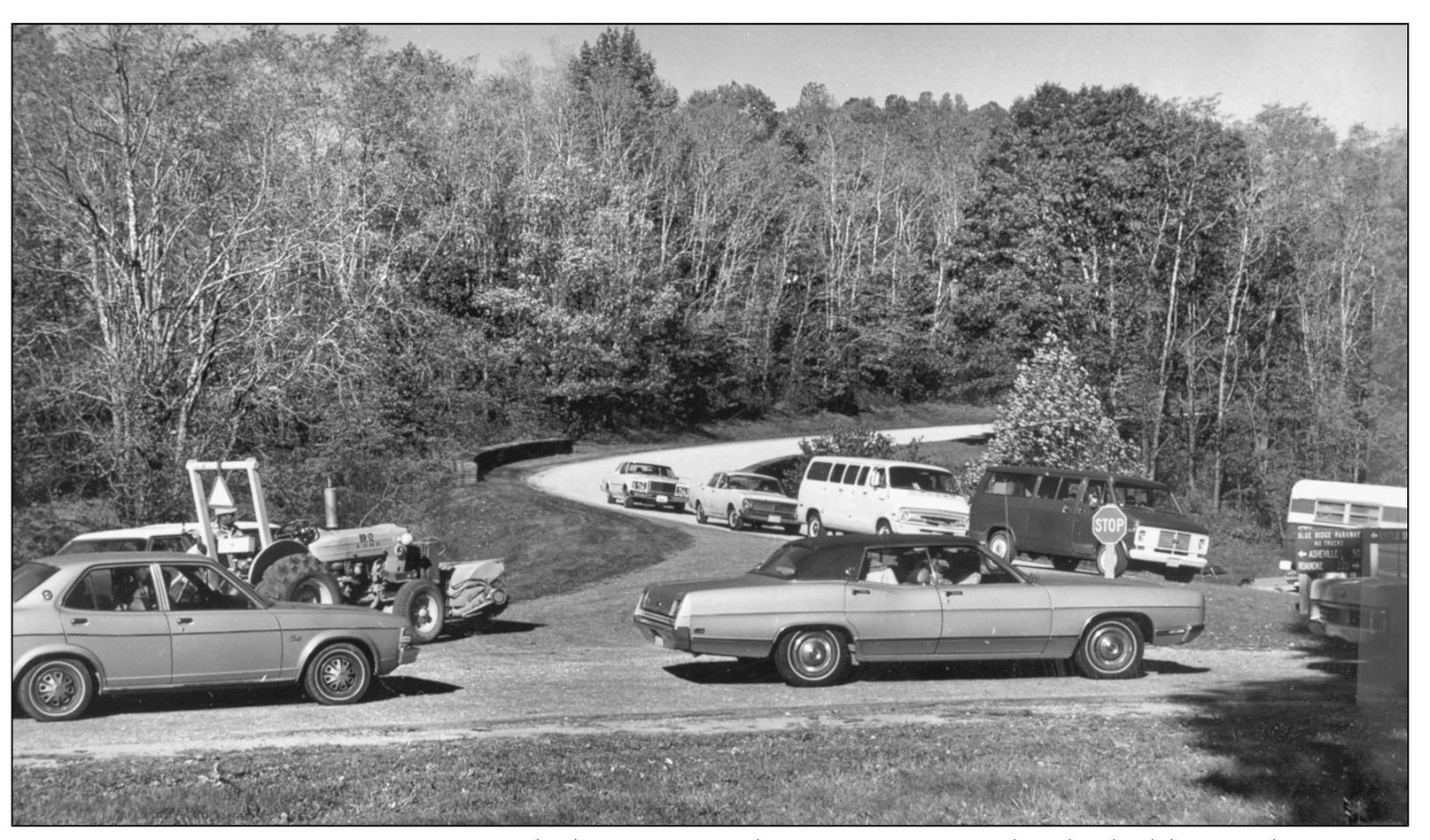

CONSTRUCTION TRAFFIC JAM. Asphalt paving and mowing seem to be the holdup in this traffic jam in 1976. Americans have always flocked to the parkway in the fall to see the changing leaves. A glitch in the timing of paving caused traffic to build up at this intersection, even though this work was probably completed during the typical work week. (Courtesy of the Blue Ridge Parkway Archives.)

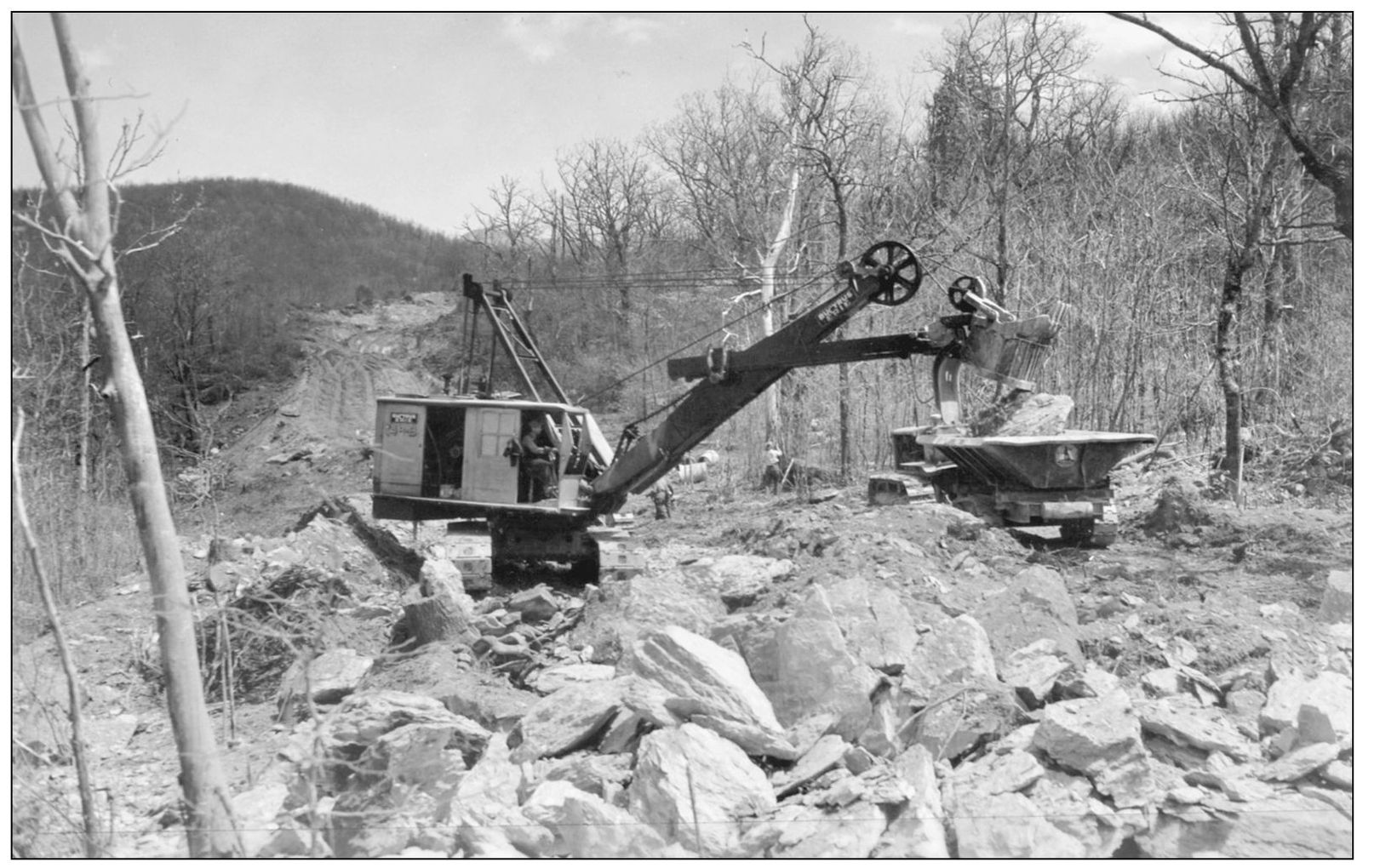

BUCKET EXCAVATOR IN LATE 1930s. Large excavators used by contractors helped to speed along the paving process of the Blue Ridge Parkway. This excavator is loading large boulders into a track tractor with a dumpbed near the Doughton Park area of the parkway. Cabins sit on top of a swivel base with tracks that grip the ground and move the vehicle in all directions. (Courtesy of the Blue Ridge Parkway Archives.)

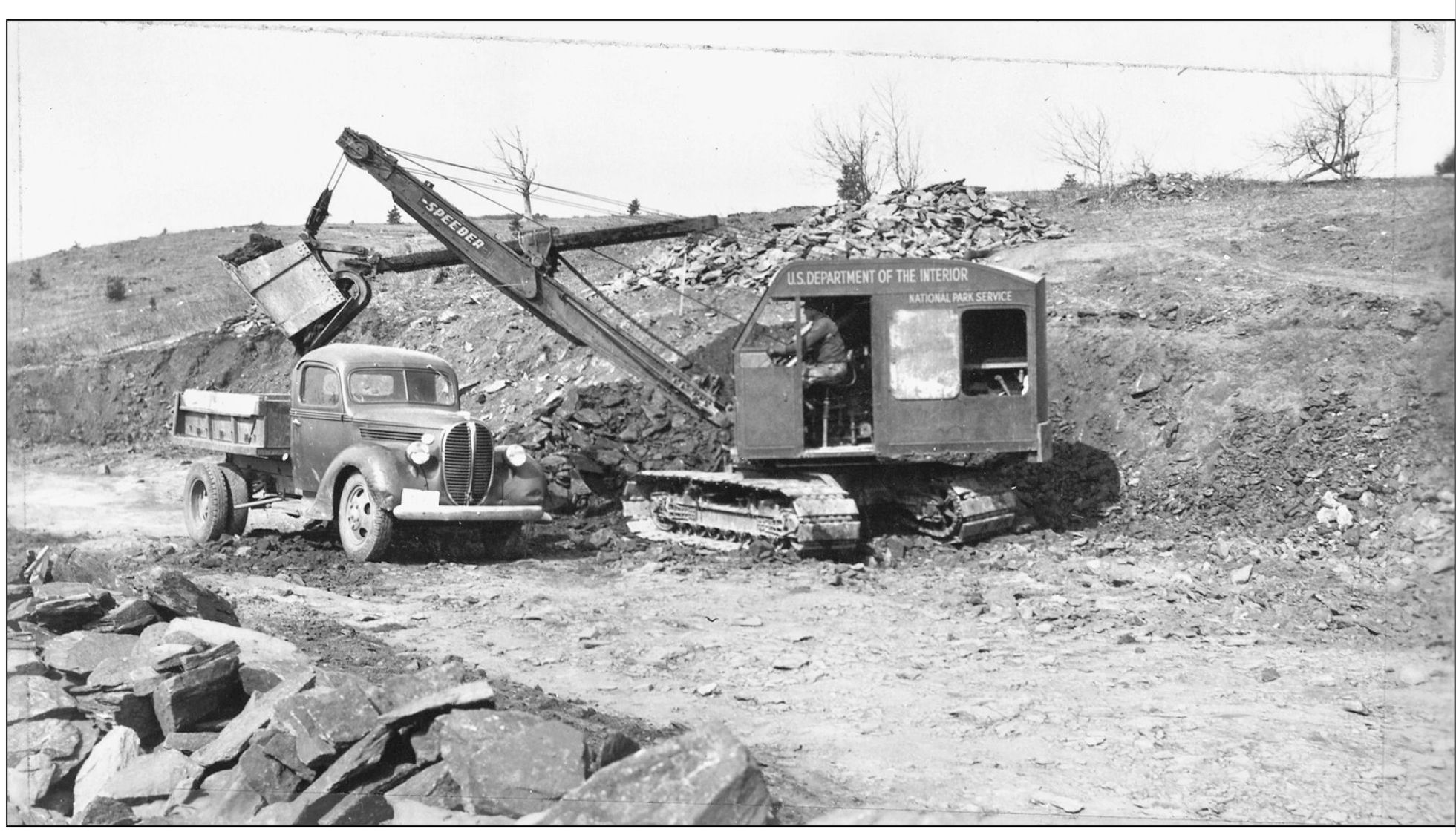

SHOVEL EXCAVATOR LOADING TRUCK. Diesel-powered excavators replaced steam shovels in the 1930s. This swivel shovel is loading large boulders into a late-1930s-model pickup with dual wheels. The Department of the Interior was sponsoring this section, as can be seen by their logo on the shovel. (Courtesy of the North Carolina Archives.)

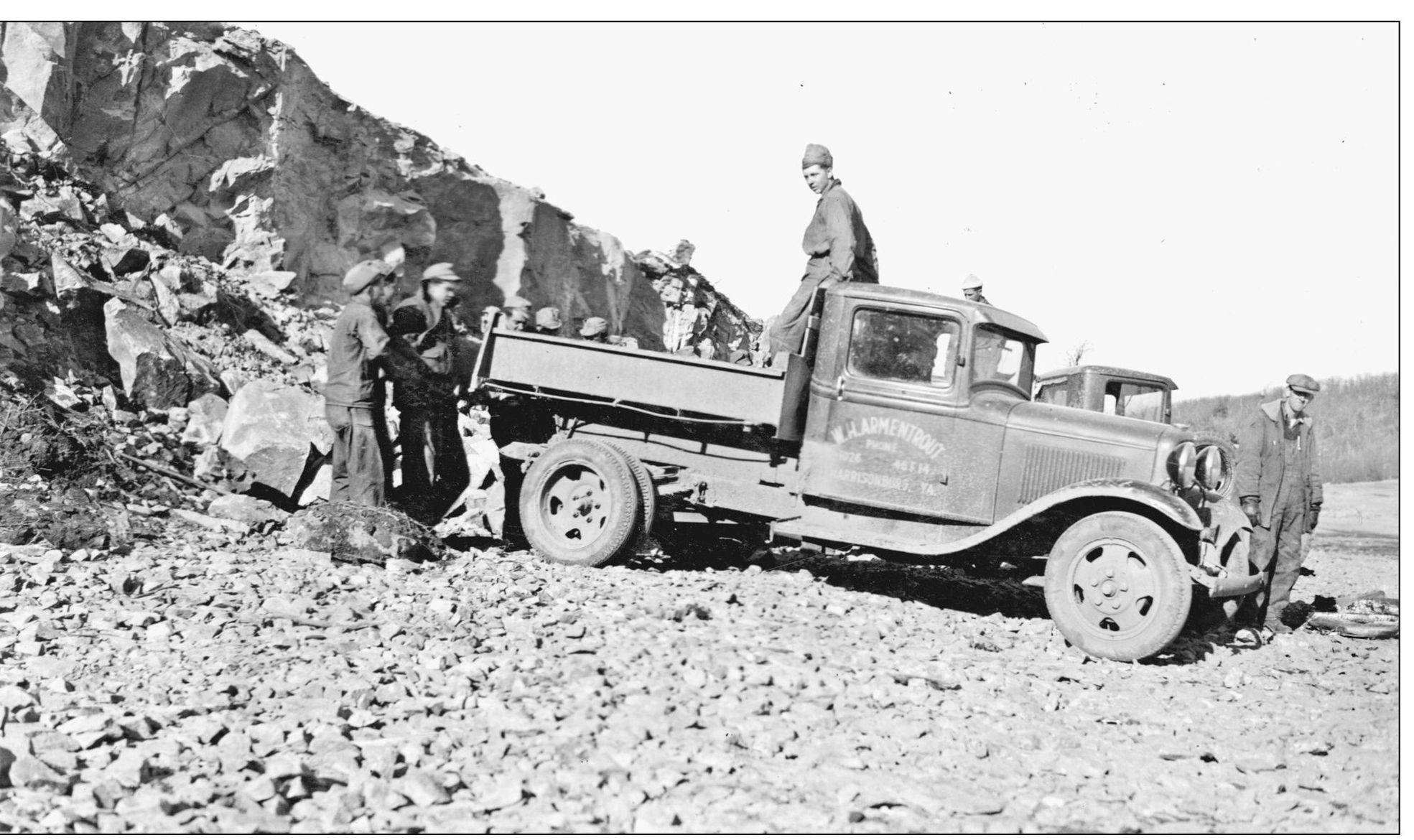

W. H. ARMENTROUT OF HARRISONBURG, VIRGINIA. W. H. Armentrout won several contracts for road construction on the Blue Ridge Parkway. Photographed here is a section in Virginia. Armentrout provided manpower, equipment, and asphalt paving. After their job was completed, the CCC would landscape the sides of the roads and plant native shrubs. (Courtesy of the North Carolina Archives.)

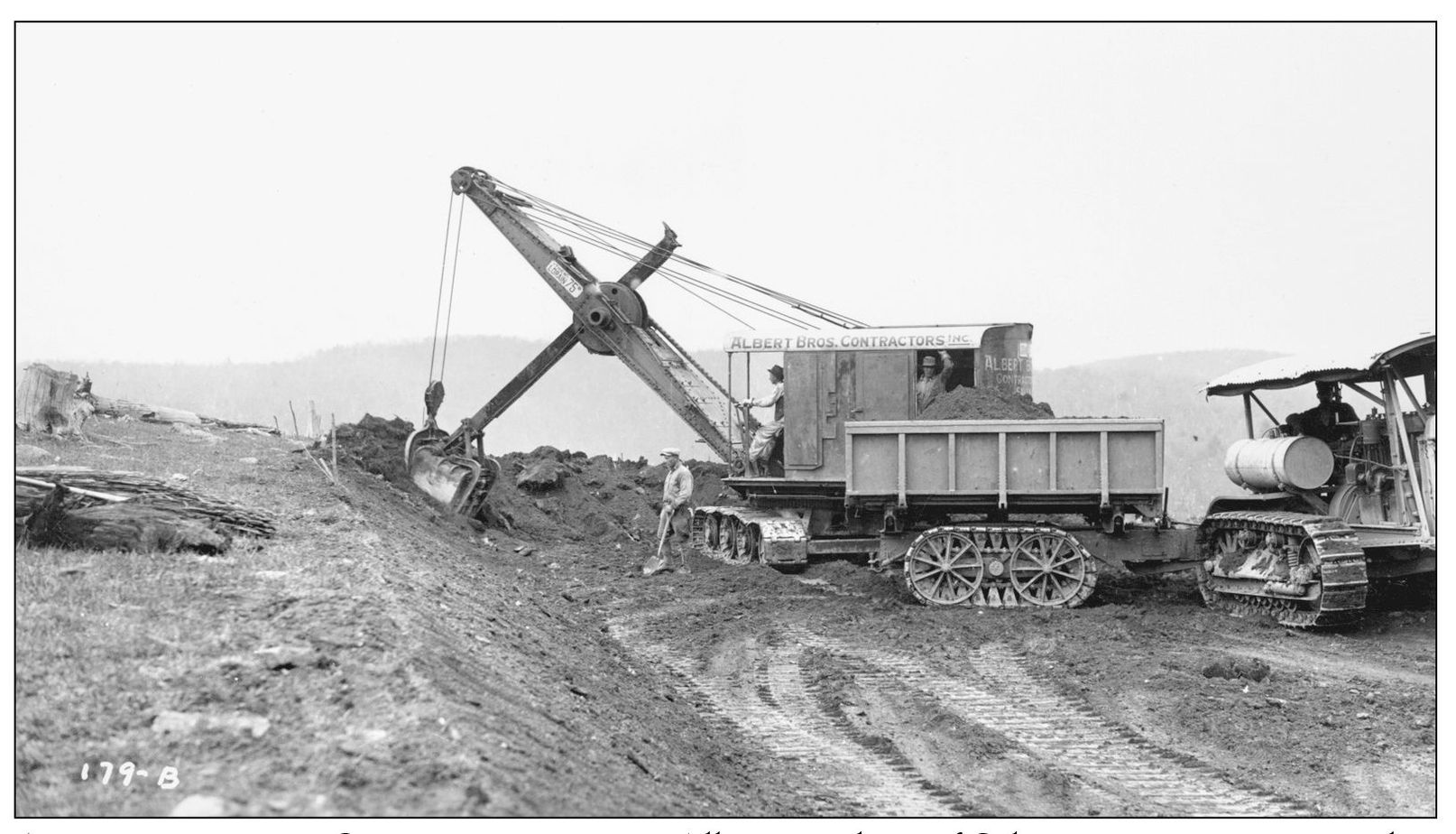

ALBERT BROTHERS CONTRACTORS, INC. Albert Brothers of Salem, Virginia, were another contributor to the construction of the Blue Ridge Parkway. Their contracts covered sections in Virginia and North Carolina. All of the equipment in this photograph is outfitted with tracks, which are best for gripping the earth in difficult terrain. (Courtesy of the North Carolina Archives.)

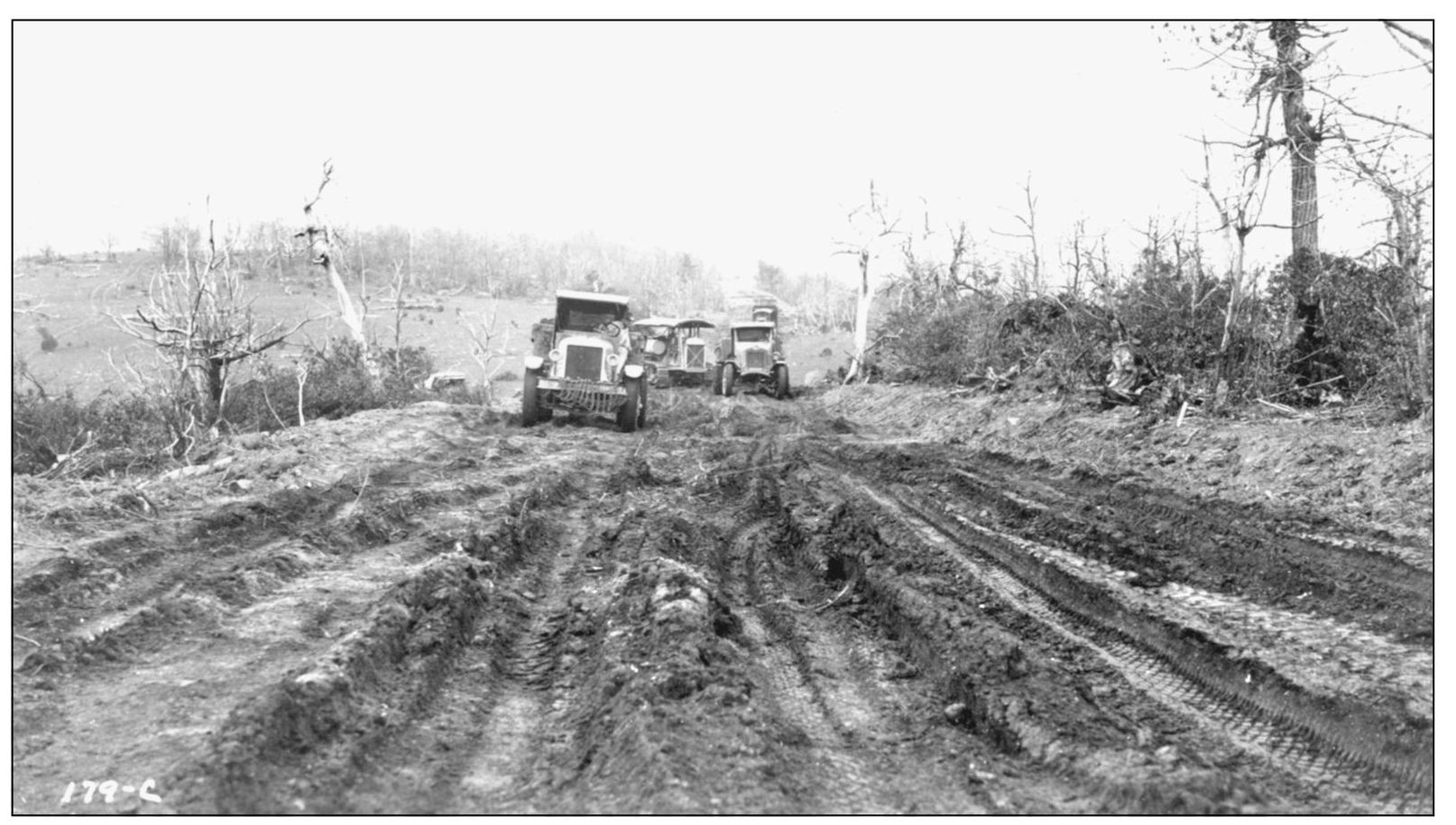

MOVING INTO THE CHESTNUT GRAVEYARD. Difficult does not even begin to describe the conditions that contractors had to move through in the early construction of the Blue Ridge Parkway. Ruts several feet deep can be seen in this wide-angle photograph taken on this section in Virginia. Large dump trucks pulling loads of soil, with track tractors following them, were moving through a section of blighted chestnut trees. (Courtesy of the North Carolina Archives.)

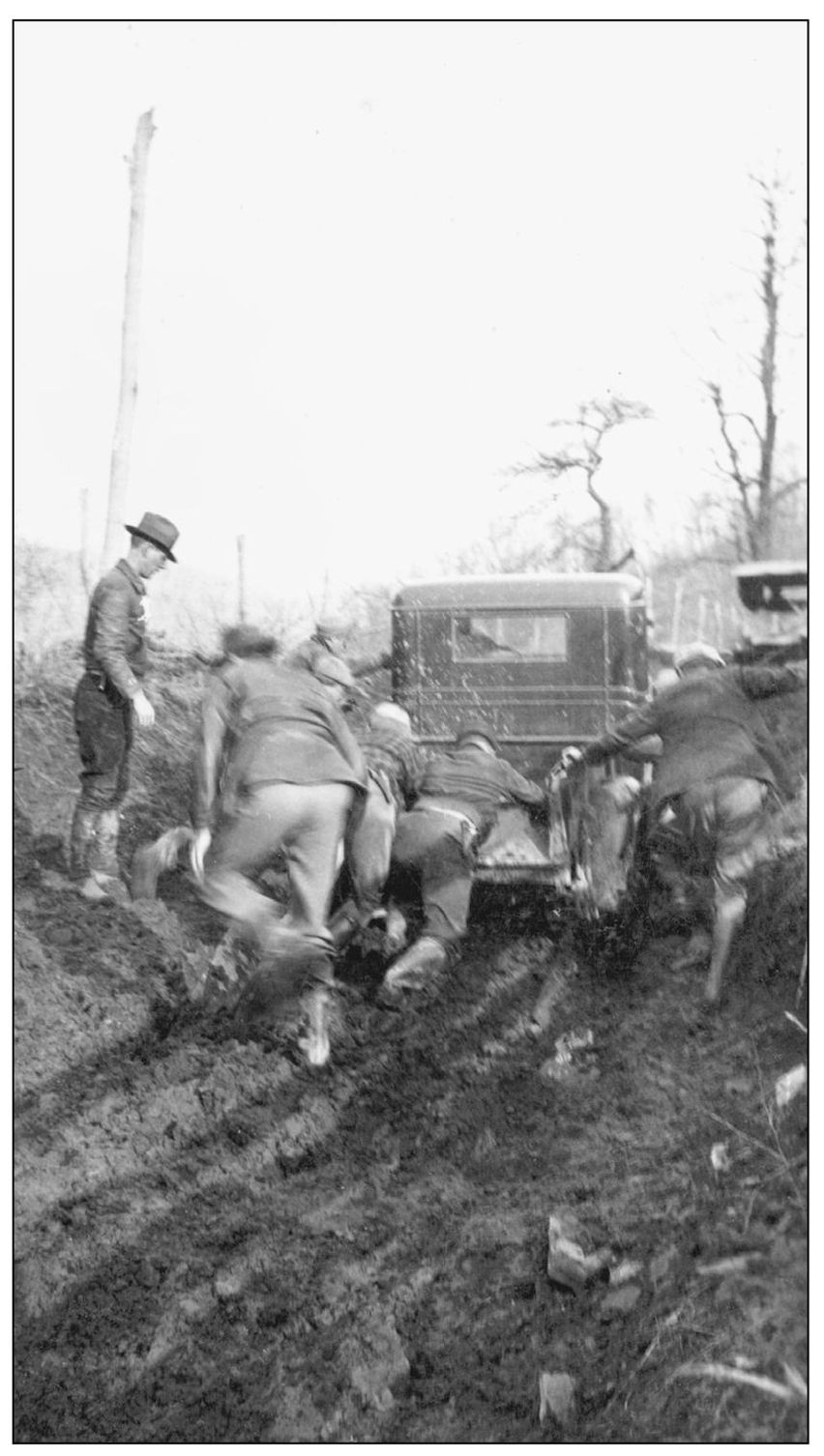

SLINGING MUD IN VIRGINIA, c. 1936. Trucks used to be light enough to push. Here we see several men pushing a pickup out of ruts that are at least 2 feet deep. The person behind the wheel could count on a good mud bath. (Courtesy of the North Carolina Archives.)

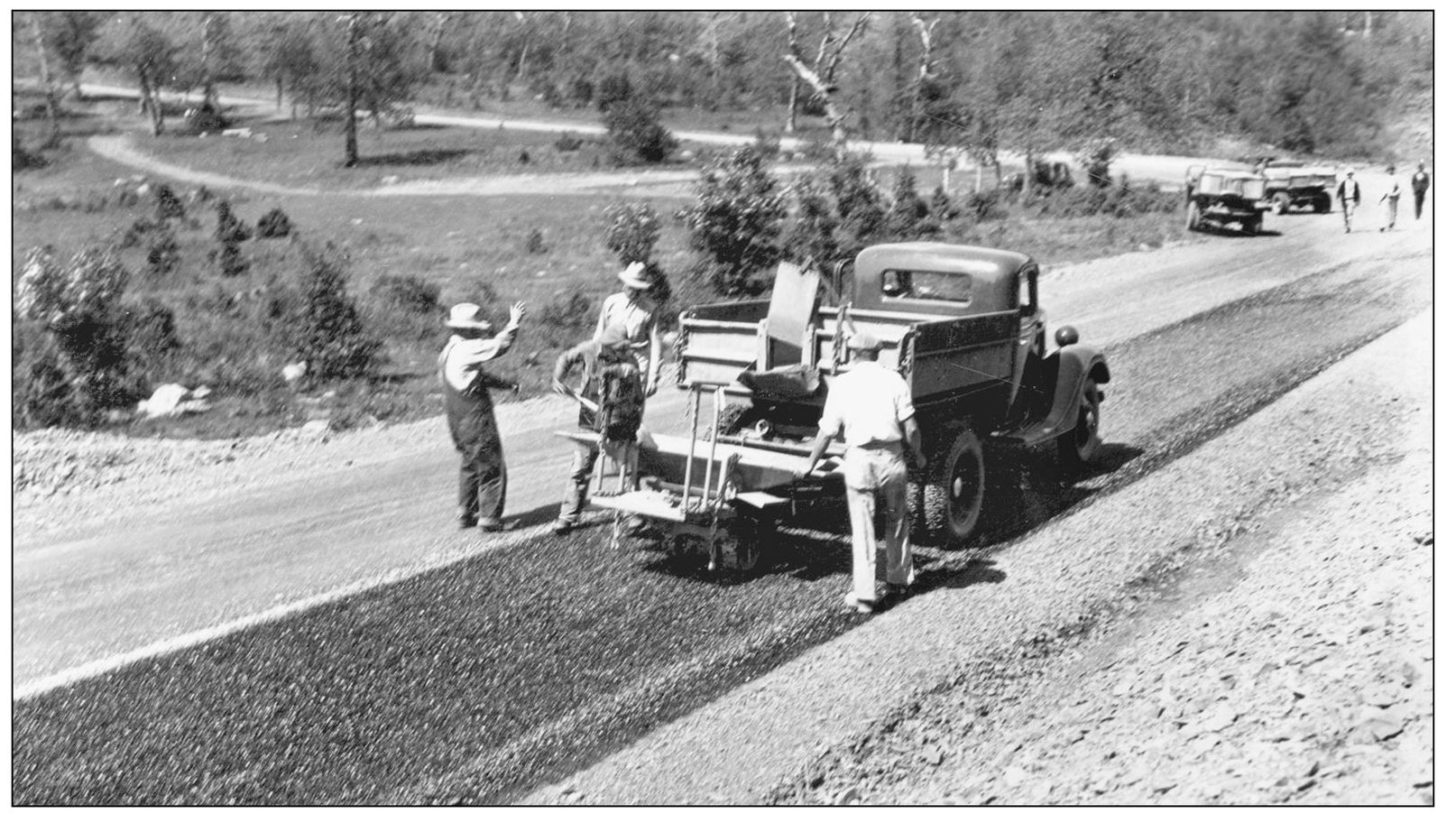

ASPHALT PAVING IN VIRGINIA. This small asphalt-paving operation must have been demonstrating patching potholes. Asphalt is fed into the paving unit and then spread on the surface. Newer models are fed by a large dump truck and span the width of the road. (Courtesy of the North Carolina Archives.)

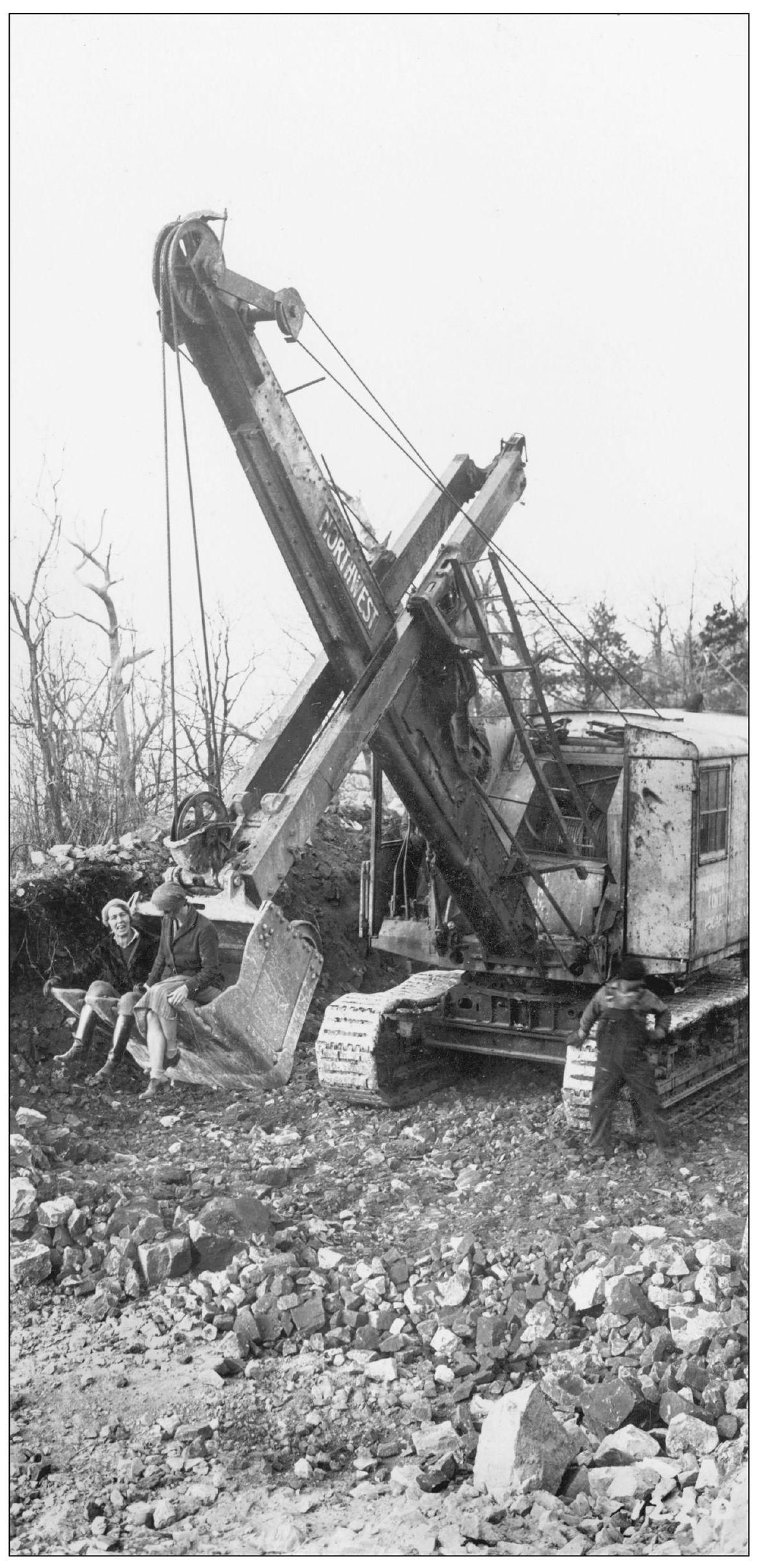

BUCKET OF TROUBLE, c. 1936. Curiosity snagged these two ladies in the early days of construction in Virginia. They are sitting in the bucket of a diesel shovel. Visitors could not wait for the road to be completed, and many would take a walk along the unfinished roadbed to get a glimpse of what was to come. Although the country was in a Depression, fashion and style did not stop. Women’s fashions moved away from the brash, daring style of the Roaring Twenties toward a more romantic, feminine silhouette. The waist was restored to its proper position, hemlines were dropped, there was renewed appreciation of the bust, and backless evening gowns and soft, slim-fitting day dresses became popular. (Courtesy of the North Carolina Archives.)

A 1930S DUMP TRUCK. Hauling tons of soil and rock, dump trucks were invaluable during the construction of the parkway. The early ones did not have a cab to cover the driver. The bed was equipped with a hydraulic lift for pouring loose gravel and dirt. One axle was under the cab, and one or more could be mounted under the bed. (Courtesy of the North Carolina Archives.)

CATERPILLAR TRACTOR. Organized on April 15, 1925, Caterpillar equipment is by far the most well-known construction equipment in the United States, and the company’s early equipment ranged from diesel and gas turbines, to natural gas. The Caterpillar tractor inspired the first tank used in World War I. Caterpillar advertised that one of their tractors replaced eight bullock teams—112 animals. (Courtesy of the North Carolina Archives.)

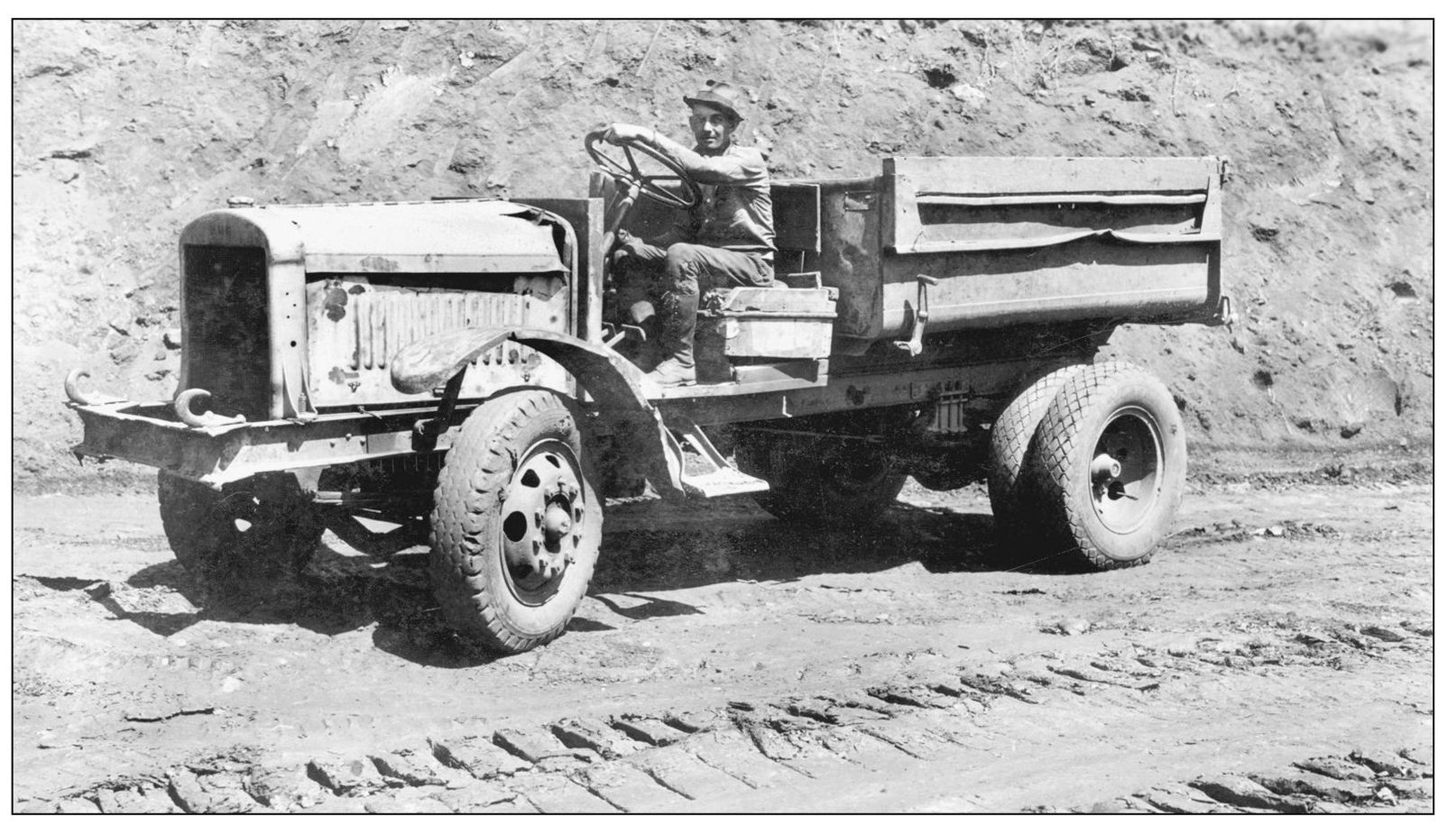

RUGGED DUMP TRUCK. A tractor engine and a dump bed connected by a frame and rolling on axles describes this simple piece of equipment. This driver was in danger of flying objects when driving this truck. It was a workhorse and could haul loads of high tonnage. (Courtesy of the North Carolina Archives.)

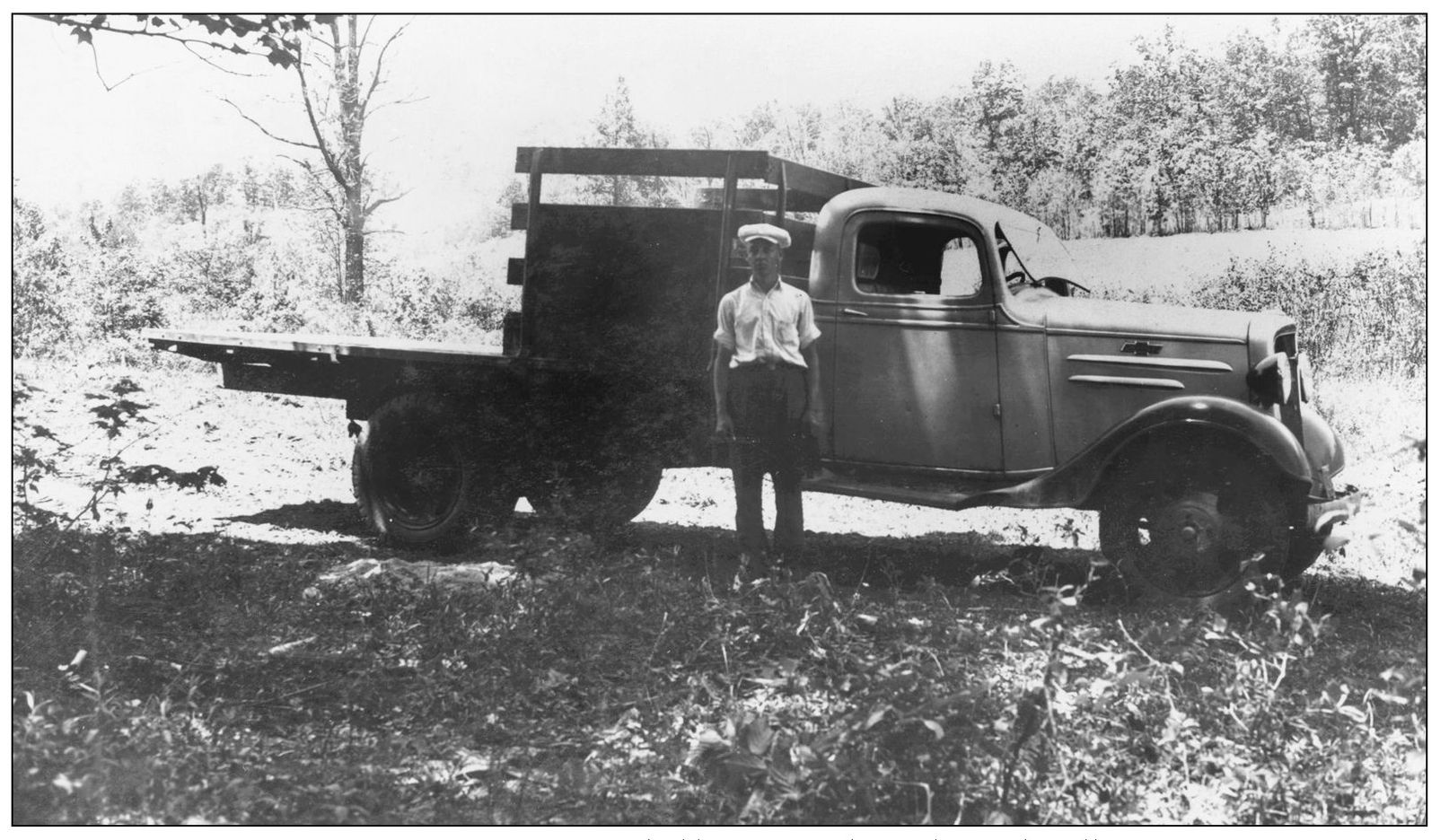

EARLY-1940S CHEVROLET TRUCK. Cofounded by Louis Chevrolet and William C. Durant in 1911, Chevrolet is the most popular brand of General Motors vehicles sold in America. The “bow tie” logo first used in 1913 by Louis Chevrolet has become the standard symbol for Chevrolet. Hauling supplies probably was the purpose of this vehicle. (Courtesy of the North Carolina Archives.)

PRE-1930S PNEUMATIC ENGINE. Stored energy in the form of compressed air, nitrogen, or natural gas enters the sealed motor chamber and exerts pressure against the vanes of a rotor. Much like a windmill, this causes the rotor to turn at a high rate of speed. Reduction gears are used to create high torque levels. This would probably have been used with a jackhammer. (Courtesy of the North Carolina Archives.)

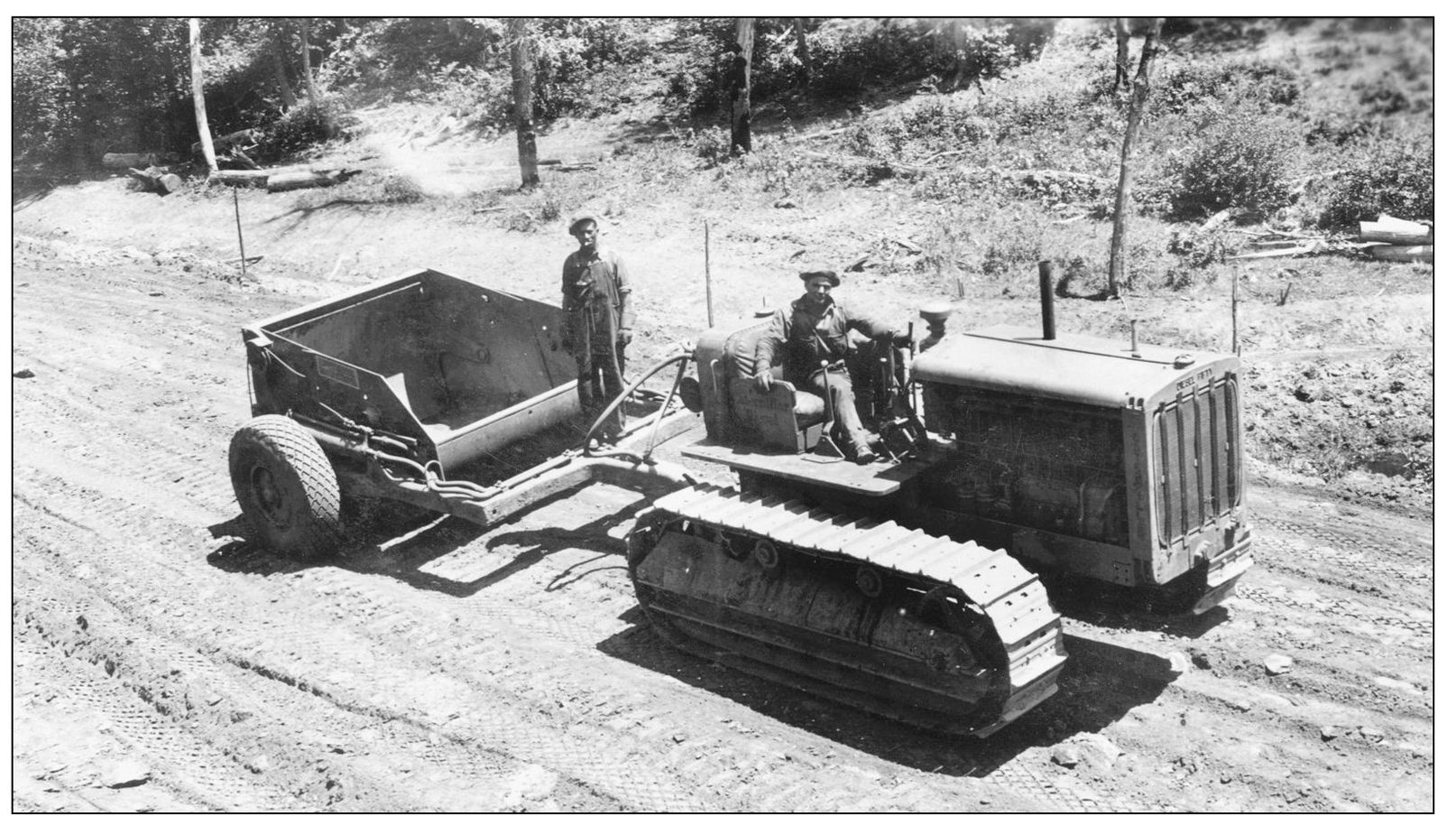

DIESEL 50 TRACTOR. After 1933, all tractors were offered with rubber tires. In 1940, ninety-five percent were sold with rubber tires. Before 1931, tractors had steel wheels with lugs jutting out. This tore up the ground like a plugger does today. Caterpillar tractors were advertised to do five times as much work as a horse. (Courtesy of the North Carolina Archives.)