5

FROM MENLO PARK TO WEST ORANGE

“TO INVENT, YOU NEED A GOOD IMAGINATION AND A PILE OF JUNK.”

MARY EDISON DIED at Menlo Park on August 9, 1884, at the age of twenty-nine. For Edison, it was the first of a series of events in his personal life between 1884 and 1886 that shifted his world from Menlo Park and New York City to West Orange, New Jersey, and Fort Myers, Florida. When her mother died, Edison’s daughter Marion remembered, “I found my father shaking with grief, weeping and sobbing.” If Edison planned to remain in Menlo Park, as Marion later claimed, that changed with Mary’s death.1

In the months after Mary’s funeral, Edison traveled with Marion. Accompanied by his telegrapher friend Ezra Gilliland, they visited the New Orleans Cotton Centennial Exposition in February 1885. At the exposition, Edison met Mina Miller, the nineteen-year-old daughter of Ohio inventor, farm equipment manufacturer, and Chautauqua Institution cofounder Lewis Miller.

In March, Edison, Marion, and Ezra Gilliland—joined by his wife, Lillian—traveled from New Orleans to Jacksonville, Florida. They stopped at St. Augustine before hiring a fishing sloop to take them down Florida’s west coast to Punta Rassa, at the mouth of the Caloosahatchee River. From Punta Rassa they sailed up the river to the small town of Fort Myers.

As Edison later recalled, “The town was at that time mostly a cattletown—mostly cattle and saloons, and the residents were mostly cattlemen and fishermen, cowboys were very common sights on the street.” The locale and climate might have appealed to Edison. Fort Myers, the local newspaper boasted, “offers advantages unequaled at any point in Florida. Its mild, bracing atmosphere tones up the system and sends the glow of health to the cheeks. To the tourist the wild, varying scenery of the tropics, interspersed with visions of grazing cattle and traces of civilization, afford much enjoyment.” Or maybe Edison appreciated the town’s booster spirit. On the eve of his visit, the Fort Myers Press predicted a boom: “Jacksonville even now regards Fort Myers as a rival and other points are jealous of our superiority.” In any case, before leaving Fort Myers he bought thirteen acres of riverfront property, about a mile from the town’s business district.

Edison and Gilliland planned to build adjoining cottages and a laboratory on the property, allowing them to escape the harsh northeastern winters. In the fall of 1885 workers began clearing the land and constructing a dock and riverfront bulkhead. Lumber for the prefabricated houses was cut in Maine. The ship carrying the lumber from Boston to Florida stopped in New York to pick up furniture for the houses and boilers and machinery for Edison’s laboratory. “The houses,” the Fort Myers Press reported, “are two story buildings, square roofed, with a broad piazza around three sides, while a large kitchen is attached to both.” They were completed in March 1886, during Edison’s honeymoon with his new wife, Mina.

In March 1885, Edison and Marion returned to New York, and Ezra and Lillian Gilliland returned to their home in Boston. Edison visited Boston several times in the late spring and summer of 1885 to discuss an experimental contract with the Bell Telephone Co. and spend time at the Gillilands’ summer cottage, Woodside Villa, on the north shore of Boston Bay. Mina Miller was a student at a Boston finishing school and a frequent visitor to Woodside Villa.

Edison winter home, Fort Myers, Florida, ca. 1909. Edison’s quote to a 1914 local newspaper, “There is only one Fort Myers in the U.S. and there are 90 million people who are going to find it out,” was adopted by Fort Myers as its motto.

Edison bought Glenmont, which included the twenty-nine-room Queen Anne–style house, a barn, a greenhouse, and thirteen acres of land, for $125,000 (about $3 million today). (© Gilbert King)

NO ONE KNOWS when Edison fell in love with Mina, but in a diary he kept in July 1885, he described being distracted by a vision of Mina on a Boston street. “Saw a lady who looked like Mina—got thinking about Mina and came near being run over by a street car—If Mina interferes much more will have to take out an accident policy.”

During their courtship Edison taught Mina Morse code so that they could communicate in private. An August visit to Chautauqua in upstate New York, where the Miller family had a cottage, gave Edison another chance to see Mina. He invited Mina to join him, Marion, and the Gillilands for a trip through upstate New York and New Hampshire, and at the end of the summer Edison tapped out a marriage proposal in Morse code on Mina’s hand during a carriage ride through the White Mountains. She tapped back, “Yes.”

Thomas and Mina were married at the Miller family home in Akron, Ohio, on February 24, 1886. Edison family lore holds that Edison gave Mina a choice of residences: a fashionable town house in New York City or a home in the country. Mina opted for a country house. Shortly before the wedding, Edison purchased Glenmont, one of the largest estates in Llewellyn Park, an exclusive residential community in West Orange, New Jersey. Designed by architect Henry Hudson Holly and constructed between 1880 and 1882, Glenmont was the home Henry C. Pedder, an executive for New York dry goods merchants Arnold, Constable & Co. In July 1884 Arnold, Constable accused Pedder of embezzlement and seized Glenmont. Eager to unload the house, on January 11, 1886, Arnold, Constable sold Glenmont—which included thirteen acres of land, a barn, a greenhouse, and several other outbuildings—to Edison for $125,000 ($3,080,000 today). Awed by the elaborate house and sprawling grounds, Edison said, “It is a great deal too nice for me, but it isn’t half nice enough for my little wife here.”

At Glenmont Mina and Thomas raised their three children: Madeleine, born May 31, 1888; Charles, born August 3, 1890; and Theodore, born July 10, 1898.

Mina and Thomas Edison, ca. 1908.

Thomas and Mina’s three children, left to right: Theodore, Madeleine (with her nurse, Helena McCarthy Doyle), and Charles.

Thomas and Charles Edison fishing at Bellaire, Florida, in 1900. In 1940, Charles wrote on the back of the photo, “We had been out in a small sailboat around the coral reefs. The biggest fish was mine!”

Mina was in charge of Glenmont. She hired and supervised the household staff, planned meals, purchased household supplies, paid bills, and dealt with repairs and maintenance. Being the young wife of a busy inventor who worked long hours was a strain for Mina. She was often lonely, especially during the 1890s when Edison spent long stretches of time working at his ore milling plant in the hills of northwestern New Jersey. But Mina had the education and upbringing to run an active household and uphold the Edison family’s social responsibilities. She defined her role as Glenmont’s “home executive,” and her goal was to provide Edison with a supportive home environment. As she told the magazine Collier’s in 1925, “My job has been always to take care of Mr. Edison—to take care that his home contributed as much as possible to his doing the work that he had to do to the best advantage. We have always put his work first, all of us. And we have tried to organize our home life to give results just as much as the laboratory.”

In an oral history interview recorded several years before her death in 1979, Madeleine was asked what she thought of all the books that had been written about her father. She liked some of them, but none were satisfactory, in her view, because they neglected his family life. From reading these books, she remarked, “You would think he was just sort of a robot and never stopped working—well, that wasn’t true.”

In one of Madeleine’s earliest memories of her father, she accompanied Mina to the Orange train station at the age of five to meet Edison upon his return from his ore milling plant in Ogden, New Jersey. “The most bedraggled man I have ever seen got off that train, and just covered in soot. I thought, my goodness, is that my father?”

Mina disciplined the children, but Thomas had definite ideas about how his children should be raised. One morning, he saw Madeleine lounging in a chair in her bedroom while a maid buttoned her shoes. Edison was furious. He told Mina, “No child of his would have her shoes buttoned by the maid, she’d button them herself.”

According to Madeleine, Edison liked the company of children and young people, but he disliked formal entertaining. Invariably, before one of Mina’s dinner parties, Edison would develop a severe case of indigestion. Mina would ask Madeleine to sit with the ill inventor upstairs, “to take his last words,” while she hosted their guests.

Edison spent Sunday mornings reading as many as five newspapers. In the afternoons he took walks with the children or enjoyed automobile rides—a favorite pastime. On Sunday evenings, the Edisons welcomed friends and members of Mina’s family, who gathered around the piano to sing songs or act out scenes from Shakespeare. At Christmas, the house would be filled with up to thirty guests, and during the winter the family regularly attended Tuesday night vaudeville shows in Newark. Mina went with misgivings. Driving past the Methodist church on the way to Newark reminded her that Tuesday was prayer meeting night.

When Thomas and Mina moved into Glenmont in 1886, he used space in the Edison Lamp Works in Harrison, New Jersey, for research. Edison planned to continue working on the electric light, but he had other ideas for new inventions and soon decided that he needed a new, larger laboratory closer to Glenmont.

Madeleine Edison married John Sloane in Glenmont’s first-floor drawing room in June 1914. The family held a private funeral service for Edison here on October 21, 1931.

IN JANUARY 1887, Edison purchased two acres of land in West Orange at the corner of Valley Road (now Main Street) and Lakeside Avenue to construct his new laboratory. To design the new facility, he hired Glenmont’s architect, Henry Hudson Holly, who submitted plans for a three-story brick building with 37,500 square feet of work space. Construction began in May. Later that spring, during a site inspection, Edison discovered that workers had built the lab’s walls one inch out of plumb. He promptly fired Holly and hired a new architect, Joseph Taft. During the summer, Edison decided that the building did not have enough research space, so he instructed Taft to add four one-story brick buildings—each 100 feet by twenty-five feet—to the original plan.

The West Orange laboratory was much larger than the Menlo Park lab, but it also reflected a significant shift in Edison’s approach to innovation. Edison still owned a controlling interest in his electric light manufacturing companies—then based in Schenectady, New York—and he planned to continue electric light research at West Orange. He also envisioned, however, developing a variety of simpler technologies that could be easily manufactured and marketed. “My plan contemplates to working on only that class of inventions which require but small investments for each and of a highly profitable nature & also of that character that the articles are only sold to jobbers. No cumbersome inventions like the electric light.”

Diversifying the products of his laboratory allowed Edison to apply ideas and concepts from one invention to another, which also helped to minimize marketing risks. If one Edison product did not succeed in the market, there were other products to support research and manufacturing operations. The Edison Manufacturing Co.—a firm that Edison organized in December 1889 to produce phonograph batteries and telephone and telegraph systems—pursued this strategy in the 1890s, when it began making a number of Edison products, including fan motors, motion picture equipment, and medical devices.

In August 1887, Edison outlined this innovation strategy in letters to two potential investors: William Lloyd Garrison Jr., a Boston wool merchant, and James Hood Wright, a partner in the banking firm of Drexel, Morgan & Co. The West Orange laboratory, Edison explained to Garrison, “will be equipped with every modern appliance for cheap and rapid experimenting, and I expect to turn out a vast number of useful inventions and appliances in industry.” Further, he told Wright that his “ambition is to build up a great industrial works in the Orange Valley starting in a small way & gradually working up.” Using skilled workers, tools, machinery, and technical knowledge, Edison would produce inventions quickly and cheaply, mass-produce them in factories, and return any profits back to the laboratory to support new research.

Edison outlined some of his new ideas for Henry Villard, another potential financial supporter, in January 1888. Along with continued work on the electric light and phonograph, he planned to develop ore milling technology and to invent a variety of other products, including a hearing aid, a mechanical cotton picker, a coal sorting machine, a machine for clearing snow off of streets, and artificial silk, ivory, and mother of pearl.

The inventor wanted Garrison and Wright to invest in his company, “which shall have sufficient capital at its disposal to erect and equip factories for the manufacture of all my inventions” and market them through a network of wholesalers and retailers. Creating this company would give Edison the capital he needed to finance laboratory research and construct factories. “I honestly believe,” Edison wrote to Wright, “I can build up a works in 15 or 20 years that employ 10 to 15,000 persons & yield 500 percent to the pioneer stockholders.” Edison reminded Wright of his reliability: “You are aware from your long acquaintance with me that I do not fly any financial kites, or speculate and that the works which I control are well managed.”

Wright politely put Edison off, telling him that he was going away on a trip and that he would talk to J. P. Morgan about the proposal when he returned. There is no evidence that Drexel, Morgan & Co. pursued the idea. Garrison expressed interest but doubted that Edison would find investors. “At present writing,” Garrison explained, “owing to the peculiar state of the money market, it is not easy to interest capital in new enterprises . . . the general attitude of capital is that of caution.”

By mid-September 1887, workers had completed half of the main building’s roof and the foundations for two of the one-story satellite buildings. Charles Batchelor, Edison’s close Menlo Park associate, came to West Orange in the fall to supervise the outfitting of the laboratory. While the workers continued construction, Edison and Batchelor scoured equipment and supply catalogs and filled notebooks with lists of chemicals, machines, tools, and supplies that Edison needed for the lab.

On November 25, Batchelor fired the boilers for the first time. On December 1 workers began laying the conductors that would supply electricity to Glenmont. In his diary on December 23, Batchelor noted that they had “lit up Edison’s house tonight for the first time from the laboratory.” No one knows when Edison occupied the lab for the first time, but the first payroll was for the week ending January 5, 1888.

The West Orange laboratory in the late 1880s.

Aerial photograph of Edison’s West Orange laboratory and manufacturing complex in the late 1920s.

EDISON SPENT $180,000 ($4,309,000 today) constructing what he called “the best equipped & largest laboratory extant.” He numbered the laboratory buildings one through five. Building 5—the main laboratory—housed a large research library, a stock room, two machine shops, a photography studio and darkroom, a lecture hall, and several experimental rooms.

Representing the forces driving the late-nineteenth-century industrial revolution—steam power, electricity, and information—Edison put the powerhouse at one end of the building and the library at the other. The steam boilers and generators in the powerhouse provided heat and electricity and powered the belt-driven machine tools in the laboratory’s machine shops. An eighty-foot brick chimney stack rose above the powerhouse.

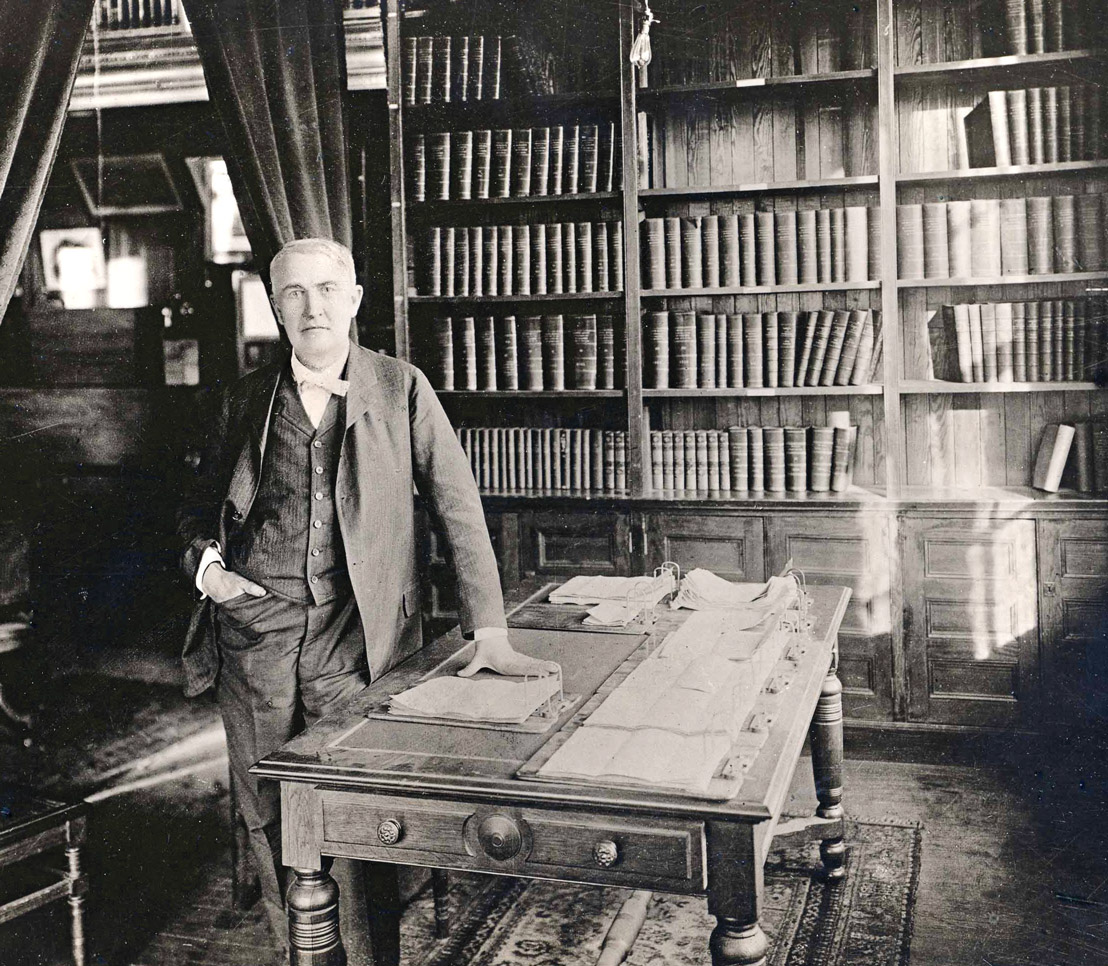

At the other end of Building 5 was the library—a large, ornate, high-ceilinged room that was paneled with varnished yellow pine. Above the main floor, where Edison and his secretaries kept their desks, were two balconies, divided into alcoves and filled with bookcases. Framed photographs, paintings, awards, and other mementos from Edison’s career decorated the library’s walls.

Edison in the library of the West Orange laboratory, 1904.

Edison used the library as a formal reception space. Mark Twain, who came to West Orange in 1888 to see Edison’s improved phonograph, was an early visitor. Twain was fascinated by new technologies (he was one of the first major authors to use a typewriter) and eager to use the phonograph as a dictating machine. Edison later recalled that Twain spent several hours in the library recording funny stories on wax phonograph cylinders. These recordings, unfortunately, were lost in a 1914 fire.

In October 1909, another notable visitor to West Orange was Baron Eiichi Shibusawa, the president of the Dai-Ichi Bank of Tokyo and chairman of a commission representing the Chamber of Commerce of Japan. On April 12, 1912, Edison entertained Rudolf Diesel, a German engineer who invented the diesel engine in 1893. Diesel was traveling through the United States with a delegation of German scientists and engineers who were studying American industrial museums.

The library was also a source of information for Edison and his staff. Today the library contains about 10,000 volumes, including published patent reports, bound scientific and technical journals, and books on a wide range of subjects. To succeed as an innovator, Edison needed information—not only the latest developments in science and technology, but also data on the economy, sources of capital, equipment and supplies, and the activities of his competitors, business associates, and partners. Innovators with better sources of information enjoyed advantages over less-informed rivals.

Stock room of the West Orange laboratory. Stock room clerks passed tools and supplies to machinists working in the heavy machine shop through this window. (Christopher Bain)

Edison kept himself informed in several ways: He was a voracious reader of newspapers and magazines. He relied on credit reporting agencies to monitor the financial standing of business partners. His West Orange staff continued a practice, started at Menlo Park, of keeping articles relating to Edison’s activities in scrapbooks. Later, in the early twentieth century, newspaper-clipping services routinely sent Edison-related articles to the laboratory, allowing him to track his image in the print media. Letters from business associates and consumers were another source of information, but keeping a well-stocked library was his primary means of keeping up-to-date on the newest scientific, technical, and business developments.

Across the hall from the library was the stock room, where Edison gathered the tools and materials his staff needed to develop new inventions. In 1927 Edison told Maurice Holland that the secret to inventing was to have a “big junk pile.” He explained to James Hood Wright in 1887, “I shall carry a stock of almost every conceivable material of every size.” Edison believed that maintaining a well-equipped stock room helped increase productivity by reducing the time experimenters would have to wait for supplies and equipment. “Inventions that formerly took months & cost a large sum can now be done in 2 or 3 days with very small expense,” he wrote.

As workers constructed the West Orange lab, Edison drew a rough floor plan in an 1887 notebook. He reserved space for a glass blower, a jeweler, and two of his principal experimenters, Charles Batchelor and John Ott. He later moved the chemistry lab to its own building.

An order list Edison drafted in the fall of 1887 included two pounds of horse hair, two pounds of hog bristles, one ounce of seal hair, four ounces of porcupine quills, a mouse skin with the hair attached, ten pounds of walrus tusks, and two ounces of shark skin. He also ordered less exotic material: iron, copper, nickel, hard and soft rubber, and chemicals. Edison did not know if his experimenters would need hog bristles, but if they did, it was better to have them on hand. The initial expense of stocking the laboratory was high, but Edison concluded that he would save money in the long run. “With the latest machinery a man will produce 10 times as much as in a laboratory which has but little material.”

Edison boasted to Wright that his laboratory was equipped to build everything from “a lady’s watch to a locomotive.” The heavy machine shop next to the stock room contained the machine tools capable of making the metal parts for large equipment, like steam locomotives. Large enough to employ fifty men, it contained drill presses, lathes, shapers, and milling and boring machines—all designed to cut, shape, and drill holes in metal. Rubber belts connected to shafts running along the ceiling on both sides of the room drove the machines. Two large direct current motors, mounted on a platform at one end of the shop, powered the two main shafts. An overhead traveling crane and six-ton chain hoist in the center of the room allowed machinists to easily move large metal pieces.

Heavy machine shop, West Orange lab. (Christopher Bain)

Precision machine shop on the second floor of Building 5. (Christopher Bain)

Above the heavy machine shop on the second floor was the precision machine shop, which contained lathes, grinders, and milling machines designed for smaller, more delicate work, like ladies’ watches. Today the precision machine shop extends from one side of the building to the other. When Edison opened the laboratory in 1887, a partition wall divided the room in half. The wall separated the precision machine shop from several experimental rooms, where Edison’s staff worked on specific projects. In one of these rooms (no longer in existence), researchers conducted the first experiments on motion pictures.

At Menlo Park, Edison and his team worked together in one large room. The West Orange laboratory floor plan allowed Edison to assign workers to specific rooms, which gave experimenters more privacy. The proximity of experimental rooms to the machine shops and stock room, however, gave researchers easy access to tools and supplies, as well as the machinists who could translate their ideas into working models and prototypes. By taking down or moving partition walls, Edison could alter the lab’s floor plan as his needs changed.

A door separated the precision machine shop from the rest of the second floor, which consisted of experimental rooms divided by a center hall. One room contained glass-blowing equipment for making experimental lamps, while another contained a mercury pump for creating vacuums in glass bulbs. Edison reserved Room 12 as his personal experimental space. Across the hall from Room 12, draftsmen took the rough sketches produced by Edison’s experimenters and turned them into the precise, measured drawings that machinists used to construct invention prototypes.

LEFT: Room 12, Edison’s private experimental room. (Christopher Bain) RIGHT: The Drafting Room on the second floor of Building 5. The proximity of the machine shops and the drafting room to experimental rooms allowed Edison and his staff to easily communicate with one another. (Christopher Bain)

The third floor of Building 5 included additional experimental rooms, exhibition space, a lecture hall, and a photographer’s studio and darkroom. The lecture hall—included in Edison’s original plan to demonstrate inventions to visitors and newspaper reporters—quickly became a music room, where researchers developed sound-recording techniques. In the early twentieth century, Edison used this room to evaluate sound recordings and audition musicians and singers for his record catalog. In the photography studio and darkroom, Edison’s staff produced the images used to advertise Edison’s products.

The one-story satellite buildings, positioned perpendicular to the main laboratory, were numbered one through four. Edison assigned specific functions or tasks to these buildings. Building 1, facing Valley Street, was the galvanometer room, which contained equipment for electrical research and testing. (A galvanometer is an instrument that measures electric current.) Because iron fittings interfered with magnetic instruments, this building was constructed with copper nails and brass pipes.

The galvanometer room reflected Edison’s continued interest in electric light research at West Orange. Most of this research during the late 1880s focused on improving the design and performance of electric lamp filaments. Contract research Edison performed during the late 1880s and early 1890s for his electric light companies was an important source of income. In 1889 these companies—the Edison Electric Light Co., the Edison Lamp Co., the Edison Machine Works, and Bergmann & Co.—merged into the Edison General Electric Co. In 1890 Edison General Electric agreed to fund half of Edison’s electrical experiments for five years. From 1890 to 1895, Edison received $121,000 ($3.3 million today) for research on direct current power systems and an alternating current motor. This contract remained in effect after April 1892, when Edison General Electric merged with a rival electrical manufacturer, Thomson-Houston Electric Co., to become General Electric. General Electric’s support of the West Orange laboratory ended in the late 1890s, when it opened its own research laboratory in Schenectady, New York.

Edison with Francis Arthur Jones in the chemistry lab, 1906. Jones, an English journalist, published a biography of Edison in 1908.

Edison in the chemistry lab, February 1908. In 1917, he told the New York Sun, “I have always been more interested in chemistry than in physics.”

The West Orange chemistry lab, as it appears today. (Christopher Bain)

A courtyard separated the galvanometer room from Building 2, the chemical laboratory, which contained a long room with rows of experimental tables and storage cabinets filled with chemicals, test tubes, Bunsen burners, and other research equipment. At the back of the chemical lab was a smaller balance room, where chemists weighed and analyzed chemical samples. (Weighing samples in a separate room, a common practice in chemistry labs, helped prevent fumes and dust from contaminating the chemicals.) A slightly inclined cement floor allowed easy spill cleanup, and eight brick chimneys ventilated chemical fumes.

Edison used the front section of Building 3 to store chemicals. The back section was a pattern shop, where carpenters made the wood patterns used to cast metal parts. The electric motors and belts that powered the shop’s saws and other woodworking tools were mounted under the floor to allow workers to move around large pieces of wood. Edison sent the patterns to local foundries for casting, but because patternmaking required close collaboration among experimenters, machinists, and carpenters, he kept this function in the laboratory.

Building 4 contained a forge, blacksmith’s shop, and metallurgical laboratory for analyzing and testing metals and ores, signaling Edison’s plan to pursue ore milling research. During the 1890s experimenters in this building designed machinery for processing iron ore. In the early twentieth century, the function of Building 4 shifted to research on phonograph record–manufacturing techniques.

Edison (front row, center) and the West Orange laboratory staff in 1893. Charles Batchelor is to Edison’s left, and John Ott is to Edison’s right. William K. L. Dickson, the principal experimenter on motion pictures, stands behind and slightly to the left of Batchelor.

DURING CONTRUCTION OF THE LAB in 1887, Edison drafted an employee wish list, which revealed that he wanted a staff that could handle a wide range of technical problems. Included on this list were a watch toolmaker, a telegraph instrument maker, a glassblower, a mechanic who could work with tin and copper, draftsmen, and a mechanic who understood lapidary—or precious stone—work. Edison also wanted someone familiar with optics, a photographer, and “one person familiar with scientific matters to translate French, German and Italian into English.”

The laboratory’s first weekly payroll in January 1888 listed sixty-six employees who were paid collectively $376.05 (about $9,170 today). Most of these workers were laborers, carpenters, and machinists who were busy “fitting up” the laboratory, but the payroll also listed experimenters who worked on the phonograph, ore milling, electric lamp filaments, telegraph systems, and wire insulation.

The number of employees fluctuated as Edison’s requirements changed. When the laboratory was busy, he added more experimenters to the payroll. During slack times he reduced the staff. The laboratory payroll for the week of June 12, 1890, for example, included fifty employees, who together were paid $805.22 (about $20,500 today). During the week of March 26, 1891, Edison employed sixty-nine workers, paid collectively $1,072.52 (about $27,400 today) to work on a variety of experiments, including ore milling, electroplating, wire insulation, phonograph record duplication, and street railway motors.

For the week of August 31, 1893, there were only forty-four workers on the laboratory payroll, including nine experimenters, seven machinists, eight draftsmen, two laborers, a patternmaker, a carpenter, and a part-time typist named Miss Mandeville. Edison’s experimenters—the highest-paid lab employees—were paid by the week. John F. Ott, the lab’s superintendent, earned $34.60 that week ($893 today). Each of the following workers earned thirty dollars ($774 today): John Ott’s brother Fred, who was one of Edison’s principal experimenters; William K. L. Dickson, who worked on ore milling and motion pictures; and Arthur Kennelly, who worked in the galvanometer room. Other occupations were paid by the hour. Edison paid machinist Charles Hopflinger 32.5 cents per hour, and for the sixty hours he worked during the week of August 31, he received $19.50 ($503 today). Draftsman Thomas Banks earned 67.5 cents per hour, while Miss Mandeville, who worked only forty hours that week, received $6.67.

Carpenters working in the pattern shop in January 1917.

BY THE EARLY TWENTIETH CENTURY, Edison had created an industrial works at West Orange. The laboratory stood at the center of a manufacturing complex that produced, among other things, motion picture equipment, phonographs, sound recordings, Portland cement, and storage batteries. Before 1910, these products had been manufactured and sold by separate companies. The Edison Manufacturing Co., for instance, made motion picture projectors and films, electric fans, and X-ray machines. The Edison Storage Battery Co. controlled storage batteries; the Edison Portland Cement Co. administered Edison’s cement business; the Edison Phonograph Works manufactured talking machines and records; and the National Phonograph Co. marketed them to consumers.

The laboratory continued to experiment on new technologies, but it also worked to improve existing Edison products and designed the tools and machines used to mass-produce factory products. Edison’s manufacturing and marketing companies, in turn, generated the profits that he needed to keep the laboratory in operation.

The informality of the Menlo Park and early West Orange periods—when Edison’s closest laboratory associates could easily move from the lab to company management positions—was replaced in the early twentieth century with a corporate bureaucracy defined by organizational charts. As always, Edison remained in control of his companies and had the final word on all major policies, but the scale and scope of the West Orange operation in the early twentieth century required him to delegate more responsibility to his company managers. It was still possible for talented lab associates to work their way up into managerial positions without professional experience, but a number of younger executives in the Edison organization had university training. For example, William Maxwell, who joined Edison in 1911 as a phonograph sales manager, had attended the University of Virginia. In 1915 he became general manager of the Edison Co. Phonograph Division. Stephen Mambert, a Cornell University–educated management engineer, began working for Edison as a cost accounting clerk in 1913. By 1916 he was a vice president responsible for implementing a plan to reduce financial costs.

Frank L. Dyer, a patent attorney who became Edison’s general counsel in 1903, also brought managerial and administrative skills to the Edison organization. Before becoming the president and general manager of the National Phonograph Co. in 1908, Dyer handled Edison’s complicated legal and patent affairs, including several contentious lawsuits that threatened the phonograph and motion picture businesses. In 1910 Dyer convinced Edison to approve a plan to consolidate his various companies into one corporate entity, Thomas A. Edison, Inc. Up to that point, Edison had used the profits from his successful phonograph and film businesses to support struggling ventures like the storage battery and Portland cement. Moving funds from healthy companies to struggling ventures allowed Edison to keep unsuccessful projects alive, but it also deprived the more profitable companies of capital for expansion. Dyer proposed merging the companies to reduce administrative expenses by centralizing accounting, legal, advertising, and other managerial functions. Another advantage, noted by Dyer—who coauthored Edison’s official biography, Edison: His Life and Inventions, in 1910—was to “bring home more firmly to the public that this is Mr. Edison’s personal business and that his personality stands behind it.”

According to folklore, lab workers placed this sign on the elevator in Building 5 as a joke, knowing that Edison preferred using the stairs. (Christopher Bain)

WHEN EDISON OPENED the West Orange laboratory at the end of 1887, he was already a world-renowned inventor who had made significant contributions in several industries. If he had done nothing else for the rest of his life, history would have remembered Edison for his work in telegraphy and the telephone, the invention of the phonograph, and the development of his incandescent electric lighting system. At age forty, however, Edison was still relatively young, and he was not content to rest on his laurels. Equipped with a steady stream of ideas, Edison worked at West Orange for the remaining forty-four years of his life—improving his phonograph; inventing a motion picture camera; developing technologies to process iron ore and manufacture Portland cement; building an improved storage battery; conceiving a method for constructing cement houses; and even attempting to cultivate a domestic source of natural rubber. Edison also became a manufacturer and marketer of his products and spent much of the First World War conducting research for the U.S. Navy. The remaining chapters discuss Edison’s “second act” as an innovator.

In the summer of 1888, researchers at West Orange conducted electrocution experiments on animals. These gruesome tests were part of Edison’s efforts to demonstrate the safety of his direct current (DC) electric power system and the dangers of George Westinghouse’s alternating current (AC) system. Edison’s system served an area of only one square mile. Alternating current, which distributed power at higher voltages and allowed power companies to serve larger areas, threatened Edison’s electric lighting system.

An opportunity to challenge the Westinghouse system came in June 1888, when New York State enacted a law changing its method of capital punishment from hanging to electrocution. The law did not specify what type of electricity would be used, and the state asked the New York Medico-Legal Society to work out the details.

Edison encouraged New York to use Westinghouse equipment. He personally opposed capital punishment, but he believed that alternating current was the quickest way to end a human life. To meet the goals of the electrocution law—which required faster, more efficient executions—experts needed more technical information, such as the amount of current and time required to kill a man, and the most effective way of wiring the prisoner to the equipment. To help New York State answer these questions, Edison offered the use of his staff and facilities at West Orange to perform electrocution experiments on animals.

From one perspective, the experiments were part of a cynical attack on a competitor. The physiological effects of electricity on living beings was poorly understood in the 1880s. Edison had a sincere concern about the safety of his electric power system, but he believed that his low-voltage DC system was safer than the AC system.

Over the course of the summer, Edison’s electrical expert Arthur Kennelly electrocuted fifty dogs, ten calves, and two horses, carefully noting in a laboratory notebook the results of each experiment. Kennelly conducted the first experiment on July 12, when he electrocuted a thirteen-pound fox terrier. Wet bandages wrapped with bare copper wire were applied to the dog’s legs. Kennelly applied a series of voltages, starting with 400 volts of DC and ending with a lethal dose of 1,000 volts.

Experimenter Arthur Kennelly carefully recorded the results of the animal electrocution experiments in a notebook. After leaving the West Orange lab, he taught electrical engineering at MIT and Harvard. (Christopher Bain)

No one knows where Edison got the animals. He had asked the American Society for the Prevention of Cruelty to Animals to send him dogs they were going to euthanize. The president of the ASPCA objected to the experiments.

The results of the electrocution experiments were tabulated and summarized in a report for the New York Medico-Legal Society. Not surprisingly, the report concluded that a 3,000-volt AC generator should be used in executions. A current of 1,000 to 1,500 volts applied for fifteen to thirty seconds was enough to cause death. In December 1888, the Medico-Legal Society accepted the report’s recommendations, and New York State prison authorities adopted alternating current.

A new word was needed to describe execution by electricity. Edison suggested “ampermort,” “dynamort,” and “electromort.” Edison attorney Eugene Lewis preferred “electricide,” but he also suggested using Westinghouse’s name. “As Westinghouse’s dynamo is going to be used for executing criminals,” he wrote, “why not give him the benefit of this fact in the minds of the public and speak of a criminal as being ‘Westinghoused.’”

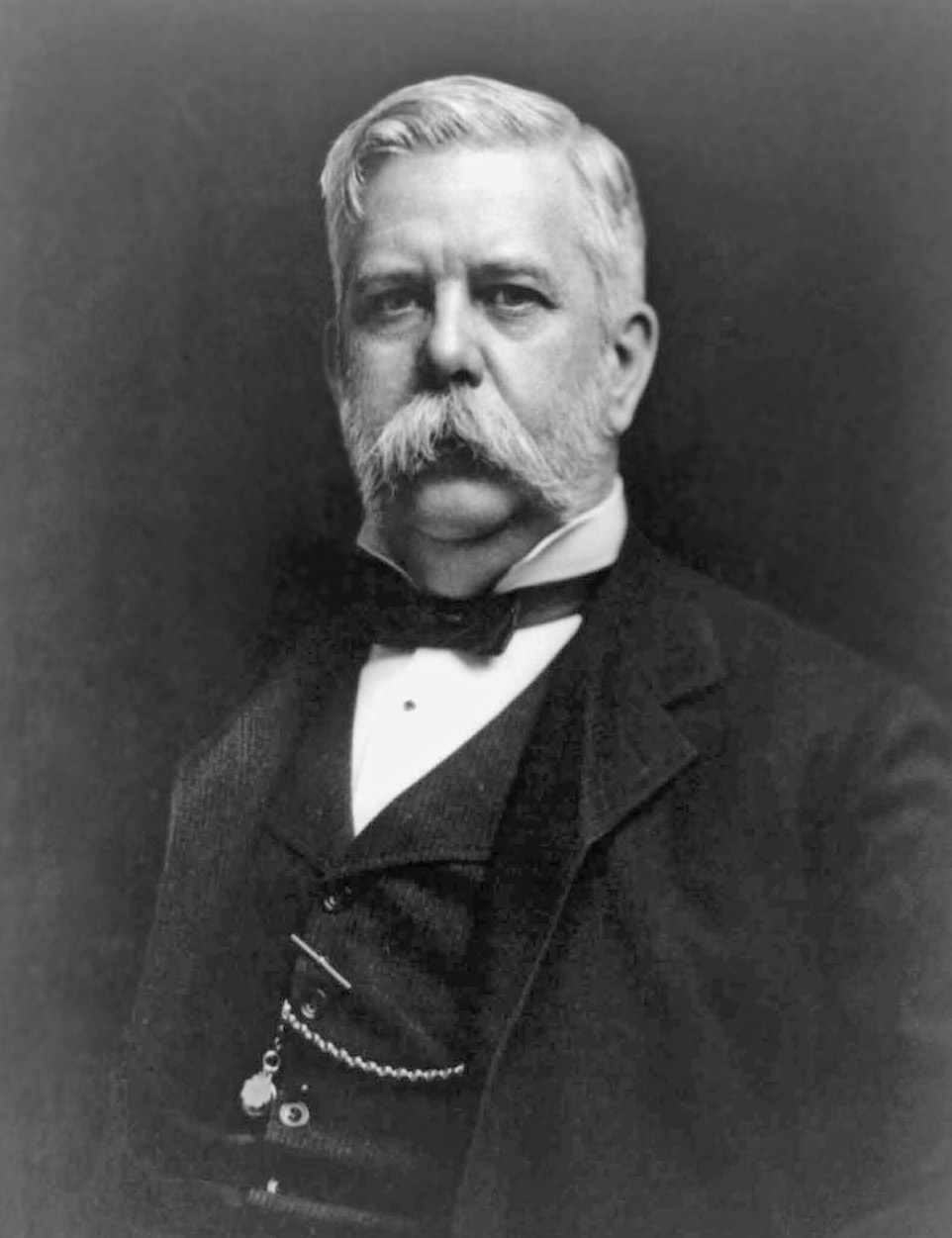

In June 1888, George Westinghouse, Edison’s competitor in the electrical industry, invited Edison to meet him in Pittsburgh to discuss cooperation between their companies. Edison politely declined. (Library of Congress)

On August 6, 1890, William Kemmler, convicted of murdering his lover Tillie Ziegler with an axe, became the first man in the United States to die in the electric chair at Auburn State Prison in New York. Kemmler’s execution was not quick and efficient, as the new capital punishment law intended, however. The first jolt of electricity failed to kill Kemmler, and a second seventy-second dose had to be applied.

Kemmler’s botched electrocution defeated the purpose of New York’s capital punishment law—to provide a more humane method of execution—but it was also a personal embarrassment to Edison. Ultimately, he lost the battle of the currents because AC was a more economical means of producing and distributing electricity. Cologne and Frankfurt were among the first cities in Europe to adopt AC electric power service in the early 1890s. In the United States, J. P. Morgan helped finance the Cataract Construction Co., organized in 1889 to generate hydroelectricity at Niagara Falls, New York. The company, which adopted the Westinghouse AC system, began servicing Buffalo in 1895.