The development of agriculture on Kangaroo Island involved a number of evolutions, especially machinery. The land needed to be cleared and then the process of understanding the limitations of the soil and livestock management took time and extensive trial and error.

An article written by J.N. Wood in 1961 at the 50th Anniversary of the MacGillivray Branch of the Agricultural Bureau reflected on the early years in MacGillivray. This is a section from the article.

One has to admire the early pioneers and their wives, who opened up the country and improved the conditions for those who followed them. Most of the land was not very fertile, and trace elements and subterranean clover were unknown. Roads were little better than bush tracks and no one had motorcars, radios or even telephones. Tractors were not used in those days and scrub was rolled down using bullocks. There was plenty of hard slogging work and very little in the way of labour saving machinery. Those were some of the local conditions when a few progressive settlers got together and formed a branch of the Agricultural Bureau. The first meeting was held on September 5th, 1911, in the MacGillivray Hall. At the first meeting Mr R. Wheaton was elected chairman and right up until the early 1960s maintained a constant interest in the bureau.

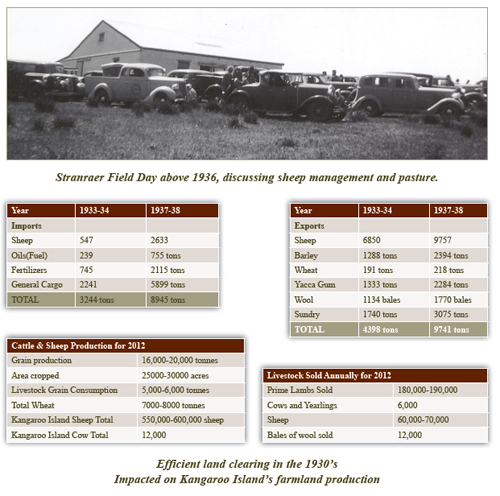

The first homestead meeting was held at Stranraer on November 6th, 1911. After reading the general business the members were shown over the property comparing different crops and the treatment they had received. Mrs Wheaton provided afternoon tea for the members, their wives and children. These homestead meeting occurred across MacGillivray and was a way to look at different farming techniques and to share knowledge and experiences, and were a forerunner to the annual tour of inspection of the farms in the whole district. The MacGillivray Branch also had members represent Kangaroo Island in Adelaide. Bureau groups were formed all over Kangaroo Island and the groups would meet once a year in Kingscote to share ideas of how to improve their farming practices.

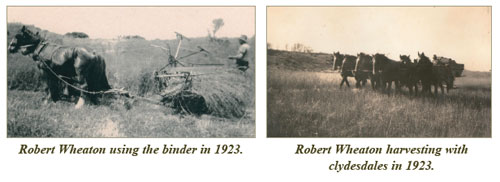

The Clydesdales were put to work on Stranraer in the 1920s and the 1930s. The horse shed, which has been filled with diesel tractors since, was the home of 30 Clydesdale horses that were in full time work. The manger ran the full length of the shed for feeding. The working day began at 5.00 am with the feeding of horses and the setting up of implements. The Clydesdales certainly worked the property hard in the early days, the feeding and maintenance of the horses was a full time job with the management of the hay and the chaff cutting operation.

A paddock known as the long paddock in the early days took over a week to cultivate with Clydesdale horses, which was 115 acres. Then, after the initial cultivation of the land, the seeding process was required. Ploughing and cultivation required 6-8 horses, while seeding required only 5 as the soil was prepared and it was easier for machinery to enter the cultivated soil, thus requiring less horse power. Harvesting crops required 6-7 Clydesdales in the team.

The conservation of hay and then the process of turning that hay into chaff required planning and hard work. Having the team of Clydesdales in peak condition was vital for the farm and its viability.

Not only were the working horses important to Stranraer, having horses to travel to Kingscote for services and supplies was equally as important. The horse and dray was used extensively. The workshop/machinery shed also operated as a blacksmith’s shop, where the anvil still exists today, for producing horseshoes and repairing farming implements. The blacksmith operated with the use of heated coals to assist in the shaping of steel, especially horseshoes. The coals were aerated via a fan to increase the flow of oxygen that increased the temperature of the coals for the process of heating the steel. The metal was then shaped using the anvil and hammers.

The soldier settlement scheme was established in the 1920s on Kangaroo Island. After World War 1, efforts were made to establish returning soldiers in some form of employment, they having sacrificed those valuable years of their lives. Most, if not all, being employed, were guaranteed their employment on their return and in many cases, the difference between their civilian and army pay was made up by their employer. This policy, while laudable, did not cover every man, especially those who wanted to make their own way independently. Efforts were made therefore, to make land available, some in fruit and some in grain growing areas. The results were somewhat less than good because of a lack of capital and indifferent seasons and prices for their products.

At the conclusion of World War 2 the issue of finding employment for the returning ex-serviceman arose. The faults of the earlier scheme were examined and efforts made to avoid a repetition. Due to the numbers of ex-serviceman involved there were only 2 areas where such a scheme could work. These areas were the southeast of South Australia and Kangaroo Island. On August 16th, 1943, Councillor’s sent a letter to the Premier and the Crown Land office suggesting that Kangaroo Island be included in any plan for land development. In 1952 the first soldiers were placed onto blocks of land on Kangaroo Island.

The reasons were twofold. Kangaroo Island had always suffered from a lack of population and with the rising costs, Kangaroo Island was seen to be uneconomic, unless production could be increased. Therefore, the scheme was seen as assisting the returning serviceman and while developing land on Kangaroo Island. This scheme involved extensive work and research to find methods of turning the land on Kangaroo Island into land that was financially economical. Most of this work was focused on fertilisers and trace elements. The CSIRO and the Waite Institute set up an experimental farm on Kangaroo Island and were heavily involved in the early days. This process of land development began in 1936. The initial findings of this research would show that the use of trace elements such as copper, zinc and molybdenum resulted in increased amount of seed set as well as improved growth of pasture resulting in healthier sheep. Dressings of copper sulphate were also applied to various properties with dramatic results in the control of numerous livestock diseases and improvements in wool quality due to the quality of pasture growth. The use of subterranean clover and grasses along with fertilisers became the basis of the research. These systems still exist today.

In 1946, the first bulldozer was brought to the island and following this, the council then purchased their own to begin road construction on the western end of Kangaroo Island which enabled further development of the land as part of the Soldier Settlement Scheme.

The growth of the Soldier Settlement Scheme meant an influx of people, from all places and numerous walks of life, not all of them skilled farmers. Within a few months, Parndana, (as the new settlement was named, meaning ‘A place of trees’), was fielding football and cricket teams. Church services began and a teacher moved into the area. An active progress association was soon operative, aiming to develop further plans for land development. The contribution that the soldier settlement had made to Kangaroo Island was significant. Not only did they occupy areas of formerly unproductive land, but they farmed it well, and by the increase in total production from Kangaroo Island, services such as medical, shops and transport also increased.

The scheme, by 1957, had spent large amounts of money on clearing, seeding and general processing of 192,000 acres. This represented 134 farms in total, averaging 1430 acres. 174 soldiers were part of the soldier settlement scheme on Kangaroo Island, primarily in the Parndana region, where a memorial exists today.

With agriculture a main source of income with wool, barley fruit and vegetables, land clearance was gaining momentum. In the early 1900s harvesting and distilling eucalyptus oil from the native narrow-leaf was permitted on roadsides, subject to payment to the council of a modest fee.

Management of roadside vegetation was always a focus of the council in the early years as it is today. Most roads on Kangaroo Island are in line with the Kangaroo Island mallee tree species. With the removal of the distilling operations along roadsides, council was then left with the management of the roadside vegetation. The management of roadside vegetation was done with a bulldozer on roads that were 3 chains wide.

What is a chain? It is a measurement of 23.2 metres.

Most roads on Kangaroo Island in the early years were 3 chains wide, some were only 1 chain wide, which made it difficult for large machinery to travel on. The three chain road in the MacGillivray-Haines area is named due to this measurement.

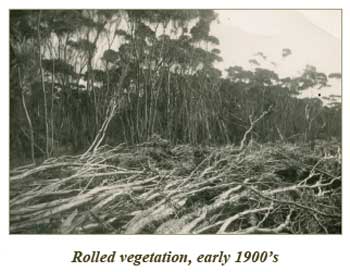

The type of vegetation that existed prior to the commencement of agriculture on Kangaroo Island

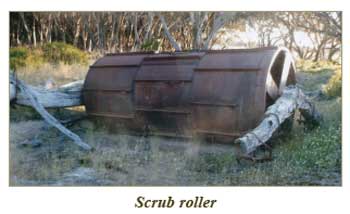

Scrub roller used in the rolling of vegetation to allow for the clearing process and then the commencement of agriculture. The scrub behind the roller was left, requested by Mary, to show the type of vegetation that existed prior to agricultural development at Stranraer. This roller is still on the property today. It is a very heavy piece of machinery requiring a lot of horsepower to move over timbered country.

Bullocks were used to tow heavy scrub rollers in the early 1900s.

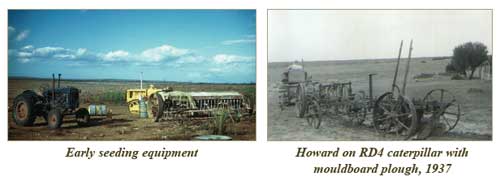

Robert travelled to England in 1936 with Mary for a holiday. Back then there were no flights and the plan was to be away for 12 months as the trip was via water. Robert said to his sons, “If the season turns out ok, I think we need to purchase a tractor.” Robert was not long into his trip when the news came through from his sons that they had purchased a D2 caterpillar. I am not sure if the season had much to do with this purchase, efficiency prevailed.

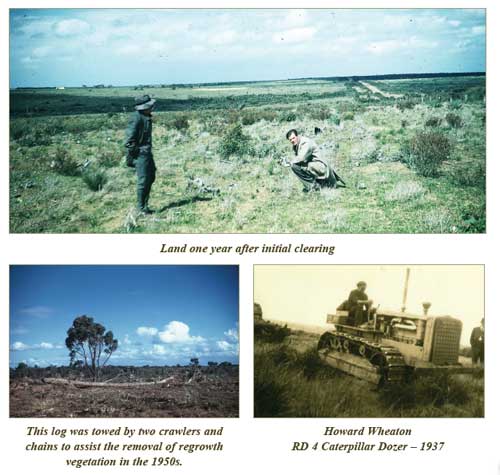

The RD 4 caterpillar mobilised farming after the use of the Clydesdale horse. Behind the crawler is the scrub roller which was used to prepare land for agricultural production.

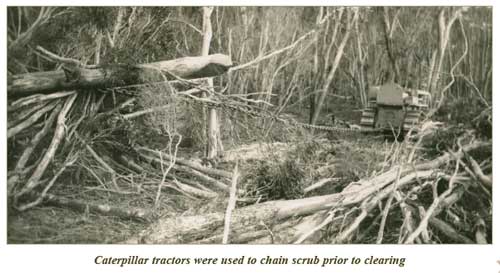

In 1937 the RD4 caterpillar arrived at the property. The arrival of this machinery certainly had an impact on land clearing. Vegetation removal involved rolling the scrub, followed by burning, then ploughing, before it was ploughed again. These paddocks were then seeded with oats and clover. Howard was involved in this process prior to his departure for Tobruk.

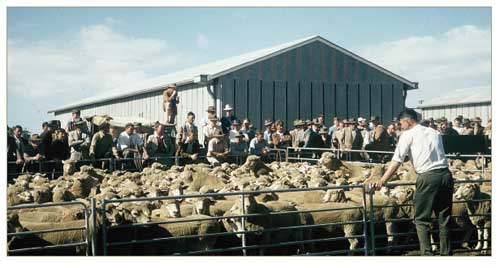

The Parndana Research station provided valuable work in the early 1950s to growers assisting in trials and valuable research and a learning environment. The focus of the research was pastures, fertilisers and stock health, especially sheep.

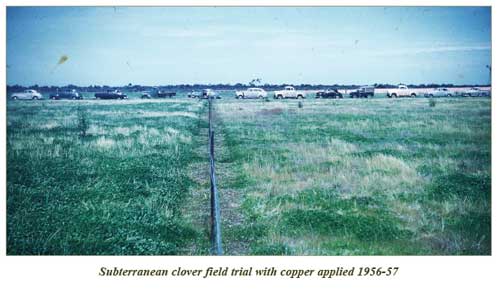

Trial work was focussed on trace elements and their ability to improve pasture performance and ultimately farmer returns.

Copper research in the early 1950s highlighted the deficiencies within the soil profile and how including this in the fertiliser and stock management increased stock performance and the overall profitability of sheep producing properties. Coastal Disease which impacted greatly on the Taylor’s in the late 1800s with their sheep was a result of limited trace elements, including copper.

The trial work assessing the impact of trace elements especially copper on pasture growth impacted on productivity for island farmers. The results were recorded and evaluated from a financial return in regards to wool cut and quality. The other trace element tested in this particular trial was molybdenum which has also been included in soil management programs on Kangaroo Island.

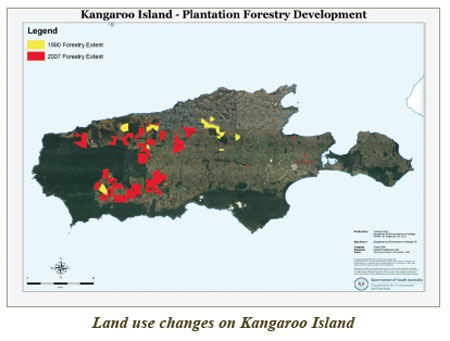

Land use changes have occurred over the generations. Sheep and cattle grazing was the initial focus and still is today however, in the early 2000s blue gum forestry consumed a percentage of land on the western end of the island. This reduced the grazing area substantially, resulting in fewer sheep and cattle. The dark areas of this map represent the national park areas of Kangaroo Island.

The yellow area versus the red area shows the increase over a twenty year period of blue gum plantations. These plantations have allowed feral pigs and deer, along with other pests such as wild cats and goats, to breed in significant numbers. The blue gum plantations exist mainly on the western end of the island due to the higher rainfall. Pine plantations exist on the northern part of Kangaroo Island and this timber is milled and used in the building industry.

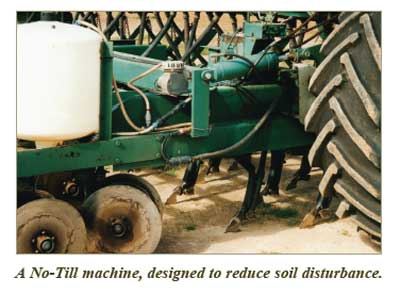

From the clydesdale to the crawler tractor to the use of minimum tillage machinery, the evolution has brought efficiency and scale to Australian agriculture. In more recent times the advancement in the technique, machinery and areas such as variety and technology has been rapid and, as a result, farms have become bigger, more efficient and more productive. The use of GPS technology allows tramline farming with our cropping systems resulting in the efficient use of chemicals and fertilisers. The progression of machinery has been very pronounced over the generations. My father has seen the most changes with the use of clydesdale horses, then the crawler tractor and now, high powered tractors with in-built technology to the point where most operations can be completed from the cabin. Technology advancement has occurred with hay making, seeding, and fertilising machinery.

The sheaves were then collected and sent to the storage shed and put through the chaff house, where the grain was threshed.

Six clydesdales were used to tow the original Sunshine harvester in the 1920s.

Machinery over the generations has gone through major changes. The caterpillar crawler was used to harvest with the Sunshine harvester behind and the grain was placed into 60-70kg bags. Occupational Health and Safety would have an issue with this today. There would be a driver and someone to bag off the grain as the crop was fed into the cutting knives on the front of the harvester.

Once land was cleared the process of managing regrowth of the Kangaroo Island narrow leaf was required for the subsequent years. The land was then seeded with combines like the one below with the use of the caterpillar tractor. Seed and fertiliser used through the box on the combine. Extensive handling of bags and seed is required for this process. Most grain and fertiliser handling nowadays is via petrol operated augers with hydraulic lifts making the process more efficient.

The mouldboard plough was used after the initial rain to turn the soil prior to seeding. As seen in this picture the machine is not very wide and this process of ploughing land took some time however, this was the most efficient process in the late 1930s.

The introduction of the Sunshine harvester was a revolution in its time and in a way changed the method of harvesting grain forever.

This method of harvesting was very time consuming, compared to the methods of today. The efficiency with which grain is harvested today and the method of getting the grain to ports for both domestic and also international trade is profound.

The Sunshine harvester was produced by H.V. McKay in Victoria in the 1920s. At the age of 18 Hugh Victor McKay developed the Sunshine harvester to create more efficiency in agriculture. HV McKay also invented the mouldboard plough which was used extensively at Stranraer for cultivation prior to crop production. This machinery technology improved productivity for agriculture on Kangaroo Island and around Australia and revolutionised farming.

The Sunshine harvester operated through the 1930s, 1940s and the 1950s before the Massey Fergusson 585 harvester was introduced. The Massey 585 header was a ground-breaking piece of machinery for its time; it brought greater efficiency into harvesting crops in Australia. Our Massey 585 is parked up and home to a few possums near the hummocks, however it reminds us of the many hectares that were harvested with this machine.

The use of two sunshine headers certainly made the process of harvesting quicker with the use of the international tractor.

There are many Sunshine harvesters parked up on farms, all of which can tell a story of a bygone era.

The grain was harvested into the main hopper on the Sunshine harvester. Once the harvester was full of grain it would stop and be bagged off with a side chute. The harvester once unloaded would continue until full again. In most cases there were 2 bagging points in the paddocks to allow the unloading of the grain into the bags. By having two stations this would allow for centralised pick up of the bags. A truck would pull up to the bagging areas and elevate the bags onto the truck via a chain operated elevator.

The Sunshine harvester had a record of bagging off 400 bags of grain in one day. These bags weighed 190 pounds. That equates to an 85kg bag of grain. Now that is hard work!

34 tonnes of grain moved in one day, in 85kg bags. As can be seen in the picture above, the Sunshine harvester had steel wheels which made it a heavy machine to pull.

The Massey Fergusson harvester operated in a similar way. The most grain harvested in one day was 600 bags.

Harvesting machinery in the 21st century provides farmers with the ability to cover larger areas more efficiently.

Harvesters have become self-propelled as opposed to the powered take off, shaft driven headers such as the Massey Fergusson 585.

Machinery for seeding in the modern era as seen above is concentrated on minimal soil disturbance and maximum seed and soil contact. This reduces the impact of soil compaction and allows for more even consistent germination of the crop.

The progression of machinery over the past 100 years has been very dramatic. Tractors were fitted with cabins in the 1970s and 80s for safety. The management of grain has also advanced with the design of the chaser bin which can follow the header in the paddock and allows the grain to be loaded from the header to the chaser bin whilst the header is still harvesting. Now that is time management!