1 Introduction

The electric power grid is arguably the most critical of all the infrastructures as other infrastructures, such as, communication, transportation and finance are heavily dependent on it. Similarly, high voltage (HV) power transformers, generators, and transmission lines are the most critical components of the electric power grid. Therefore, an untimely loss of HV transformers can be catastrophic for not only the electrical infrastructure, but also the other critical infrastructures that depend on it. Accordingly, it will be helpful if it can be recognized before the event, that a transformer is heading towards a failure, so that corrective measures can be undertaken. Fortunately, before a transformer reaches its critical failure state, there are “cues”(or indicators) which, if monitored periodically, can alert an operator that the transformer is heading towards a failure. One of the indicators is the signal to noise ratio (SNR) of the voltage and current signals in substations located in the vicinity of the transformer. During normal operations, the width of the SNR bands are small. However, when the transformer heads towards a failure, the widths of the bands increase, reaching their maximum just before the failure actually occurs. This change in width of the SNR can be observed by phasor measurement units (PMUs) located nearby.

Identifying Code is a mathematical tool that enables one to uniquely identify one or more objects of interest, by generating a unique signature corresponding to those objects, which can then be detected by a sensor. In this paper, the objects of interest are HV transformers. When a transformer is heading towards failure, it generates “indicators”, which, if monitored by some “sensors”, may provide information to an operator in the control center about the impending failure of the transformer. Since the number of transformers in the grid is large, and the sensors are expensive, one would like to deploy as few sensors as possible (fewer than the number of transformers) and yet retain the capability that, when a transformer is heading towards a failure, it can be uniquely identified.

PMU is a device that can be utilized as a “sensor” for monitoring the health of transformers. When placed on a generator, load, or zero injection bus, in the power grid, PMUs give the voltage of that particular bus, as well as the currents flowing in the branches (lines or transformers) incident on that bus (while being subjected to the PMU’s measurement channel limitations). Since a power transformer can only be placed between two buses, a judicious placement of a few PMUs (sensors) can effectively monitor health of all the transformers, and in case a transformer heads towards a failure, the sensors can create a unique fault signature that enables the operator to identify the troubled transformer.

In this paper, we, (i) describe the Rudd power transformer failure incident that motivated this study, (ii) describe how Identifying Code can be utilized for unique identification of the transformers that are heading towards a failure, and, (iii) provide a technique to compute the fewest number of sensors to be deployed, to ensure unique identification of the transformers that are heading towards a failure in standard test systems.

2 Related Work

Prior research on health monitoring using PMUs have been mostly directed towards improving security and stability of the power system [1]. In addition, a number of studies have focused on placement of PMUs [2, 3] to realize a variety of objectives. The problem under study in this paper can also be viewed as a PMU placement problem as it computes the fewest number of PMUs and their locations, so that the unique identification capability is realized. It is important to highlight here that none of the PMU placement strategies proposed so far had the unique identification capability as the objective for PMU deployment.

Karpovsky et al. introduced the concept of Identifying Codes in [4] and provided results for Identifying Codes for graphs with specific topologies, such as binary cubes and trees. Using Identifying Codes, Laifenfeld et al. studied covering problems in [5]. A special case, where only a subset of nodes needs a unique code, can be modeled with a bipartite graph, and was studied as “Discriminating Codes” in [6]. This special case is relevant for our study as we focus on finding unique signatures for a subset of nodes, instead of all the nodes, as is done in Identifying Codes.

3 Lessons Learnt from Rudd Power Transformer Failure

Transformer fire at Salt River Project (SRP)’s Rudd substation in Avondale [7].

is the signal mean or expected value and

is the signal mean or expected value and  is the standard deviation, or an estimate thereof. It is difficult to directly compare different signals (such as voltages and currents). However, SNR (in decibels) is a relative metric and therefore, it can be used to compare diverse signals and create alerts/alarms. The Rudd transformer failure data obtained from SRP, comprises of PMU readings (voltages and currents) one year away from the day of the failure (June 1, 2016) up to the data collected only a few hours prior to the actual failure event.

is the standard deviation, or an estimate thereof. It is difficult to directly compare different signals (such as voltages and currents). However, SNR (in decibels) is a relative metric and therefore, it can be used to compare diverse signals and create alerts/alarms. The Rudd transformer failure data obtained from SRP, comprises of PMU readings (voltages and currents) one year away from the day of the failure (June 1, 2016) up to the data collected only a few hours prior to the actual failure event.Two important pieces of observation were made from the SRP data.

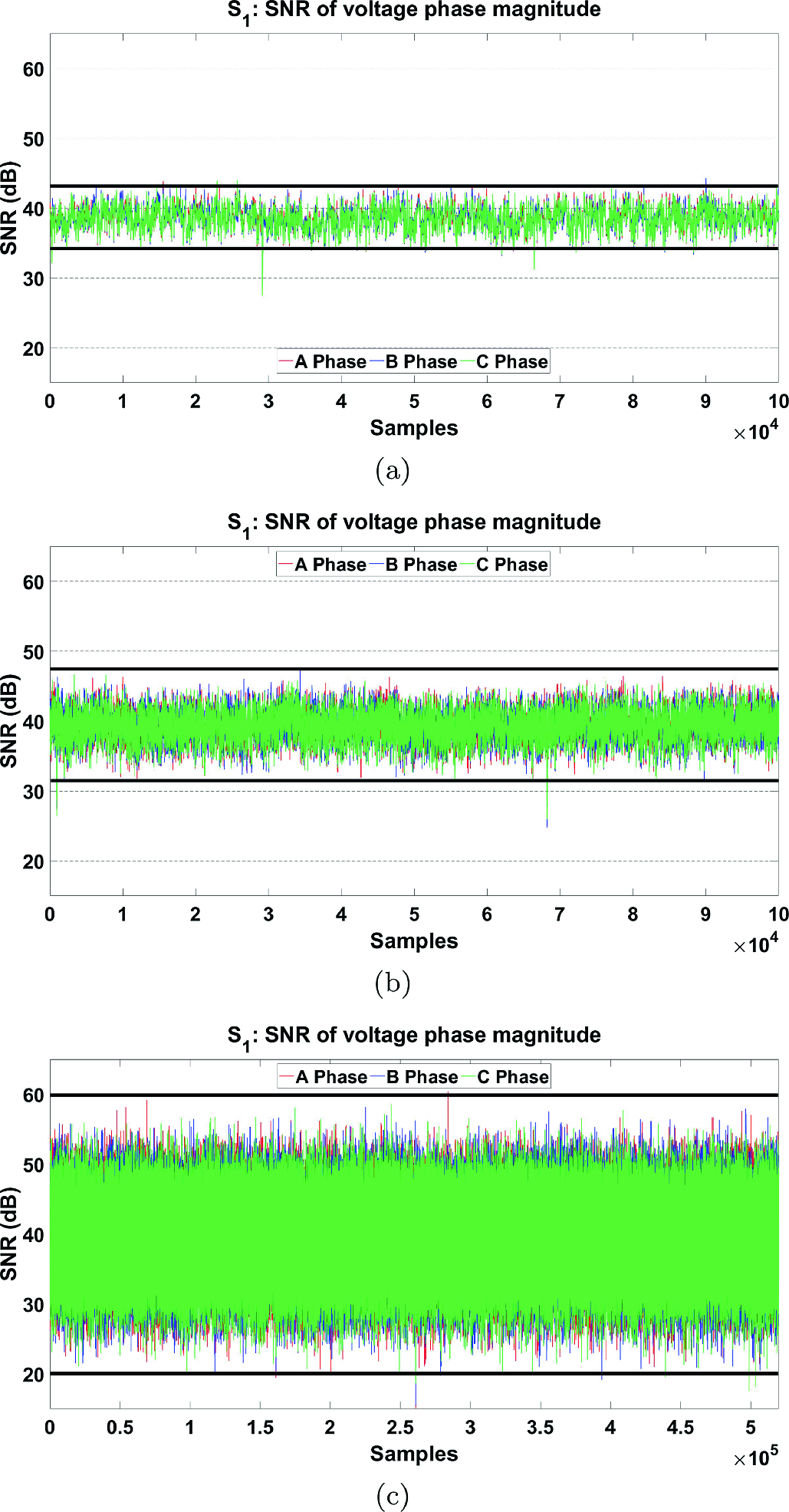

Observation 1: A steady growth in the width of the SNR bands (computed from the voltage magnitude measurements obtained from neighboring substations), was observed over a period of time, till the transformer failed. The observations for three instances of time, as it approached the actual time of failure, are shown in Fig. 2. Since the growth was similar in all three phases, it was concluded that the SNRs were capturing an event that was affecting all three phases, and not due to a single phase failure event, contributed by a current or a potential transformer failure. Moreover, as the width was uniform over the observed time period (an hour worth of data), it is clear that the captured event was not a random transient event.

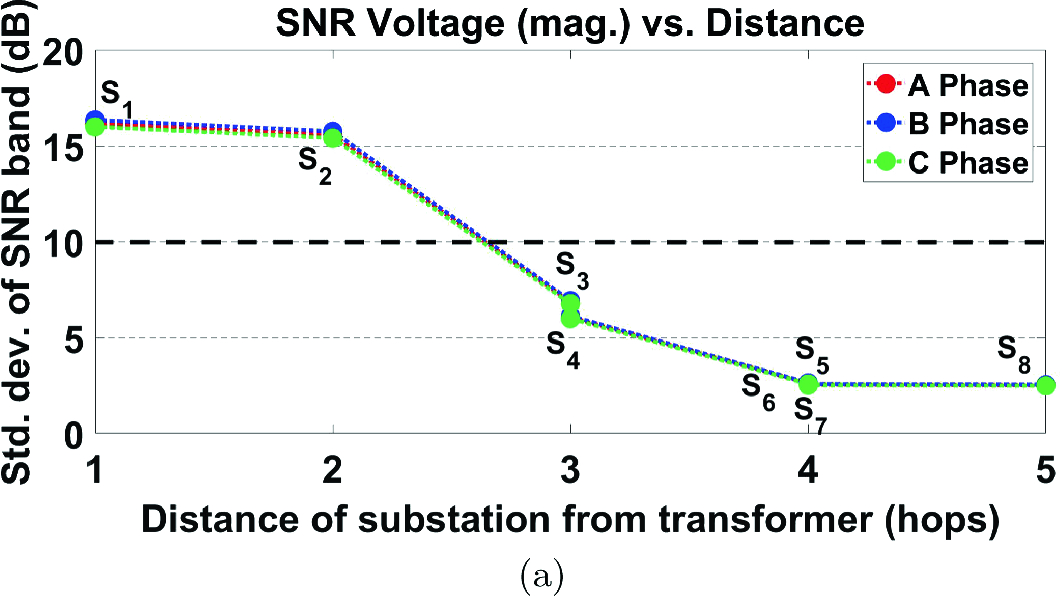

Observation 2: In observation 1, we noted that the width of the SNR band at a specific PMU (sensor) location, increases as time approaches the actual failure event. From the data it was also clear that, as the distance of the PMU (sensor/monitoring device), from the transformer (monitored device) increased, the width of the observed SNR decreased. Figure 3 shows the decrease in the width of the SNR bands as a function of the electrical distance (termed as hops) from the Rudd transformer. The data was collected from eight substations (S1, ..., S8) that neighbor Rudd, and had PMUs placed on them. It may be noted that the Rudd substation itself did not have a PMU on it during the time of failure.

Given that the deteriorating condition of a transformer can be noticed by PMUs located within a certain distance of the transformer, signals indicating the deteriorating condition, can be utilized to deploy effective monitoring strategies, so that an alarm is generated before a transformer reaches a critical failure state. Identifying Code is a mathematical tool that can be used for monitoring transformers in the power grid. Using this technique, the fewest number of sensors needed to enable an operator to uniquely identify the failing transformer before it reaches a critical failure state can be computed.

4 Overview of Identifying and Discriminating Codes

of a graph

of a graph  is defined as the Identifying Code Set (ICS) for the vertex set V, if for all

is defined as the Identifying Code Set (ICS) for the vertex set V, if for all  ,

,  is unique where,

is unique where,  and N(v) represents the set of nodes adjacent to v in

and N(v) represents the set of nodes adjacent to v in  . The Minimum Identifying Code Set (MICS) problem is to find the Identifying Code Set of smallest cardinality. The vertices of the set

. The Minimum Identifying Code Set (MICS) problem is to find the Identifying Code Set of smallest cardinality. The vertices of the set  may be viewed as alphabets of the code, and the string made up with the alphabets of

may be viewed as alphabets of the code, and the string made up with the alphabets of  may be viewed as the unique “code” for the node v. For instance, consider the graph

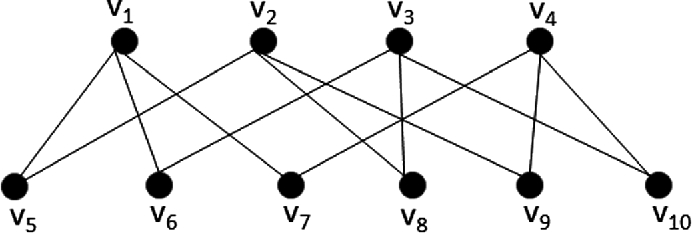

may be viewed as the unique “code” for the node v. For instance, consider the graph  shown in Fig. 4. In this graph

shown in Fig. 4. In this graph  is an ICS as it can be seen from Table 1 that

is an ICS as it can be seen from Table 1 that  is unique for all

is unique for all  . From the table, it can be seen that the code for node

. From the table, it can be seen that the code for node  is

is  , the code for

, the code for  is

is  , the code for

, the code for  is

is  , etc.

, etc.

Variation in width of SNR as one moves closer (in time) to instant of failure.

Standard deviation of width of SNR as one moves (spatially) away from the failing equipment.

Graph with Identifying Code Set { ,

,  ,

,  ,

,  }

}

results for all

results for all  for the graph in Fig. 4

for the graph in Fig. 4

|

|

|

|

|

|

|

|

|

|

Graph Coloring with Seepage (GCS) Problem: The MICS computation problem can be viewed as a novel variation of the classical Graph Coloring problem. We will refer to this version as the Graph Coloring with Seepage (GCS) problem. In the classical graph coloring problem, when a color is assigned (or injected) to a node, only that node is colored. The goal of the classical graph coloring problem is to use as few distinct colors as possible such that (i) every node receives a color, and (ii) no two adjacent nodes of the graph have the same color. In the GCS problem, when a color is assigned (or injected) to a node, not only does that node receive the color, but also the color seeps into all the adjoining nodes. For example, if a node  is adjacent to two other nodes

is adjacent to two other nodes  and

and  in the graph, then if the color red is injected to

in the graph, then if the color red is injected to  , not only

, not only  will become red, but also

will become red, but also  will become red as it is adjacent to

will become red as it is adjacent to  . Now if the color blue is injected to

. Now if the color blue is injected to  , not only

, not only  will become blue, but also the color blue will seep in to

will become blue, but also the color blue will seep in to  as it is adjacent to

as it is adjacent to  . Since

. Since  was already colored red (due to seepage from

was already colored red (due to seepage from  ), after color seepage from

), after color seepage from  , it’s color will be a combination of red and blue (purple). At this point, all three nodes

, it’s color will be a combination of red and blue (purple). At this point, all three nodes  ,

,  , and

, and  will have “distinct” colors red, blue, and purple, respectively. The color assigned to a node may be due to: (i) only injection at that node, (ii) only seepage from other adjoining nodes and (iii) a combination of injection and seepage. The colors injected at the nodes are referred to as atomic colors. The colors formed by the combination of two or more atomic colors are referred to as composite colors. The colors injected at the nodes (atomic colors) are all unique. The goal of the GCS problem is to inject colors to as few nodes as possible, such that (i) every node receives a color, and (ii) no two nodes of the graph have the same color.

will have “distinct” colors red, blue, and purple, respectively. The color assigned to a node may be due to: (i) only injection at that node, (ii) only seepage from other adjoining nodes and (iii) a combination of injection and seepage. The colors injected at the nodes are referred to as atomic colors. The colors formed by the combination of two or more atomic colors are referred to as composite colors. The colors injected at the nodes (atomic colors) are all unique. The goal of the GCS problem is to inject colors to as few nodes as possible, such that (i) every node receives a color, and (ii) no two nodes of the graph have the same color.

Suppose that the node set  is an ICS of a graph

is an ICS of a graph  and

and  . In this case if p distinct colors are injected to

. In this case if p distinct colors are injected to  (one distinct atomic color to one node of

(one distinct atomic color to one node of  ), then by the definition of ICS for all

), then by the definition of ICS for all  , if

, if  is unique, all nodes of

is unique, all nodes of  will have a unique color (either atomic or composite). Thus computation of MICS is equivalent to solving the GCS problem.

will have a unique color (either atomic or composite). Thus computation of MICS is equivalent to solving the GCS problem.

Identifying Code is useful when the goal is to monitor all nodes of the graph (i.e., each node is required to have a unique signature). However, in this paper our focus is on monitoring the health of only power transformers. Moreover, in Identifying Code a color can be injected at any node of the graph (i.e., a sensor can be placed at any node of the graph). However, in the health monitoring problem, a sensor placed far away from the equipment to be monitored, may not be useful as “cues” (signals) indicating failing state of the equipment, may not even reach this sensor because of its distance from the equipment. Accordingly, some modification to the original concept of Identification is needed. The following modifications are sufficient to capture the new scenario: (i) We identify a subset  that needs to receive a unique color; (ii) For each node

that needs to receive a unique color; (ii) For each node  , we compute

, we compute  , where

, where  represents the k-hop neighbors of v (i.e., the set of nodes in the graph whose shortest path distance to v is at most k); (iii). We construct a Bipartite graph

represents the k-hop neighbors of v (i.e., the set of nodes in the graph whose shortest path distance to v is at most k); (iii). We construct a Bipartite graph  such that (a)

such that (a)  , (b)

, (b)

, and (iii) for nodes

, and (iii) for nodes  and

and  , there is an edge

, there is an edge  , if and only if

, if and only if  . With this modification, the transformer health monitoring problem with the fewest number of sensors is equivalent to computation of the smallest subset

. With this modification, the transformer health monitoring problem with the fewest number of sensors is equivalent to computation of the smallest subset  such that injection of colors to this set of nodes ensures that each node in

such that injection of colors to this set of nodes ensures that each node in  receives a unique color through seepage. In this study, we restrict our attention to

receives a unique color through seepage. In this study, we restrict our attention to  or

or  only, as cues of deteriorating health of transformer may not be observable at distances

only, as cues of deteriorating health of transformer may not be observable at distances  (See Fig. 3).

(See Fig. 3).

A variation of Identification Code when restricted to Bipartite graphs is known as Discriminating Code [6], and is defined as follows: Let  be an undirected bipartite graph and let N(v), denote the neighborhood of v, for any

be an undirected bipartite graph and let N(v), denote the neighborhood of v, for any  , a subset

, a subset  is called the Discriminating Code of G if

is called the Discriminating Code of G if  is unique. We will refer to critical equipment health monitoring problem, with the fewest number of sensors, as the Monitoring Critical Equipment (MCE) problem, which may be stated formally in the following way:

is unique. We will refer to critical equipment health monitoring problem, with the fewest number of sensors, as the Monitoring Critical Equipment (MCE) problem, which may be stated formally in the following way:

MCE Problem: Find the smallest subset  , such that injection of colors at these nodes, ensures that each node

, such that injection of colors at these nodes, ensures that each node  , receives a unique color through seepage.

, receives a unique color through seepage.

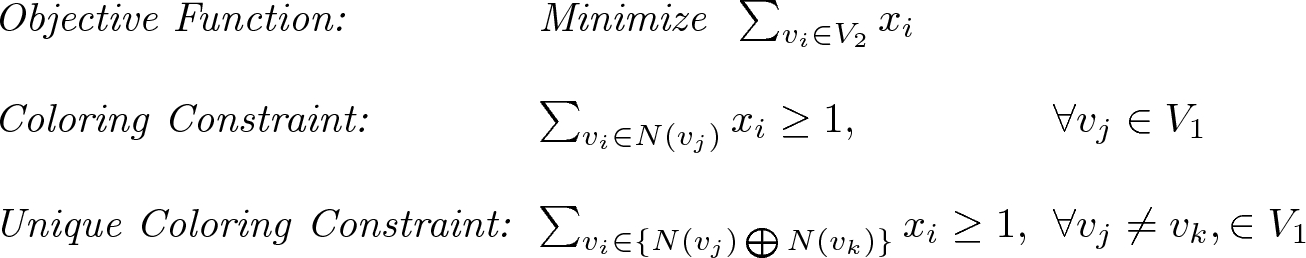

5 Problem Formulation

In this section, we formalize the problem of computing the fewest number of sensors to be deployed to monitor all critical equipments (HV transformers) in the power grid, so that, if they show signs of potential failure, then an operator in the control room, can uniquely identify them. Once the failing equipment is identified, corrective measures can be undertaken, such as a planned shutdown.

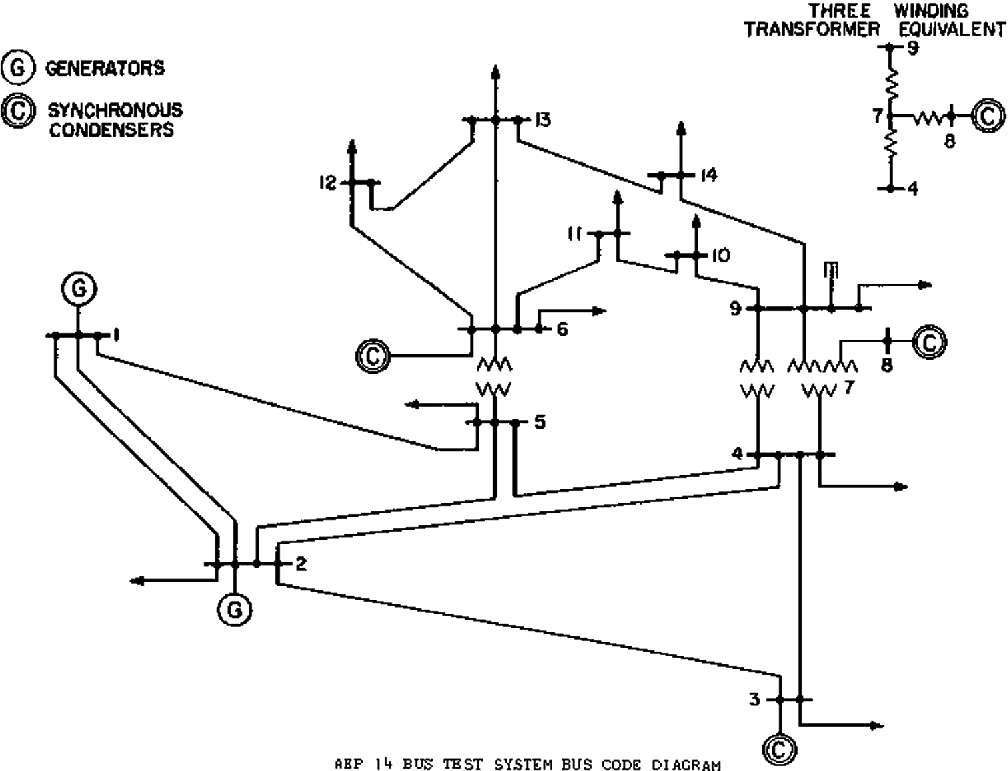

From our discussion in Sect. 4, it is clear that Identifying Code relates to an underlying graph. In order to use Identifying Code to find the fewest number of sensors to be deployed to monitor critical equipments, we first have to construct a graph from the single line diagram (SLD) of the power system. Consider the IEEE 14 Bus System shown in Fig. 5. We construct a graph  from the SLD, where each node represents either a bus or a transformer, and two nodes are connected by an edge if the corresponding buses, or bus and transformer are connected. The Fig. 6 shows the graph

from the SLD, where each node represents either a bus or a transformer, and two nodes are connected by an edge if the corresponding buses, or bus and transformer are connected. The Fig. 6 shows the graph  constructed from the IEEE 14 Bus SLD, shown in Fig. 5. In Fig. 6, the buses are represented by black circular nodes and the transformers by red square nodes. In power systems, the monitoring devices (such as the PMUs) can be placed on the ends of the transmission lines, next to the buses [2]. In Fig. 6, the potential locations where a monitoring device can be deployed are shown by small green squares.

constructed from the IEEE 14 Bus SLD, shown in Fig. 5. In Fig. 6, the buses are represented by black circular nodes and the transformers by red square nodes. In power systems, the monitoring devices (such as the PMUs) can be placed on the ends of the transmission lines, next to the buses [2]. In Fig. 6, the potential locations where a monitoring device can be deployed are shown by small green squares.

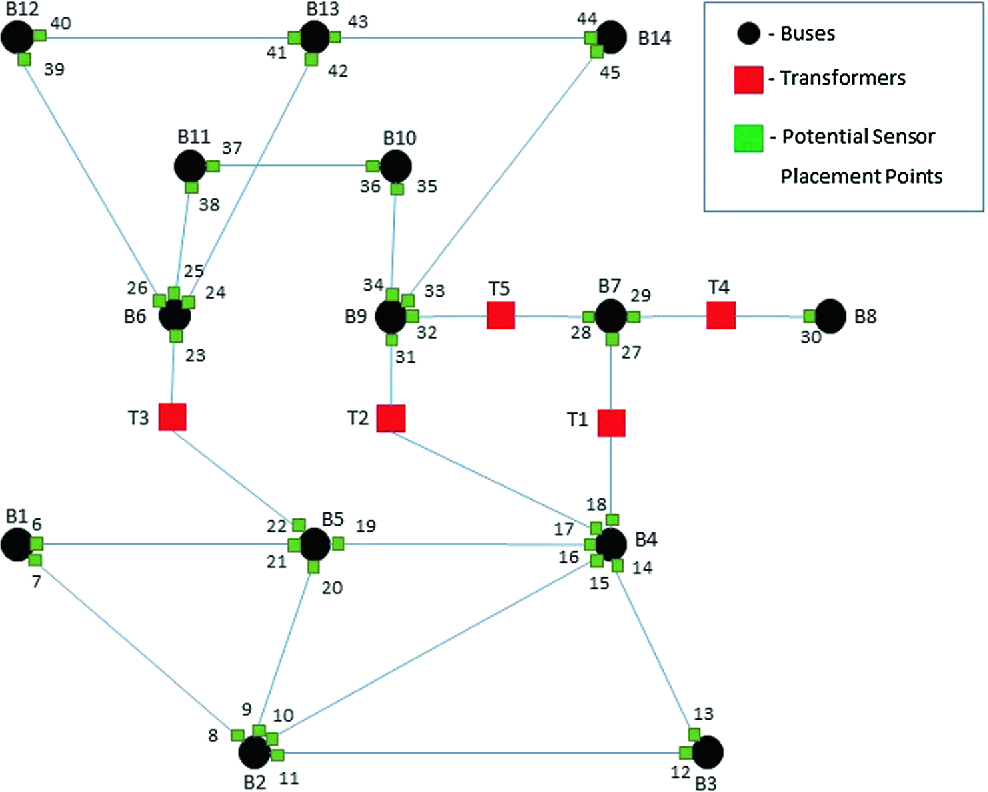

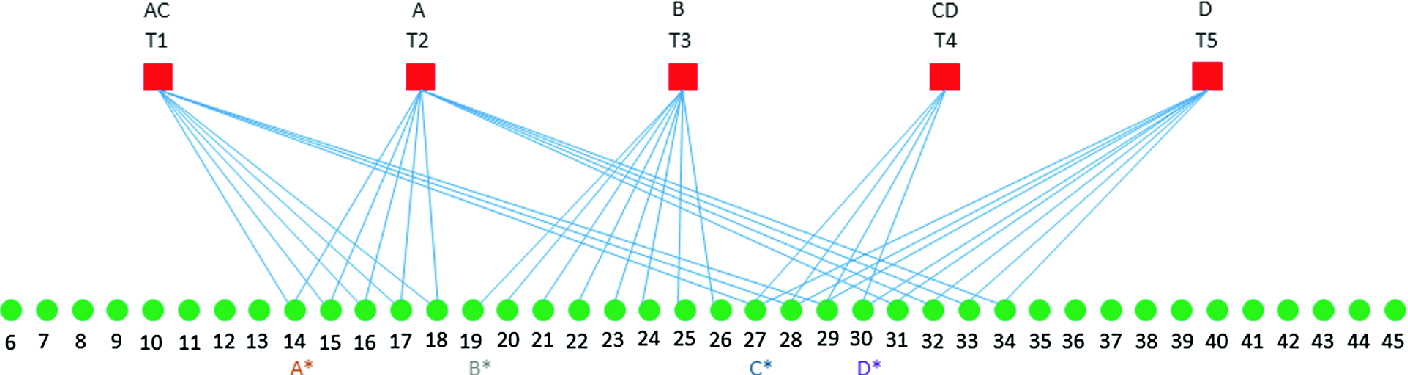

, where each node

, where each node  represents a red square and each node

represents a red square and each node  represents a green square. There is an edge

represents a green square. There is an edge  connecting nodes

connecting nodes  and

and  if the signal from the red square

if the signal from the red square  , represented by node

, represented by node  in Fig. 6, can reach the green square

in Fig. 6, can reach the green square  , represented by node

, represented by node  in Fig. 6. Such graphs corresponding to the IEEE 14 Bus System, with

in Fig. 6. Such graphs corresponding to the IEEE 14 Bus System, with  and

and  , are shown in Fig. 7 and Fig. 8, respectively. Since the IEEE 14 Bus System has 5 transformers (red squares in Fig. 6), the vertex set

, are shown in Fig. 7 and Fig. 8, respectively. Since the IEEE 14 Bus System has 5 transformers (red squares in Fig. 6), the vertex set  in the bipartite graphs shown in Figs. 7 and 8 has 5 nodes. Since, in the IEEE 14 Bus System, there are 40 potential locations for placement of sensors (green squares), in Fig. 6, the vertex set

in the bipartite graphs shown in Figs. 7 and 8 has 5 nodes. Since, in the IEEE 14 Bus System, there are 40 potential locations for placement of sensors (green squares), in Fig. 6, the vertex set  , in the bipartite graphs shown in Figs. 7 and 8, has 40 nodes (numbered from 6–45), denoted by green circles. It may be noted that when

, in the bipartite graphs shown in Figs. 7 and 8, has 40 nodes (numbered from 6–45), denoted by green circles. It may be noted that when  , only 21 out of 40 potential locations are viable locations for placement of sensors as the other 19 locations are not within 1-hop neighborhood of the transformers. However, when

, only 21 out of 40 potential locations are viable locations for placement of sensors as the other 19 locations are not within 1-hop neighborhood of the transformers. However, when  , all 40 nodes are viable locations for placement of sensors, as all of them are within the 2-hop neighborhood of the transformers. It may be noted that some of the nodes in Figs. 7 and 8, are labeled with strings such as “A”, “AC”, etc. The explanation and significance of these strings are given in Sect. 7.

, all 40 nodes are viable locations for placement of sensors, as all of them are within the 2-hop neighborhood of the transformers. It may be noted that some of the nodes in Figs. 7 and 8, are labeled with strings such as “A”, “AC”, etc. The explanation and significance of these strings are given in Sect. 7.

IEEE 14 Bus Test System

6 Problem Solution

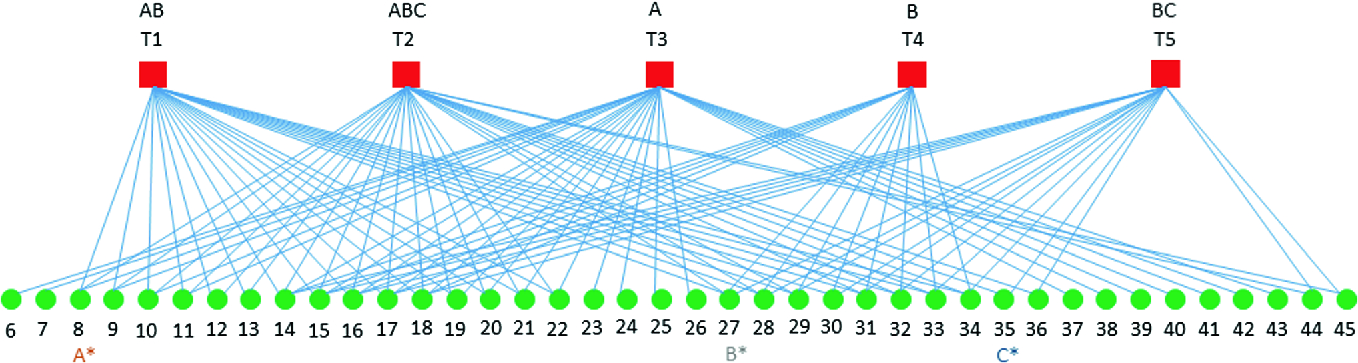

In this section, we provide an Integer Linear Programming (ILP) formulation for solving the MCE problem, as stated below.

Instance:  , an undirected bipartite graph.

, an undirected bipartite graph.

Problem: Find the smallest subset  , such that injection of colors at these nodes, ensures that each node

, such that injection of colors at these nodes, ensures that each node  , receives a unique color (either atomic or composite) through seepage.

, receives a unique color (either atomic or composite) through seepage.

to denote the neighborhood of

to denote the neighborhood of  , for any

, for any  . Corresponding to each

. Corresponding to each  , we use an indicator variable

, we use an indicator variable  ,

,

Potential sensor placement locations in IEEE 14 Bus System (Color figure online)

Bipartite graph corresponding to IEEE 14 bus system with for k = 1 (Color figure online)

Bipartite graph corresponding to IEEE 14 bus system with for k = 2 (Color figure online)

denotes the Exclusive-OR (symmetric set difference) of the node sets

denotes the Exclusive-OR (symmetric set difference) of the node sets  and

and  . It may be noted that the objective function ensures that the fewest number of nodes in

. It may be noted that the objective function ensures that the fewest number of nodes in  are assigned a color. The Coloring Constraint ensures that every node in

are assigned a color. The Coloring Constraint ensures that every node in  receives at least one color through seepage from the colors injected at nodes in

receives at least one color through seepage from the colors injected at nodes in  . A consequence of the Coloring Constraint is that, a node in

. A consequence of the Coloring Constraint is that, a node in  may receive more than one color through seepage from the colors injected at nodes in

may receive more than one color through seepage from the colors injected at nodes in  . The Unique Coloring Constraint ensures that, for every pair of nodes (

. The Unique Coloring Constraint ensures that, for every pair of nodes ( ) in

) in  , at least one node in the node set

, at least one node in the node set  is injected with a color. This guarantees that

is injected with a color. This guarantees that  and

and  will not receive identical colors through the color seepage from the nodes in

will not receive identical colors through the color seepage from the nodes in  .

.

7 Experimental Results and Discussion

In this section, we present the results of our technique on standard power system test cases, such as IEEE 14, 30, 57, 118, PEGASE 89 bus, and Polish 2383 bus systems. As discussed in Sect. 5, the IEEE 14 bus system has 5 transformers and 40 potential locations for placement of sensors. The bipartite graphs for the IEEE 14 bus system for  and

and  are shown in Figs. 7 and 8. Our results obtained from the solution to the ILP show that the 5 transformers can be monitored with 4 sensors when

are shown in Figs. 7 and 8. Our results obtained from the solution to the ILP show that the 5 transformers can be monitored with 4 sensors when  , and 3 sensors when

, and 3 sensors when  . As shown in Fig. 7, for

. As shown in Fig. 7, for  , if 4 sensors are deployed at nodes 14, 19, 27, and 30 (equivalently 4 colors A, B, C, and D are injected at these nodes, shown in Fig. 7 by A*, B*, C*, and D*), the 5 transformers T1 through T5 will receive unique colors AC, A, B, CD, and D, respectively. Similarly, for

, if 4 sensors are deployed at nodes 14, 19, 27, and 30 (equivalently 4 colors A, B, C, and D are injected at these nodes, shown in Fig. 7 by A*, B*, C*, and D*), the 5 transformers T1 through T5 will receive unique colors AC, A, B, CD, and D, respectively. Similarly, for  , if 3 sensors are deployed at nodes 8, 27, and 35 (equivalently 3 colors A, B, and C are injected at these nodes, shown in Fig. 8 by A*, B*, and C*), the 5 transformers T1 through T5 will receive unique colors AB, ABC, A, B, and BC respectively.

, if 3 sensors are deployed at nodes 8, 27, and 35 (equivalently 3 colors A, B, and C are injected at these nodes, shown in Fig. 8 by A*, B*, and C*), the 5 transformers T1 through T5 will receive unique colors AB, ABC, A, B, and BC respectively.

No. of sensors needed in IEEE, PEGASE, and Polish systems for  .

.

Bus system | No. of transformers | No. of sensors | |

|---|---|---|---|

|

| ||

IEEE 14 | 5 | 4 | 3 |

IEEE 30 | 7 | 6 | 4 |

IEEE 57 | 14 | 13 | 10 |

PEGASE 89 | 10 | 10 | 6 |

IEEE 118 | 9 | 9 | 5 |

Polish 2383 | 155 | 155 | 106 |

Our results for power system test cases are tabulated in Table 2. The results show that the number of sensors needed to monitor all the transformers are fewer than the number of transformers. On an average there were 6.90% and 37.90% savings in the number of sensors using our technique for  and

and  , respectively. From Fig. 3, it can be seen that the difference in the width of the SNR band in dB at substations

, respectively. From Fig. 3, it can be seen that the difference in the width of the SNR band in dB at substations  and

and  (1 and 2 hop distance away respectively, from the transformer) is minimal. Accordingly, we can use

(1 and 2 hop distance away respectively, from the transformer) is minimal. Accordingly, we can use  results, which implies that significant savings (37.90%) can be realized using our technique. The ILPs for the test cases were computed using GUROBI for python. An Intel Core i5-6300HQ CPU with 2.30 GHz and 32 GB RAM was used for our experiments. The computation time varied from 0.17 s, for the smallest test case (

results, which implies that significant savings (37.90%) can be realized using our technique. The ILPs for the test cases were computed using GUROBI for python. An Intel Core i5-6300HQ CPU with 2.30 GHz and 32 GB RAM was used for our experiments. The computation time varied from 0.17 s, for the smallest test case ( = 5,

= 5,  = 40, |E| = 36, k = 1), to 25.18 s (

= 40, |E| = 36, k = 1), to 25.18 s ( = 155,

= 155,  = 5,772, |E| = 3,655, k = 2) for the largest. As the computation times for these test cases were only a few seconds, we expect that for larger systems involving thousands of buses and hundreds of transformers, the problem can still be solved within a short period of time.

= 5,772, |E| = 3,655, k = 2) for the largest. As the computation times for these test cases were only a few seconds, we expect that for larger systems involving thousands of buses and hundreds of transformers, the problem can still be solved within a short period of time.

8 Conclusion

We present a novel technique involving PMU-based metrics and Identifying Code to find the least number of sensors to monitor the health of the critical equipments, such as HV power transformers. In the future, we plan to investigate (i) a fault tolerant monitoring system, where the system will be able to uniquely identify a failing critical equipment, even when one or more of the sensors are malfunctioning, and (ii) multiple simultaneous failure of critical equipments, in the sense that, not only failure of individual equipments will have a unique signature, but also failure of a set of equipments will have a unique fault signature.