Chapter 1

Things Every Driver Should Know

In This Chapter

Knowing when to do it yourself

Knowing when to do it yourself

Paying attention to safety

Paying attention to safety

Filling the tank yourself

Filling the tank yourself

Getting under the hood

Getting under the hood

Taking things apart (and putting them back together again)

Taking things apart (and putting them back together again)

Jacking up a vehicle and changing a tire safely

Jacking up a vehicle and changing a tire safely

Getting into your car when you lock yourself out

Getting into your car when you lock yourself out

If you’re not particularly mechanically inclined, you may watch those who are with admiration, amazement, and exasperation because they have something you don’t: an understanding of how things work and how things fit together. When they take something apart, they can reassemble it the way it was. When they say that they want to take a look under the hood, they can actually get the darn thing open. And when they need to change a flat, they don’t spend ten minutes trying to figure out which end of the jack is up.

The good news is that you don’t have to be born with a wrench in your hand to know how to fix things — even things as seemingly complicated as a car. I know; I’ve been there. The Introduction tells you all about my automotive epiphany.

Of course, the simplest tasks can sometimes be the biggest hurdles to overcome. After all, if you can’t even figure out how to open the hood, how can you check the oil or the coolant level? That’s why I begin this book with the basics: simple jobs that you’ll need to do again and again — like opening the hood, jacking up a car, and changing a tire. I also include instructions for filling the fuel tank yourself (it’s cheaper than full-service), a surefire method for taking anything apart and putting it back together again, and safety pointers that every mechanic — experienced and beginner — should heed.

Before You Tackle Any Job

It’s wonderful to do things yourself. You spend less money, you get a sense of power knowing that you did it on your own, and you know that the job’s been done right. Nevertheless, to avoid getting in over my head, I always ask myself the following questions before undertaking any job:

Do I really want to do this? Will it be fun — or horrendous? (I try never to do anything that doesn’t feel good unless it’s absolutely necessary.)

Do I really want to do this? Will it be fun — or horrendous? (I try never to do anything that doesn’t feel good unless it’s absolutely necessary.)

Do I know how to do it? If not, where do I go to learn?

Do I know how to do it? If not, where do I go to learn?

Does it require such expensive tools that it would cost less to have someone do it for me than to buy those tools? Can I borrow or rent the tools I need?

Does it require such expensive tools that it would cost less to have someone do it for me than to buy those tools? Can I borrow or rent the tools I need?

If I goof, can something be seriously damaged? Can I be hurt?

If I goof, can something be seriously damaged? Can I be hurt?

How long will it take, and what is my time worth? From that perspective, how much money will I save by doing it myself?

How long will it take, and what is my time worth? From that perspective, how much money will I save by doing it myself?

You’ll be happy to know that almost every job in this book should pass the test of these questions. If you find a task that doesn’t, don’t hesitate to turn it over to a professional — after you read enough to know that the job is definitely necessary, what it entails, whether the work has been done properly, and how to get satisfaction if it isn’t. With that in mind, let’s get on to the very first thing you need to know in order to work on your vehicle.

What the big guys taught me about busting things loose

If you try to remove a bolt or a spark plug and you can’t budge it, don’t feel like a weakling. At first I thought that I had trouble because I was female, so I asked the biggest guys in my auto class for help because it would have been embarrassing if some little guy could do it. To my amazement, I found that often the big guys struggled, too! The difference was that they always prevailed. What I learned from them is that strength depends less on size or sex and more on the way in which we’ve been taught to focus our strength. People who are handy with tools usually have learned to pour their strength down their arms and into their hands, and focus it on the tool they’re using. The guys also showed me that the longer the handle, the more leverage you have. And from watching them struggle, I learned that the patience to persevere comes from having the confidence that eventually you will succeed. So now I approach hard-to-move objects with the proper tools, focus, and patience. It works!

Buying the right parts for your vehicle

Before you go shopping for parts to replace those on your vehicle, read the tips in this section carefully. They can help you avoid what’s probably the most annoying part of any automotive job: disabling your vehicle to work on it only to find that you need it to drive back to the store to exchange the stuff they sold you in error! Before I learned how to do it right, this happened at least two out of every three times on every job I did.

To buy the proper parts for your vehicle, you must know its specifications (or “specs,” as they’re often called). Most of this information should be in your owner’s manual, and a lot of it is also printed on metal tags or decals located inside your hood. You can usually find these in front of the radiator, inside the fenders, on the inside of the hood — anywhere the auto manufacturer thinks you’ll find them. I know of one car that has its decal inside the lid of the glove compartment. These ID tags also provide a lot of other information about where the vehicle was made, what kind of paint it has, and so on.

The service manual for your vehicle should have the specs for the parts you need, and the parts department at your dealership or a reputable auto supply store can also look them up for you.

.jpg)

How to dispose of empty gasoline cans safely

Although gasoline simply burns, gasoline plus air forms an explosive vapor that can literally take out your entire neighborhood. For this reason, it’s wise not to store or carry gasoline unless you’re heading far away from any source of fuel (and in that unlikely event, use only a specialized, vented gas can). If you have an old gasoline can around, get rid of it, and do it in a way that won’t pollute the environment: Fill the can with water, and, as soon as you can, take the can to a recycling center that handles toxic waste. If there’s no center nearby, ask your local service station if they’ll dispose of it for you.

Some people keep gasoline around to clean parts with, but this is extremely dangerous. Mechanic’s solvent, available at gas stations and auto supply stores, works better and has been treated with a flame retardant to keep it from burning too freely.

Following safety rules

.jpg)

Don’t smoke while you’re working on your car — for obvious reasons!

Don’t smoke while you’re working on your car — for obvious reasons!

Never work on your vehicle unless the parking brake is on, the gearshift is in Park or Neutral, and the engine is shut off. If you have to run the engine to adjust something, turn it on and off yourself to avoid the risk that a friendly helper may misunderstand and turn the engine on while your hands are in the way.

Never work on your vehicle unless the parking brake is on, the gearshift is in Park or Neutral, and the engine is shut off. If you have to run the engine to adjust something, turn it on and off yourself to avoid the risk that a friendly helper may misunderstand and turn the engine on while your hands are in the way.

Be sure that the parts of the engine you’re working on are nice and cool so that you don’t get burned. If you’re doing a job that calls for a warm engine, be very careful.

Be sure that the parts of the engine you’re working on are nice and cool so that you don’t get burned. If you’re doing a job that calls for a warm engine, be very careful.

Never jack a vehicle up unless the wheels are properly blocked. I go into more detail about this later in this chapter in “How to Use a Jack Safely” and “How to Change a Tire.”

Never jack a vehicle up unless the wheels are properly blocked. I go into more detail about this later in this chapter in “How to Use a Jack Safely” and “How to Change a Tire.”

Use insulated tools for electrical work.

Use insulated tools for electrical work.

Before using a wrench or ratchet on a part that’s “stuck,” make sure that if the part suddenly comes loose, your hand won’t hit anything. To avoid the possibility of being injured because your hand slams into something, pull

on wrenches rather than push them whenever possible.

Before using a wrench or ratchet on a part that’s “stuck,” make sure that if the part suddenly comes loose, your hand won’t hit anything. To avoid the possibility of being injured because your hand slams into something, pull

on wrenches rather than push them whenever possible.

Take off your tie, scarf, rings, long necklaces, and other jewelry. If they get caught on parts, they — and you — can be damaged.

Take off your tie, scarf, rings, long necklaces, and other jewelry. If they get caught on parts, they — and you — can be damaged.

Tie back long hair. If your hair accidentally gets caught in a moving fan or belt, you can literally be scalped.

Tie back long hair. If your hair accidentally gets caught in a moving fan or belt, you can literally be scalped.

If you’re working with toxic chemicals, such as coolant, cleaners, and the like, keep them away from your mouth and eyes. Wash your hands thoroughly after using them, and either store them safely away from pets and children or dispose of them in a way that’s safe for the environment.

If you’re working with toxic chemicals, such as coolant, cleaners, and the like, keep them away from your mouth and eyes. Wash your hands thoroughly after using them, and either store them safely away from pets and children or dispose of them in a way that’s safe for the environment.

Know that gasoline is extremely dangerous to have around. Not only is it toxic and flammable, but the vapor in an empty can is explosive enough to take out a city block. If you must keep a small amount of gasoline on hand for a lawn mower or chain saw, always store it in a ventilated gasoline can designed specifically for that purpose. Unless you’re going far into the wilds, never carry a can of gasoline in or on your vehicle. (See the sidebar “How to dispose of empty gasoline cans safely.”)

Know that gasoline is extremely dangerous to have around. Not only is it toxic and flammable, but the vapor in an empty can is explosive enough to take out a city block. If you must keep a small amount of gasoline on hand for a lawn mower or chain saw, always store it in a ventilated gasoline can designed specifically for that purpose. Unless you’re going far into the wilds, never carry a can of gasoline in or on your vehicle. (See the sidebar “How to dispose of empty gasoline cans safely.”)

Work in a well-ventilated area to avoid breathing in carbon monoxide if you have to run the engine, or breathing in toxic fumes from chemicals and gasoline. If possible, work outdoors in your driveway, your backyard, or a parking lot. If you must work in your garage, be sure to keep the garage door open and move the vehicle as close to the door as possible.

Work in a well-ventilated area to avoid breathing in carbon monoxide if you have to run the engine, or breathing in toxic fumes from chemicals and gasoline. If possible, work outdoors in your driveway, your backyard, or a parking lot. If you must work in your garage, be sure to keep the garage door open and move the vehicle as close to the door as possible.

Use a work light in dark areas. If you don’t already have one, Chapter 3 tells you what you need to know about buying one.

Use a work light in dark areas. If you don’t already have one, Chapter 3 tells you what you need to know about buying one.

Keep a fire extinguisher handy. Chapter 3 contains reasons for this precaution that may surprise you.

Keep a fire extinguisher handy. Chapter 3 contains reasons for this precaution that may surprise you.

So much for the scary stuff. Auto repair safety is all a matter of common sense, really.

How to Fill ’Er Up Yourself

More and more gas stations are shifting toward self-service. If you’ve been reluctant to abandon the luxury of the full-service lane, chances are that it’s going to get more and more difficult to find one. Knowing how to fill ’er up yourself not only prevents you from being stranded with an empty tank when there’s no one available to fill it for you, but it also saves you money on every gallon, every time.

.jpg)

Here are the steps for pumping your own gas:

1. Look at the price window on the pump.

If a previous sale is registered there, reset it by following the next steps to activate the pump and select the grade of gasoline. If the price doesn’t disappear, try inserting your credit card or have the attendant clear the machine so that the price window reads “$0.00.”

2. If you’re using a credit card, insert it into the slot and follow the instructions in the credit card window.

3. Select the grade of fuel you want, and move the lever on the pump to ON.

4. Unscrew the cap from your fuel tank.

5. Unhook the pump nozzle and hose from the pump, and place the nozzle into the fuel tank opening.

Some nozzles have rubber vapor-recovery sleeves that must be depressed to allow the fuel to flow, so push the nozzle as deeply into the filler tube of your vehicle as it will go.

6. Squeeze the trigger on the pump nozzle to allow fuel to flow out of the hose and into your fuel tank.

There’s usually a little latch near the trigger that keeps the trigger open so that you don’t have to stand there holding onto it and inhaling gasoline fumes. Don’t worry about overflows; gas pumps shut off automatically when your tank is almost full.

Engaging the trigger latch gives you time to take advantage of the other services available. You can wash the windows or check the air pressure in your tires and add air if they need it (Chapter 17 has instructions). The trigger latch also enables you to get farther away from the pump instead of standing there breathing in the toxic fumes while the tank is filling.

7. When the fuel stops flowing, the trigger clicks closed and the numbers in the pump window stop moving. Remove the nozzle from the fuel tank and hang it back on the pump.

Never “top off” a tank by adding fuel after the pump shuts off automatically. If you overfill your tank, the fuel may overflow the fill hole or leak out onto the road through an overflow outlet. This is not just a waste of your money; spilled fuel ruins asphalt, pollutes the air, and is a fire hazard. This kind of leakage is especially prone to happen if it’s a hot day because heat makes the fuel in your tank expand.

8. If you used a credit card, press Yes for a receipt and replace the cap on your fuel tank while the receipt prints.

How to Open the Hood

How can you do even simple under-the-hood jobs — such as checking the oil, coolant, and transmission fluid; refilling windshield wiper fluid; and checking accessory belts — if you don’t know how to get the hood of your vehicle open?

The good news is that opening the hood is easy and uncomplicated — if you know how to do it. Although the location of the hood release may differ from one vehicle to the next, all releases work in pretty much the same way.

Here’s how to open the hood yourself:

1. Find your hood release and pop open the hood.

Either consult your owner’s manual, or try to remember the last time a service station attendant opened the hood of your car. Did he or she ask you to pull a lever inside the vehicle? Or did he or she go directly to the front grill?

In newer models, the hood release is often inside the vehicle, somewhere near the steering column or on the floor next to the driver’s seat. (It generally displays the word “Hood” or a picture of a car with its hood up.) In older models, the hood release is behind the grill or the bumper.

If the hood release is inside the vehicle, press, push, or pull it until you hear the hood pop open. If the hood release is at the front, look around and through the grill and feel under the grill and behind the bumper to find a handle, lever, arm, or button. Then press, push, or pull it from front to back and side to side until it releases the hood.

The hood will open a little, but it will probably be stopped by the safety catch — a metal lever that, when pressed one way or the other, releases the hood so that it can open all the way. This gizmo prevents the hood from opening accidentally and obscuring your vision while you’re driving.

2. With one hand, raise the hood as far as it will go. With the other hand, feel along the area between the hood and the grill for the safety catch. Release it and raise the hood the rest of the way.

3. Secure the hood if necessary.

If the hood stays up all by itself, fine. If it doesn’t, look for a hood prop —a long, thin metal rod attached either to the underside of the hood or to the bottom edge of the hood opening. Either lower or lift the rod (depending on where it’s located) and fit the end of it into the slot that’s provided to hold it in place.

.jpg)

On some vehicles, the hood is held up by two gas-pressurized cylinders known as hood shocks. If the hood doesn’t feel secure, gas may have leaked out of these units and the hood could come down at any moment. If you’re not sure, secure the hood with a broom handle or similar object and have these units checked — or replaced, if needed — as soon as you can.

How to Take Anything Apart — and Get It Back Together Again

I’d never been able to follow the “easy” instructions to put my kids’ toys together until I learned the technique that follows. Then I was able to get at my brakes to check them and even lubricate the wheel bearings and put everything back together again! The bonus is that this procedure works for anything that you need to take apart and put back together again — flat tires, toasters, bicycles, you name it.

Allow yourself plenty of time. If things get rough, have some water or a cup of coffee. You may get a whole new perspective when you go back to work. Limit distractions: Turn on your answering machine or take the phone off the hook, keep the kids and the dog away, and relax. If you hit a snag, sit quietly and think about it — don’t panic. If the parts fit together before, they’ll fit together again.

Follow these instructions, breathing slowly and deeply:

1. Lay a clean, lint-free rag down on a flat surface, near enough to reach without having to get up or walk to it.

You’ll lay each part on this rag as you remove it. Consequently, the rag shouldn’t be in an area where oil or dust or anything else can fall on it and foul up the parts. If you plan to use something that blasts air for cleaning purposes, leave enough of the rag uncluttered to fold it over the parts resting on it.

2. Before you remove each part, stop and ask yourself the following questions, and if you’re worried about forgetting your answers, make notes:

• What is this thing?

• What does it do?

• How does it do it?

• Why is it made the way it is?

• How tightly is it screwed on (or fastened down)?

.jpg)

Most amateurs put things back very tightly, in hopes that the part won’t fly off. But some things, like bolts that hold gaskets in place, shouldn’t be tightened too securely because, for example, the bolt threads could be stripped or the gasket could be squeezed out of shape, allowing whatever it’s holding in to get out. It’s helpful to make notes about how hard each thing was to remove. “Don’t over-tighten” or “Be sure it’s secure.” Some parts require exact torque specifications, but we don’t deal with them in this book.

3. As you remove each part, lay it down on the rag in clockwise order, with each part pointing in the direction it was in before you removed it.

This is the key to the whole system. When you’re ready to reassemble things, the placement and direction of each part tells you when to put it back and how it was oriented.

4. If you’re making notes, assign each part a number indicating the order in which you removed it — Part #1, Part #2, and so on.

You can even put numbers on the parts with masking tape if you’re afraid that the rag may be moved accidentally. Also, note what each part was attached to; for example, “Part #6: Hook at end of arm on left hooks onto knob to right of Part #7.” Add a sketch if it helps.

If you work systematically and understand the function of each part, you won’t be left with what seem to be extra nuts and bolts at the end of the job.

5. When you’re ready to reassemble everything, begin with the last part you removed, and proceed counterclockwise through the parts on the rag. If you’ve numbered the parts, they should go on in reverse order.

Now you’re ready to tackle the first job that will give you a chance to apply this technique: Using a jack and changing a tire. You may never need to do it, but if you’re stuck with the need to change a flat, you’d better know how.

How to Use a Jack Safely

The most obvious reason to jack up a car is to change a tire, but other jobs such as inspecting brakes may also require you to get under the vehicle. (Even if you’re skinny enough to squeeze yourself between the pavement and the underside of your car, you still need room to move around and manipulate tools.) Chapter 3 has detailed information about the different types of jacks as well as items such as jack stands (essential) and creepers (nonessential, but nice). This section explains how to use a jack safely and efficiently. The next section tells you how to change a tire after the vehicle is in the air.

.jpg)

Jacks are used only to get a vehicle off the ground. They should never be used to hold a vehicle in place.

Jacks are used only to get a vehicle off the ground. They should never be used to hold a vehicle in place.

You must use jack stands when you work underneath your vehicle. If you don’t, you run the risk of serious injury or even death. People have been crushed to death when vehicles that were improperly secured fell on them.

You must use jack stands when you work underneath your vehicle. If you don’t, you run the risk of serious injury or even death. People have been crushed to death when vehicles that were improperly secured fell on them.

Never jack up a vehicle without blocking the wheels to keep it from rolling. Use bricks, wooden wedges, or metal wheel chocks to block the wheels at the opposite end of the car from the end that is to be raised. (Chocks are available at a low cost at auto supply stores.) Keep whatever you use for blocks in the trunk so that you don’t have to go hunting around if you have to change a flat tire.

Never jack up a vehicle without blocking the wheels to keep it from rolling. Use bricks, wooden wedges, or metal wheel chocks to block the wheels at the opposite end of the car from the end that is to be raised. (Chocks are available at a low cost at auto supply stores.) Keep whatever you use for blocks in the trunk so that you don’t have to go hunting around if you have to change a flat tire.

If you find yourself faced with the job of changing a tire and you have nothing with which to block the wheels, park near the curb with the wheels turned in. This may not keep you from getting hurt if the car rolls off the jack, but at least innocent motorists and pedestrians won’t have to deal with a runaway driverless vehicle!

Never change a tire on a freeway or highway. Not only can you be seriously injured, but you can also fall prey to carjackers. Don’t exit the vehicle; instead use a cellphone to call road service or an automobile association such as the AAA. If you don’t have a cellphone, hang a white rag or a white piece of paper out of the driver’s side window and wait for the highway patrol to rescue you.

Never change a tire on a freeway or highway. Not only can you be seriously injured, but you can also fall prey to carjackers. Don’t exit the vehicle; instead use a cellphone to call road service or an automobile association such as the AAA. If you don’t have a cellphone, hang a white rag or a white piece of paper out of the driver’s side window and wait for the highway patrol to rescue you.

Even if you hate cellphones, I recommend that you buy one and keep it in the vehicle for emergencies. You can find a very affordable model that just lets you call 911, road service, and those you’d want to notify in an emergency. It could save your life.

Always park a vehicle on level ground before you jack it up. If you get a flat tire on a hill and can’t coast to the bottom without killing the tire completely, park close to the curb, turn the wheels toward the curb, and block the downside wheels securely to prevent the car from rolling.

Always park a vehicle on level ground before you jack it up. If you get a flat tire on a hill and can’t coast to the bottom without killing the tire completely, park close to the curb, turn the wheels toward the curb, and block the downside wheels securely to prevent the car from rolling.

These precautions won’t eliminate the risk of changing a tire on an incline. If you can’t get to level ground or wait for assistance, you change the tire at your own risk.

Be sure that your gearshift is in Park (or in First if you have a manual transmission) and that the parking brake is on before you jack up the vehicle. The only time you don’t want the parking brake on is when you have to be able to rotate a rear wheel or remove rear brake drums to inspect the brakes. In such a case, make sure that the front wheels are blocked securely.

Be sure that your gearshift is in Park (or in First if you have a manual transmission) and that the parking brake is on before you jack up the vehicle. The only time you don’t want the parking brake on is when you have to be able to rotate a rear wheel or remove rear brake drums to inspect the brakes. In such a case, make sure that the front wheels are blocked securely.

.jpg)

After you’ve observed all the safety precautions, follow these steps to jack up a vehicle:

1. If you’re going to remove a wheel to change a tire or check your brakes, remove the wheel cover or hubcap (if there is one) and loosen the lug nuts.

After the vehicle is jacked up, the wheel will turn freely, which makes it harder to get a wheel cover off and almost impossible to start turning the nuts. Instructions for removing a wheel cover and loosening lug nuts are in the next section, “How to Change a Tire.”

2. Place the jack under the part of the vehicle that it should contact when raised. If you’re using jack stands, place them near the jack.

Where you place your jack depends on whether you’re planning to do a one-wheel job, such as tire changing or brake checking, or a two-wheel, whole-end repair job. Many vehicles now have special flat spots on the underside specifically for jack placement.

If you place your jack incorrectly, you can injure your car. To find the proper place to position the jack for your particular vehicle, check your owner’s manual. If you don’t have a manual, ask the service department at your dealership to show you the proper placement. In any event, follow these guidelines:

• Never place the jack so that the weight of the vehicle rests on something that can bend, break, or give.

• If your manual is incomprehensible or lacks jack placement information, try to place the jack so that it touches either the vehicle’s frame or the big bar that supports the front wheel suspension.

• You can also place jacks near the rear-wheel axle, but until you become more proficient at this, I’d stick to jacking up one wheel at a time.

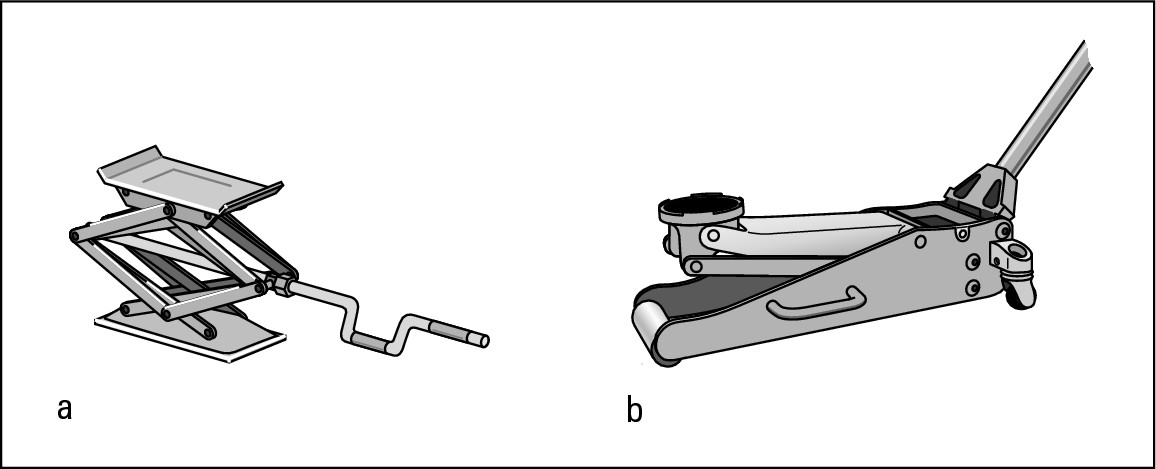

3. Lift the vehicle by using the jack. How you accomplish this depends on the type of jack you’re using (see Figure 1-1):

• If you have a scissor jack, insert the rod or wrench over the knob, and then crank.

• If you have a hydraulic jack, place the handle into the appropriate location and pump up and down. Use nice, even strokes, taking the jack handle from its lowest point to its highest point on each stroke to cut down on the labor involved.

|

Figure 1-1: A scissor jack (a) and a hydraulic jack (b). |

|

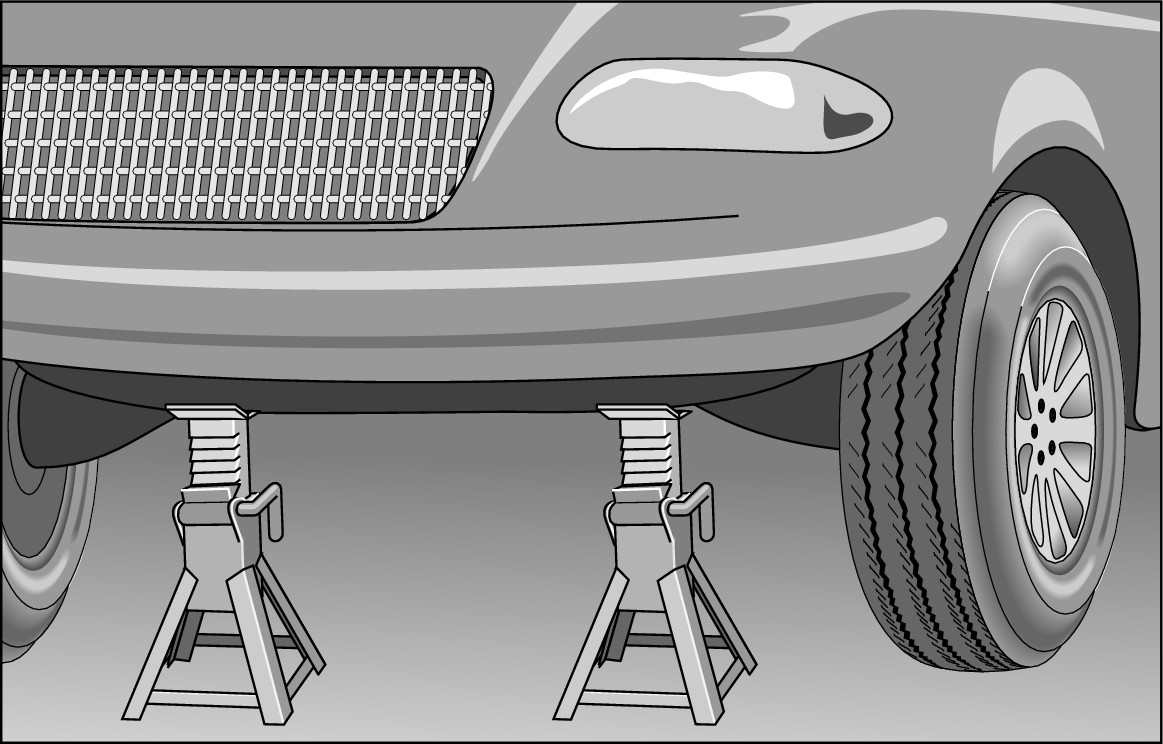

4. Place the jack stands under the vehicle, near where the jack is touching it (see Figure 1-2). Raise the stands until they’re high enough to just fit under, and lock them in place. Lower the jack until the vehicle is resting on the jack stands.

.jpg)

Substituting boxes, stones, or bricks for jack stands is very dangerous. They can slip out or break while you’re under the car. A jack can do the same thing, so be sure to buy a pair of jack stands and stow them in the trunk if you’re traveling out of reach of help if you get a flat tire. You can find information about buying jack stands in Chapter 3.

5. Before you begin to work, wiggle the vehicle a little to make sure that it’s resting securely on the jack stands. Then remove the jack.

Wiggling the vehicle also tells you whether you have the wheels blocked properly. It’s better if the vehicle falls while all four wheels are in place. (It will bounce just a little.)

|

Figure 1-2: Jack stands hold your vehicle up safely. |

|

6. When you’re finished working, replace the jack, remove the stands, and lower the vehicle to the ground.

If you’re using a scissor jack, simply turn the crank in the opposite direction. If you’re using a hydraulic jack, use the rod to turn the pressure release valve. The jack will do the rest of the work for you.

How to Change a Tire

These days, working on your vehicle at roadside can be risky, so the best thing is to use your cellphone to call an automobile association or another source of help. But if you have a flat tire in an area where you can’t get a cellphone signal, you can be helpless unless you know how to change a tire yourself. For this reason, everyone should have a general idea of what’s involved. The task seems easy enough to do:

1. Secure the vehicle so that it won’t roll.

2. Jack up the vehicle, following the instructions in the preceding section, “How to Use a Jack Safely.”

3. Remove the old tire.

4. Put on the new tire.

5. Put away the jack stuff and the old tire.

6. Drive happily into the sunset.

These may be the basic steps of changing a tire, but the job can get sticky in a couple of places if you’re not properly equipped. The following sections explain the steps involved in changing a tire in detail and in order. Check out Chapter 3 for a list of the tools you need.

Removing a wheel cover or hubcap

The first task in changing a flat is to remove the wheel cover or hubcap on the injured tire. The following steps tell you how:

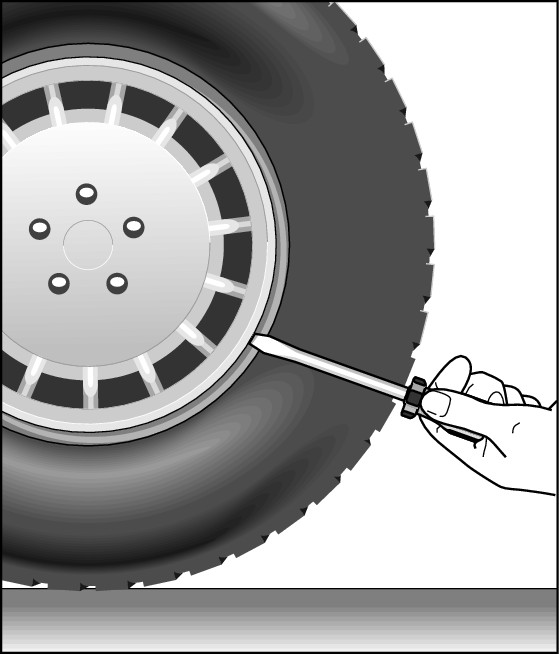

1. If your car has a standard wheel cover or hubcap, use a screwdriver or the flat end of a lug wrench (see Figure 3-16 in Chapter 3) to pry it off.

Just insert the point of the tool where the edge of the cover meets the wheel, and apply a little leverage (see Figure 1-3). The cap should pop off. You may have to do this in a couple of places, as if you were prying the lid off a can of paint.

|

Figure 1-3: You can use a screwdriver to pry a wheel cover loose. |

|

.jpg)

If the cover has a delicate finish, consult your owner’s manual for instructions on how to remove it without damage. It may pry off or unscrew.

2. Lay the cover down on its back so that you can put the lug nuts into it to keep them from rolling away and heading for the nearest sewer.

If you’re afraid of marring the finish, lay the cover on a rag.

After you remove the wheel cover or hubcap, the next task is to loosen the lug nuts.

Loosening the lug nuts

Lug nuts are those big nuts that hold the wheel in place. How you remove the lug nuts on your vehicle depends on whether you have alloy wheels that are held on by lug nuts with delicate finishes, or hubcaps or wheel covers with standard lug nuts behind them.

Lug nuts with special finishes

.jpg)

Lug nuts with standard finishes

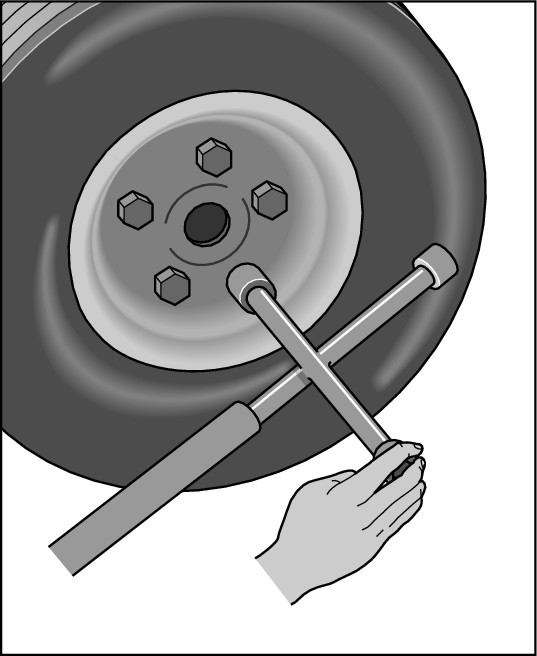

Most garages retighten ordinary lug nuts with a power tool, and unless you’ve done the job yourself by hand, they’re pretty hard to loosen yourself. (Take my advice in Chapter 3 and buy a cross-shaft lug wrench. Figure 3-16 shows what one looks like.)

1. Find the end of the wrench that fits the lug nuts on your vehicle, and fit it onto the first nut.

Always work on lug nuts in consecutive order so that you don’t forget to tighten any later.

2. Apply all your weight to the bar on the left.

This starts turning the nut counterclockwise, which loosens it.

I don’t suggest using this kind of strong-arm tactic on lug nuts with special finishes, but if an ordinary nut has been put on with a power tool and you can’t get it started, a piece of hollow pipe, fitted over that left-hand arm of the cross-shaft wrench, magically adds enough leverage to start the nut easily (see Figure 1-4). After you replace the nut yourself, this aid is no longer necessary. But remember, the longer the arms on your lug wrench, the more leverage you have.

|

Figure 1-4: A hollow pipe and a cross-shaft wrench can loosen the tightest lug nuts. |

|

Changing the tire

Before you jack up your vehicle, remove the spare from the trunk. After the vehicle is safely jacked up and the lug nuts are off, follow these instructions to change the tire:

1. Roll the spare tire to the scene of the action if you haven’t already done so.

2. Grasp the flat tire with both hands and pull it toward you.

The flat tire sits on the exposed bolts that the lug nuts screw onto. As you pull the flat off, it should slide along the bolts until, suddenly, it clears the end of the bolts and you find yourself supporting its full weight. Tires are heavy, and you’ll be quite happy to lower it to the ground (if you haven’t already dropped it).

3. Roll the flat along the ground to the rear of the vehicle to get it out of the way.

4. Lift the spare onto the lug bolts.

Because tires are heavy, you may have a little trouble lifting the spare into place — especially if you’re not accustomed to lifting heavy things.

5. After you have the spare tire in place, replace the lug nuts and tighten them by hand.

Give each lug nut a jolt with the wrench to get it firmly into place, but wait until the car is on the ground before you really try to tighten the lug nuts.

6. Replace the jack, use it to lift the vehicle off the jack stands and lower the car to the ground.

7. After the vehicle is resting on the ground, use the lug wrench to tighten the lug nuts as much as you can.

.jpg)

If your vehicle has alloy wheels, tighten the lug nuts until the lug wrench won’t move any more, then press down on the wrench’s cross arm with all your weight, but don’t jerk it or kick it or jump on it as you could cause the wrench to damage the finish on the nut.

Standard lug nuts are sturdier than those on alloy wheels, but you don’t want to twist them off the bolts or ruin the threads. However, you don’t want the wheel to fall off, either. If you’re worried about tightening them sufficiently, use your hollow pipe, or step on the right-hand arm of the lug wrench after the nut is tight.

8. Replace the wheel cover or hubcap.

If your car has wheel covers with a delicate finish, the owner’s manual should provide instructions for replacing it. If not, reverse the order of things you did when removing it (if you had to pry it off, then it probably pops back in with a sharp tap of your hand; if it unscrewed like a big jar top, then it screws back in).

If your car has hubcaps, place the hubcap against the wheel and whack it into place with the heel of your hand. Cushion your hand with a soft rag first so that you won’t hurt it. And don’t hit the hubcap with a wrench or hammer — you’ll dent it. Whack it a couple of times, in a couple of places, to be sure that it’s on evenly and securely. (Even secondhand hubcaps can be expensive to replace, and that’s if you can find the one you need.) If it’s too much of a hassle, or if you don’t have the time to replace the hubcap, you can take it home and install it later; it’s mostly ornamental, and you can drive for a while without it. But do replace it soon because it helps keep dust and dirt out of your brakes and bearings.

9. Put the flat in the trunk where the spare was located, and put your tools (including wheel blocks) away.

.jpg)

How to Get In When You’re Locked Out

.jpg)

Fortunately, many new vehicles come with electronic door openers or “digital keys” that don’t allow you to lock the doors with the keys in the vehicle. The downside is that if you lose the gadget, it can take days and hundreds of dollars to replace it, and you’ll probably need to have the vehicle towed to a dealer who will order a new key.

Assuming that you’ve decided not to risk hiding an extra set of keys on your car, here are a few things you can try to get in without a key:

If your vehicle has door locks that are recessed inside the interior door handle, get professional help.

If your vehicle has door locks that are recessed inside the interior door handle, get professional help.

If you have the old-style door locks with little buttons on the window ledge, straighten a wire coat hanger and bend the end into a little hook. Insert it between the rubber molding and the side window and then carefully hook it around the door button and pull it up.

If you have the old-style door locks with little buttons on the window ledge, straighten a wire coat hanger and bend the end into a little hook. Insert it between the rubber molding and the side window and then carefully hook it around the door button and pull it up.

If you have smooth buttons, you can try to hook one using the hanger technique, but most will refuse to budge.

If you have smooth buttons, you can try to hook one using the hanger technique, but most will refuse to budge.

If you happen to lock yourself out of the vehicle while you have the trunk open, you may be able to move the rear seat out of the way and gain access to the rear of the car (or you can hide an extra ignition key in the trunk).

If you happen to lock yourself out of the vehicle while you have the trunk open, you may be able to move the rear seat out of the way and gain access to the rear of the car (or you can hide an extra ignition key in the trunk).