Bob Schirmer has a problem on his hands. On an otherwise ordinary Tuesday morning in the life of a radiator repair whiz, he has a customer that is trying to make his life easy.

And it’s driving him a little nuts.

Schirmer, who along with his father Ray Sr. and brother Ray Jr. — R.C. for short — runs Glen-ray Radiators in the northern Wisconsin city of Wausau, almost can’t bear the thought of sending out a radiator that looks, well … crappy. But that’s what the customer wants, strangely enough — a radiator that doesn’t need to look good, just one that won’t leak or overheat. In fact, the customer has requested that the radiator for his 1973 Plymouth Duster be ugly.

But it all just goes against Schirmer’s nature.

“He wants it for some kind of 24-hour endurance race,” Schirmer chuckles. “He doesn’t want us to make it look good. I can’t even de-dent it or anything. He just wants us to get it done and send it out… It’s all I can do to not take that thing and start working on it. It’s kind of driving me crazy. But that’s what he wants, so …”

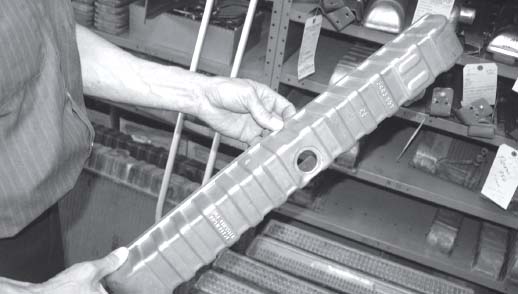

Lenny Fronholtz does all the assembling and testing on all the repaired and reproduction big-block MoPar radiators. “He makes them exactly the way I want them,” said Bob Schirmer. Here Fronholtz solders and assembles a radiator for a 1973 Plymouth Duster.

Clearly, having any radiator, power steering cooler or transmission cooler wind up in a customer’s hands that doesn’t reflect Glen-ray’s absolute best effort goes against the grain for Schirmer, which probably helps explain why the family-run shop has been humming along nicely since 1964. The venture started when Ray Sr. and his brother Glen moved from Chicago to Wausau to open their own radiator business. For many years, the company did what most radiator shops do all day every day — it fixed and sold radiators to local car owners.

R.C. joined the business after high school, and Bob eventually did the same in 1987. “When I got married, Dad said I should come and work for the family business,” Bob recalled. “I had worked for the Chrysler dealer in town, so I really knew them. I started off on the phone and installing heaters and radiators.”

Bob knew Chryslers so well, in fact, that he spent plenty of weekends walking car shows and swap meets looking for Chrysler radiators that he knew car buffs needed, namely big-block MoPar muscle cars from the late 1960s and early ’70s, including Hemis. That idea worked pretty well for a while, but finding such radiators became harder and harder, eventually getting to the point where Schirmer figured it might be easier to figure out how to get a licensing deal with Chrysler and just try to make some authentic replacement radiators himself.

“I’d buy ’em, and restore ’em and re-sell them,” he said. “Mainly because I worked at the Chrysler dealer, I was looking for Chrysler radiators. At the time I never really knew enough about the Fords or the GMs … I just kind of gravitated to the Chrysler stuff, because I knew which ones I was getting calls on.”

Glen-ray is the only licensed producer of authentic, numbered and logoed big-block MoPar radiators. That means using dyes to stamp each radiator correctly to make sure it matches the car’s original radiator.

Schirmer and Glen-ray had the repair work on the MoPar muscle car radiators dialed in. They knew how to do that just fine. The tricky part was not only getting a license from Chrysler to reproduce numbers-matching radiators with all the correct numbering and logos, but also finding suppliers for the tanks and cores, and then getting dyes made so tank shells could be stamped correctly to match any radiator that might need to be replicated.

It took Shirmer a couple of years of planning and teeth gnashing to pull it off, but the operation has been a success.

“As far as I know, I’m the only guy in the world that can make these tanks and logo them,” he said. “With Chrysler, I got in good with the people that licensed me and they are happy with the product, and there is such a limited [demand] … You need so many parts to make these right, you’d just have to have won the lottery to get into it like this. I think it was two years in development to do it… People tell me I should do Fords and Chevys, but I only know enough about them to be dangerous.”

Now, Schirmer is armed with two attractive options when a MoPar owner needs a radiator. He can put his years of experience and perfectionist personality to work to fix a customer’s existing radiator, or he can make them up an identical replica using all the correct factory stampings.

“When I go to a show now, most of the time I have restored ones and I have reproductions,” he said. “So I can show people the difference between a new one and the ones we have restored.

“I’d say [demand] leans a little more toward restoring old ones, just because of the cost. You pretty much double up the price to restore an original ’66 Charger radiator when you’re putting in a reproduction one. And a lot of times they have the original radiator for the car, so I really push people to do that because it’s nice when you have all the original parts to the car. It’s one of those things if you can do it, I think you should.”

Schirmer knows he’s going to be working on the radiator either way, regardless of whether a customer decides to fix his existing part or get a replica made. On the new ones, Schirmer stamps the tank and does all the prep work, then turns it over to assembly man Lenny Fronholtz, who solders it together, assembles it and tests it. Schirmer then finishes the job, priming and painting everything and carefully packaging it with expandable foam for shipping.

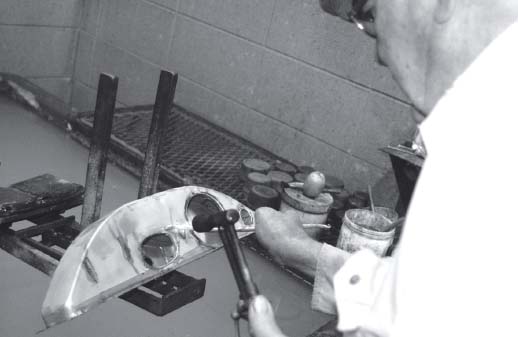

Things can get a little more complicated and time consuming, of course, when he has to try to make an old, tired radiator “look new again.” In most cases, he has to spend a day or two carefully tapping out dents and patching and soldering on the tanks.

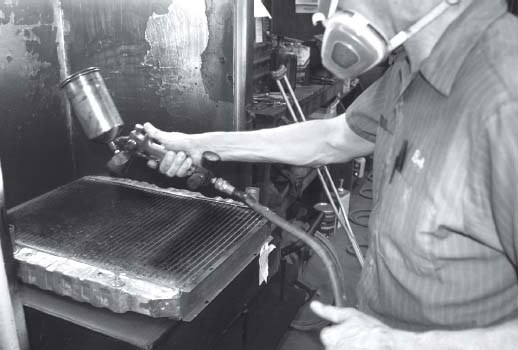

“We take it all apart, bead blast everything and I primer the brackets quick so they don’t flash rust,” Schirmer said. “Then we go around and pull all the connections out and rebuild the cooler if needed. I de-dent everything. Then we go and silver-solder inside the top tank. Lenny takes it and pressure washes it and throws it in the boiling tank. We let it sit in the boiling tank for approximately 20 to 30 seconds, to neutralize any acid or fluxes that are on there, because you do use a lot of active chemicals in soldering a radiator … Then we dry it inside and outside. I go over it with my band file, which is a little tool that is Scotchbrite on a roller. It gets solder off the brackets and all the little nibs off the tank … I go all over with a acid etched primer so the paint isn’t coming off within a year, and I spray it with Sherwin Williams Ultra 7000 — two coats for the tanks and one for the core. I spray it all black with a little hardener and a little flattener to give it about the same look the factory did.

“Sometimes you have to ask the guy, ‘Do you want me to clean it up and make it look good, or do you want me to leave eall those solder drips, put it back the way the factory did, make it look kind of crappy when I’m done. Some guys want it crappy, some guys want it nice.

Schirmer chuckles and adds, “Thankfully, most guys want it nice, because it takes more time to make it look crappy!”

Clearly, Schirmer knows he has plenty at stake every time he works on a radiator for a customer — most of whom he will never meet in person. Not only does he have the reputation of his father and uncle’s company to preserve, he also has a Chrysler licensing deal on the line.

Schirmer does all the de-denting and finishing on the repaired Hemi radiator tanks. He has a variety of small wooden blocks that he uses to tap out the dents on the tanks (left). Before primer and paint, the tanks are also smoothed over with an electric band file.

Ray Schirmer Sr. still does plenty of hands-on work on collector car radiators. Here he solders a 1931 Buick tank.

Bob Schirmer applies some black finishing paint to a radiator at Glen-ray Radiators in Wausau, Wis. The family- run business began in 1964, and in recent years has been specializing in repairing and reproducing radiators for big-block Chrysler Corp. muscle cars.

“I do sell the connections if people need them. I will sell brackets and I will sell the bottom tank, as long as it’s not logoed, and I will sell a non-logoed tank. But as soon as it has a logo on it, I won’t sell it to another shop,” he said, referring to his reproduction radiators. “If I sold something like that to somebody and they used it and did a sloppy job with it and it ever got out that it was one of my tanks, I can’t afford to have Chrysler come back and say, ‘Bob, we hear you’ve got some bad product out there. We need to take a look at your license.’ If that happens, I’m really hurting because then I can’t make anything anymore, and that would just destroy us.”

More than that, though, the thought of having unhappy customers just rankles the affable Schirmer to no end. When he tells you he just flat out refuses to gamble on even the slightest possibility that one of his radiators will fail and sully his relationship with a car owner, you believe him. “I don’t want to go to a show and get ambushed, I’ll tell you that,” he says. “If I’m at a show and have five guys around, and one guy comes in and says, ‘That radiator doesn’t cool worth crap!’ those five guys scatter like ants! I just can’t ever have that happen.

Hemi radiators are small potatos compared to some of the pieces the company takes on. This radiator came out of an International semi tractor.

“There are a lot of good radiator shops out there that do really good work …. I’m not knocking anybody else — not at all — we just do it differently. We make sure our header joints are soldered good. Our tank joints our soldered good … We’re anal about making sure we tin these things up really good. Because when the guy is out there in his collector car, and he’s out in the middle of nowhere and his coolant is leaking — that’s not a good call to get on Monday!

“The cores we use cost me more than $300 now, just for the core. I can get cheaper ones, but why do that and risk getting one that doesn’t cool? We engineer the core so you can be anywhere in the country and your car will not run hot. I’ve got some in Australia where it’s always hot, and they never run them hot… I had one guy, I made him a radiator. He had been taking his car to Hot August Nights and his car was overheating so he had to drive with his heater on, and his wife was NOT happy. I told him I’d make him a radiator that would never overheat, and I know that it won’t!”

Schirmer and his sidekick Lenny aren’t the only ones working on radiators at Glen-ray, however. The company has 10 employees and a stream of regular drive-in customers who need radiator and air-conditioning work on their daily drivers. The shop also does a lot of work on semi-tractors, farm tractors and heavy equipment radiators.

Oh, and you’ll still find Ray Sr. in the back working on any old or unusual pieces that come through the door. “Dad can do it with one eye closed, he’s been doing this for so long,” Bob laughed. “If Dad can’t fix it, it’s junk. Flat out. Raymond’s got a pretty good touch. Lenny’s got a pretty good touch, but Dad works on anything older than about 1960, because he knows more about the older stuff than I do.

“For me, typically it’s the ’69 to ’71 cars, the big blocks, that I work on. But we’ll do anything from a little snowmobile radiator up to a D11 Caterpillar. We’ve done old Mercedes, old MG’s … Pretty much, if it’s got a radiator, we’ll get it in the door.”

For now, Schirmer is content to keep the MoPar big-block radiator end of the business a two-man operation and let it grow slowly over time. The company’s new website, www.hemiradiators.com, has already helped the shop become more visible around the U.S. and abroad, and Schirmer plans to continue to make appearances at big gatherings such as Carlisle where large numbers of Hemi car owners might congregate. If things go well, he hopes to add 22-inch radiators to the product mix in the future.

“We only do 26 inches, we don’t do 22-inch ones,” he said. “We were getting into 22-inch ones in 2008 when the economy tanked, but I have the tool and dye stuff ready for it.”