Chapter 16

Steering and Suspension Systems Smooth the Way

In This Chapter

Understanding how the steering system works

Understanding how the steering system works

Checking your steering

Checking your steering

Looking at the various types of suspension systems

Looking at the various types of suspension systems

Except for the steering wheel, you probably consider the steering and suspension systems on your vehicle to be unknown territory, and up until now, you’ve probably been content to leave it that way. But these systems are the unsung heroes that smooth out the driving process and keep you headed exactly where you want to go. This chapter can help you get a good idea of how the type of steering and suspension your vehicle possesses works so that you can deal intelligently with a technician if something goes wrong.

The Steering System

The steering system consists of a series of linkages and gears that link the driver to the wheels. On most vehicles only the front wheels turn in response to the steering wheel, while the back wheels just follow along. When you make a turn, each of the front wheels has to turn at a different angle because one wheel is closer to the direction you’re turning in than the other one is (think of the “snap the whip” game).

There’s a difference between how far you turn your steering wheel and how far the wheels of your vehicle turn during one rotation of the steering wheel. This is called the steering ratio. The more you have to turn the steering wheel to get the wheels to respond, the higher the steering ratio. To find the steering ratio, you divide one complete rotation of the steering wheel (360 degrees) by the amount of degrees the wheels turn. The steering ratio in most cars is between 12 and 20:1. For example, if the wheels on your car turn 20 degrees during one rotation of the steering wheel, the steering ratio would be 18:1 (360 divided by 20).

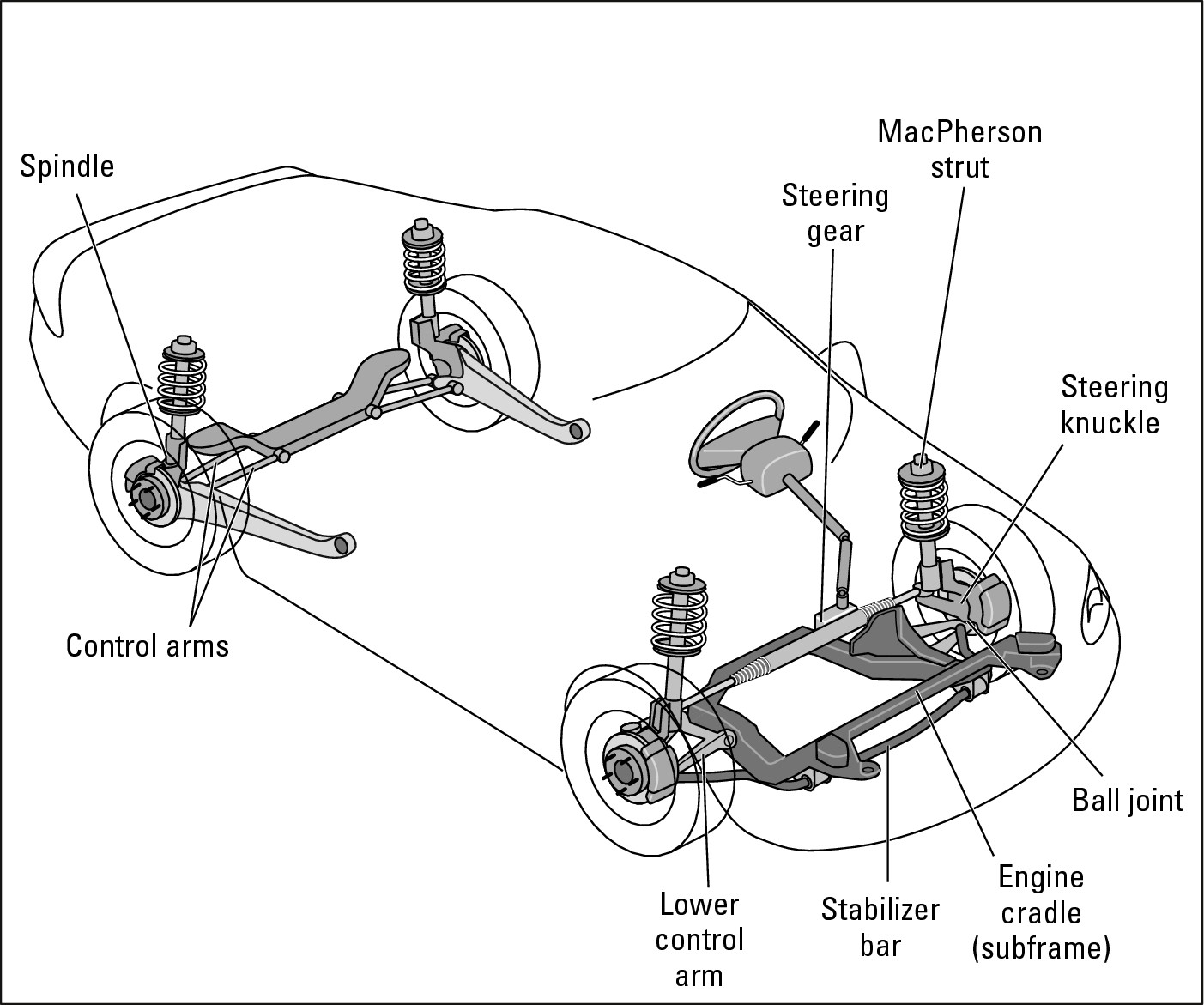

The steering linkage

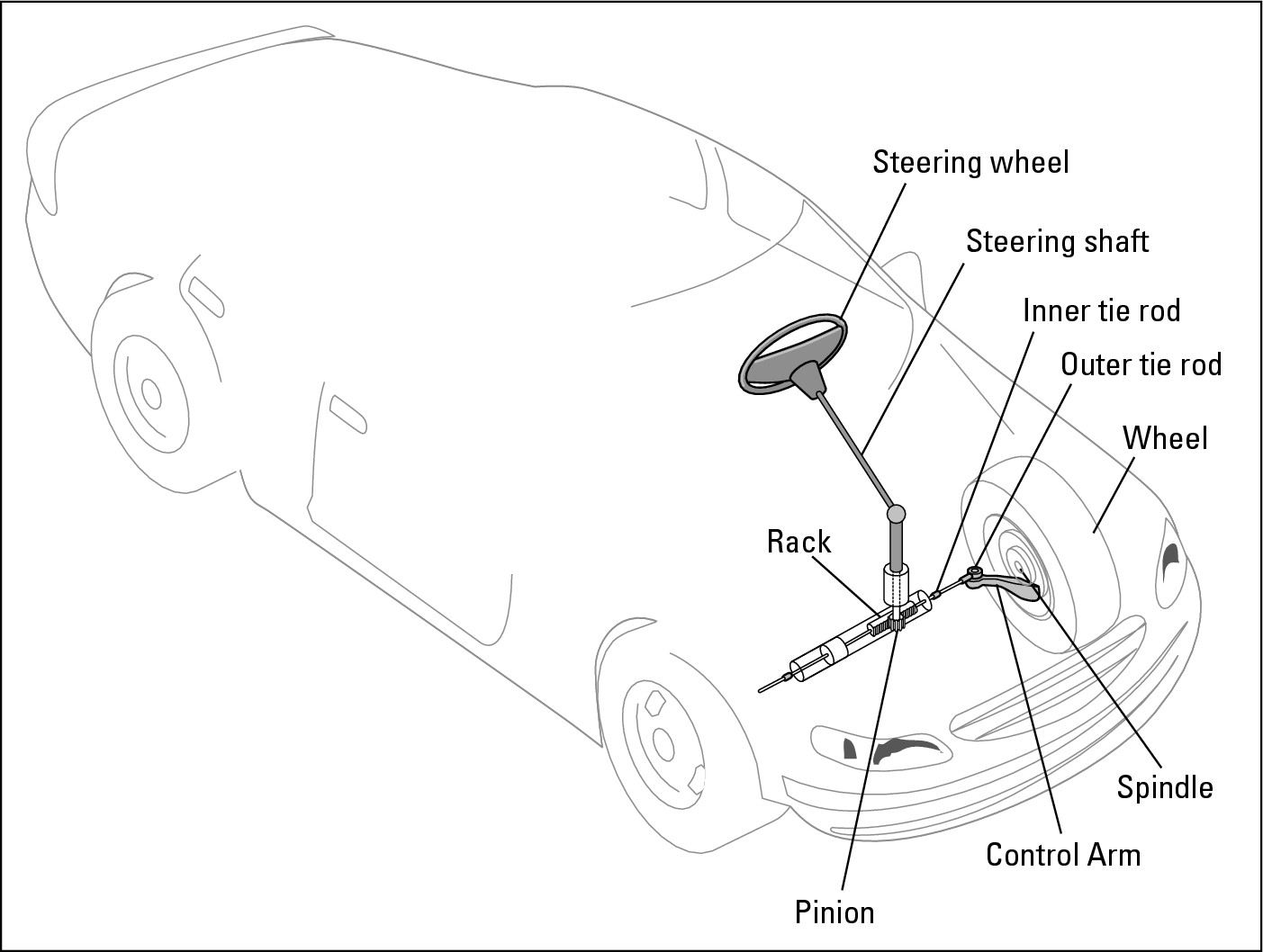

The steering linkage is composed of all the parts of the steering system that connect the steering wheel to the front wheels (see Figure 16-1). When you turn your steering wheel, the steering linkage causes your front wheels to respond by moving in the proper direction. The principal parts of the steering linkage are the tie rod ends, ball joints, and control arms.

|

Figure 16-1: A rack-and-pinion steering system. |

|

Tie rod ends

As you can see in Figure 16-1, the tie rod ends are a type of ball socket assembly located where the steering linkage connects to the wheels. As the two parts of the linkage move against each other, the grease in the tie rod ends cushions them. The grease keeps the parts moving freely and prevents friction that would wear them away.

Control arms

The steering linkage actually connects to the wheels, which are held in place by a spindle that goes through the wheel and is attached to one or two control arms, or steering arms that allow the wheels to turn in any direction. To keep things moving freely, ball joints are located at points where movement takes place.

Ball joints

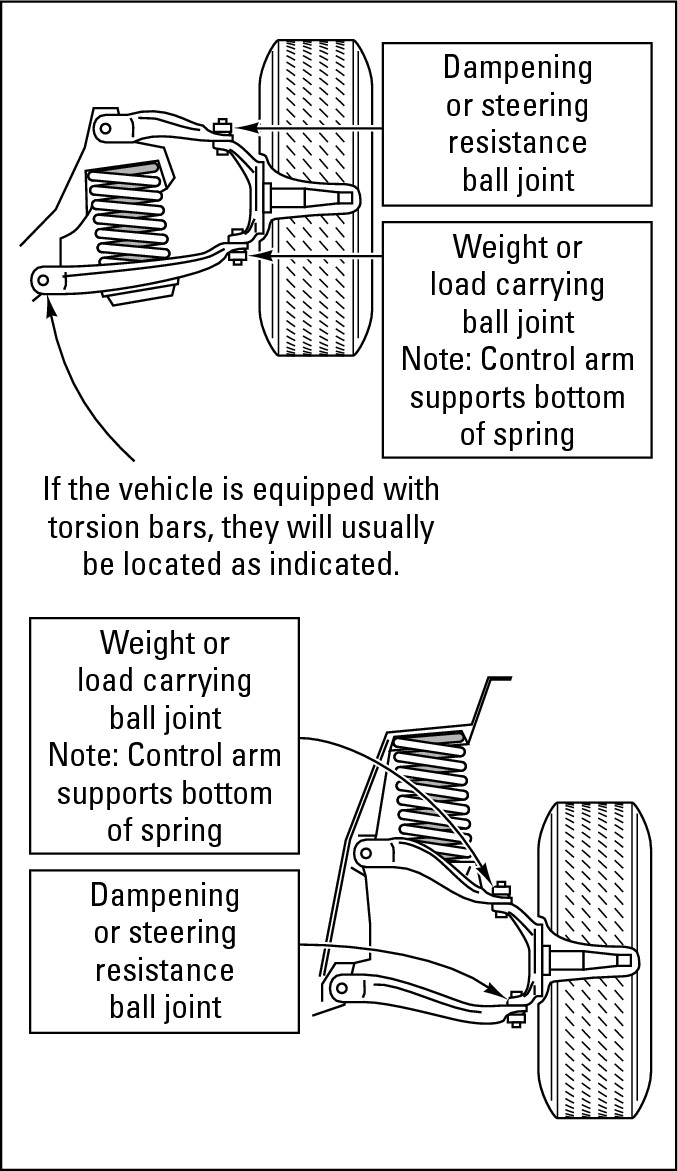

Ball joints are important parts of the steering systems on all vehicles. A ball joint is a ball socket assembly that attaches the steering knuckle to the suspension system. The ball joint allows for pivotal and rotational movement of the wheel as it moves up and down and is steered left to right. You can see where ball joints are located in Figures 16-6, 16-10, and 16-15, which show various configurations.

Power steering systems

When power steering was first introduced, it was intended to help drivers of large or heavy vehicles to steer more easily when parking or heading around curves. Then it became a luxury option for passenger vehicles. Today, virtually every vehicle on the road comes equipped with a power steering system. This section describes the most popular types of power steering.

Three types of power steering systems are in use today, or are scheduled to make their appearance in a very short time: rack-and-pinion, recirculating-ball, and steer-by-wire. The following sections take a closer look at each of them.

Rack-and-pinion steering

Rack-and-pinion steering is found on most modern passenger vehicles (refer to Figure 16-1). The pinion is a gear that connects to the shaft of the steering wheel. The rack has notches cut in it that engage the teeth on the pinion gear. Each end of the rack connects to an inner and outer tie rod, which connect to the control arm, which connects to the spindle on the wheel at that side of the vehicle. As the steering wheel turns, the gear turns, moving the rack, which moves the tie rods, which cause the wheels to turn.

A rotary valve senses whether the driver is turning the steering wheel or just driving straight ahead. It does this via a steering shaft that connects to the steering wheel at one end and to the pinion gear at the other. As the steering wheel turns, the torsion bar twists, and the pinion gear responds accordingly.

Rack-and-pinion power steering is powered in two basic ways. Other steering systems described in this chapter may work on the same principles, but the clearest way to view them is to relate them to rack-and-pinion systems:

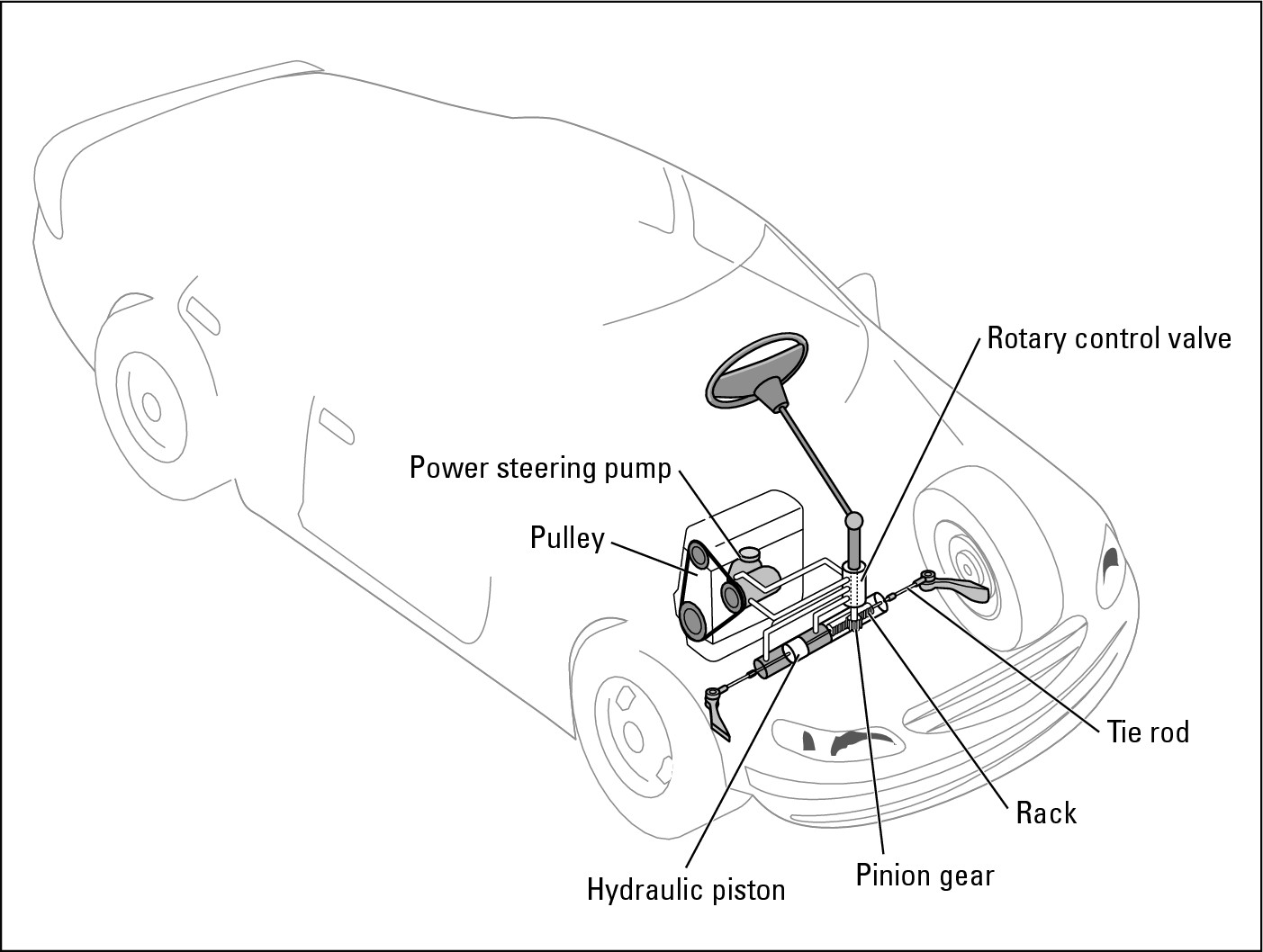

Hydraulic power steering systems incorporate a power-steering pump that’s connected to the engine by a belt wrapped around a pulley (see Figure 16-2). As vanes inside the pump turn in response to the speed of the engine, they force power-steering fluid under hydraulic pressure into a piston located at the center of the rack. As you can see in Figure 16-2, the hydraulic piston has an opening on either side of it that allows the fluid to enter. The direction in which the steering wheel is turned forces the fluid into one side of the piston or the other. This causes the piston to move the rack in that direction, which moves the tie rods and the wheels accordingly.

Hydraulic power steering systems incorporate a power-steering pump that’s connected to the engine by a belt wrapped around a pulley (see Figure 16-2). As vanes inside the pump turn in response to the speed of the engine, they force power-steering fluid under hydraulic pressure into a piston located at the center of the rack. As you can see in Figure 16-2, the hydraulic piston has an opening on either side of it that allows the fluid to enter. The direction in which the steering wheel is turned forces the fluid into one side of the piston or the other. This causes the piston to move the rack in that direction, which moves the tie rods and the wheels accordingly.

|

Figure 16-2: A hydraulic power steering system. |

|

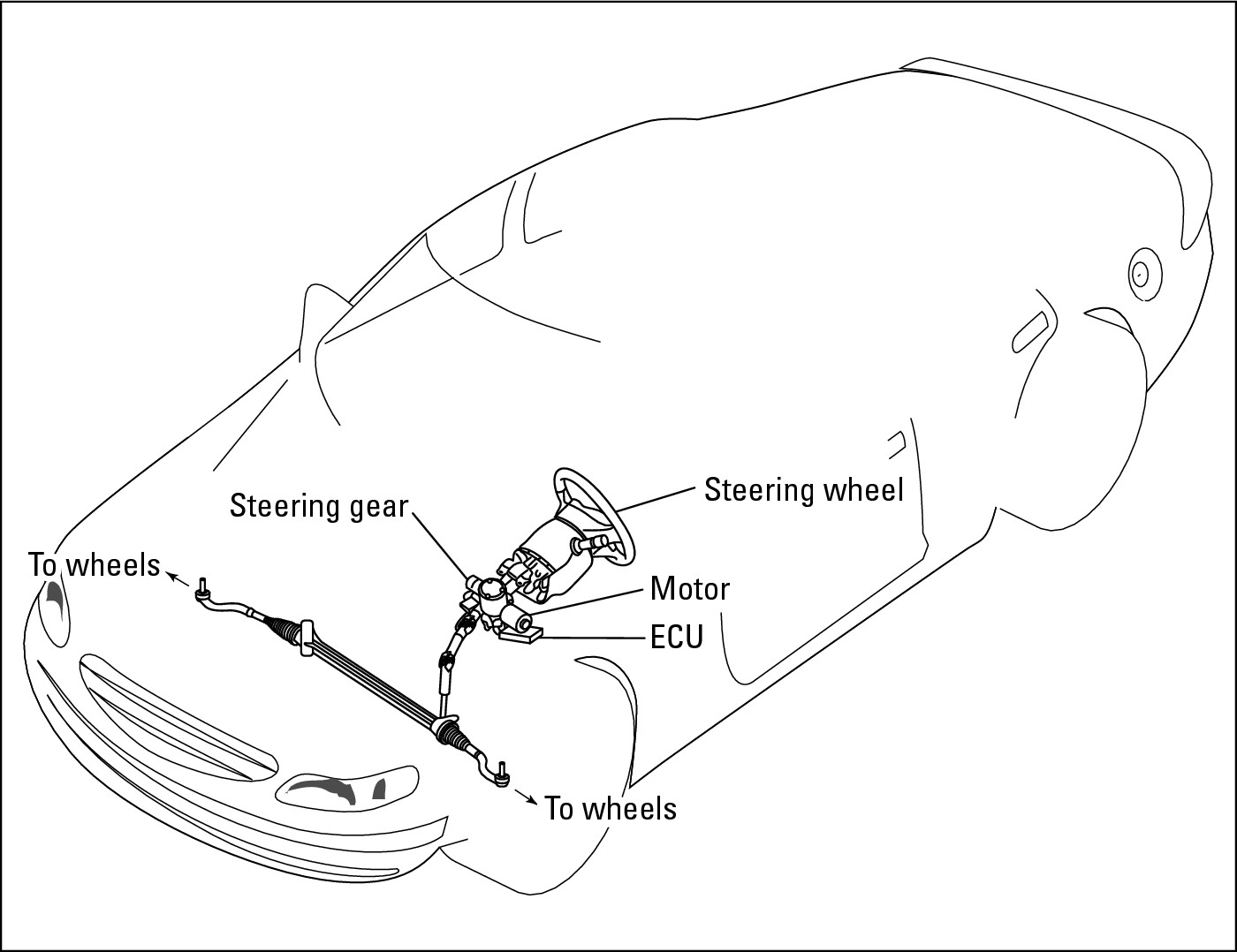

Electronic power steering systems, also called electronically assisted steering, use an electric motor or motors instead of hydraulics to drive the steering mechanism (see Figure 16-3). An

ECU

controls the operation of the system. If the electronic system fails, the rack-and-pinion system continues to operate as unassisted (or unpowered) steering.

Electronic power steering systems, also called electronically assisted steering, use an electric motor or motors instead of hydraulics to drive the steering mechanism (see Figure 16-3). An

ECU

controls the operation of the system. If the electronic system fails, the rack-and-pinion system continues to operate as unassisted (or unpowered) steering.

|

Figure 16-3: An electronic power steering system. |

|

Recirculating-ball steering

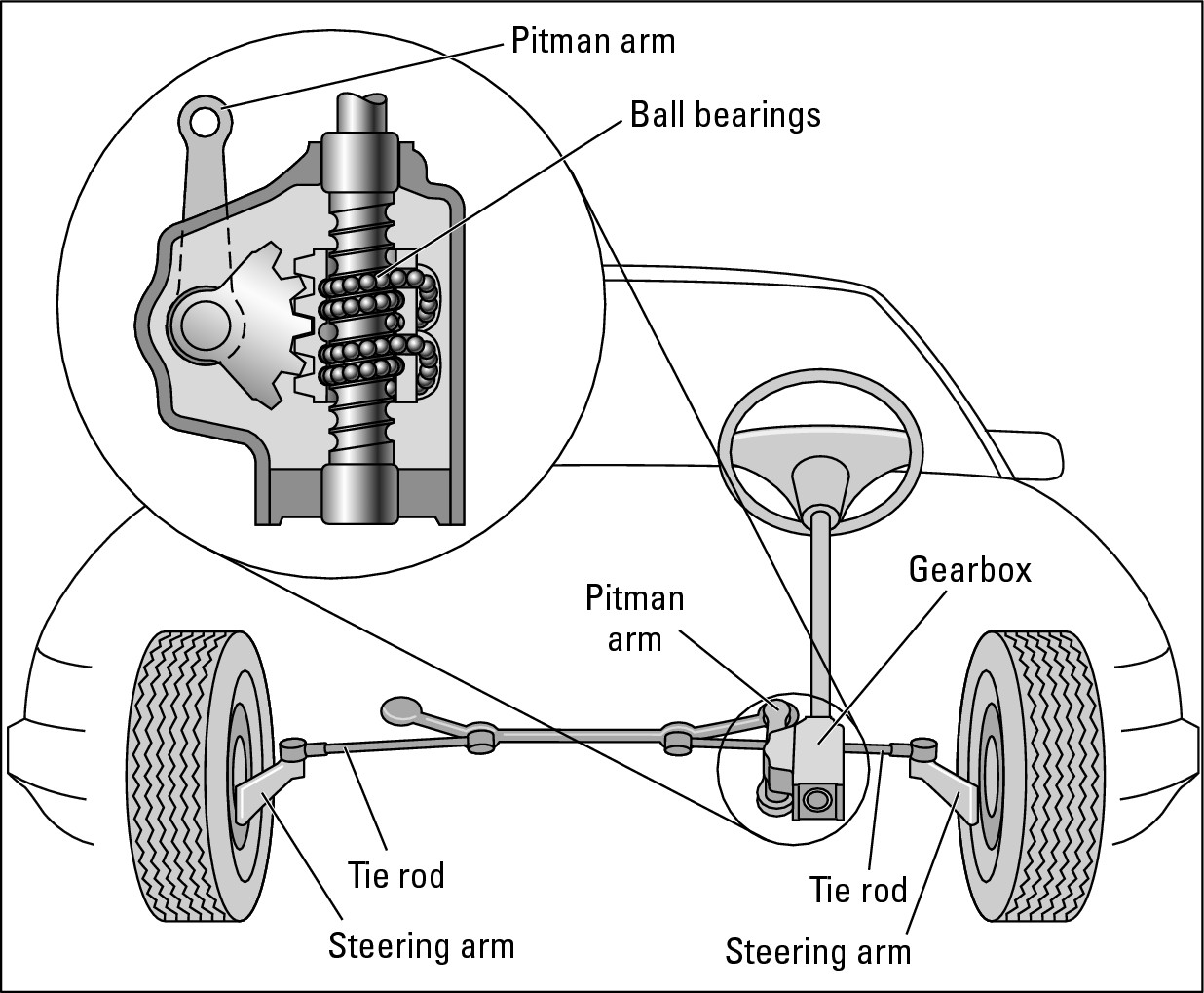

Another type of steering system most often found on trucks and SUVs is called recirculating-ball steering because it features a recirculating-ball gear (see Figure 16-4). The outer part is a block that has a hole in it and gear teeth on the exterior. A rod with threads at one end screws into the threads inside the hole. The threads in the rod are filled with ball bearings that reduce friction between the threads in the rod and the threads in the hole and keep the rod moving firmly in place.

The rod is connected to the steering wheel at the other end. When you turn the steering wheel, it turns the rod, which turns the block it’s screwed into. The gear teeth on the outside of the block move the wheels in whatever direction the block is turning in response to the steering wheel. If the system is power assisted, the power-steering pump sends hydraulic fluid under higher pressure to one side of the block or the other, depending on which way the steering wheel is turned.

|

Figure 16-4: Recirculating-ball steering. |

|

Steer-by-wire

Steer-by-wire is a new and innovative steering system that’s controlled electronically. It senses the direction, force, and speed with which the driver is turning the steering wheel and conveys that information to a motorized steering system. Figure 16-5 shows a prototype steer-by-wire system. Because this system eliminates the pumps, hydraulic lines, pulleys, and other mechanical gizmos that connect the steering wheel to the wheels in rack-and-pinion and recirculating-ball systems, it steers more smoothly, frees up room under the hood, reduces the possibility of mechanical failure, lightens the weight of the car, and increases fuel economy. Such a deal!

|

Figure 16-5: Steer-by-wire. |

|

Checking your steering

Checking your steering is easy. Just stand outside your vehicle, near the door on the driver’s side. Stick your hand through the open window and move the steering wheel, with your eye on the left front tire. If you can move the steering wheel at all before the tire starts to move, then you need to have both your steering and alignment checked. There should be no “play” in the steering wheel before the signal is transmitted to the tires.

.jpg)

Suspension Systems

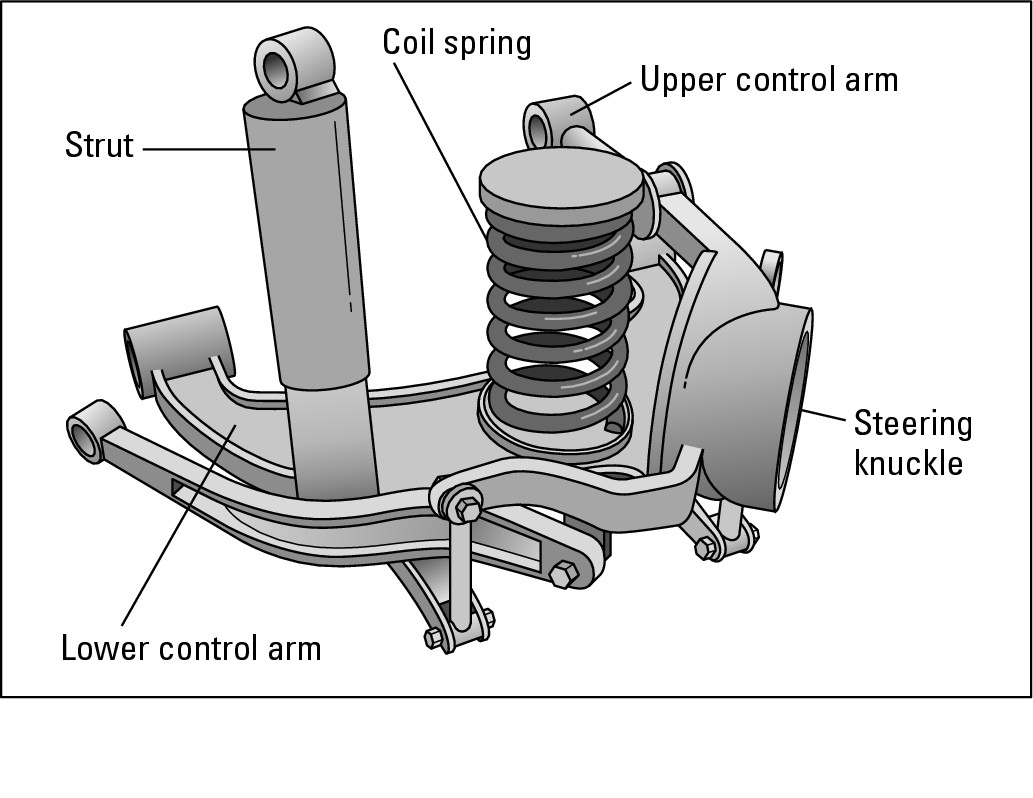

Underneath your vehicle are the main elements of the suspension system, which supports the vehicle and keeps the passenger compartment relatively stable on bumpy roads. This section deals with the most important parts involved in these systems and then with the major types of suspension systems. Figure 16-6 shows you a typical suspension system.

|

Figure 16-6: A typical suspension system. |

|

Major parts of the suspension system

You’ll understand the different types of suspension systems best if you’re familiar with the major parts involved.

Control arms

Control arms are sometimes referred to as A arms, A frames, I arms, or links (look ahead to Figure 16-15). Ever hear the term multi-link suspension? It means that more than one link is holding the wheel to the frame or body.

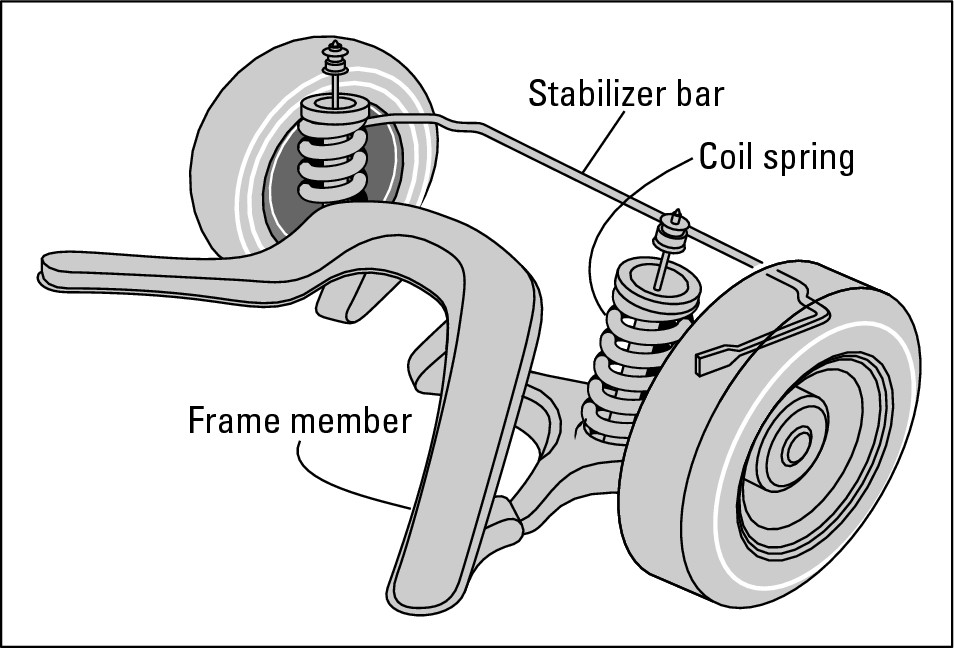

Stabilizer bars

Stabilizer bars (see Figure 16-7) are designed to prevent a vehicle from swaying and lurching on sharp curves and turns and when the wheels are traveling over uneven ground (a better solution than the legendary mountain goat that had shorter legs on one side than on the other for traveling along slopes!). These stabilizers (or anti-sway bars) also improve high-speed stability. Most vehicles have a front stabilizer bar and some also have a rear stabilizer bar. The stabilizer connects one side of the suspension to the other through the frame. As your car begins to dip on one side, the stabilizer bar restricts that side’s movement, depending on the diameter of the bar. Larger-diameter stabilizers restrict more than smaller ones do. More and more modern vehicles are offering stability control systems that perform more efficiently. Chapter 19 tells you how these work.

|

Figure 16-7: A typical stabilizer bar and linkage. |

|

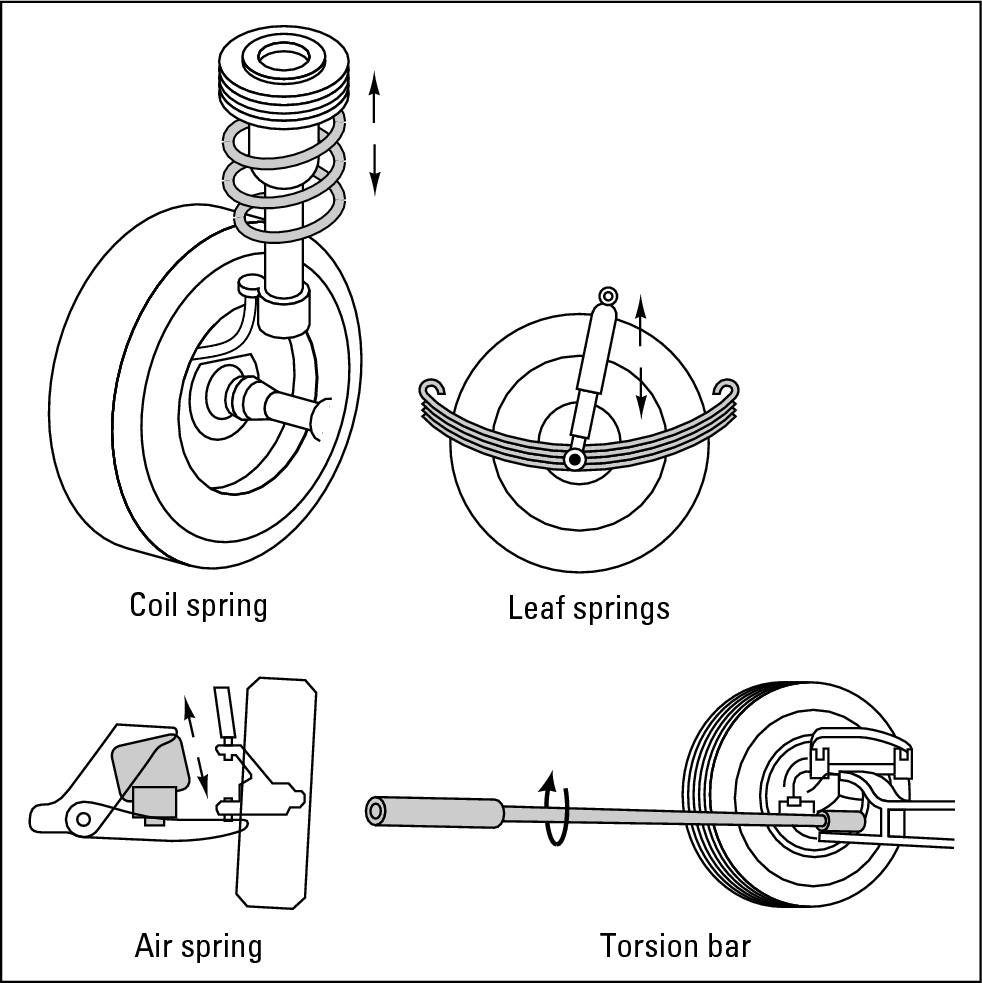

Springs

Springs are the core of the suspension system. Various types of springs are used to carry the weight of the vehicle and keep it off the tires, absorb the bumps, and keep your car at its proper trim height. These can be leaf springs, coil springs, torsion bars, or air springs (see Figure 16-8). Most cars use either coil or leaf springs; SUVs use coil springs, torsion bars, or leaf springs.

|

Figure 16-8: Coil springs, leaf springs, torsion bars, and air springs. |

|

Here’s a rundown of each type of spring:

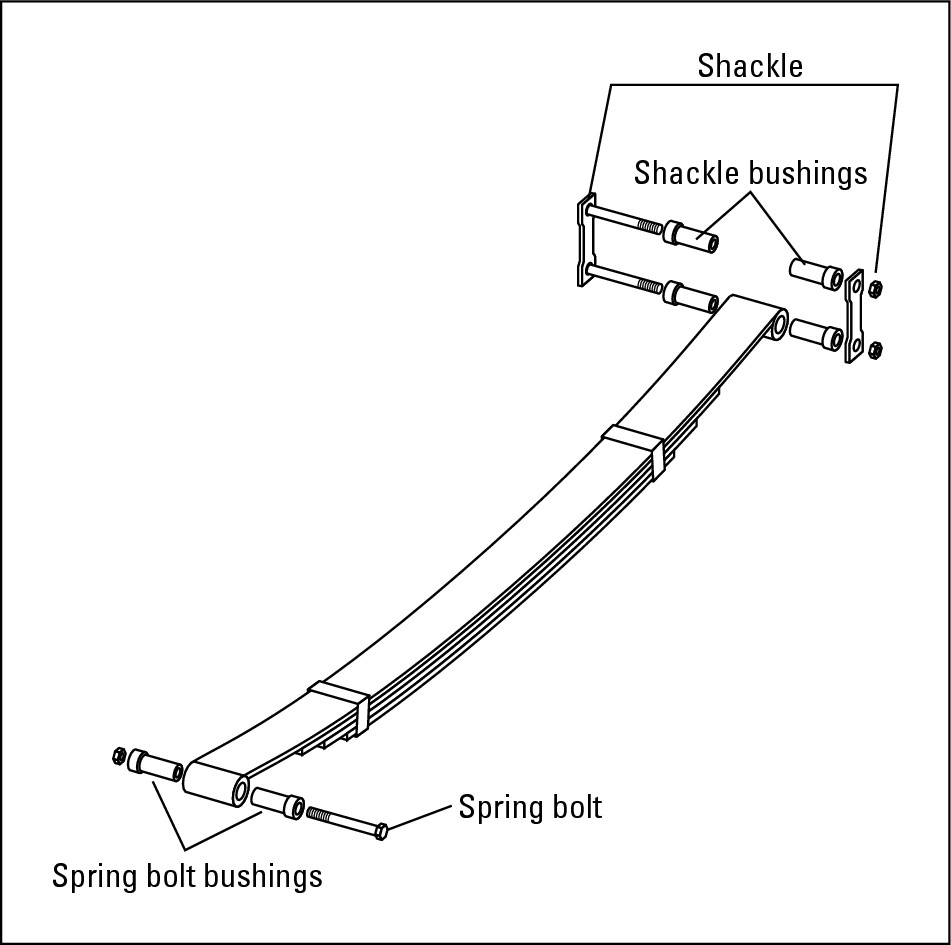

Leaf springs, still found on pickup trucks and pickup-based SUVs, are usually made up of several relatively thin metal plates, called leaves, piled one on top of the other. The reason for using these layers instead of one thick metal bar is that, as a bar bends, the top of the bar has to stretch a little. Unlike a single, thick bar, which, if bent too far, would split from the top down, leaf springs are more flexible; each leaf bends independently, and the leaves can slide on one another instead of breaking (see Figure 16-9).

Leaf springs, still found on pickup trucks and pickup-based SUVs, are usually made up of several relatively thin metal plates, called leaves, piled one on top of the other. The reason for using these layers instead of one thick metal bar is that, as a bar bends, the top of the bar has to stretch a little. Unlike a single, thick bar, which, if bent too far, would split from the top down, leaf springs are more flexible; each leaf bends independently, and the leaves can slide on one another instead of breaking (see Figure 16-9).

|

Figure 16-9: Leaf springs bend but don’t break because they can slide flexibly on one another. |

|

Each end of a set of leaf springs is attached to the frame at the rear of the car with fittings that allow the springs to bend and move freely. These fittings usually have rubber bushings that allow the fittings to bend and twist freely; they also absorb some of the vibration and prevent it from reaching the passenger compartment.

Coil springs look like old- fashioned bed springs. They’re usually found at the front of the car, although they can be at both the front and the rear. At the front end, coil springs also help cushion the bumps, vibrations, and steering movements. Front coil springs can sit on either the upper or lower

control arms.

They’re cushioned by

ball joints

(see Figure 16-10). At the rear, they’re often suspended between control arms that have rubber bushings. Figures 16-10, and 16-16 through 16-18 show the location of coil springs on a variety of suspension systems. If the coil springs are making noise, you may be able to lube them with spray-on grease at the points where they connect at the top and bottom. However, I recommend that you check with the service department at your dealership before undertaking the job yourself.

Coil springs look like old- fashioned bed springs. They’re usually found at the front of the car, although they can be at both the front and the rear. At the front end, coil springs also help cushion the bumps, vibrations, and steering movements. Front coil springs can sit on either the upper or lower

control arms.

They’re cushioned by

ball joints

(see Figure 16-10). At the rear, they’re often suspended between control arms that have rubber bushings. Figures 16-10, and 16-16 through 16-18 show the location of coil springs on a variety of suspension systems. If the coil springs are making noise, you may be able to lube them with spray-on grease at the points where they connect at the top and bottom. However, I recommend that you check with the service department at your dealership before undertaking the job yourself.

|

Figure 16-10: Bushings and ball joints on front coil springs. |

|

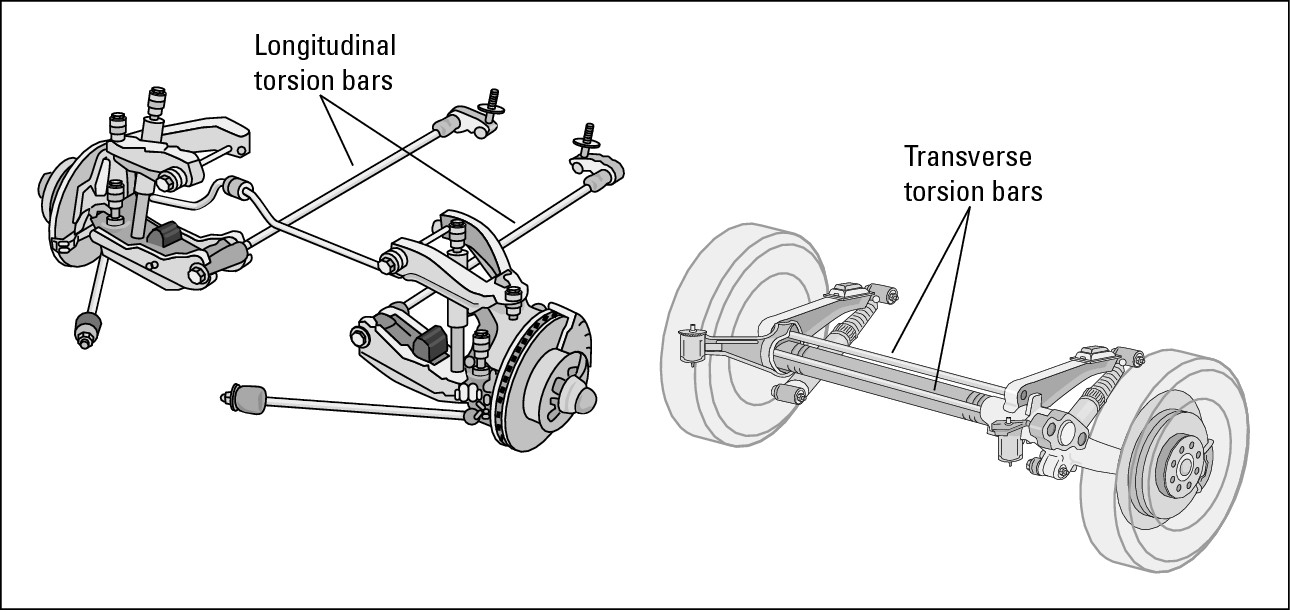

Torsion bars are used mainly in SUVs and trucks. They’re located at the front of the vehicle, connected at one end to a control arm. What they connect to at the other end differs from one vehicle to another. (Figures 16-10 and 16-11 show some configurations.) Torsion bars twist to accommodate differences in the load that the vehicle may be carrying, which allows the front wheels to move up and down freely. Think of torsion bars as coil springs that didn’t get wound into a spiral.

Torsion bars are used mainly in SUVs and trucks. They’re located at the front of the vehicle, connected at one end to a control arm. What they connect to at the other end differs from one vehicle to another. (Figures 16-10 and 16-11 show some configurations.) Torsion bars twist to accommodate differences in the load that the vehicle may be carrying, which allows the front wheels to move up and down freely. Think of torsion bars as coil springs that didn’t get wound into a spiral.

|

Figure 16-11: Torsion bars provide stability. |

|

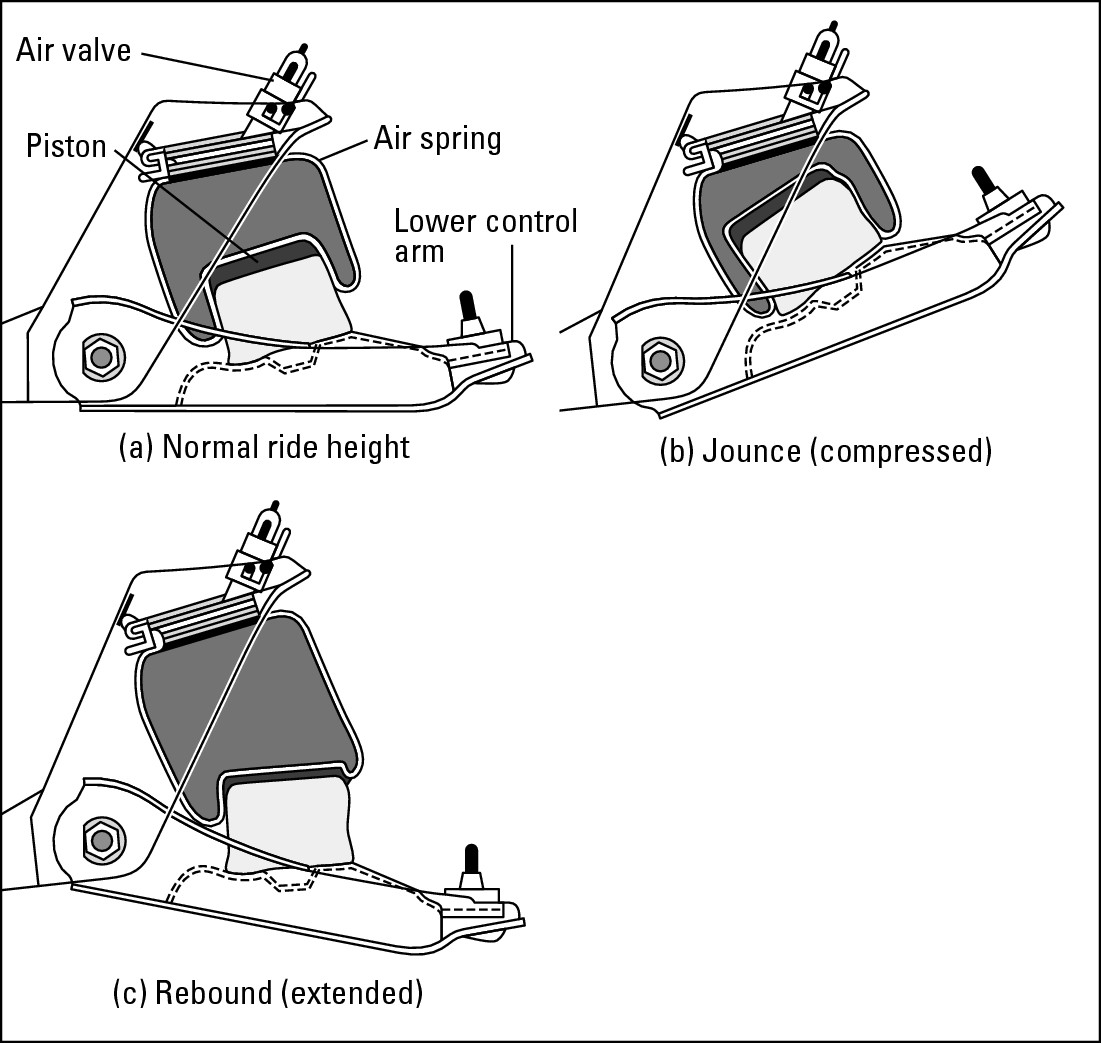

Air springs are usually found on luxury vehicles. A rubber air spring can be filled with the right amount of compressed air to control the ride and maintain the proper height. With this type of system, a computer monitors the ride height and signals an onboard air compressor to pump more air into the air springs when weight is added to the vehicle. When the weight is removed, the computer turns on an exhaust solenoid to let air out of the air springs (refer to Figures 16-8 and 16-12).

Air springs are usually found on luxury vehicles. A rubber air spring can be filled with the right amount of compressed air to control the ride and maintain the proper height. With this type of system, a computer monitors the ride height and signals an onboard air compressor to pump more air into the air springs when weight is added to the vehicle. When the weight is removed, the computer turns on an exhaust solenoid to let air out of the air springs (refer to Figures 16-8 and 16-12).

Usually, there’s nothing to lubricate with air springs. But check with the dealer to find out whether it’s okay to apply a rubber conditioner to the air bags to prevent them from wearing out prematurely.

|

Figure 16-12: How air springs work. |

|

Shocks and struts

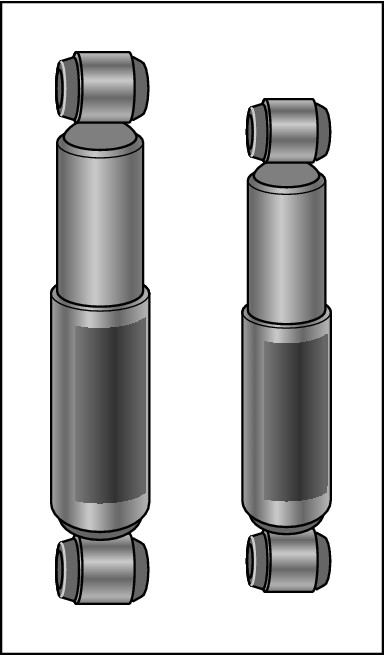

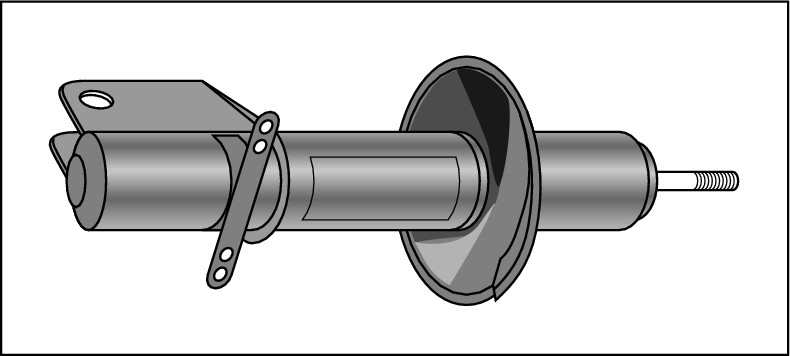

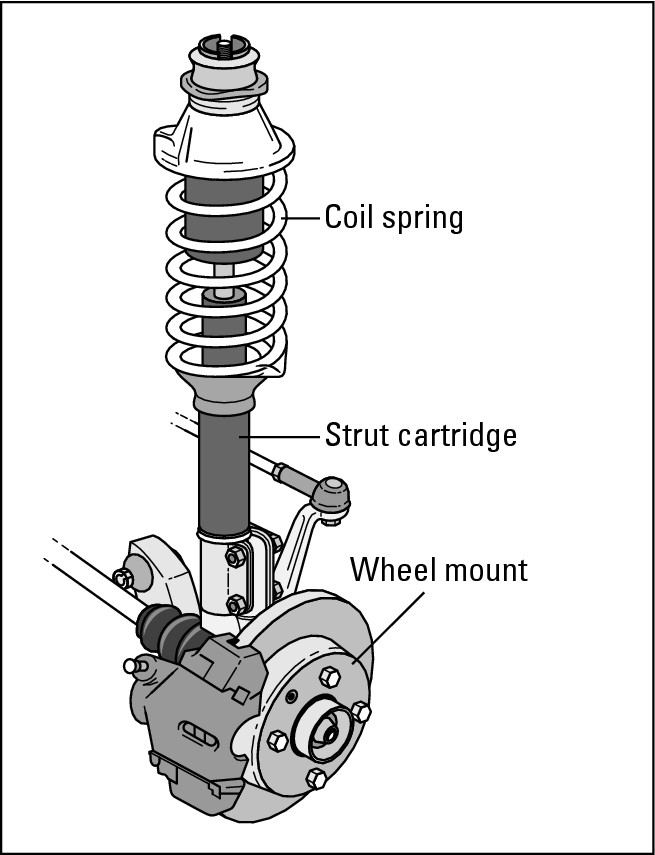

Shock absorbers and MacPherson struts (see Figures 16-13 and 16-14) do most of the work of protecting the passenger compartment from bumps. One or the other is located near each wheel. The way they cut down on vertical movement is interesting. When a wheel hits a bump, the wheel tends to keep bouncing up and down long after the bump has been left behind unless the movement is controlled. The bouncing effect is due to the inflated rubber tire on the wheel and also to the fact that a coil spring that’s pulled or compressed doesn’t just snap back into its former shape but keeps moving up and down for some time afterward. Shock absorbers and struts allow the springs to compress freely and to return or rebound slowly — like the door check on a storm door that opens quickly and easily but closes gently.

|

Figure 16-13: Standard shock absorbers. |

|

|

Figure 16-14: A MacPherson strut. |

|

Here are some points to keep in mind regarding your shocks and struts:

.jpg)

Shock absorbers that are faulty or worn increase tire wear and can cause you to lose control of the steering if you go over bumps and dips at high speeds.

Shock absorbers that are faulty or worn increase tire wear and can cause you to lose control of the steering if you go over bumps and dips at high speeds.

There are a couple of ways to tell whether your vehicle needs new shock absorbers. One is by leaning heavily on a fender or placing your weight on a bumper and then releasing it suddenly, watching to see whether the vehicle returns slowly to its original position. If the vehicle continues to bob up and down, you need new shocks. Another way is to stop fairly short. If your car dips up and down a couple of times before coming to rest, you need new shocks if your vehicle has them. If it doesn’t, a professional should troubleshoot the suspension system to identify the problem.

There are a couple of ways to tell whether your vehicle needs new shock absorbers. One is by leaning heavily on a fender or placing your weight on a bumper and then releasing it suddenly, watching to see whether the vehicle returns slowly to its original position. If the vehicle continues to bob up and down, you need new shocks. Another way is to stop fairly short. If your car dips up and down a couple of times before coming to rest, you need new shocks if your vehicle has them. If it doesn’t, a professional should troubleshoot the suspension system to identify the problem.

MacPherson struts do more than shock absorbers do. Both shocks and struts control the ride, but a strut is also a structural member of the suspension system.

MacPherson struts do more than shock absorbers do. Both shocks and struts control the ride, but a strut is also a structural member of the suspension system.

Electromagnetically adjustable shocks contain a hydraulic fluid whose viscosity can be altered by electromagnetic current.

Sensors

determine how stiff or soft the shocks need to be. Some are driver- controlled by a switch in the cabin that usually offers “sport” and “comfort” settings, and sometimes “tow” or “load” settings, as well.

Electromagnetically adjustable shocks contain a hydraulic fluid whose viscosity can be altered by electromagnetic current.

Sensors

determine how stiff or soft the shocks need to be. Some are driver- controlled by a switch in the cabin that usually offers “sport” and “comfort” settings, and sometimes “tow” or “load” settings, as well.

Although replacing standard shock absorbers isn’t hard, the job can be brutal because you have to jack up your vehicle and crawl under it. Unless you can replace them under supervision on the lift at an auto class, I strongly recommend having a professional do it for you.

Types of suspensions

Several types of suspension systems have been developed to make riding in your vehicle safer and more comfortable. Most cars have independent front suspension systems in which each front wheel is attached separately and can move independently of the others. Some vehicles also have independent rear suspensions, hence the term four-wheel independent suspension. Older rear-wheel drive vehicles and many of today’s trucks use a dependent type of rear suspension that incorporates the rear drive-axle assembly.

Traditionally, double-wishbone suspensions and strut suspensions have been the most common suspension systems found on consumer vehicles. But air suspensions are becoming more popular, and electromagnetic suspensions are coming into play.

Double-wishbone suspension

Double-wishbone suspension systems use a shorter upper control arm and a longer lower control arm that hold the wheel to the frame. The control arms allow the wheel to move up and down, kind of like a hinge allows a door to swing open and closed. The lower arm is larger because it bears most of the load when the vehicle moves up and down. There are rubber bushings at the inboard end of the control arms, and a ball joint at the outboard end of the control arm allows the wheel to rotate and pivot (see Figure 16-15).

|

Figure 16-15: A double-wishbone suspension system. |

|

Multi-link suspension

Multi-link suspension (see Figure 16-16) is a more sophisticated version of double-wishbone suspension, and it comes in a variety of configurations. The main advantage of all of them is greater flexibility that enhances a vehicle’s ability to adjust to changes in driving conditions on the road. Although multi-link suspension systems still have “wishbones,” each of the arms connect to the spindle separately rather than as one solid unit. As a result, each can pivot independently in response to the movement of the steering wheel.

|

Figure 16-16: Multi-link suspension. |

|

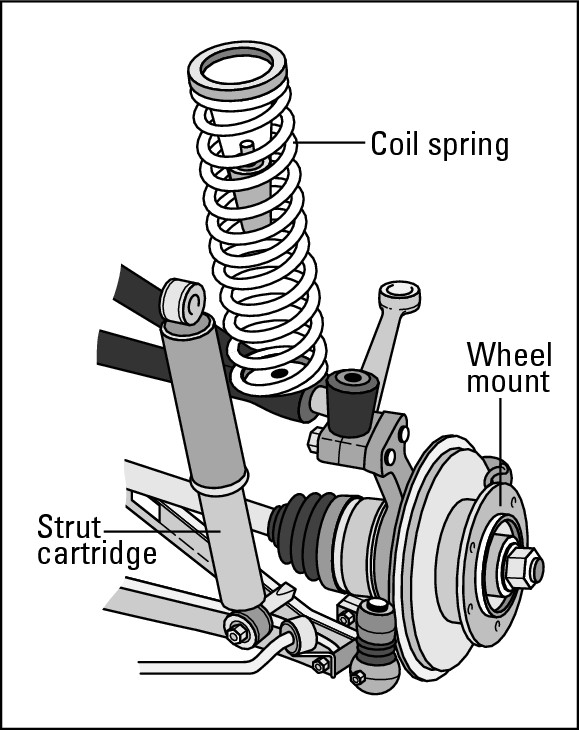

Strut suspension

There are two types of strut suspensions: conventional and modified (see Figures 16-17 and 16-18). Conventional struts have the coil spring wrapped around the strut cartridge, and modified strut suspensions have a remotely mounted spring. Strut suspensions use no upper control arm. The upper strut mount is what holds the wheel in place. You can find more information about different types of shocks and struts in the earlier section, “Shocks and struts.”

|

Figure 16-17: Conventional strut suspension. |

|

|

Figure 16-18: Modified strut suspension. |

|

Air suspension systems

Air suspension is found on some luxury cars and SUVs. It employs air-filled bags or tubes controlled by sensors that determine when the suspension needs to be softened or stiffened and pumps air into them or lets air out of them accordingly. Some air suspension systems are controlled by the driver, whereas others are automatic.

Bose acoustic suspension

Bose acoustic suspension is a product of the same company that builds those sensitive and expensive sound systems and earphones. By applying acoustic technology Bose has come up with a unique suspension system that represents a major automotive advance. Instead of conventional springs, shock absorbers, or hydraulics, Bose suspension employs an electromagnetic motor at each wheel. As the movement of the vehicle compresses and expands the system, amplifiers send electricity to boost the power at each of the wheel motors, enabling them to adjust the suspension much faster than conventional systems can. This sophisticated and sensitive system of controlling the motion of each wheel enables the rest of the vehicle to remain level when the driver steps on the accelerator or the brake pedal or makes a sharp turn, and it virtually eliminates vibrations in the passenger compartment. Bose expects to have this system available — at least on high-end vehicles — by 2009. Hopefully, as has happened with other significant advances in automotive technology that have enabled vehicles to operate more efficiently and safely, the system will swiftly become more widely available.