Adam Knibb Architects

Winchester, Hampshire, United Kingdom

© Ben Savage

![]()

The clients’ brief called for the creation of a pool house to replace a disused tennis court. Their desire for a self-build project required a design that would allow for simplified building processes facilitated by a prefabricated timber structure.

The new construction harnesses nature, maximizes views, and minimizes environmental impact. Sited with its “back” to woodland, the pool house is a folded rectangular form that frames views across the garden and fields. The design links movement from public to private areas through purposively designed elements, which promote fluidity rather than physical separation. The decking acts as a “catwalk,” enhancing the experience.

Site plan

A. |

Existing house |

B. |

Existing garage |

C. |

Replanted/landscaped area |

D. |

Patio |

E. |

Pool |

F. |

Timber decking |

G. |

Pool house |

1. |

Shower extract vent to atmosphere |

2. |

Rainwater downpipe |

Designed to respond to its surroundings, the pool house is clad in timber, with a vertical orientation to mimic the trees. Natural oak cladding, softening over time, and a sedum roof help the building blend further into the environment.

Site plan

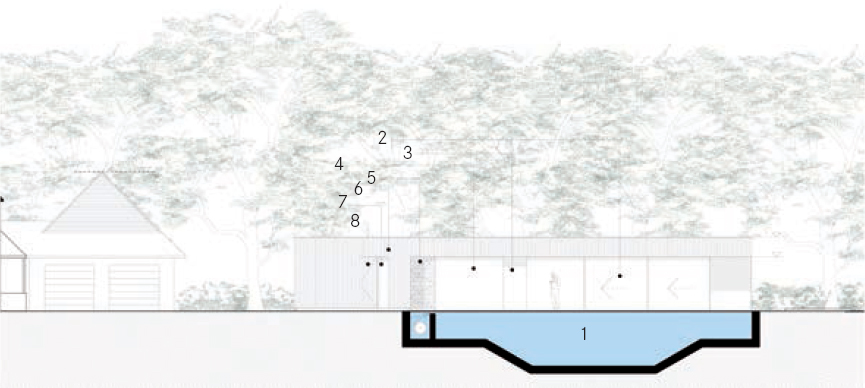

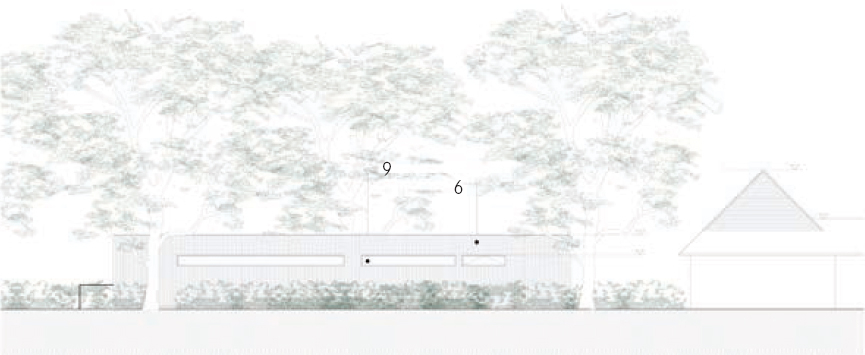

East elevation

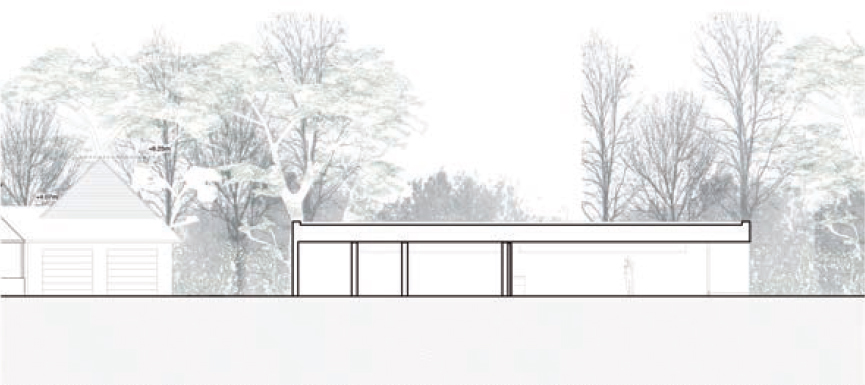

South elevation

West elevation

South elevation

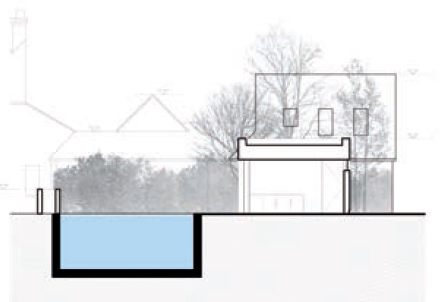

East section

1. |

Pool |

2. |

Double glass sliding doors |

3. |

Aluminum solid panel, mid gray |

4. |

Fixed window |

5. |

Stable door, oak clad |

6. |

Vertical oak cladding |

7. |

Opaque glass |

8. |

Shower room door |

9. |

High level slot windows |

10. |

Planter |

11. |

Existing house in background |

North section

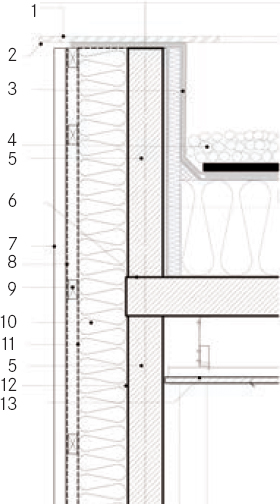

Parapet section detail

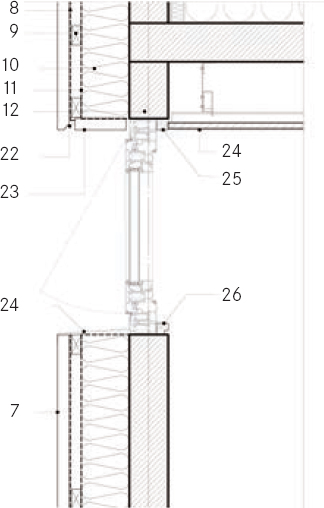

Parapet and glazing head detail

Parapet section detail

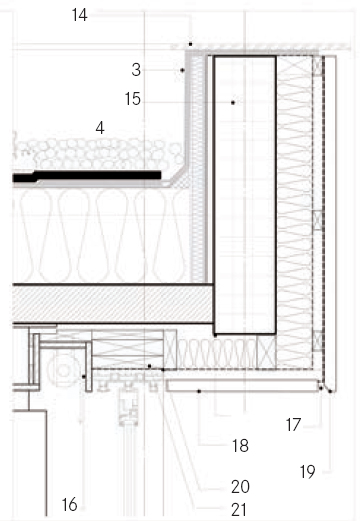

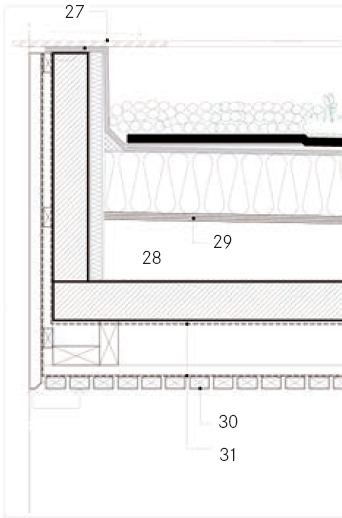

Flat roof-gutter detail

High-level window detail

1. |

5 mm steel sheet as coping fixed through to parapet. MIO painted |

2. |

8 mm water-drip notch |

3. |

Flat roof waterproofing barrier lapped up and underneath coping |

4. |

Gravel border |

5. |

94 mm CLT wall panel |

6. |

CTL structure |

7. |

50 x 22 mm vertical oak cladding |

8. |

Black insect mesh |

9. |

25 mm air gap with diagonal battens fixed through CLT structure |

10. |

125 mm Kingspan K12 rigid insulation |

11. |

Continuous vapor membrane |

12. |

Steel post |

13. |

MF suspended ceiling with 12.5 mm plasterboard, skimmed and painted |

14. |

15 mm steel sheet as coping, fixed through parapet. MIO painted |

15. |

Glulam beam |

16. |

Recessed blind box |

17. |

10 mm ventilation gap with insect mesh |

18. |

50 x 22 mm oak cladding, laid on soffit, to follow lines from façade |

19. |

Vertical cladding to have 45-degree chamfer on exposed edge |

20. |

Vapor barrier to continue behind glazing track |

21. |

SW timber packing as required |

22. |

45-degree chamfer for water drip. Continuous insect mesh |

23. |

30 mm oak plank to window head reveal |

24. |

PPC aluminum window sill. Part of window package. To be installed post cladding |

25. |

30 mm MDF window reveal lining |

26. |

30 mm MDF window reveal lining with 100 mm shadow gap to wall |

27. |

Coping to have slight fall into fall roof |

28. |

Timber furring to create fall of 1:60 |

29. |

18 mm WBP plywood deck |

30. |

Oak battens to clad soffit |

31. |

Insect mesh and vapor barrier |

32. |

Leaf guard to all outlets |

33. |

300 mm wide gutter trough |

34. |

12.5 mm plasterboard, skimmed and painted on MF suspended ceiling |

35. |

Internal RWP |

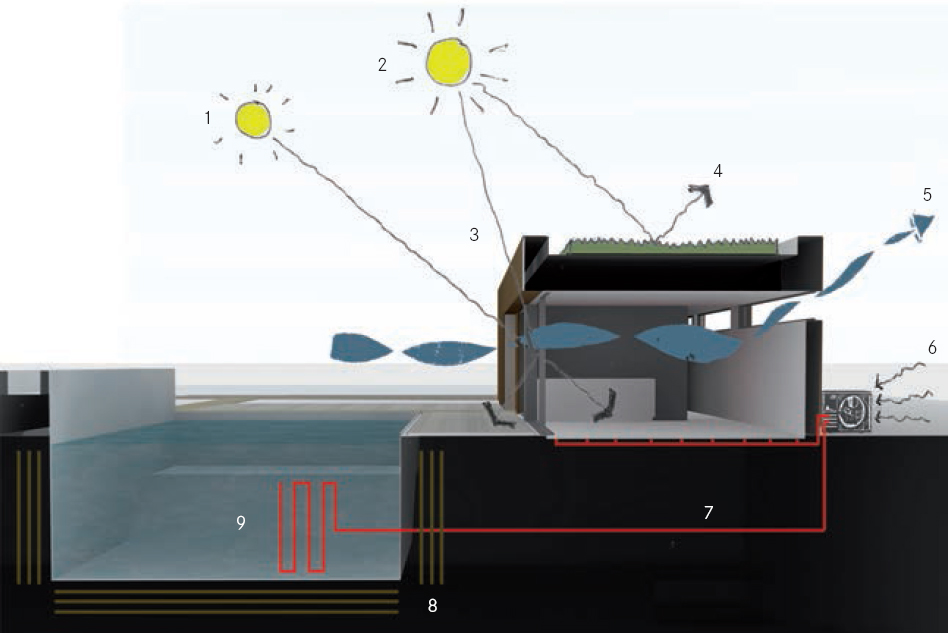

Environmental strategy diagram

1. |

Winter sun |

2. |

Summer sun |

3. |

Recessed glazing to minimize summer solar gains |

4. |

Sedum roof. Provides habitat and reflects heat |

5. |

Natural ventilation flows through building |

6. |

Air-source heat pump intake |

7. |

Air-source heat pump supplying pool heat |

8. |

Sunken swimming pool to increase thermal mass, reducing heat loss |

9. |

Air-source heat pump supplying subfloor heating |

Large sliding doors blur the boundaries between interior and exterior spaces. Large glazed surfaces help maximize solar gain during winter months. Set back under a parapet overhang, they contribute to temperature control during summer months.