8

“THERE IS MORE MONEY IN IRON THAN IN GOLD.”

EDISON SPENT MUCH OF THE 1890S developing a process for mining low-grade iron ore. His ore milling plant at Ogdensburg, New Jersey—the most expensive and complicated engineering project of his career—was based on a simple idea: Use powerful electromagnets to separate iron ore from rock.

Edison was interested in ore milling as early as May 1875, when he included “a cheap process for the extraction of low grade ores” on a list of proposed experiments. In 1879 he experimented on a process to magnetically separate platinum, which he sought for his electric light filament from the tailings, or waste, of gold mines. He also considered separating gold ore but soon focused on iron.

Charles Batchelor recorded these notes on ore milling magnet experiments on October 13, 1889.

With the support of two Edison Electric Light Co. investors, James Banker and Robert Cutting, in December 1879 Edison organized the Edison Ore Milling Co. to finance ore-processing research. On April 3, 1880, he signed a patent application for a magnetic ore separator, which consisted of a hopper that dropped a stream of crushed iron ore past an electromagnet. The magnet attracted the iron ore away from the nonferrous rock, forcing it to fall into a separate bin.

Edison planned to separate a deposit of black sand on a Long Island beach, but a storm washed it away before he could test the separator. Edison found another deposit of black sand on a beach at Quonochontaug, Rhode Island, but a fire in September 1881 destroyed the separator before it began operating. Edison quickly rebuilt the separator, which processed up to seven tons of black sand per day. The Poughkeepsie Iron and Steel Co., the only iron producer with a furnace that could smelt the ore’s fine particles, ordered 200 tons per month. Because of financial problems, however, the company canceled its order before the first shipment left Rhode Island. Edison closed the Rhode Island separator in December 1882.

When he resumed separator experiments in the spring of 1887, Edison increased the capital of the Edison Ore Milling Co. from $350,000 to $2 million in October 1887 to finance the endeavor. On December 27, 1888, he organized the New Jersey and Pennsylvania Concentrating Works to “mine, separate, smelt or otherwise heat, concentrate and deal in iron and other metallic ores.”

Although Edison was initially interested in using his ore milling process to separate gold ore, eastern U.S. iron manufacturers encouraged him to apply the technology to iron. During the 1880s, iron and steel production began shifting from blast furnaces in the East to mills in Illinois, Ohio, and western Pennsylvania, which were closer to newly discovered deposits of high-grade iron ore in the Midwest. Midwestern iron ore was easier and less expensive to mine because it was deposited near the surface. It was also low in phosphorus, which makes iron brittle. Many blast furnaces in Pennsylvania’s Lehigh Valley closed because they could not afford the cost of shipping iron ore from the Midwest.

There were ample deposits of low-grade iron ore in the East, but it contained a high percentage of nonferrous rock that had to be removed before it could be smelted. Conventional wisdom in the mining industry held that processing iron ore at the mine was expensive and inefficient. Edison turned this view around, betting that he could revive the eastern iron industry by inventing machinery to economically mine and concentrate low-grade iron ore.

Other inventors also worked on developing ore separators in the 1880s. By 1890 there were more than twenty experimental ore separators in the East, most operating on a small scale. Edison planned to process iron ore on a large scale, constructing plants that would mill up to 5,000 tons of ore per day. Further, he believed that lower shipping costs—he estimated that he could ship ore to eastern foundries for sixty-eight cents per ton compared to three dollars per ton of ore from the Midwest—would give him a competitive advantage.

In January 1889 Edison established the Edison Iron Concentrating Co., which constructed an experimental ore separator in Humboldt, Michigan. Walter Mallory, a Chicago iron manufacturer who later worked for Edison at Ogdensburg in the 1890s, managed the Humboldt plant, where he encountered a number of technical problems. Dust clogged the machinery, and iron particles stuck to the magnets, so he temporarily closed the mill while Edison worked on solving the problems at West Orange. Mallory reopened the separator in the spring of 1889, but the Edison Iron Concentrating Co. lacked capital for expansion. Edison abandoned the Humboldt project after a fire burned the separator in December 1890.

The Ogden mill separator building. The three towers housed ore dryers. In 1894 Edison wrote, “The mill as it stands today is the largest crushing plant in the world.”

“The giant rolls are what might be called the spectacular feature of the whole plant . . . to see them seize a 5-ton rock and crunch it with less show of effort than a dog in crunching a bone gives one a vivid sense of the meaning of momentum.” Scientific American, January 22, 1898.

In the spring of 1889 at the Gilbert Mine in Bechtelsville, Pennsylvania, Edison constructed his first eastern iron ore separator. The endeavor was short-lived; although he was pleased with the performance of this separator, the poor quality of the mine’s iron ore forced him to close it in April 1890.

Humboldt and Bechtelsville were small experimental plants that gave Edison and his staff valuable technical experience, but for his process to succeed economically, he needed to test it on a large scale. To find a site for this larger plant, Edison identified iron mines on geological and topographic maps, then sent out teams of surveyors with magnetic dipping needles to survey and map the ore deposits. By 1893 Edison had mapped the primary iron ore deposits from Connecticut to Virginia. “It is certain,” he boasted, “that there is no magnetic deposit of ore of any considerable extent in the East that is not known to us.”

An engineer stands next to a Corliss steam engine in the Power House. Steam from the large engine powered the crushing rolls and generated electricity for the separator magnets.

Edison found a promising location for his ore milling plant in the highlands of northwestern New Jersey, two miles south of the village of Ogdensburg. The Ogden Mine, which had been worked since 1772, contained a deposit of iron ore three miles long, 600 feet deep, and an average width of 400 feet. It also was near the New York, Susquehanna, and Western Railway, which allowed Edison to easily transport supplies and equipment for the plant, as well as providing rail access to eastern iron foundries. In July 1889, the New Jersey & Pennsylvania Concentrating Works approved the construction of an ore milling plant at the location and, to finance it, increased its capital stock from $30,000 to $150,000 ($757,000 to $3.8 million today). Edison purchased or leased mineral rights for 19,000 acres at Ogden in October.

LEFT: A worker stands atop the giant crushing rolls at the Ogden ore milling plant, 1895. RIGHT: In this 1897 pocket notebook, Edison listed daily salaries for crushing plant employees. Managers earned $4 per day ($112 today), and cleaners were paid $1.25 ($35 today).

Completed in 1890, the Ogden ore milling plant used jaw-type crushers to process iron ore, shipping 100 tons of ore to the Bethlehem Iron Works and the Pennsylvania Steel Co. in April 1891. The Bethlehem Works ordered 100,000 tons in May, but the iron companies complained about the ore’s high phosphorus content. Edison also faced several technical problems that prevented the mill from operating at full capacity, including separators that left too much iron in the tailings and separator screens that became clogged with wet or damp ore. More significantly, the plant could not concentrate iron ore at a price competitive with high-grade midwestern ore because of high operating expenses—particularly the labor necessary to mine and load iron ore into the separator. Edison decided that the jaw-type crushers were unsatisfactory and began experimenting on roll crushers. Charles Batchelor, semiretired but an occasional helper of Edison at West Orange, researched the phosphorus problem and found that it was caused by dust clinging to wet crushed ore. To solve the problem, he added a drying and washing step to the ore milling process.

Edison left the operation of the Ogden mill to Harry Livor, the general manager of the New Jersey and Pennsylvania Concentrating Works, and P. F. Gildea, the Ogden plant superintendent. In the spring of 1891, though, Livor resigned following allegations of mismanagement of the company, and Edison fired Gildea after he recommended that Edison abandon the separator and extract ore in the traditional manner.

In June 1891, Edison assumed personal responsibility for the ore milling plant and went to Ogden to “fix all the problems.” Walter Mallory, who began working at Ogden in early 1892, later testified that Edison had spent $1.4 million ($35.7 million today) on the ore milling project at that point, primarily to purchase the mining property, construct the mill, and pay for experiments. Before Edison ended the ore milling project in 1900, he would spend much more.

IN APRIL 1892, Edison added a bricking plant to the ore milling process. The Ogden mill shipped its ore to iron foundries in fine particle form, so when the iron producers loaded it in furnaces in large quantities, the fine particles blew out. Edison corrected this problem by developing a resin that, when mixed with the crushed ore, allowed it to be molded into briquettes the size of hockey pucks.

At the end of 1892, Edison decided to dismantle the plant and build a new one from the ground up. To pay for the new plant, the New Jersey and Pennsylvania Concentrating Works increased its stock to $1 million. However, a severe economic depression in 1893 dried up sources of capital, and the next two largest stockholders after Edison refused to invest further in the project. Undaunted, Edison decided to support the ore milling plant with his own money.

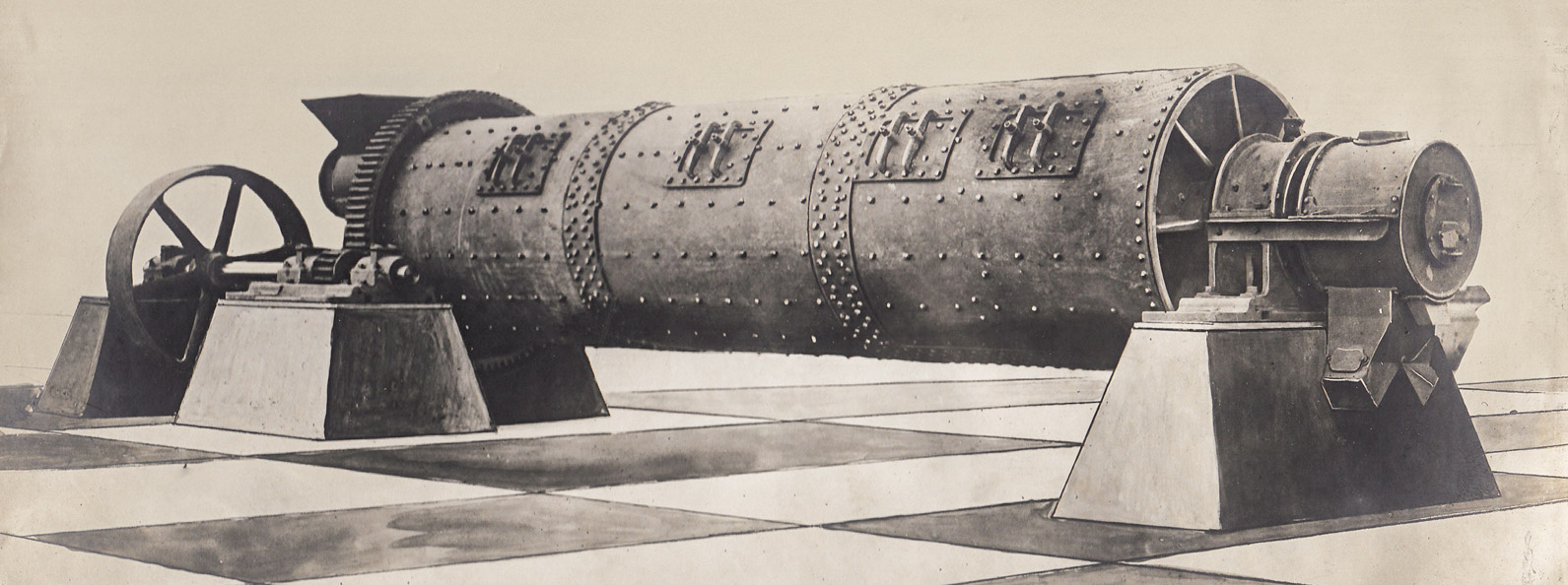

To increase the capacity of the new ore milling plant, Edison replaced the inefficient jaw-type crushers with a set of thirty-five-ton crushing rolls, each five feet long and six feet in diameter, which could crush rocks weighing as much as six tons. Edison calculated that it would be less expensive to crush rock with machinery powered by coal at $3 per ton than blasting the rock with dynamite at $250 per ton.

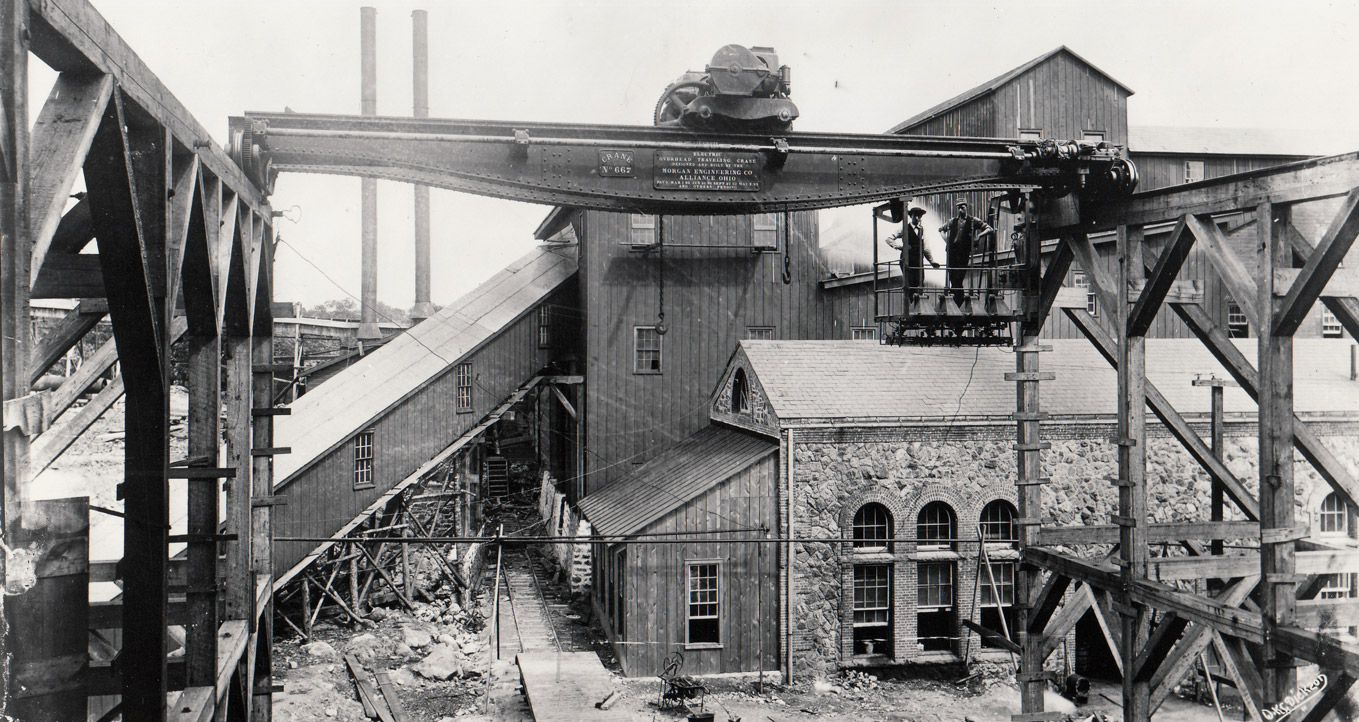

Edison installed a six-ton electric crane at the Ogden mill to move giant boulders in 1893. Behind the crane are the stone power house, the crushing mill, and part of the bucket conveyor shed.

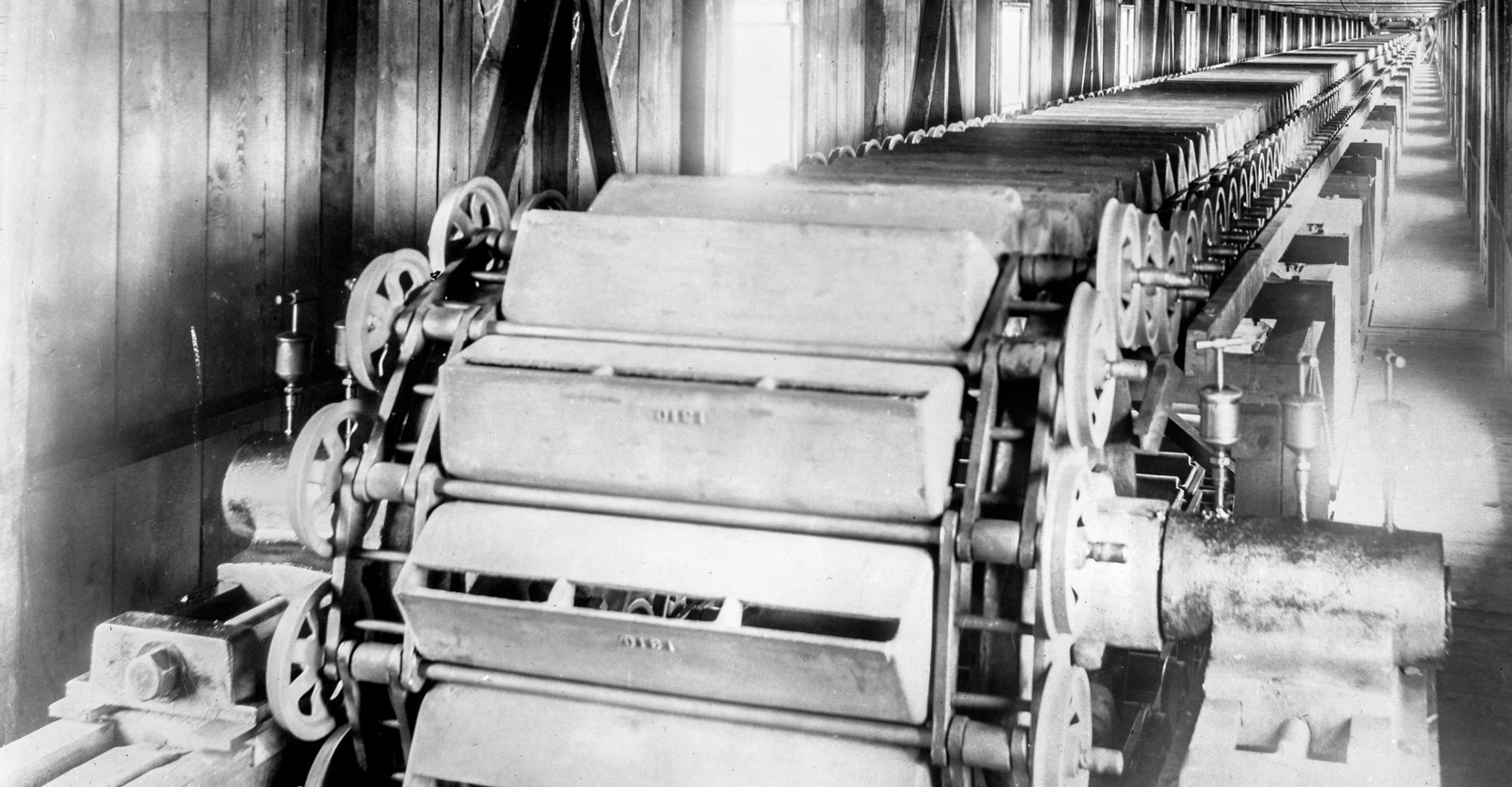

Edison automated as much of the plant as possible. Instead of employing workers to move iron ore by hand, the plant used steam shovels to scoop up the rocks, and traveling cranes loaded them onto rail cars, which brought them to the crushing rolls. A crane then dropped the ore between two giant rolls that turned in opposite directions. After the ore passed through the giant rolls in the crushing house, conveyor belts and elevators moved the ore through a series of successively smaller crushers that reduced the rock to fine particles. The ore was dried before conveyors moved it to the stock house.

From the stock house, conveyor belts transported the ore to the separating mill, where it passed through a series of screens and magnets to separate the iron from sand. Wasting nothing, Edison recovered the sand and sold it as a building material. Phosphorus on the concentrated ore was removed in a dusting chamber (the dust was also recovered and sold as a paint additive). After de-phosphorizing, the ore was molded into briquettes and loaded onto rail cars.

Construction of the giant crushing rolls, a critical component of the ore milling plant, was completed in early 1894. When Edison conducted his first test of the rolls in April, he discovered a number of flaws. The wood foundations supporting the rolls were not strong enough to prevent them from misaligning, which jammed the shaft bearings. The pulleys and belts driving the rolls broke. When a large rock was dumped into the rolls at an improper angle, it merely jumped up and down atop the crusher. Thus, Edison had to spend the remainder of 1894 and the first six months of 1895 redesigning the rolls.

Edison patented a bucket conveyor system to move crushed ore around the plant. Preventing dust from clogging the rollers and bearings was a difficult technical challenge.

The problems didn’t end there, though. In late 1895, Edison’s workers discovered that the links controlling the plant’s elevators had deteriorated, requiring the redesign and reconstruction of the mill’s entire elevator system. Further, lack of funds prevented Edison from working on the ore milling plant during the first six months of 1896. Construction work resumed at Ogden only on a limited basis in the latter part of the year because the endeavor was still short of cash.

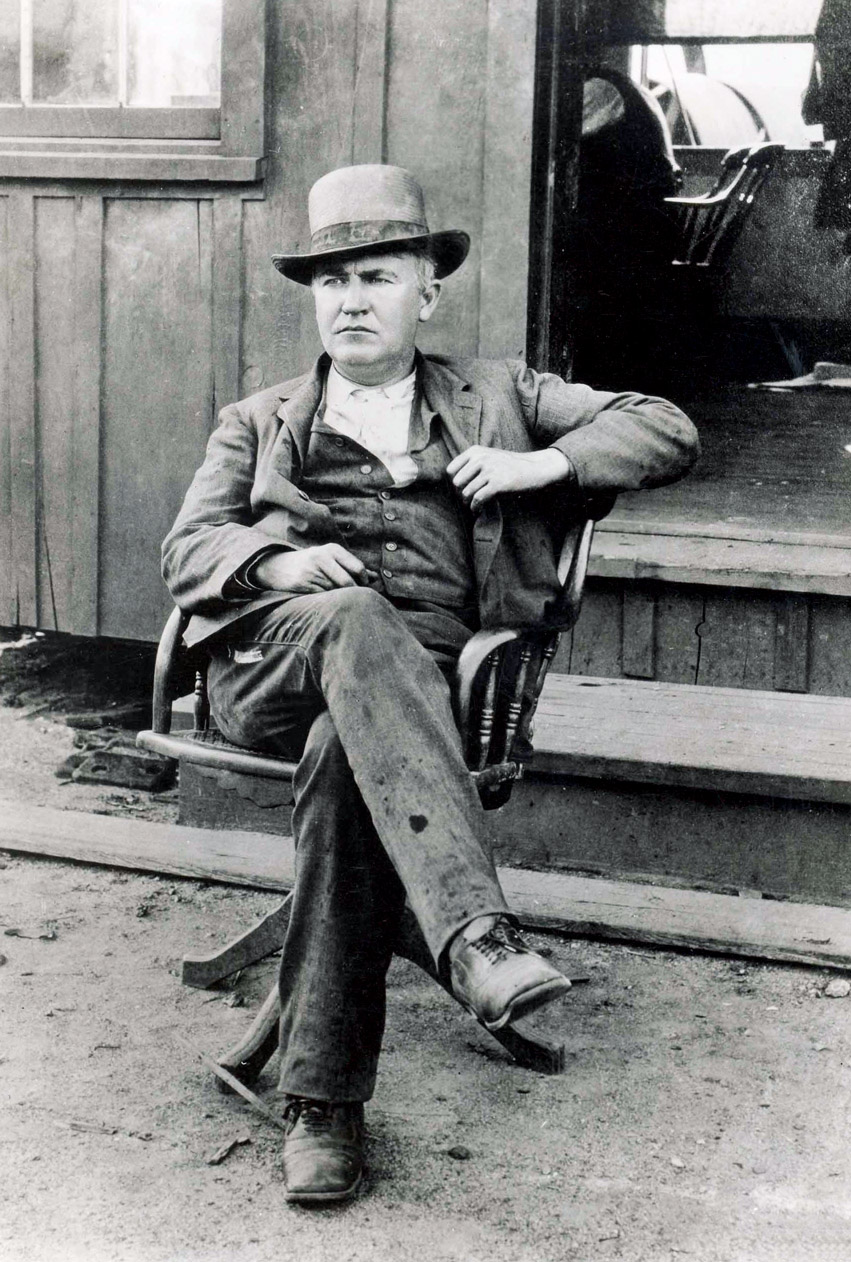

DESPITE THE HARDSHIPS and long hours—Edison typically clocked sixteen- to eighteen-hour days, except on Sunday, when he returned to West Orange—the inventor relished his time at Ogden. Former mine employee Dan Smith recalled that “these were happy days for Mr. Edison—Fine air, plenty of work, good food.” The challenges of solving complex technical problems free from investor interference and other distractions were only part of the appeal. Edison and his workers (as many as 2,000 at one point) formed a community that worked, lived, and played together in what Smith called “a lovely setting of woods with gorgeous chestnuts and other trees.”

Edison outside his office at the Ogden mill, 1895.

Edison’s workers and their families lived in comfortable bungalows equipped with electric lights. The men had little time to keep gardens, but some raised pigs and cows. To amuse themselves, workers staged boxing matches and rattlesnake and cockfights. The mill workers, Smith remembered, “liked the comfortable homes, the pleasant community life. Life might have seemed lonely to an outsider but it wasn’t. Even the women were sorry to leave when the great experiment was over.”

According to Smith, Edison’s personal courage inspired loyalty. “He would never send a man anywhere that he would not go himself,” Smith recalled. “Often the men would remonstrate with him for going into dangerous places.” The ore milling plant was a hazardous work site. In August 1892, five workers were killed and twelve injured when a partially constructed stock house collapsed. Edison supervised the rescue of injured employees buried under heavy wood timbers.

Benjamin Odell, an electrical engineer who worked at Ogden, noted that the men liked Edison “because he was one of them. He ate with them, slept with them. He loved to swap lunches with them. He preferred the workmen’s fare of hard-boiled eggs & corned beef to chicken.”

Edison’s love of practical jokes also endeared him to his workers. On one occasion Edison entertained a visiting titled Englishman, who was, as Smith described him, “a bit fussy about the dust from the mine on his clothes.” When Edison became bored with the visitor, he told Smith, “Let’s initiate him. When I get him under that platform you dump that chalk over him.” Smith followed orders. “When the Britisher arrived at the fatal spot, over went the chalk. The Englishman’s eyes, nose and mouth were filled & he had to be carried out half stifled.” Edison simulated a “towering rage and swore like a pirate,” while the workers pretended as if they didn’t know anyone had been under the platform.

With Edison’s assent, workers also mocked his reputation. When too many visitors showed up at the mill, an employee would ask Edison to come out of his office and “walk up & down and show ’em what genius looks like.” Obligingly, Edison would “saunter up & down a few times & then turn his back on the lion hunters who would go away satisfied.”

At the end of a long day, after the evening meal, Edison gathered his men to talk about work problems in sessions he called “going to school.” Edison, Smith remembered, “loved to rag his men, to haze them with questions—just to see if they really knew what they were doing.” During these evening meetings, Edison sat in the background, puffing on a cigar, while the men discussed and debated technical issues. The inventor appeared inattentive until someone raised an interesting argument, at which point he would join the conversation. Edison, according to Smith, “always could hear what he wanted to, or when you didn’t want him to.” He expected his workers to argue with each other and with him. If he won an argument, he would pull out a pair of large donkey ears and prance around the room. If an employee scored a point, he would get to wear the ears. When the oral history interviewer asked Smith what happened if you did not go to school, Smith answered grimly, “We went.”

The oral histories left by Dan Smith and Benjamin Odell portray Ogden as an idyllic work environment, but there were also hints of the strife that plagued labor-management relations in the late nineteenth and early twentieth centuries. In August 1896, machine shop workers, demanding time and a half for more than ten hours of work and double time on Sundays, threatened to strike. Edison fired all of the employees except for a few workers before the machinists could hold a strike vote.

IN EARLY 1897, the inability of the giant crushing rolls to efficiently break up large rocks was Edison’s biggest challenge. He improved the crushing rolls by adding steel plates with four-inch-high knobs, and tests were promising, but some of the larger rocks stripped the bolts from the plates. After Edison found a way to secure the bolts in the summer of 1897, he told Mallory, “That damn Giant Roll problem is at last solved, the rolls will now crush anything that will go into the hopper.”

Nevertheless, during the late 1890s, Edison and his staff faced other engineering problems and equipment failures that prevented the plant from operating at full capacity. These technical issues required constant attention, prompting Edison to design and redesign machines for crushing, conveying, screening, separating, and drying iron ore.

Employees of the New Jersey & Pennsylvania Concentrating Works in 1894. Edison expected automation to reduce the number of workers he needed to operate the Ogden mill, but in the mid-1890s there were about 400 employees on the payroll.

The improvements were expensive. Of the $2.5 million invested in the ore milling experiment ($69.1 million today), Edison spent $2,174,000 of his own money. Work at Ogden proceeded irregularly during 1898 and 1899, as Edison and Mallory scrambled to find money to pay the plant’s expenses. Edison drew funds from his two profitable companies, the Edison Manufacturing Co. and the National Phonograph Co. According to Mallory, “Mr. Edison and I would figure up the probable profits for the next few months and proceed to spend them and then later on go back to the manager of the Phonograph Co. and other company and tell him that we had these debts, which had to be paid.” This angered the manager of the National Phonograph Co., William Gilmore, who needed company profits to expand the phonograph business. This continued until 1900, when Edison had expended all of the money available to him. Reluctantly, he closed the Ogden mill in September 1900.

The ore milling story did not end at Ogden, however. In response to international interest in Edison’s ore milling process, a group of investors organized the Edison Ore-Milling Syndicate, Ltd., in June 1898. The syndicate, created to control Edison’s foreign ore milling patents, initially planned to license the ore milling technology outside of the United States and Canada on a royalty basis. It soon decided, however, to operate its own ore milling plant on the west coast of Norway, 200 miles north of Trondheim. Edison believed that an ore milling plant at the site, known as the Dunderland tract, would “pay an interest on 50 million dollars if done on a large scale.”

The Standard Construction Corp., Ltd., organized in February 1902, constructed the mill, rail lines, docks, and other plant facilities at the remote location. The Dunderland Iron Ore Co., Ltd., established in the spring of 1902, operated the plant.

The operators at Dunderland experienced the same problems that Edison had faced at Ogden, including dust-clogged machinery, but by 1908 the plant produced 800 tons of ore per day and had shipped 30,000 tons of briquettes. Declining iron ore prices, however, prevented the plant from operating at a profit. In 1909, it slipped into bankruptcy.

Edison’s laboratories did not pursue scientific research. As he told a Brooklyn newspaper in 1888, “I am not a scientific man, I am an inventor. . . . A scientific man busies himself with a theory. He is absolutely impractical. An inventor is essentially practical.” Nevertheless, Edison kept informed of scientific advances, and when news of German scientist Wilhelm Röntgen’s discovery of X-rays reached the United States in January 1896, he quickly began experiments to investigate the phenomenon. Optimistically, he told reporters that he could invent a practical X-ray apparatus in “two or three days.”

While studying electrons emitted by a vacuum tube, Röntgen noticed that the electrons caused a nearby fluorescent screen to glow. Röntgen eventually produced an image of the bones of his wife’s hand, but producing X-rays required a stable vacuum and precise voltages—a consistency that was difficult to achieve with available vacuum tubes.

Edison’s X-ray experiments focused on designing a more reliable vacuum tube. Relying on the expertise of his chemists and glassblowers and on his own experience working with vacuum tubes during his electric light research, Edison designed a marketable X-ray tube. The laboratory staff also tested the effect of X-rays on different substances and made X-ray images on photographic plates. At the request of newspaper publisher William Randolph Hearst, the lab attempted, without success, to X-ray a human brain.

To reduce the time it took to expose an X-ray image on photographic film, Edison’s experimenters began work on a “real-time” X-ray image viewer. This involved identifying the substance that produced the best fluorescence. Tests of more than 1,300 chemicals revealed calcium tungstate as the most fluorescent material.

Edison touted the medical benefits of his X-ray viewer, which he named the “fluoroscope.” On March 26, 1896, a press release announcing the invention noted, “It will be invaluable to surgeons in locating the seat of injuries.” For several years, the Edison Manufacturing Co. sold X-ray “outfits” that included vacuum tubes, fluoroscopes, and accessories to doctors and hospitals.

By the fall of 1896, news reports that X-rays might play a role in curing blindness competed with accounts of the health risks of prolonged X-ray exposure. Weeks of experimenting with X-rays caused stomach and eye problems for Edison, and Clarence M. Dally, his principal researcher on the project, eventually succumbed to cancer in October 1904.

LEFT: German physicist Wilhelm Röntgen’s experiments on vacuum tubes led to the discovery of X-rays. (National Library of Medicine) RIGHT: Page from an Edison notebook, listing chemicals tested during the X-ray experiments.

The tension between the benefits and risks of X-rays emerged in the medical treatment of President William McKinley, who was shot on September 7, 1901, while attending the Pan-American Exposition in Buffalo, New York. The president’s secretary called West Orange and asked Edison to send his best X-ray machine and technicians so that doctors could locate a bullet lodged in McKinley’s abdomen.

The X-ray machine and two Edison employees arrived at Buffalo on September 8. Doctors wanted to test the machine on another person before using it on the president, but they needed someone of McKinley’s size. A local doctor with a fifty-six-inch waistline reluctantly agreed to the test. The test succeeded, but McKinley’s doctors, concerned about side effects, decided not to expose him to X-rays. The bullet was never located, and McKinley died of a gangrene infection on September 14.

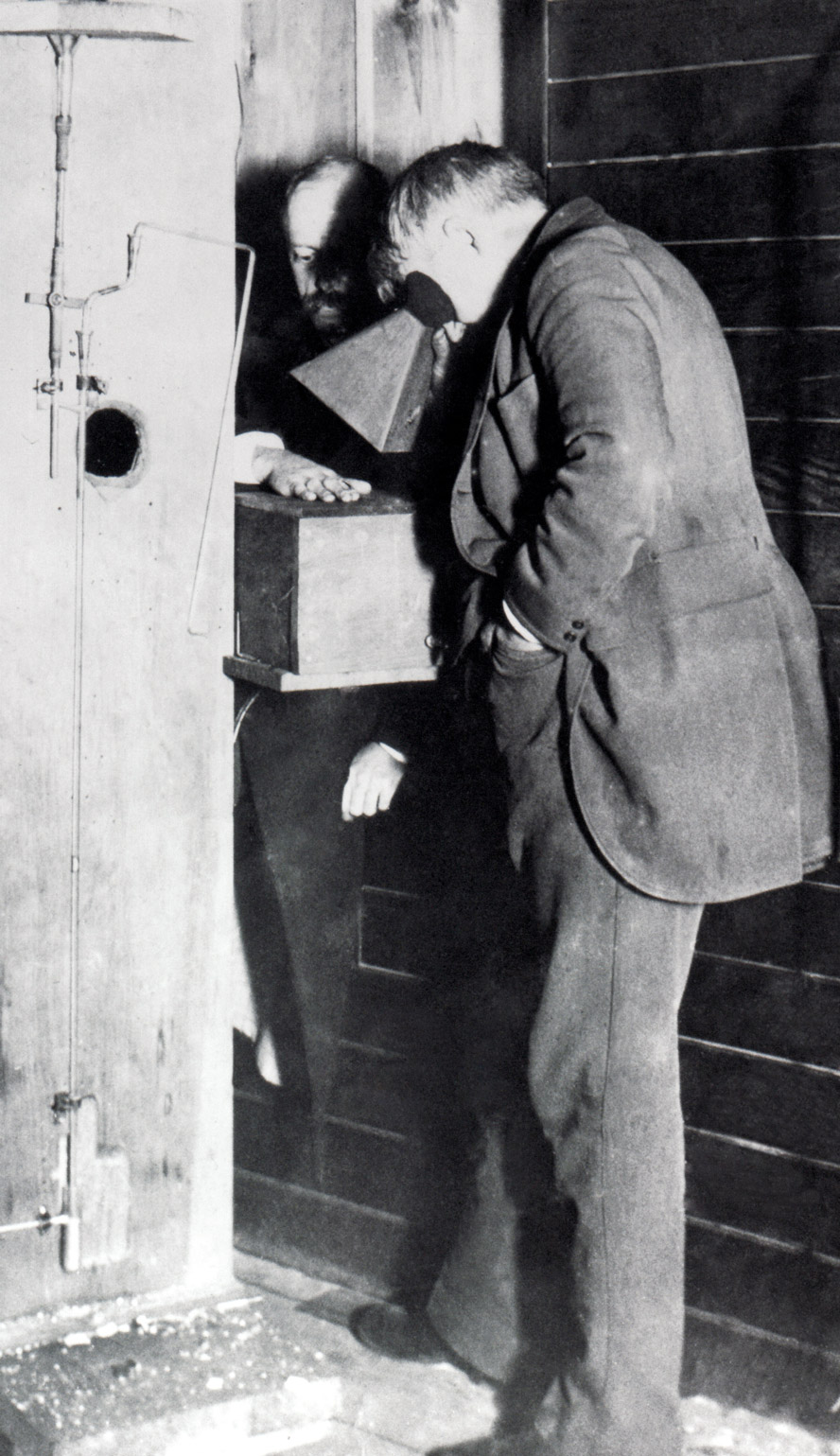

Edison peering into a fluoroscope in 1896.