Parking lots filled with dreaded abandoned shopping carts, playful children, other drivers and even ourselves can be the cause of dents, but few of these groups can undo the damage they can cause. However, by practicing these steps, you can join the list of people who can pound out dents like the pros.

To demonstrate this project, Jeff Lilly Restorations of San Antonio used a 1936 Ford truck cab with three dents of different depths. The steps outlined here are the top three methods used by the professionals and can be used on any vehicle with a steel body.

Example No. 1: Deep Dents

1. Three dents with different depths were found on this 1936 Ford truck cab to demonstrate dent repair. The three top methods of dent repair will be shown using these dents.

2. The tools of the dent repair trade include these items: hammers, dollies, slap files, angle grinders and metal files.

3. In this example, we’ll start with the deepest dent. In general, any dent that is 1⁄8 inch in depth or more should be worked out to around 80 percent using a hammer with the correct face and a matched dolly.

4. This hammer has a slight crown or dome, which keeps it from making contact on the outside edge, thus providing a smoother finish. The dolly has the same slight crown.

5. Pounding out a dent in a spiral design is the key to dent removal. More often than not, a dent is not perfectly round, but we will use this for demonstration purposes. Start on the outside of the dent and work the dolly and hammer in a circular motion until you meet in the center, thus gathering up the metal bit by bit.

6. Bob, a south-paw, holds the hammer in his left hand and the dolly in his right (a right-handed person would place them in opposite hands). Bob holds the dolly so the center makes most of the contact. If you do not have the vehicle apart, you cannot gain access to the back side. This is important, but in the final steps, we will show you another technique that will allow you to remove smaller dents without access to the rear of the dent.

7. Get comfortable so you can get a nice swing and make even contact with the panel. How you hold the dolly is important. Pounding just 1⁄8 to 1⁄4 inch inside the dent, away from where the hammer strikes on the outside of the dent, is best. This will allow easy dent removal without having to strike the panel so hard.

8. Bob works his magic and the dent is disappearing. After he removes about 80 percent of the dent, he moves on to slap filing for final removal. In the next step, we will show you how to use this slap file method, which is how this dent is finished.

Example No. 2: Mid-Depth Dents

9. This second dent is 1⁄8-inch deep, and we chose it to demonstrate its removal using a slap file and dolly without a hammer.

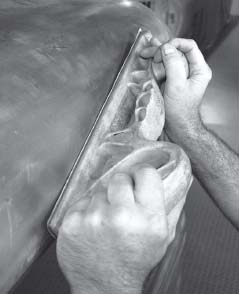

10. This dolly is smaller and has an hourglass configuration, which allows its user to hold it with their fingers and get closer to the panel. We will remove this entire dent using this technique. As noted in Step 8, this second technique is how we will finish out the first dent to completion, but to avoid duplication of steps, we will use this second dent to show this different technique.

11. This close-up view shows the serrated teeth of a slap file. This method of dent repair is actually reverse of the hammer-and-dolly method. You still use the spiral technique, but instead of pounding out the dent the opposite way it was put in, you actually slap the panel the same way the dent was put into the panel. The dolly is placed on the back side and with a small amount of force (about 2 pounds), place it on the outer edge of the dent. When using the slap file, it needs to be directly placed on the same spot where the dolly is placed on the opposite side. In other words, they should “meet.” The teeth on the file allows the metal being pushed from the dolly to work itself into the teeth, allowing the dent to come back to the surface.

12. The same spiral method is used again.

13. Bob uses a vinyl-reinforced slap file, but gloves should be worn if it is a bare file, because this style of slap file can abuse hands.

14. Bob places the dolly on the outside perimeter of the dent and slaps the same spot. Bit by bit, the serrated teeth fill with metal, which pulls the steel to a level surface.

Example No. 3: Shallow Dents

15. In this section, we’ll take dents with a depth of 1⁄8 inch or less and repair them with a pin-spot welder.

16. The pins come in different sizes: 7⁄64 inch, 1⁄8 inch, etc.

17. Most pin spotters are set to weld the pin to the metal without burning. We place it in the designated center of the dent and pull the trigger.

18. The pin is welded on

and ready for a pull.

19. Bob now uses the “Ding Near Perfect” tool (see the circular basket). It is very similar to a rivet gun with a circular basket on the end.

20. It pulls the dent right out.

21. Bob grinds the pin weld down to nothing, and it is now time to run the metal file over it to see what remains of the dent.

22. This metal file has eight teeth per inch, so it works well and cuts metal nicely.

23. Slide the file in an “X” pattern across the panel, and it will shave a thin layer off the top. This shows the highs and lows and gives you a gauge to where you are in the straightening process. If you need to slap some more, now is the time.

24. Bob likes to work his metal to the “nth” degree, so he uses a 17-inch block with 80-grit to give it a final check. He feels satisfied when total contact is made on the panel, denoting a finished repair.

25. The finished product. A few coats of high-build primer and the panel is ready to paint.

SOURCE:

Jeff Lilly Restorations LLC

11125 F.M. 1560, San Antonio, Texas

www.jefflilly.com

210-695-5151