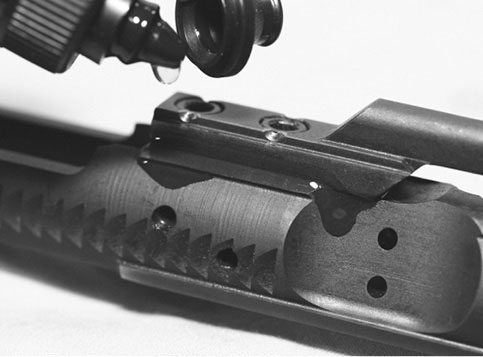

Here is a lower that has been degreased. The anodizing keeps it a gray-black. Adding a drop of oil and then wiping it as much as possible creates the “dry lube” effect.

Here is a lower that has been degreased. The anodizing keeps it a gray-black. Adding a drop of oil and then wiping it as much as possible creates the “dry lube” effect.

If you open any firearms magazine, you will be pummeled by the attributes of the latest wonder lube. It solves all problems, keeps your rifle running and smells as fresh as a spring day.

No, it doesn’t. No lube does.

In a nutshell, they do three things: reduce friction, create a film that seals the surface against oxidation, and keep powder residue, dirt and grit loose, so they can’t wedge moving parts in place.

That’s it. Anything else is a bonus, or superfluous, or non-existent.

When people ask me what lubricant I use, the only truthful answer is, “Whatever I have handy, whatever I got for free.” I really don’t care which. What I do care is where and how much.

Lubrication comes in four levels: dry lubed (not to be confused with dry lube), wiped damp, gleaming and wet. No one level is appropriate for all parts of your rifle. Each has its own needs, its own requirements, and you have to treat them as they need to be treated.

For an example of dry lube lubrication, take your upper receiver (just because it is handy) and degrease it. You started with a black upper, and now you have a charcoal gray upper. Spray the upper with a lubricant (not WD40, please) and wipe it with your bare hands until the surface is evenly coated. Now, take a shop cloth and wipe the surface until all the excess lube has been wiped up and the surface is evenly coated. It will still be black, but it will no longer be dry. In this instance, the oil is trapped in the interstices of the anodizing on the surface of the aluminum. The anodizing creates a sponge-like layer, only a couple of thousandths of an inch or so thick, and when you degreased you stripped that out. Now that you’ve oiled, it is back, but you have wiped the excess off the surface, while leaving the oil in the “sponge” layer.

Steel parts that have been black oxided or parkerized present much the same situation. Surfaces that are oiled and then wiped with the stereotypical “oily cloth” are dry lube surfaces. The lubrication serves mostly as a bar to oxidation, while providing a small amount of friction reduction.

Wiped damp is a similar situation, except when you wipe the receiver, you do not use the oily cloth. You only use your hands, and you only wipe as much off as you can with your bare hands. The surface is visibly oiled, but it does not drip oil if left upright.

Here, you wipe with your hands, but you do not try to squeegee off the excess oil. The surface is visibly oiled, and may even drip if left unattended for some time, or left in the heat or direct sun.

A wet-lubed surface has a visible layer of lubricant on it. If you, for example, take a bottle of oil and run a bead of lube down the side of the receiver, the bead is the wet lube.

This is a couple of drops of oil, soon to be wiped to the wiped-damp or gleaming stage.

The oil drops wiped to make it gleam.

This is wet. When the lube can run off, it is past damp,

it is wet.

You’ll need a bit more than this to cover the whole side of the carrier and make it wiped damp or gleam.

The barrel, flash hider, buffer tube on a tele-stock carbine, iron sight housings, free-float forearm if aluminum – these all get the dry lube treatment. The receivers, upper and lower, inside and out, get the dry lube treatment. You need to simply bar oxidation from their surfaces. If you over-oil the barrel, for example, then when you heat it up in a shooting string, you will evaporate and oxidize the oil on the surface, and you’ll have a smoking barrel even before it is smoking hot. Now, this is subject to adjustment. In the desert, say living in Arizona or New Mexico, you may not even need to put this much oil on the barrel. And you may want to keep the exterior of the buffer tube dry so as to not attract dust, dirt and grit. On the other hand, if you live in the bayou, you may need to apply a heavier amount of oil to the barrel to control rust, and then just live with the hot barrel smoking.

This is what the buffer weight, the buffer spring and the carrier need, with an extra step on the carrier in a moment. The buffer and spring need a small amount of lube, as they rub back and forth inside the tube. The body of the carrier needs only enough lube to keep carbon from adhering to it. However, the guide rails, the raised portions of the carrier need to be lubed wet.

To make a part gleam, you need a drop of oil applied directly to it. The drops go into the plunger that keeps the front sight locked in place, but not the front sight itself. It should be dry lube. The rear sight windage screw threads get a drop. The rear sight gets a drop at the edge of the adjustment plate (A1) or drum (A2) and the A2 also gets a drop on the threads of the elevation adjustment wheel. The plunger for the buffer retainer gets a drop. The plunger for the takedown pins, front and back, get a drop. The bolt hold open pivot gets a drop. The takedown pin tunnels on the upper get a drop each.

The hammer pivot and spring loops each get a drop, as do the trigger spring loops and their pivot pin. The disconnector gets a drop at its spring. The safety/selector gets a drop on each end, where it goes into the inside wall of the lower receiver.

What gets wet? Simple: the bolt and cam pin. The bolt, at the rotation band, and once assembled in the carrier, at the bolt/carrier junction. Hose the extractor and ejector and the locking lugs. Get oil into the cam pin slot, and put a drop into each of the gas vent holes on the side of the carrier.

Now, you can over-do this. If your first shot produces a splatter of oil that looks like a drilling rig spill on the side of your shooting bench, you’ve over-oiled it. This can be a particular problem for left-handed shooters, as the oil splatters out directly at them.

Before we dive into the “should I or shouldn’t I” discussion, let’s take a look at a few places that have not been mentioned. One, the gas tube and gas key. You can lube the outside of the key to control carbon and make it easier to clean off, if you want to. You not only do not need to lube the gas tube, you don’t want to. It is a direct recipient of hot gases and will self-clean. Adding lube just provides more carbon-containing product to be scorched and dried and then blown out when the pressure gets high enough.

The bore has not been lubed. There is no need, unless you have a barrel that is not stainless or not hard-chrome lined. A carbon steel barrel, in some climates, needs to be swabbed with oil to protect the surface. But outside of that limited requirement, no lube in the bore or chamber.

Some of you reading this are becoming increasingly skeptical because your local gun show expert, the guy who “knows a guy who knows a SEAL,” says to not lube your AR. Run it dry.

He is wrong. In some very limited circumstances, as in Arctic conditions, dry air and tens of degrees below zero, lube is a bad idea. It will freeze, unless it is specially formulated. He’ll tell you of his buddy-of-a-buddy and the experience of being in Iraq/Afghanistan/that special op in Iran, and the dust-clogged rifles that had been lubed.

Lube flushes away grit. Lube holds grit in suspension, so it can’t build up and lock into an immovable mass. “But, the grit and carbon stays in the oil, and acts as a grinding compound.” Ahem. Grinding compound is a specially-formulated mixture of super-hard grit and grease. Not oil, grease. The grease stiffens the mix, and keeps the grit pressed against the surface to be ground. Lube does not stiffen, and the grit in it then floats, not grinding the surface it is next to at the moment.

I have a few firm opinions on this. One is that you should not be using WD40. WD40 is the fourtieth mixture, or formula, developed to be a water-displacing oil. It is meant to get water away and keep it away. However, the more volatile constituents of the mixture will evaporate, leaving a surprisingly lacquer-like film behind. When I was a full-time gunsmith, I’d regularly see rifles and shotguns brought in, with their various smaller parts glued together by age and heat-hardened WD40.

One common lubricant is CLP. The military bought it by the trainload because they could use it to both clean and lubricate. It does both reasonably well in the original formula that the military bought, but if you want to clean, clean. If you want to lube, lube. Don’t expect one thing to do both. If it is what you have, use it. But don’t expect anything magical to happen just because your bottle is mil-surplus and holds CLP.

Various motor oils, both distilled petroleum and synthetic, can be used as lubricants. Your engine goes a minimum of three thousand miles between oil changes, if you go by the most aggressive schedule. That can easily be ten million cycles of the engine. Ten million, and your shooting buddies scoff that motor oil isn’t “good enough” to be used as a firearm lube?

It is August, in the Midwest and in farm country. Hot, dry, under a blazing sky, and you’re in the fifth day of a high-volume class. If you don’t use lubricant, you won’t make it this far, your rifle will have quit on Tuesday afternoon.

Sometimes we get just a bit silly. Here, we’re gooping up an AR with spray-on margarine as a lubricant as a test.

The bolt and carrier should be wet with lubricant, in this case, margarine.

Everything gets sprayed with margarine.

After a magazine of ammo, your rifle smells like a bucket of popcorn. Mmmm.

The big problem with motor oil is that you can’t buy less than a quart, which is a decades worth of lubrication for most owners of an AR.

In the realm of the “let’s get strange,” I’ve been involved in testing where we have used sunscreen as a firearms lubricant and managed to go a whole day without a malfunction. Then there was the episode where one of the guys used margarine in his AR. What you use isn’t nearly as important as using it properly, in the right place, and in enough volume.

Now that doesn’t mean that there aren’t really good lubes out there. I know some of the inventors, and they are earnest in their attempts to make something that is better than what exists. It’s just that none of them are perfect.

Get some, use it, and clean when you are done.