CHAPTER ONE

Beginnings

This is a story of great adventures, of men in sola topees hacking their way through the jungles of uncharted lands. It is a tale of epic proportions, of armies of men travelling half-way round the world to shovel foreign soil into English wheelbarrows. It is also a story of high finance, of millions being raised in London for such exotic sounding enterprises as the Ferrocarril al Oeste or the Bombay, Baroda and Central Indian Railway. The crest of the latter hangs by my desk showing four Indian porters staggering up a stony path under the weight of an ornate palanquin, while a resplendent train puffs its way over a viaduct behind them, the driver leaning nonchalantly out of his cab window. Somehow it seems to sum up much of what one thinks of as the great railway empire: the old giving way to the new, the splendours of British manufacture looking down, literally and metaphorically, on the crudities of an older world. But how did all this come about? It is not difficult to imagine why British India should turn to the British engineer for help, but why should the French, the Russians, the Argentinians and the Japanese have turned in the same direction for manpower, machines and money to build their railways? It is too easy to say ‘because Britain was first’, too easy and not altogether true.

The story begins in Germany. Georg Bauer was a mining engineer who spent his life recording the best mining techniques of the age. In 1556, a year after his death, his work appeared in print, in suitably classical guise, as Agricola’s De Re Metallica. It features superb woodcuts illustrating the machinery of the mines, among which scurry the miners themselves. If they seem mildly comical today, that is because they have comical associations. Walt Disney used these drawings as the basis for the costumes of the Seven Dwarfs: the first known illustration of a railway shows a truck being handled by a close relation of Happy, Sleepy and Dopey. The system Bauer showed is not strictly speaking a railway, as the wheels run on planks and the trucks are kept in place by a pin running in a groove on the track, but the elements of a railway were certainly there, half a century before there is a record of anything of the sort appearing in Britain. When that happened, however, the system was so evidently superior to the earlier model that it became generally accepted in the mining community, and even the Germans knew it as the ‘Englischer Kohlenweg’.

The earliest records of this type of railway system date from the early 1600s. Huntingdon Beaumont was both colliery owner and engineer. Some time in 1603 he laid down approximately two miles of track from the pithead of his colliery at Wollaton near Nottingham. The track was still wooden, but now there was no plank and groove; this track consisted of rails on which trucks ran with double-flanged wheels, looking very similar to ordinary pulley-wheels. There were other routes in Shropshire, but the most popular area for the new ‘wagon-ways’, as they soon became known, were the coalfields of the north-east of England. By the middle of the eighteenth century, the system was already sufficiently interesting to foreign engineers for them to wish to inspect it. Among these was a Frenchman, Monsieur Jars, who came over in 1765 and wrote a description of what he saw, entitled Voyages Metallurgiques. The ‘nouvelles routes’ ran from pits near to the river bank, where the trucks could be unloaded into waiting ships that took the coal round the coast. The trucks were arranged on a gradual, steady descent so that gravity did most of the work, and they could be hauled back by horses. The system had squared-off rails, 6 or 7 inches broad by 4 or 5 inches thick, carried on parallel rows of oak sleepers, 4 to 8 inches square. The rails were held together by wooden pins, and the joints were protected by iron strips. By the time of Jars’ visit, there was already a movement towards replacing the old wooden wagon wheels by cast-iron. The wagons were fitted with a hinged bottom, which would be knocked open at the riverside staithes, allowing the whole load to be deposited into a chute. It was also not unknown for the flap to be jolted open in transit, dumping the coal on to the track resulting in what locals called a ‘cold cake’.

Where it all began: the first “railways” were used in mines in Germany. The trucks ran on a plain wooden track, with a groove down the middle. A pin on the truck engaged with the groove keeping the truck on course. This illustration comes from Agricola’s De Re Metallica of 1557.

By the end of the eighteenth century the simple wagon-ways were becoming increasingly sophisticated. The improvement in iron making that began with the Darbys of Coalbrookdale made it possible to improve the track by laying a metal strip over the wood and eventually to replace the wood altogether by metal. Again many of the early experiments came in the colliery districts. In 1776 the mining engineer John Curr introduced the metal plateway to the underground workings. The rails, or plates, had an L-shaped cross-section, which held the wagon to the track. Previously, coal had been moved from the face in baskets, manhandled, or rather child-handled since most of the work went to boys and girls, along the low, narrow galleries. The plateway represented such an immense improvement, and saved so much grindingly hard labour that Curr found himself celebrated in verse – with a suitably Geordie accent.

God bless the man wi’ peace and plenty

That first invented metal plates,

Draw out his years to five times twenty,

Then slide him through the heavenly gates.

For if the human frame to spare

Frae toil an’ pain ayont conceevin’

Hae aught te de wi’ gettin’ there,

Aw think he mun gan’ strite to heaven.

The simple plateway soon became part of a complex web of railways, requiring ever more elaborate engineering works. As early as the 1720s one of these lines, the Tanfield tramway in County Durham, had to be taken across the Houghwell Burn, where it carves its way through a deep, wooded valley. The job of bridging the gap went to a local mason, Ralph Wood, who designed a bridge as a single, graceful span of 103 feet. And there it stands today, the world’s oldest surviving railway bridge. Although the plateway or tramway system was developing rapidly, the greatest changes in the field of transport came with the spread of canals from 1760 onwards. A horse pulling a boat or a barge could shift far more cargo than a horse hauling wagons on even the best made tramway. Locks conquered the problem of hills; valleys were crossed on high embankments and soaring aqueducts; hills pierced by cuttings and tunnels. The engineering skills that were to be vital in the railway age of the nineteenth century were being learned in the canal age of the eighteenth. But there were places where even the most ambitious canal engineer could never take a waterway. The valleys of South Wales, for example, run largely parallel to each other in a north-south direction, separated by high spines of hills. East-west connections brought engineers such as Benjamin Outram to construct tramways to link industry to canal and one canal to another.

The surprise is, in some ways, that so many of these advances were occurring in Britain. An unbiased observer casting his eye over Europe at the beginning of the eighteenth century would probably have elected the French for the role of great engineering innovators. The British marvelled at the privately financed Bridgewater Canal in 1760 with its aqueduct over the River Irwell, yet a century earlier, in the 1660s, the French had already built the Languedoc Canal, 150 miles long with 100 locks, a tunnel and three major aqueducts. British engineers had, in effect, been reinventing the wheel. The work on the canal was organized with great professionalism by Pierre-Paul Riquet, and at one time 8000 men were employed in the works. Voltaire went to view the Louvre and Versailles, but he said, ‘le monument le plus glorieux par son utilité, par sa grandeur, et par ses difficultés, fut ce canal de Languedoc qui joint les deux mers’

The French worked in a systematic and orderly way and were soon to become the first European country to put the profession of engineering on to an official footing. The Corps des Ponts et Chaussées was formed in 1716 to supervise public works. Just as importantly, the French, unlike the pragmatic British, established an engineering school to train the next generation of builders. So important were the Ecole and the Corps that British engineers who wanted to remain up to date in their field and, just as importantly, wanted to grasp the theoretic basis of their subject, had no option but to learn French. France it seemed was leading the world in engineering and science. Yet by the 1830s when two Hungarian noblemen wanted to find the best way of building a bridge across the Danube in order to unite the cities of Buda and Pest, they had no doubt that the thing to do was to go to England, ‘there consulting with men of experience and skill’, because ‘far more has been done there worth going to see, than is to be met with on the whole continent of Europe’. What had happened in the century between? The short answer is the French Revolution. While the French were preoccupied with overturning the social order which had given birth to the strict formalism of the Ponts et Chaussées, the British had been transforming the old economic order of their country in the Industrial Revolution.

The British invented little that was new in terms of the civil engineering of railways; they did, however, rapidly come to lead the world in the development of the invention that was to combine with the railway to create a whole new transport system: the steam engine. Once again the early experimental work occurred in continental Europe, while the British led the way in finding practical applications of steam power. It all began with the discovery that the atmosphere exerted pressure, first demonstrated by Evangelista Torricelli, a pupil of Galileo in 1643, and it was soon realized that if a vacuum could be created on one side of a piston, air pressure would work on the other side to drive it into the piston. The Dutchman Christiaan Huygens produced his vacuum by the alarming device of exploding gunpowder, but it was his assistant Denis Papin who first suggested the more sensible solution of condensing steam. His little demonstration engine was a curiosity – the only practical device he came up with was the pressure cooker. It was left principally to Thomas Newcomen to use the same idea to produce a practical engine for pumping water from mines. His steam engine was soon nodding its ponderous head over mines all over Britain. This was the beam engine, where pump rods at one end of a beam dropped under their own weight, to be hauled up again by the piston attached to the other. It was a cumbersome process with steam in the cylinder being sprayed with cold water to condense it, after which air pressure worked on the open top cylinder. It was hugely expensive in terms of fuel, which was no great problem in the middle of a coal field, but which made it ruinously expensive in the coal starved areas of the metal mining regions.

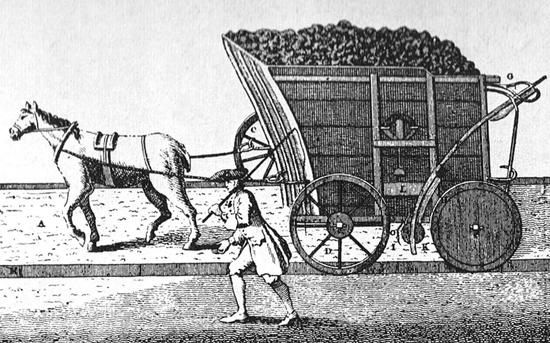

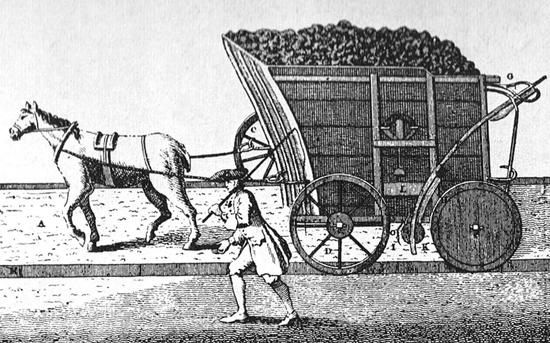

A more sophisticated version of the tracks shown in Agricola developed in the late 16th and early 17th century, also in the mining industry, but this time using a railed track, at first with wooden and later with cast iron rails. As mine trucks in north east England were known as trams, the systems became known as tramways The illustration shows a typical horse drawn tram: it was on such tracks hat the first railway locomotive was to run.

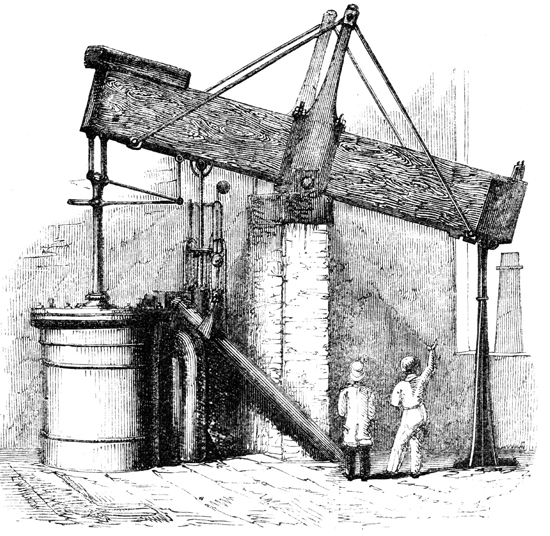

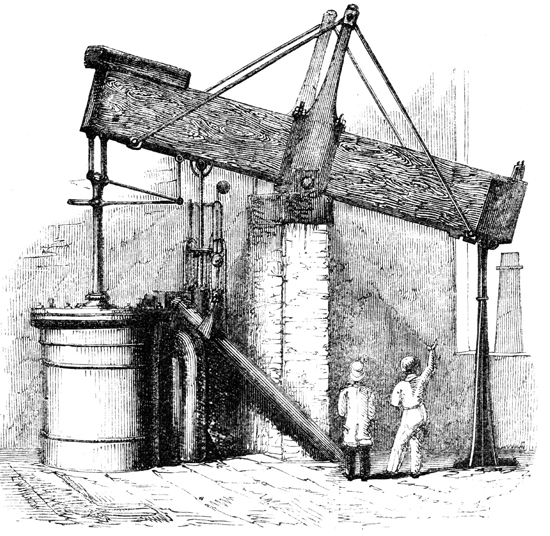

The development of steam engines, such as this early Boulton & Watt, paved the way for the development of the locomotive.

A solution was found by James Watt, who realized that the steam could be condensed in a separate condenser outside the cylinder. This meant it was no longer necessary to alternately heat and cool the main cylinder. It also meant that he could use the steam on either side of the piston. The atmospheric pressure engine had become a steam engine proper, but was still using the notion of condensing the steam rather than using the pressure of the steam itself. But James Watt firmly believed that high-pressure steam was a dangerous monster – he would have none of it. And since he had acquired a patent that virtually excluded everyone else from making any kind of steam engine whatsoever, he ensured that the monster was kept caged until the patent expired in 1800. The Watt engine, however, was already a versatile machine, and the closed cylinder meant that the piston could be made to work in two directions, not just in one as in the Newcomen engine. It was not much of an imaginative leap to see that if you attached a crank you could turn a wheel: you could use it to work machinery in a factory, to turn the paddle wheels of a boat on water or even to turn the wheels of a vehicle on land.

The first vehicle to be moved over land by steam power was demonstrated in Paris in 1769 by its inventor Nicholas Cugnot. It was an extraordinary looking object with three wheels and a huge boiler that hung over the solitary front wheel. It was a masterpiece of instability as it proved after a few tottering metres of movement when it tumbled over amidst much hissing of steam and showering of sparks. Monsieur Cugnot was not encouraged to continue with his experiment. James Watt himself contemplated a steam carriage, but his nervousness about the dangers of high-pressure steam prevented him from holding any trials. His bolder employee, William Murdock, was less reluctant and his model bowled cheerily down an English lane in 1784. The only acknowledgement he received was a prompt warning that any more tampering with such devices would see him out of a job. Matters had reached an impasse, but if the road engine was temporarily stymied, steam was beginning to find its place on the infant railway system of Britain.

The tramways serving the canals often included quite steep inclines on which the descent was controlled by a brake-man, in theory at least. The Duke of Rutland visited South Wales in the first decade of the nineteenth century and described the system he found at work on the tramway linking the Brecon and Abergavenny Canal to a local iron works.

This rail-road is adapted to the size of the waggons, or carts, which convey the coal to the canal. On each side is an iron groove, which extends the whole length of the road, and on which the wheels (four or six in number) run. They are so contrived as to run downwards the whole way (sometimes for the extent of some miles) from the works; so that when laden, they require no horses to draw them down. Indeed they acquire so great a degree of velocity in their descent, that a man is forced to walk or run behind the cart, with a kind of rudder or pole affixed to the hind-wheel, which he locks up when it proceeds too fast. Should this pole break (which it sometimes does) the waggon flies away, and overturns everything it meets. Of course, any one who is coming up the road, is in imminent danger, unless he can by any means get out of the way; which is very difficult, as the road is narrow, and runs along a precipice. Last year, Mr. Frere, the proprietor of the iron works, was returning from London, and going along the rail-road in a post-chaise, when about a hundred yards from him, he saw one of those waggons coming down upon him with astonishing velocity. He could not possibly get out of the way, and must have been crushed to pieces, if fortunately the waggon had not broken over the iron groove, which had hitherto kept it in the track, and run forcibly up an ash-tree by the side of the road, in the branches of which it literally stuck, and thus saved him from immediate destruction.

One way of avoiding this alarming situation was to control the movement by cable and drum, with the added advantage that if two tracks were built, the weight of the full trucks going down could be used to lift the empties back up again. This was fine as long as the tramways were always working downhill, but it was clear that the problem could be overcome by combining winding drum and stationary steam engine. So it was that in many mines, men became used to working with the new machines, whether pumping water from the pit, raising and lowering men and materials, or acting as a motive power for the trucks of a tramway system. These were not ‘educated men’ in the conventional sense – such education as they had came from practical experience. They were often openly scornful of the advantages of any other form of education, no matter how grand they themselves were: the great civil engineer John Rennie declared that ‘after a young man has been three or four years at the University of Oxford or Cambridge, he cannot, without much difficulty turn himself to the practical part of civil engineering’. Rennie might have taken a more charitable view of the French engineering school, but there was still nothing of the sort to be found in Britain. The future of the steam railway was to lie in the hands of men such as George Stephenson, who received no formal schooling at all and started his working life at the age of eight. Stephenson, however, was by no means the first in the field of steam locomotion. That story really begins in 1800.

In 1800 the Boulton and Watt patent at last expired and the way to experimentation lay officially open. Nowhere was the news greeted with more enthusiasm than among the tin and copper mines of Cornwall. With no local source of fuel, they were desperate to find more efficient ways of using steam than those offered by Watt and his condenser. One answer was ‘strong steam’, or high-pressure steam, and there was no more enthusiastic advocate than the young son of a mine ‘captain’, Richard Trevithick. He was twenty-six years old when he began his experiments in 1797, and he was soon trying out his first road locomotive. On Christmas Eve 1801 his little engine successfully pulled a party of local worthies up a hill near Camborne. “Old Stephen Williams” gave this first hand account: “Captain Dick [Trevithick] got up steam, out in the high-road, just outside the shop on the Weith. When we get see’d that Captain Dick was agoing to turn on steam, we jumped up as many as we could, may be seven or eight of us. ‘Twas a stiffish hill going from the Weith up to Camborne Beacon, but she went off like a little bird.

Richard Trevithick, the Cornish engineer who built the first steam locomotive to run on rails.

When she had gone about a quarter of a mile, there was a roughish piece of road with loose stones, she didn’t go quite so fast, and as it was a flood of rain, and we were very squeezed together, I jumped off. She was going faster than I could walk.” It was a great success – up to a point. On a second excursion on Boxing Day, the engine hit a gulley and the steering mechanism was damaged. His companion Davies Gilbert related what happened next: ‘The carriage was forced under some shelter, and the Partners adjourned to the Hotel, & comforted their hearts with a Roast Goose and proper drinks, when, forget-full of the Engine, its Water boiled away, the Iron became red hot, and nothing that was combustible remained either of the Engine or the house.’

Trevithick continued despite this somewhat inauspicious beginning, and built another road engine which trundled around the streets of London, without it appears exciting any enthusiasm in anyone. It is interesting, if no more, to think what the future of transport might have been had the road engine been a success. Trevithick was not a man temperamentally inclined, however, to dwell on failures or to pursue his notions beyond what he considered a reasonable distance. He paid a visit to Coalbrookdale, with its extensive tramway, and there it seems possible that he made tentative experiments in putting his steam locomotive on rails. But the great event finally occurred in 1804.

Trevithick’s 1803 engine: The replica seen at the Blister Hill Museum was successfully tested on the Penydarren tramway in South Wales in 1804. He was unsuccessful in getting his engines accepted, mainly because they broke the brittle cast iron rails.

Trevithick had sold a share of his patent in the road locomotive to a Welsh ironmaster, Samuel Homfray. Partly to publicize the engine, and partly because it seemed a good bet anyway, Homfray made a wager of 500 guineas that the locomotive could haul a load of 10 tons along the Penydarren tramway that ran from a point near Merthyr Tydfil for nearly 10 miles to Abercynon and the Glamorgan Canal. It is still possible to walk much of the route of the old line, where lines of stone sleeper blocks lie embedded in the ground, and imagine the scene when the tiny locomotive came panting its way up the lonely valley of the River Taff. Gilbert again was on hand to record the event.

Yesterday we proceeded on our journey with the engine; we carry’d ten tons of Iron, five waggons, and 70 men riding on them the whole of the journey. Its about nine miles which we perform’d in 4 hours & 5 Mints [sic], but we had to cut down some trees and remove some large rocks out of the road.

The engine was a success: the railway was not. The cast-iron rails cracked under the weight of the engine, which rather spoiled the experiment. In many ways the Penydarren engine showed its pioneering nature in devices such as the huge cumbersome flywheel; in other ways it was to foreshadow later developments. The exhaust steam was turned up the chimney to increase the blast to the fire, a device that was to be reinvented by Robert Stephenson a decade later. Trevithick was able to sell one of his locomotives to the collieries of the north-east, but the Wylam tramway proved as inappropriate as the Penydarren for taking the weight and force of a locomotive. The engine suffered the indignity of being taken off its wheels and used as a primitive stationary engine. Trevithick was to make one last bid to get publicity for his invention, by running an engine round a circular track near the site of the present Euston station. ‘Catch-me-who-can’, as it was called, was unfortunately looked on more as an amusing side-show exhibit than a serious form of transport. The world did not rush to Trevithick’s door demanding steam locomotives, and he turned his inventive genius to other applications of high-pressure steam. It was not quite the end of Richard Trevithick’s involvement with railways and steam locomotives. The world did at least recognize him as a master of steam and he was recruited to build engines for the silver mines of Peru in 1816. He had years of great success, but then war ravished the industry and he reached Cartagena on his way home in 1827, an impoverished, but far from broken man. There he met a young Englishman, whom he had dandled on his knee when he had taken his colliery engine to Tyneside, Robert Stephenson. Trevithick was returning to an uncertain future; Stephenson was going home to work on the great Liverpool & Manchester Railway. There can scarcely have been a more poignantly symbolic moment than this: the young man who was shortly to design the Rocket had to lend the inventor of the steam locomotive £50 to get home. It might have been a consolation to know that future Trevithicks were to be among the band of engineers who were to go on to build railways for the world.

Steam locomotive development was undoubtedly held back by the brittle cast-iron track. In 1808 John Blenkinsop took over a colliery near Leeds and one of the problems he faced was the high cost of getting coal from pit head to the River Aire. The cost of fodder during the Napoleonic Wars made horse transport on the Middleton Colliery railway very expensive and Blenkinsop favoured steam – but what to do about the broken rails? He took the problem to a local engineer, Matthew Murray, whose enthusiasm for steam was well known – his house was even called Steam Hall. He realized that only by building a lighter engine could the permanent way be saved from breaking up every time a train passed over it. But light engines could not pull heavy loads. The answer was to find a way of increasing the tractive power. He designed a rack-and-pinion engine, of the sort still used on mountain railways throughout the world. It was suggested by some later commentators that Murray believed smooth wheels would slip on smooth rails but this was never the case. What Murray came up with was a practical solution to a very real problem. The 5-ton engine could haul around 15 tons without the rack-and-pinion – with it the load went up to 90 tons, and no smashed rails.

The Middleton Colliery Railway was a triumph. Thousands came to see it run, but more importantly a regular service was in operation by 1812 with two locomotives. Two more were added the following year. This was no gimmick, but a genuine commercial steam railway. It attracted immense interest and not just from local sightseers. George Stephenson came down from Tyneside to take a look in 1813, and the next year he built his very own first locomotive for Killingworth colliery. It cannot be pure coincidence that the main dimensions – piston diameter, stroke, boiler size, flue diameter – were virtually the same in the Murray and the Stephenson engine. And now, for the very first time, the wider world began to pay attention. Grand Duke Nicholas of Russia, soon to become Emperor, made the pilgrimage to the Yorkshire colliery in 1816 and according to local reports showed a ‘curious appreciation and an expression of no small admiration’. But already the Middleton Railway had become obsolete, overtaken by an improvement in rail technology which had made heavier locomotives viable and the rack-and-pinion redundant.

Early locomotive development now became centred on the collieries of the north-east. There were a good many developments between the years 1813 and 1815, with numerous engineers putting forward ideas, but for the next decade there was only one man in England, or indeed the world, actively engaged in designing and building locomotives, George Stephenson. He received some encouragement. One fanatical railway prophet was Thomas Gray of Nottingham, regarded by some of his contemporaries as certifiably lunatic. He actually suggested covering the whole country with a network of railways carrying freight and, even more astonishingly, passengers. His book of 1818, Observations on a General Iron-Railway, has a frontispiece showing a Murray-type locomotive chuffing along with what can only be called three stage coaches, complete with horn-tooting postilions. His vision was neatly expressed in a short verse on the title page.

No speed with this, can swiftest horse compare;

No weight like this, canal or vessel bear

As this will commerce every way promote

To this, let sons of commerce grant their vote.

Contemporaries were unimpressed. John Francis writing of Gray in 1851, said: ‘With one consent he was voted an intolerable bore’. But the intolerable bore was to see the first step being taken towards the realization of his dream in 1825.

The Stockton & Darlington Railway has gone down in history as the first public railway to be built specifically with steam locomotives in mind and to be designed to carry both passengers and freight, which is certainly true enough. But such a simple statement tends to mask the fact that it was essentially still a halfway house on the road to a wholly modern railway system: it was a colliery line writ large. For a start, hills were still overcome by inclines along which trains were hauled by cable, and although freight was shifted by steam, the first passengers were carried in what was in effect a stage coach with flanged wheels, pulled by a horse. It fell short even of Gray’s fantasy railway. Stephenson designed new locomotives, but they featured very little in the way of improvements over what had gone before. But in the end it was not so much what the Stockton & Darlington was that counted, as what it was seen to be. It was perceived as something wholly new. Henry Booth who was to become treasurer to the Liverpool & Manchester Railway, and an engineering innovator in his own right, described it as ‘the great theatre of practical operations upon railways’. It was an international theatre as well: visitors came from all over Europe, and they included the French engineer Marc Seguin, who was to share with Booth and Robert Stephenson the honour of producing the first multi-tubed boilers. The grandly named Pennsylvania Society for the Promotion of Internal Improvement sent over William Strickland to see what all the fuss was about. A climate was being created in which railways could grow. Within the next ten years railways were to open in France, Belgium, Germany and North America, and work would have begun in many more. And the call went out for the British to help build them.

It is not difficult to see why British steam locomotives were in demand: the British were the only people in the world building them. One of the first things the astute George Stephenson did following the success of the Stockton & Darlington Railway was to establish a locomotive works in the name of his son, Robert – and Robert was not to disappoint him. Although 1825 had been a triumph, not everyone was convinced that steam locomotives would provide the power – and certainly not all the power – for a railway system. When the Liverpool & Manchester was begun, hard on the heels of the Stockton & Darlington, there was still a faction that wanted to see trains hauled by cable, passing on from stationary engine to stationary engine. There was a strong feeling that interesting though the steam locomotive was as a novelty, it was not really up to the task. That question was decisively answered in the famous Rainhill Trials of 1829. The nature of the test was clearly spelled out. A 6-ton locomotive had to show itself ‘capable of drawing after it, day by day, on a well-constructed Railway, on a level plane, a Train of Carriages of the gross weight of Twenty Tons, including the Tender and Water Tank, at a rate of Ten Miles per Hour, with a pressure of steam in the boiler not exceeding Fifty Pounds on the square inch’. There were to be three serious contenders. Timothy Hackworth, locomotive superintendent of the Stockton & Darlington Railway, built Sans Pareil at the company’s Shildon works – at his own expense. It was a sturdy engine using what were then well established principles, but failed at the trials when a cylinder cracked. John Braithwaite and John Ericsson’s privately constructed Novelty looked the greyhound of the pack, but was to prove fatally short of stamina; and there was Rocket, built at the Stephensons’ own Newcastle factory. Rocket contained all the principal design features that were to form the basis for locomotive design for the remainder of the century. The engine not only managed 10 miles an hour, it positively flew along at 30m.p.h.; and the plans for cable-worked inclines were quickly scrapped when Rocket tore up the slopes, with huge élan. No wonder engineers all over the world were unanimous that for a time, at least, British really was best.

The actual technology of locomotive construction was not immensely complicated; hence there seems no good reason why overseas engineers should not speedily follow where Stephenson, Hackworth and others had led. Had there been a mechanical engineering school in France similar to their school of bridges and roads, no doubt they would have quickly followed. But this was not the case.

The locomotive evolved slowly from the giant pumping engines that drained mines and its development ran parallel with the life of its principal developer, George Stephenson. Born in 1781, a collier’s son, he followed his father to the pit, being placed in charge of a winding engine that lifted men and coal from pit bottom to the surface, a responsible job which he was given at the age of just seventeen. He soon showed himself to be a resourceful practical engineer, able to spot problems when engines went wrong and devise methods of overcoming them, yet this expertise came from native wit and experience. He had virtually no formal education and was, at best, semi-literate.

In 1812, a violent explosion at the Felling colliery resulted in the deaths of ninety-two men and boys. It was due to the lethal combination of ‘fire damp’ – methane gas – and naked lamps. A committee was set up offering a prize for a safety lamp. One of the winners was Sir Humphry Davy, who applied scientific principles in designing a lamp which was named after him. The other was George Stephenson, who employed trial and error, even to the point of taking his own lamp down to a spot where ‘a blower’ was sending out great gusts of gas. Had he been wrong, Stephenson would never have built a railway, or anything else, ever again. The interesting feature here is Davy’s reaction. He absolutely refused to believe that an illiterate collier was capable of such a thing, and when the mine managers of the north-east raised a special fund for Stephenson, he was incensed. He railed against the address of thanks ‘which every Man of Science in the Kingdom knows to be as fake in substance as it is absurd in expression.’ Practical working men could not possibly be the equal of educated men of science. But it was practical working men who were to develop the steam locomotive.

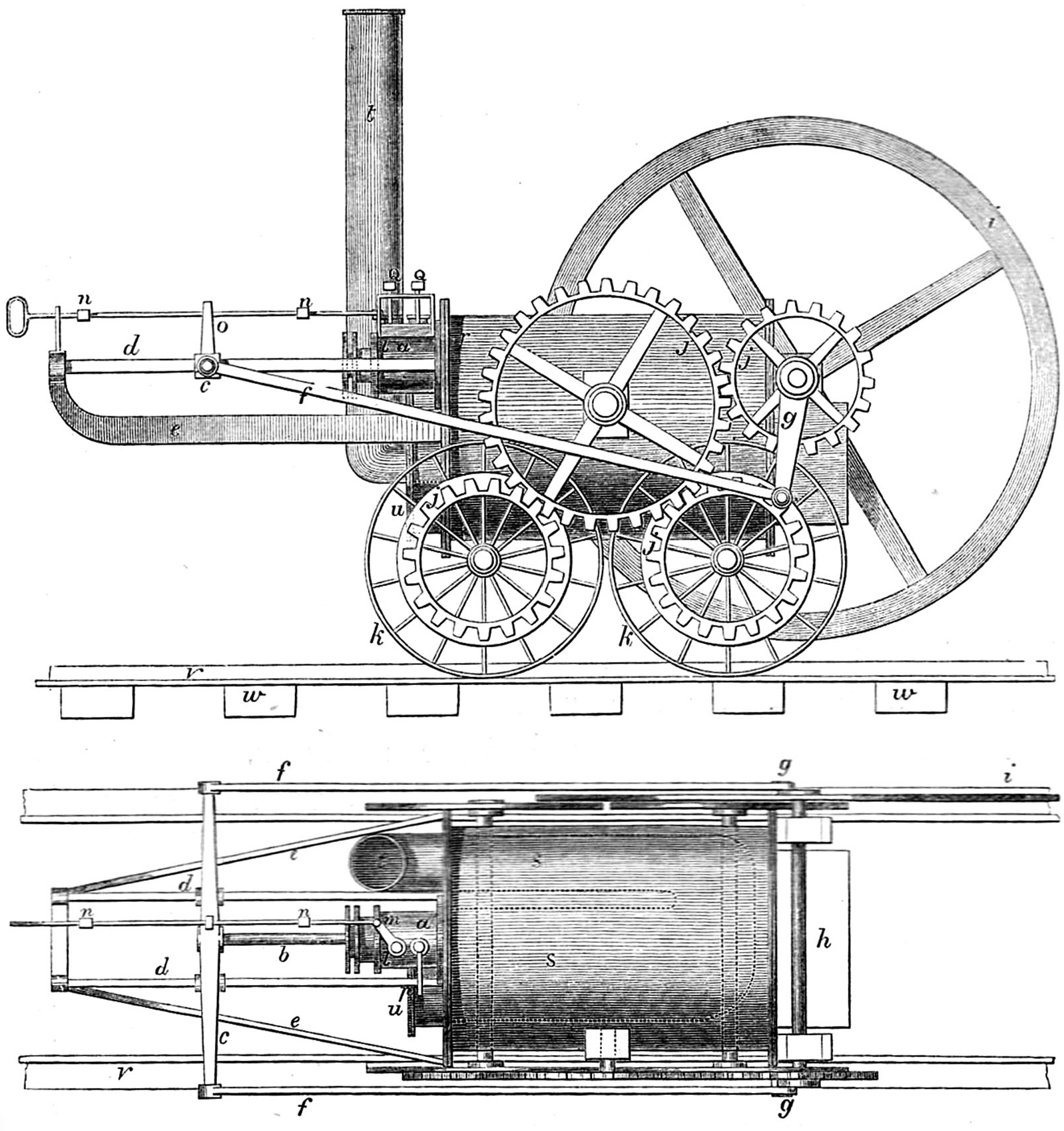

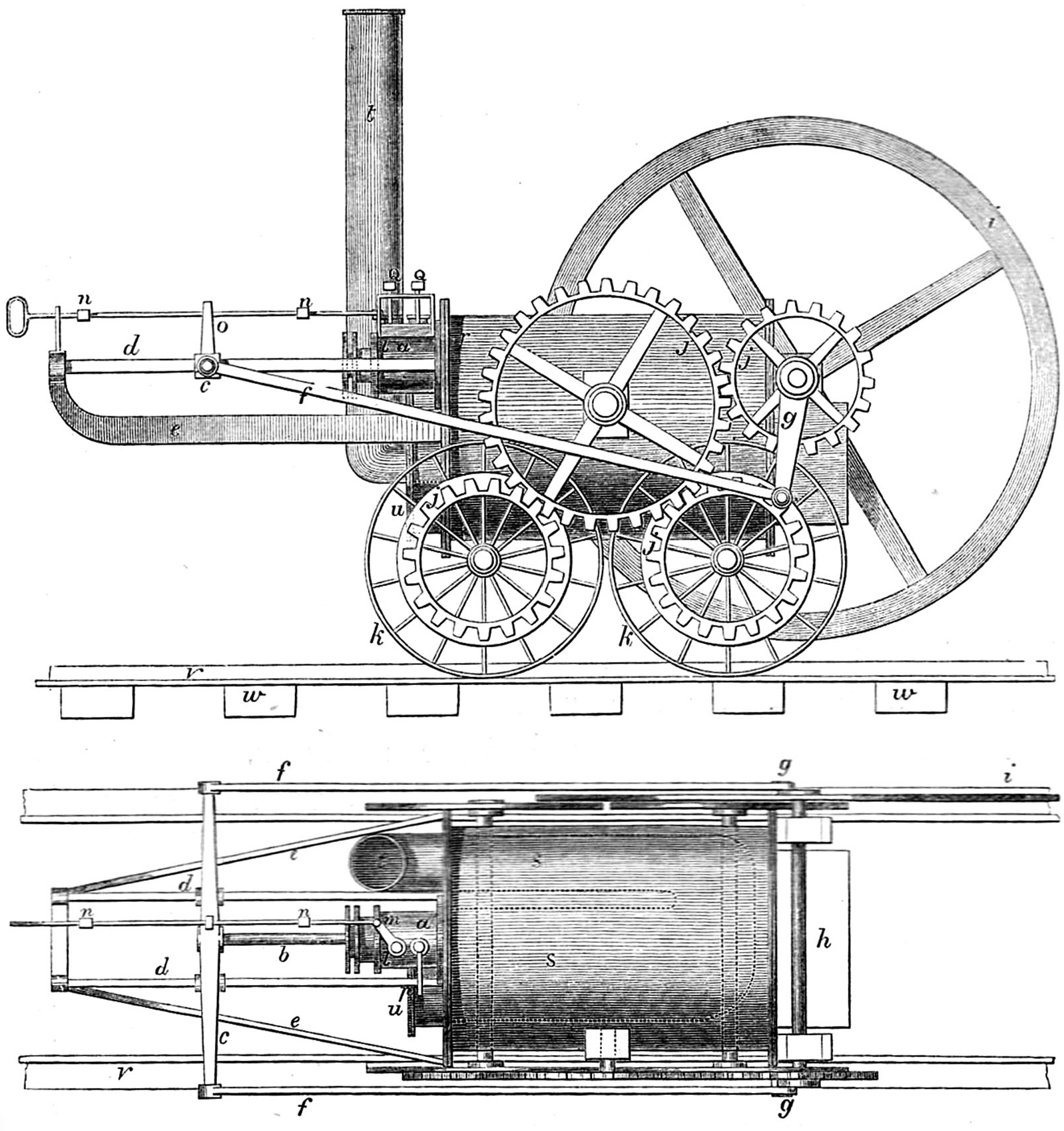

The locomotive developed by Blenkinsop and Murray using a rack and pinion system to provide extra traction for the Middleton Colliery Railway.

As Stephenson continued to rise in the colliery world, other men of similar background were also doing innovative work. Trevithick had sent his locomotive up to Christopher Blackett of the Wylam colliery, and Blackett in his turn encouraged his manager William Hedley to try his hand at engine design. The result was hard-working, sturdy engines like Puffing Billy, which with numerous modifications was to go on puffing right up to 1860. And Hedley brought in others to help. The Wylam blacksmith Timothy Hackworth joined in the exciting new work and though he was to be disappointed at Rainhill, he was to go on to build magnificent engines of great power, starting with the innovative Royal George. All these men shared the same background – strong on practice, virtually bereft of theory. George Stephenson had enough sense to see that his son Robert obtained a great deal more formal education than he had ever had, right up to university. Robert went to Edinburgh, the place with the highest reputation for science, but was unimpressed by what he learned there. University science came a poor second to the practical science of engineering works and mines. In 1822, he wrote a letter to an old family friend.

The Middleton colliery railway in Leeds. It was the first successful commercial railway, running on a rack and pinion system. It attracted a great deal of attention, and Grand Duke Nicholas of Russia was among those who visited the site.

Mr Jameson’s Lectures have hitherto been confined chiefly to Zoology, a part of Natural History which I cannot say I am enraptured with; nor can I infer from many of his Lectures any ultimate benefit, unless to satisfy the curiosity of man. Natural historians spend a great deal of time in enquiring whether Adam was a black or white man. Now I really cannot see what better we should be, if we could even determine this with satisfaction; but our limited knowledge will always place this question in the shade of darkness. The Professor puzzles me sadly with his Latin appellations of the various divisions, species, genera, &c, of the animal kingdom. He lectures two days a week on Meteorology and three on Zoology. This makes the course very unconnected.

I have taken notes on Natural Philosophy, but have not written them out, as there has been nothing but the simplest parts, and which I was perfectly acquainted with.

There was no denying it, advances in the early days of the railways were the result of the practical experiences of working men – and that experience was most readily available in Britain. America, already showing its new spirit of independence, was to be one of the few countries that was to employ home-built locomotives from the start, but then an American, Oliver Evans, had taken his steam vehicle out on the road as early as 1804. It was not, of course, simply knowhow that was required, there had to be the industrial base there as well. That meant power and iron and engineering works, all of which Britain had been building up during the dramatic, and often traumatic, years of the Industrial Revolution. Britain had not just produced the first successful steam locomotive, it was also home to the first iron bridges, the first iron boat and a whole range of inventions and innovations. Yet this is only part of the story of the Railway Empire. Britain could, and indeed did, take a role as the engineering workshop for that Empire, shipping out locomotives to the rest of the world. But the world wanted more. Countries on every continent turned to Britain to build their railways, survey the routes, design their viaducts, dig out the ground and hack through the rock. Surprisingly, often they wanted Britain to find the money to pay for their railways as well. This, on the face of it, may seem strange. To find out why one has again to turn back to a period before the railway age began.

The French had, as we have seen, a great tradition of canal building. The British were slow to follow their lead. Once they did, however, they did so with immense energy, developing a huge and complex network of canals. What is of interest here is how these canals (and then railways) were financed.

A canal was not like a factory or mill. You could not just set up a canal in a modest way and use the profits to develop the business. Canals required very large capital sums indeed, running into hundreds of thousands of pounds, millions in today’s terms. Allowing promoters to encourage the public to invest in such projects with promises of large profits was an obvious solution, but the South Sea Bubble had shown that the public was, alas, just as willing to invest in a hopeless scheme as a sound one. Following this disaster, the government stepped in to regulate investment. Although canals were largely built by joint-stock companies, before anything could be done a scheme had to be approved by Act of Parliament. The company and its plans were subject to parliamentary scrutiny. It was not a fool-proof system, but it did offer the investors some guarantee that a disinterested third party had given the plans consideration and approved them as practical. In fact, companies regularly underestimated the construction costs by an alarming amount and overestimated the profits similarly. The relevant point is that a method had been found for financing very large capital projects, and on the whole it worked. The canals were built, and the best of them provided handsome dividends. A public had appeared that was quite ready to invest in such major capital projects. In the early days of French canal construction, the costs were born by the state; in Britain they were carried by a variety of people, ranging from speculators to sober industrialists. As the lure of the canals began to fade, these investors happily switched to railways. And the railways did not have to be on British soil.

The engineers of the canal age had shown themselves more than competent, and men such as Jessop, Telford and Rennie rose to international as well as local fame. Civil engineering was put on a professional basis with the founding of the Institution of Civil Engineers in 1820. Thomas Telford was its first president. It became not so much a forum for ideas as a collecting house for practical projects. Telford wrote to Count von Platen of Sweden, who had invited him to work on the Gotha Canal in 1808, to ask for material to be sent to the library, but made it very clear precisely what was wanted: ‘You will remind them to send me drawings and descriptions of works really executed. We have no wish for learned discussions; facts and practical operations are to compose our collections and we should leave project and theory to those who are disposed to create new systems.’ There speaks the voice of the pragmatic British engineer, the man who had worked his way up from humble beginnings to the highest pinnacle of his profession, the very model of Samuel Smiles’ self-made man. To a large extent it was this quality that made the British engineer so popular with overseas promoters. He might not have been able to supply written answers to examination papers – some of the older generation of engineers could scarcely have read the questions – but he got ten out of ten in the practicals. He could be relied on to start a job and see it through to a successful conclusion. He was an engineer with muck on his hands.

Even at the beginning of the railway age, not every engineer conformed to the stereotype. Men came from a great variety of backgrounds, and advanced by as many different routes. At one end of the spectrum stood stout, stolid George Stephenson, who spoke loudest and best when he spoke through his works rather than his words. Throughout his life he smarted from the verbal battering he received when Alderson, counsel for the canal interest opposing the Liverpool & Manchester Railway Bill, cross-examined him on his surveys. The engineer had been forced to rush the work and rely on untested figures supplied by equally harrassed juniors. He had made mistakes, but now these mistakes had been held up to public ridicule and he had been made to look at best a fool, at worst a dishonest charlatan. It all served to magnify his prejudice against the socially adept, sophisticated ‘London men’.

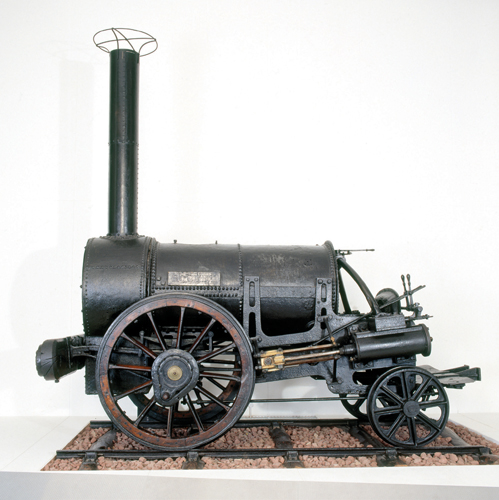

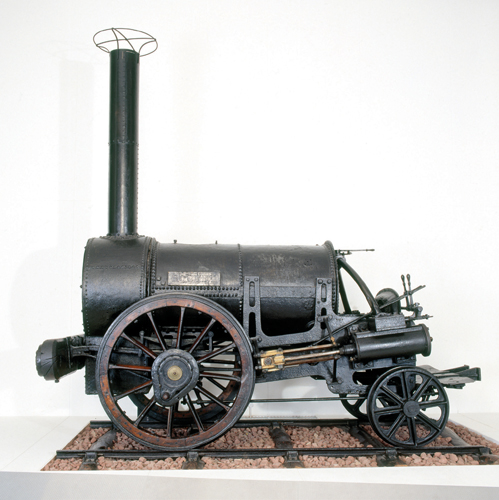

Robert Stephenson’s Rocket, the famous locomotive that set the pattern for future development.

Just such a man was Charles Blacker Vignoles, whose family had come to Ireland as Huguenot refugees. His early career was made in the army according to the conventional route of a gentleman – Sandhurst, followed by a commission in the York Chasseur. He saw active service in the Napoleonic Wars after which he spent two years travelling. He had little prospect of a successful military career: there was a glut of ambitious young officers at the time. So in 1817 he began a new career, in the event an adventurous one, as a surveyor in South Carolina. Back in England in 1824, an experienced surveyor and engineer, he was at once taking part in the world of railway construction. Almost his first job was to resurvey the Liverpool & Manchester line after Stephenson’s first survey had been demolished by the opposition. Having done a sound job of work, Vignoles must have hoped for more than he received in reward – a post as Stephenson’s assistant, an uncomfortable position for a critic. And Vignoles himself admitted he was no flatterer; he saw Stephenson’s faults and his prejudices. In his own words he ‘neglected to court Mr S’s favours by crying down all other engineers, especially those in London, for though I highly respect his great natural talents, I could not shut my eyes to his deficiencies.’ There followed an inevitable parting of the ways. In spite of his quarrel with Stephenson, Vignoles’ career culminated in his being elected President of the Institution of Civil Engineers – he was also chief engineer for railways as far apart as England and Mexico.

The most important event in terms of generating enthusiasm for railway construction was the opening of the Liverpool & Manchester Railway. Most of the work was done by Robert Stephenson’s locomotives, with a design based on the one illustrated here, Planet. The design was to find its way to many other countries.

The backgrounds of the engineers who took railways to the world could not, then, have been more varied; yet all in those days shared something far more important than social difference. Their skills were learned and tested in the hands-on world of muddy cuttings and dripping tunnels. If anyone could be said to typify this breed of engineer it is John Fowler. Fowler followed in his father’s steps as a surveyor, but although he had opportunities for further education he left school at sixteen, at his own request, to be taken on as a pupil of J.T. Leather, engineer for the Sheffield Water Works. Later in life he was to declare with a not unreasonable pride: ‘Before I was nineteen I was a good engineering leveller, could set out works, and measure them up for certificates to be paid to contractors.’ He first came into contact with railways when Stephenson arrived to look at the line for the North Midland Railway that was to link Derby and Leeds. He went for the easy option, choosing the low ground but missing out, much to the indignation of the locals, the thriving town of Sheffield. Fowler was engaged to help look for alternative routes and this brought him into contact with Vignoles. This gives an indication of just how small the world of railway building was in the 1830s. Fowler, not yet out of his teens, was meeting the great men of the age. He was also getting a taste of the rough and tumble of railway life. Not all the gentry wanted railways, or even railway surveyors, anywhere near their properties, and did what they could to obstruct the work. On one occasion Fowler was taking levels when a local landowner’s servant firmly placed himself in front of the theodolite, declaring he had the right to stand where he liked on the public road.

On this, one of my stalwart assistants inquired if he also had the right to stand or walk where he pleased on a public road. Unthinkingly the landowner’s man admitted that any man had such a right. ‘Then’, said my man, ‘my right is here, and if you obstruct me I shall remove you’; and walking up to the man, he took him in his arms and deposited him in a ditch.

An English squire could, as many an engineer found out, prove more intractable than any peasant farmer, and a deal more prickly than any cactus. John Fowler learned his trade on the moors of Yorkshire and the downs of Suffolk and he was to apply his expertise, as eminent Sir John Fowler, in Europe, Africa and Asia.

The chief, or consulting, engineers were the grand panjandrums of the railway world, so grand that some never even set foot in the countries – nor indeed the continents – where their advice was sought. The actual work of surveying, laying out the line and supervising the work went to subordinates, resident engineers and their assistants. Even then, the engineering staff rarely supervised the workforce itself. Once again they used a system developed and refined in the canal age. Work was let out to contractors. The latter provided the everyday tools of the works, which were simple enough – shovel, pick-axe, barrow – and, most importantly, the men. They accepted a price for doing the job and were then responsible for wages. There were many advantages to the railway company. They were able to set fixed-price contracts which, in theory if seldom in practice, should ensure that work remained within budget. They did not have to waste time recruiting labour, and they could disclaim all responsibility for a rowdy, troublesome workforce. At the end of construction they were not left with piles of unwanted tools and materials on their hands: the contractors could use the barrows and shovels on the next job. There were disadvantages: contractors in general had an overriding aim to finish a job quickly, collect the cash and move on, regardless of quality. The engineering staff wanted to see a job well and thoroughly done. It was a source of endless bickering throughout the canal age. A letter written in 1793 by the long-suffering and finally exasperated secretary for the Lancaster Canal to the contractors Pinkerton and Murray, could have been written by any of a score of secretaries to their firm of contractors.

Thomas Brassey began his career as a railway contractor in Britain, but over the years he was to take his work force around the world.

The Comc are sorry that they have reason to observe that the General tendency of your Management is to get the works hurried on without regard to the convenience of the public, the loss of the land occupiers or the advantage of the Company. You seldom provide the necessary accommodations before you begin to make the Bridges, and in the excavation you place your men in so many various places without either finishing as you proceed or making your fence wall & posts & railing – that the whole Country is laid open to damage. This grievance which has already caused so much trouble and expence is so very obvious & so much owing to your neglect that the Company will no longer suffer it … The not fulfilling the promises you make & the want of attention in yourselves, your agents & workmen to the direction of the Company Agent, are evils there is great reason to complain of.

These words could also have been repeated verbatim in the railway age. Yet the system survived, largely because the railway companies considered that the alternative of hiring direct labour was generally a good deal worse, combining inefficient use of basic resources and an often arbitrary system of payment. The contracting system was so well established by the 1820s that it was a source of astonishment to Thomas Telford, when he was asked to report on the progress of the Liverpool & Manchester Railway in 1828, to find that it was not in use. George Stephenson had divided responsibility for construction between his three principal assistants.

Each has 200 day men employed and pay them every fortnight as Company’s men for laying temporary roads, moving planks, making wheelbarrows, driving piles and, in short, doing everything but putting the stuff into the carts and barrows which is done by a set of men which is also under their direction and to whom they pay 3½d per yard to 5s as they think it deserves.

This was seen as an aberration, a curiosity – and not to be repeated.

In practice, the word ‘contractor’ could be used to describe at one end of the scale a semi-literate workman who had managed to acquire some primitive tools and persuaded a few old mates to work for him, and at the other a financial giant with a capital of millions in cash and a workforce with more men than some European armies. A few of the former in due course achieved the status of the latter. Some of the contractors, such as William Mackenzie, who was to play an important role in the construction of European railways, gained early experience on the canals, while others grew and developed with the railway age. Of these, two men were quite outstanding, Thomas Brassey and Samuel Morton Peto. On occasion they worked together; at other times separately. Of the two Brassey was probably the more successful, for Peto was to suffer seriously in the great crash that hit the world of banking and finance in 1866, and from which he never recovered. Brassey was hit likewise but managed to rebuild his fortune. According to his biographer, Sir Arthur Helps, Brassey had during his career a total of ninety-seven contracts in Britain for the construction of 2051 miles of railway; his forty-two overseas contracts covered an astonishing 4472 miles of line.

Thomas Brassey’s beginnings were modest. His family owned land and farmed at Buerton in Cheshire, and he received a decent education before leaving school at the age of sixteen to be articled to a surveyor, a sound training for his later career. He was perhaps fortunate in being in the right place at the right time. The Holyhead road was being improved by Thomas Telford at the time, and Brassey had the opportunity to work on the survey. His employer, Mr Lawton, also proved a man of some foresight in recognizing the growing importance of Merseyside, and took his protégé into partnership establishing him in a new office in Birkenhead. Brassey was there when George Stephenson came to the area, hunting out good stone for the mighty Sankey viaduct on the Liverpool & Manchester Railway. Young Mr Brassey had the management of just such a quarry and took the engineer along to see it. Stephenson must have been impressed, for he was soon suggesting that railway contracting was a good business to be in. Brassey subsequently put in a bid for the Dutton viaduct on the Grand Junction. His first shot at estimating for a railway viaduct came in too high and was rejected; his second for the Penkridge viaduct hit the target. He won the contract and was fortunate enough to establish a rapport with the engineer for the line, Joseph Locke. It was to be a working partnership that was to prove profitable to both men.

Helps’ biography of 1872 has more than a touch of hagiography about it. There is no denying that Brassey was immensely successful: he died in 1870 leaving an estate of over £3 million. It is also clear that he was not only a man with a keen business sense, but that he combined it with generosity of spirit. He was a leader who was not afraid to delegate, once he was certain that trust was justified. A young estimator described how Brassey called him in and went through all his figures with immense precision, but having done so once, did not feel it necessary to do so again. He knew his office staff and appreciated their worth, and he knew his labourers equally well; he was aware that ultimately it was on their muscle-power that his fortune depended. An employer who can gain the affection as well as the respect of a gang of hard-drinking navvies has to be a man of special qualities. The tender-heartedness of Thomas Brassey is praised by Helps: ‘At the busiest period of his life he would travel hundreds of miles in order to be at the bedside of a sick or a dying friend, and to give what aid or consolation he could give him.’ A copy of the book was sent to the family of William Mackenzie, and a tart note pencilled in the margin declares that he never came anywhere near the sick-bed of his old partner. Edward MacKenzie, William’s younger brother who was also at the works at the time, was deeply shocked by this oversight and had a number of unflattering things to say about Brassey in his diary. Clearly the event was never forgotten by the McKenzies. It is comforting, after reading a biography such as this, to discover that the hero was not perhaps a paragon of all the virtues.

The British rail system depended on the work of vast armies of navvies and the British navvy would, like Brassey, travel the globe. These men are working on the Grand Central Railway in Britain.

Morton Peto at the start of his career was more privileged than Brassey. He inherited his father’s already prosperous building company, based in East Anglia but undertaking national projects, including the erection of Nelson’s Column in Trafalgar Square. He always retained a very strong local interest, promoting dock facilities and rail connections to build up the local port of Lowestoft. Like Brassey his reputation was made on the basis of fair dealing: he delivered what he promised to the railway companies he dealt with around the world, and he treated those who worked for him with equally scrupulous fairness. Although men such as Peto and Brassey made immense fortunes, much of their wealth was in the form of shares and bonds, taken in part payment of a contract. When there was a general collapse in financial confidence and banks were even forced to close their doors, as happened in 1866, their fortunes were seen to consist of almost worthless pieces of paper, while their commitments had to be met in the coin of the realm.

If a railway construction unit was a pyramid with the chief engineer at the apex, then the whole structure rested on a massive base made up of tens of thousands of workers, the navvies. They too had their origin in the canal age; the the name is an abbreviation of ‘navigators’, referring to the fact that they dug out a navigation. When the canal age began the full-time navvy had not come into existence, and labour was recruited locally. By the 1780s, the Reverend Stebbing Shaw, visiting the works on the Basingstoke Canal was noting that

The contractor, agreeable to the request of the company of proprietors, gives the preference to all the natives who are desirous of this work, but such is the power of use over nature, that while these industrious poor are by all their efforts incapable of earning a sustenance, those who are brought from similar works, cheerfully obtain a comfortable support.

In other words, the professional navvy had been born. Tramping from one working site to the next, he could outwork any rival. His reputation, for hard living as much as for hard working, was fearsome. No one could match him for strength and stamina, not the rural workers from the fields of England, and certainly not, both in his own estimate and in that of many others, any foreign workers.

So it was that as the railway age began to gather momentum, Britain was established as the one country where every element for achievement was to be found. There were investors keen for new railway schemes in which to place their funds. There were engineers skilled and experienced in the new technology of the modern age of transport, who understood everything from the complex workings of a steam engine to the best method of building a high, stable embankment across a deep valley. There were contractors who could be trusted to understand the engineer’s plans and carry them out in earth, brick, stone and iron. And there was a labour force with special skills and strong sinews, ready to tackle any scheme their employers could devise. Small wonder that as men all over the world began to dream of a web of iron rails spreading across their countries, they looked to the British to turn their dreams into reality.