Propulsion systems

There are four types of propulsion – the outboard engine, the inboard engine, the inboard/outdrive and the waterjet. All these propulsion systems rely on the screw propeller to provide the thrust.

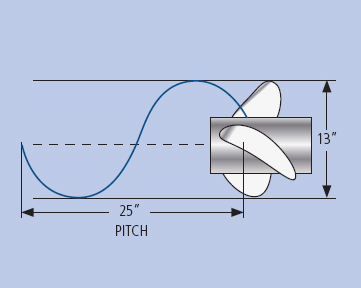

The propeller has radiating blades that form part of a helical or spiral surface and operates like an auger cutting a hole through wood. A propeller’s thrust is proportional to the mass of water it is acting on. Large-bladed propellers with less pitch are more efficient than smaller props with a deeper pitch. On small pleasure boats, limited draft and constraints of clearance from the hull conspire to limit prop diameter to something smaller than optimal size. Their performance depends on the area and pitch of the blades. This is measured by the theoretical amount the propeller will move forward with each complete turn. Thus, a 251/4-inch (33cm) pitch propeller will move that distance with each revolution.

Pitch is the theoretical distance that the propeller will travel on one rotation.

In practice, propellers perform well below their theoretical pitch figure because no account is made for the weight of the hull and the resistance the boat generates in the water. The figures are distorted even more by the speed at which the propeller turns.

In practice propellers perform well below their pitch figure because of cavitation and slippage.

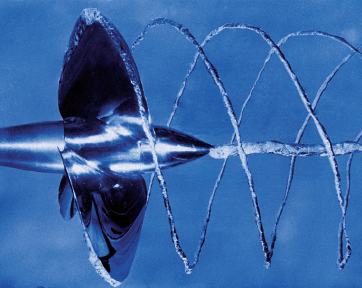

The faster the spin, the greater the cavitation, or bubbles that form on the blade tips when the prop is under load. Cavitation is caused when the pressure on one part of the blade falls below ambient pressure (atmospheric + hydrostatic head), and a vacuum is formed. This is often experienced during fast acceleration and sharp cornering. The telltale signs are a sudden increase in revs and a reduction in speed.

Propellers have improved considerably over the years, and most engine manufacturers offer an advice service to match propeller type and pitch with the type and use of your boat Three-bladed propellers provide a greater top speed at the expense of low end accelerations. Four-bladed designs have better low-end power but at the expense of top-end speed. Volvo Penta’s Duoprop and IPS forward facing dual prop outdrive legs have two contra-rotating props which increase efficiency by as much as 15% and eliminate prop walk.

Zinc sacrificial plate fitted close to shaft and bronze prop, rudder and P-bracket save them from electolytic action.

Standard propellers supplied with outboard and outdrives are invariably aluminium. These are easily damaged, and since any chinks on the trailing edge of the blades can have a marked effect on performance, these are often replaced with more durable stainless steel propellers.

Lightweight electric outboard.

Composite props provide a cheaper alternative and some designs have the provision to replace individual blades if they are damaged.

Bronze propellers are often used on inboard powered boats kept afloat because of their greater resistance to corrosion. Zinc sacrificial anodes must be fitted on the shaft and hull to overcome electrolysis problems associated with saltwater applications.

The outboard motor is the most common form of propulsion for smaller boats, offering compact weatherproof units from 1.5hp to more than 300hp. At one end of the market are the light, simple, battery powered electric auxiliaries used to power a tender or provide super-quiet manoeuvrability when fishing. At the other end are the compact 2–3 litre race-bred models with sophisticated electronic engine management systems. In between is an enormous choice of engines, including two and four-stroke, powering props or waterjet systems.

Two and four-stroke systems have very different characteristics. The two-stroke has a better power-to-weight ratio and superior low-down torque than a four-stroke, making them a better choice for waterskiing and other applications where fast acceleration is required. On the downside, they use more fuel than a four-stroke and produce greater emissions.

The four-stroke really scores with more torque at the top end of the rev range, coupled with quieter, smoother running without the smoky exhaust that remains a trademark of all two-strokes.

Most marine inboard engines are adapted car and truck motors. Inboard installations offer the ability of placing the engines where their weight has the least effect and are connected via a reduction gearbox directly to the prop shaft. However, the exposed shafts, struts and P-brackets all contribute to parasitic drag. The greater the incline of the shaft, the less efficient forward thrust becomes. The shaft rotation in the water generates a surprising amount of friction and can also lead to considerable vibration.

Twin inboard engine installation with props and rudders.

The problems of drag and vibrations associated with inboard installations are largely overcome by the inboard/outboard configuration, where an inboard engine drives a steerable outdrive leg that can be raised like an outboard when navigating in shallow waters and allow the boat to take to the ground.

Twin inboard/outdrive installation.

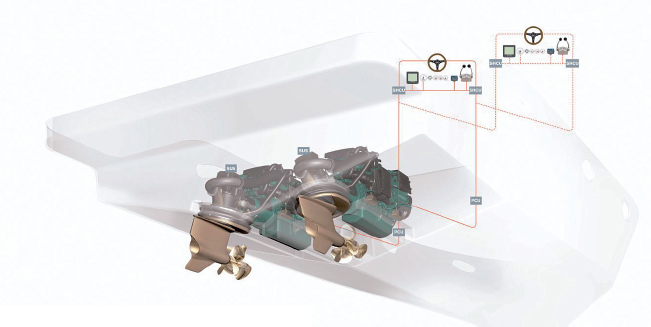

Their advantages are simple installation, and low noise and vibration levels. Their disadvantage is that engine weight is centred well aft, which can cause some boats to hobbyhorse badly when heading into rough seas. Volvo’s IPS forward facing drive system overcomes this by fitting the outdrive leg through the bottom of the boat, rather than the transom which has the effect of moving the weight forward.

Twin Volvo IPS forward facing inboard/outdrives.

Waterjet units follow Newton’s Third Law of Motion in which every action has an equal and opposite reaction. Just like the backward thrust that is felt when holding a powerful fire hose, the discharge of a high-velocity stream of water from the jet unit generates a reaction force in the opposite direction, which is transferred through to the boat to propel it forward.

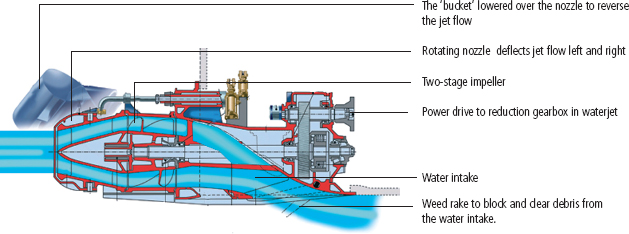

The one-piece jet unit is mounted inboard at the back of the boat with the nozzle extending through the transom. The water intake fits flush within a flat section in the bottom of the hull. As the water enters, the flow is accelerated by an impeller through a reducing diameter tube to be discharged at high velocity through the nozzle. Steerage is achieved by turning the outer nozzle to port or starboard to deflect the water one side or the other, and reverse is achieved by a ‘bucket’ that hinges down over the nozzle to deflect the jet stream back under the boat. These controls are remarkably efficient, and in an emergency, the boat can be stopped within its own length when the bucket is deployed and full thrust maintained.

Waterjets operate at the high end of the power spectrum more efficiently than prop driven boats, but are more susceptible to weed and flotsam gumming up the works in badly weeded or polluted waters.

Cutaway of a Castoldi waterjet propulsion unit.

Photo of twin Castoldi waterjet propulsion units with the intake and ‘bucket ‘positioned over the outlet to reverse the jet flow in clear view.