11

“MODERN WARFARE IS MORE A MATTER OF MACHINES THAN MEN.”

EDISON WAS AN OUTSPOKEN ADVOCATE of military and industrial preparedness during the First World War. Recognizing that new technologies—including the submarine, machine gun, and airplane—were rapidly changing warfare, Edison told the New York Times in October 1915, “The soldier of the future will not be a sabre-bearing, blood thirsty savage. He will be a machinist.” Future military conflicts, he believed, would be wars “in which machines, not soldiers, fight.” In another interview with the Times several weeks later, Edison remarked, “Science is going to make war a terrible thing—too terrible to contemplate. Pretty soon we can be mowing men down by the thousands or even millions almost by pressing a button.”

Edison (passenger seat), Navy Secretary Josephus Daniels (rear seat, left), Miller Reese Hutchison (rear seat, right), and Charles Edison (obscured) arriving at the Brooklyn Navy Yard on October 12, 1914. Theodore Edison is at the wheel.

If recent inventions like the submarine and airplane raised security challenges for the United States, Edison believed that technology combined with industrial organization offered solutions. In May 1915, he outlined a preparedness plan based on the idea that military training and equipment procurement should be organized along industrial lines. He called for the stockpiling of airplanes, battleships, and munitions and for the recruitment of a large army of reservists trained by private industry. To develop new inventions quickly, he proposed the creation of military research laboratories.

As president of the Naval Consulting Board and a researcher for the U.S. Navy during the war, Edison had an opportunity to address these issues, but he faced a more immediate challenge when the war began in August 1914: a shortage of German and British phenol, or carbolic acid. Edison used carbolic acid to manufacture phonograph records, but because the chemical was also used to make explosives, the British and German governments embargoed its export.

These ads reminded Edison factory workers of the part they played in the war effort and encouraged them to increase production.

Each day Edison’s phonograph factory used one and a half tons of carbolic acid, a by-product of coal tar. As he told the editor of Iron Age in September 1914, “Carbolic acid is not obtainable in this country, our tar having scarcely any, so we are dependent on England & Germany. I am the largest user of carbolic here & the embargo put on shipments by England and the impossibility of getting any from Germany put me in a pretty tight space.”

At first, Edison worked through political and diplomatic channels to reestablish his supply line. At his request, New Jersey senator William Hughes and Congressman Edward W. Townsend petitioned the State Department to intervene with the British on his behalf. Secretary of State William Jennings Bryan asked the British to lift the embargo and allow Edison to ship fifty tons of carbolic acid per month. The British Foreign Office approved the request, but the British Board of Trade, which regulated merchant shipping, blocked Edison’s waiver because of a shortage of ships.

Congressman Townsend wanted to know why, if the chemicals were so important, they were not manufactured in the United States. Edison explained that the United States had ample raw materials and ingenious chemists, but American companies did not have an economic incentive to produce chemicals because U.S. tariff policies allowed German manufacturers to dump their products on the American market at low prices. “If you & your friends in Congress will get together at once and pass a bill the same as the Canadians have passed to prevent ‘dumping’ in this market,” Edison wrote to Townsend, “it will build up & make Americans dominant in the chemical trades.”

Townsend appreciated the information but did not seem to understand the problem. “I do not quite ‘get you’ as the saying is, and during my next visit home I shall want to talk this matter over with you personally,” he wrote to Edison. At this point, Edison, who scrawled the word “hopeless” across the top of Townsend’s letter, may have concluded that political leaders could not solve his chemical problem.

Edison preferred to act, not talk. He learned that most American chemical manufacturers needed six to nine months to figure out how to make carbolic acid. Merck & Co.—based in Rahway, New Jersey—had assigned a chemist to the task and promised Edison shipments in three months. He could not wait that long.

Believing that he could invent a process in three weeks, Edison and his chemists began studying phenol-manufacturing techniques in September 1914. Within days they had developed a method of making synthetic phenol from other chemicals. Moving rapidly, Edison assigned three shifts of workers to design and construct a chemical plant on the grounds of his factory in Silver Lake (now Bloomfield), New Jersey. Nineteen days later, the carbolic acid plant was in operation, producing enough of the chemical to keep the phonograph factory “running without interruption.”

By early January 1915, Edison was producing 3,400 pounds of carbolic acid per day. To make carbolic, however, Edison needed benzol, a liquid hydrocarbon (known today as benzene). The British had ample supplies of benzol, but shipping costs were prohibitive. “They have plenty of benzol in England, and there is no embargo on its shipment to America,” Edison wrote to a Canadian steel manufacturer, “but the price is so high, the shipping facilities so bad, and the cost of drums so great, that I cannot afford to buy it.”

Benzol, like phenol, is a by-product of coal tar or coal gas. Steel manufacturers produced these by-products when they turned coal into coke, a fuel used in steel furnaces and created via the heating of coal in enclosed ovens. A variety of chemicals could be extracted from the coal tar and coal gas driven off during this process. Edison’s solution to the benzol problem: extract the chemical from coal gas by building absorption plants near the coke ovens of iron and steel companies.

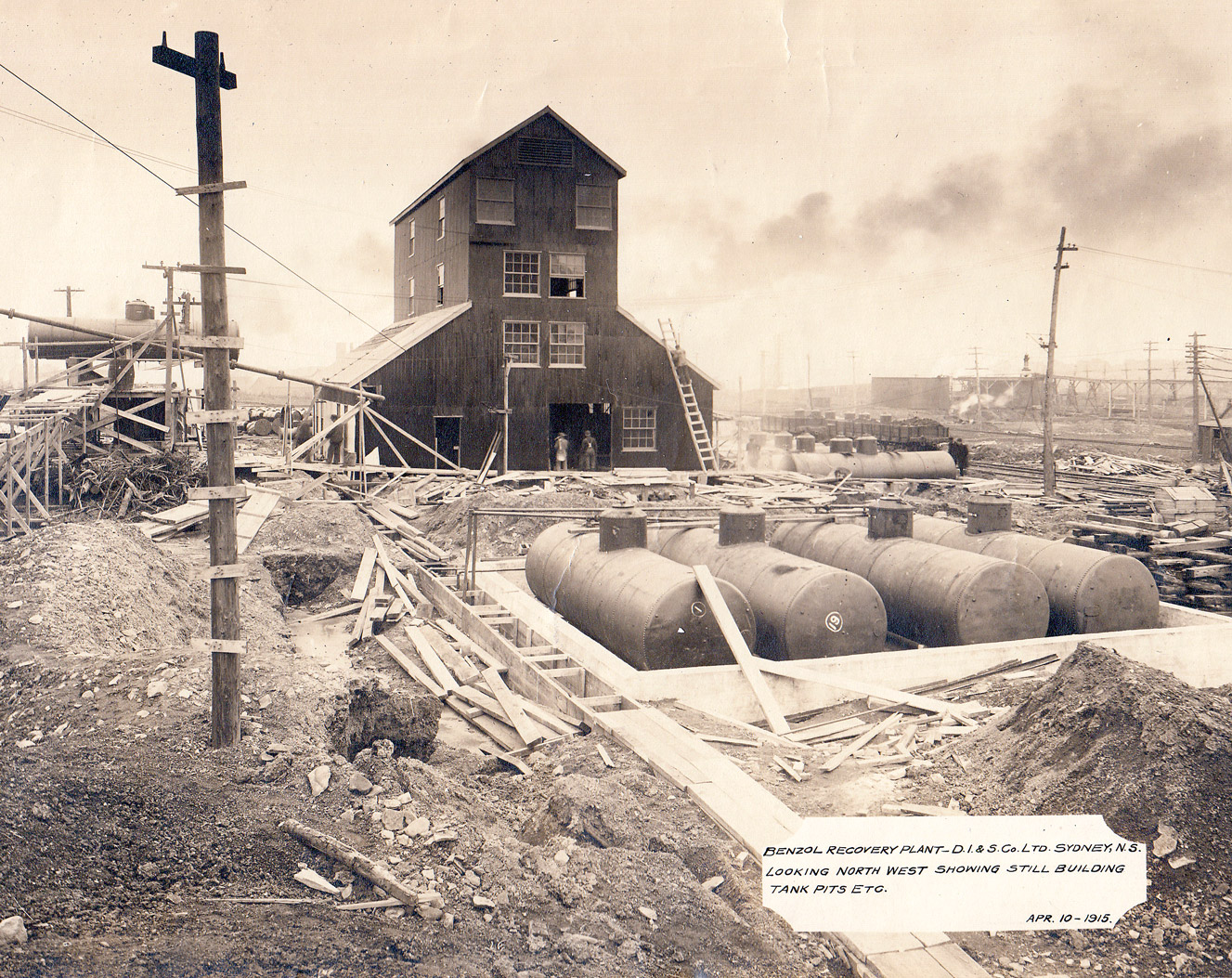

On December 18, 1914, Edison asked the Dominion Iron & Steel Co. in Sydney, Nova Scotia, if it would allow him to build a benzol absorption plant near its coke oven. He sent the same proposal to the Cambria Steel Co. in Johnstown, Pennsylvania, on December 23.

Edison benzol plant at the Dominion Iron & Steel Co., Sydney, Nova Scotia, April 1914.

Edison proposed a three-year contract, under which he would design, construct, and operate absorption plants at his own expense. The steel companies would permit Edison to absorb all of the liquid hydrocarbons produced in the coke ovens (up to 1,800 gallons per day) and sell him the steam he needed to operate the plant. In exchange, Edison agreed to pay eighteen cents per gallon for the benzol he extracted. Edison also agreed to purchase other coke oven by-products, including tuloul (now known as toluene), xylol (today called xylene), and solvent naptha. Edison would then sell these chemicals, used as industrial solvents, to other manufacturers.

The Cambria Steel Co. accepted Edison’s proposal on January 12, 1915, and the Dominion Iron & Steel Co. signed a contract with Edison a month later. On February 22, he completed construction of his absorption plant at Johnstown, and Edison’s benzol plant in Nova Scotia began operating on April 12. In early March, the inventor formed a partnership with Mitsui & Co., a Japanese industrial conglomerate, or zaibatsu, to construct a third benzol recovery plant in Woodward, Alabama. The Alabama plant, constructed at the Woodward Iron Co., began operating on May 31.

EDISON’S VIEWS ON MILITARY PREPAREDNESS attracted the attention of U.S. Secretary of the Navy Josephus Daniels. In July 1915, Daniels asked Edison to head an advisory board to evaluate technical ideas submitted to the navy by the public. Edison agreed, provided that he would not have to handle administrative matters and would be free to pursue his own war-related research. Edison’s chief engineer, Miller Reese Hutchison, joined him on the board.

Eleven technical and scientific societies, including the American Chemical Society, the American Institute of Mining Engineers, the American Aeronautical Society, and the American Institute of Electrical Engineers, selected the other board members. These societies named several prominent engineers and inventors, including General Electric research director Willis R. Whitney; Leo H. Baekeland, a chemist who invented an early plastic called Bakelite; gyroscope inventor Elmer Sperry; and Frank J. Sprague, an electric railroad inventor who had worked for Edison in the 1880s.

Edison with members of the Naval Consulting Board on the east steps (facing the White House) of the State, War and Navy Building, October 7, 1915. Navy Secretary Josephus Daniels stands to Edison’s left, and Assistant Navy Secretary Franklin D. Roosevelt is in the first row, far left.

The Naval Consulting Board met for the first time on October 7, 1915, adopting operating rules and creating fifteen subcommittees organized by subject, including submarines, ordnance and explosives, mines and torpedoes, and ship construction. These subcommittees evaluated invention proposals submitted by the public.

The board received approximately 11,000 suggestions, most dealing with the submarine. Of these submissions, only 110 were referred to one of the subcommittees for evaluation, while only one—the Ruggles Orientator—was produced during the war. The orientator, a simulated pilot’s seat mounted on gimbals, allowed instructors to simulate the aircraft motion for pilot trainees. The orientator also allowed the military to study the physiological effects of different flight conditions on pilots.

LEFT: On January 19, 1918, the Naval Consulting Board appropriated funds to construct a model of William Guy Ruggles's orientator, a flight simulator. Ruggles built several orientators for the U.S. Army Air Service. (Courtesy of the National Museum of the U.S. Air Force) RIGHT: American inventor Peter Cooper Hewitt, pictured in this early-twentieth-century photograph, worked with Elmer Sperry to develop the pilotless Hewitt-Sperry Automatic Airplane as part of the Naval Consulting Board. (Library of Congress)

In February 1917, the board created a Special Problems Committee to address the issue of protecting ships from submarine attack. This committee received thousands of suggestions from the public for shields and nets to protect surface vessels from submarines. Other ideas for camouflage and smoke reduction (to reduce the visibility of ships) were also tested. None of these ideas, however, were practical.

The technical research conducted individually by board members was more consequential. Elmer Sperry developed a number of improvements for airplanes and submarines, including a device to detect hydrogen in submarines, improved steel airplane propellers, and remote-control devices for aerial bombs. Hudson Maxim invented improved contact mines and torpedo fuel. Peter Cooper Hewitt experimented on helicopters, while Frank Sprague developed depth charges, underwater fuses, and armor-piercing shells.

Edison began researching war-related technical problems in January 1917. He outfitted a laboratory in a vacant casino on Eagle Rock Mountain—near the West Orange laboratory—to test equipment for locating gun positions by sound. In the spring he conducted experiments at the Sandy Hook, New Jersey, naval station. Between August and October, he spent six weeks on Long Island Sound, experimenting on the USS Sachem, a 186-foot private yacht that the navy had acquired for Edison’s research.

Most of Edison’s naval research in 1917 focused on protecting surface ships from submarine attack. He studied methods of camouflaging ships and recommended that cargo ships burn anthracite coal, which would lessen smoke emissions. He also investigated ways to quickly turn ships under torpedo attack and equipped the Sachem with electrical instruments to detect submarines by sight, sound, and magnetic field.

Edison learned that previous submarine detection research had been conducted on stopped ships that had all their machinery shut down. He did not think this was practical. “Of course in trying to save a cargo boat, I could not stop her. I had to hear her going at full speed. All experiments were conducted when seas were high and at 10 1/2 knots.” To detect submarines under normal operating conditions, Edison attached listening devices to a ship’s bowsprit. As he recalled, “I had discovered, while you could get good listening in undisturbed water, it was a different proposition when you had waves or another boat disturbing you . . . finally we got her so it would run in any sea.”

Charles Edison with U.S. Army soldiers and the Army and Navy phonograph. To entertain soldiers in the field, Edison sold a portable disc phonograph to the U.S. government and service organizations like the Red Cross.

In the fall of 1917, Edison moved his war research to Washington, D.C. From October 1917 to January 1918 he used an office in the State, War, and Navy Building near the White House (now called the Eisenhower Executive Office Building) to collect data on Allied shipping losses. At the conclusion of this research, Edison discovered that the United States and its Allies were using prewar shipping routes, which made it easier for enemy submarines to target ships, and that many ships were passing through danger zones during daylight. Edison recommended that the allies change their shipping schedules to avoid German submarines.

AT ITS FIRST MEETING on October 7, 1915, the Naval Consulting Board adopted Edison’s proposal for a permanent naval research laboratory. The proposal called for a laboratory constructed at a tidewater location deep enough to dock a battleship and near—but not in—a large city. Proximity to a large urban area would give the lab easy access to supplies and labor. As the New York Times reported, “The laboratory should be of complete equipment to enable working models to be made and tested . . . there should be a pattern shop, a brass foundry, a cast iron and cast steel foundry, machine shops for large and small work.” Managed by civilians rather than naval officers, the laboratory would also include a chemical lab, an optical grinding department, a motion picture department, and drafting rooms.

Edison’s notes on smoke screen techniques designed to protect surface ships from submarine attack.

Edison wanted a well-equipped laboratory, capable of producing new inventions rapidly. He wrote Benjamin Tillman, a U.S. senator from South Carolina, “For quick action, it is necessary to have a considerable stock of supplies of every kind in order that there shall be no delay when the naval authorities want results quickly.” Edison considered the proposed laboratory vital to national defense. “If the USA desires that the fighting machinery be kept up to date & not excelled or even approached by that of any other nation . . . then the experimental laboratory is the only possible way this object can be obtained.” The board recommended an appropriation of $5 million ($115 million today) to construct and equip the laboratory, with an annual operating budget of $2.5 to $3 to three million ($57.7 to $69.3 million today).

In 1916, Congress appropriated $1 million ($21.1 million today) for the new laboratory—considerably less than the recommended $5 million. A committee of the Naval Consulting Board subsequently revised the first proposal. Instead of a fully equipped facility to design and construct full-scale prototypes, the committee recommended a scaled-back laboratory under the supervision of naval officers that would focus on basic scientific research and testing. The committee also recommended Annapolis, Maryland, near the U.S. Naval Academy, as the site of the laboratory.

Edison aboard the USS E-2 to inspect his storage batteries, December 1915. Launched on June 15, 1911, the E-2 patrolled for German submarines off the U.S. East Coast during the war.

Edison disagreed with the committee’s report. He preferred Sandy Hook, New Jersey, as the site for the laboratory. More significantly, he objected to the lab’s focus on pure scientific research and continued to advocate a fully equipped facility capable of producing practical inventions. Because of the war, construction of the naval research laboratory in Washington, D.C., did not begin until 1920. When it opened in 1923, operations focused on radio and sound detection research.

Lloyd N. Scott—the naval officer who wrote the Naval Consulting Board’s official history in 1920—framed Edison’s objections to the new laboratory plan as a dispute between his old-fashioned, nineteenth-century approach to industrial research and younger, university-trained engineers and scientists, who placed a higher value on scientific research. While Edison was not opposed to pure scientific research generally, he believed that the vast sums of money the government and industry had spent on this type of research had yielded few practical results and that a laboratory devoted exclusively to scientific investigation would be ill prepared to deal with the navy’s technological problems.

Edison with Navy secretary Josephus Daniels aboard the battleship USS New York at the Brooklyn Navy Yard, October 12, 1914. The fourth U.S. Navy ship named after the state of New York, she was stationed on blockade duty in the North Sea during World War I.

Underlying this perspective was Edison’s view that the navy was not an innovative organization. In 1918 he jotted in a pocket notebook, perhaps while at sea as he worked on the navy’s problems, “Nobody in Naval will do anything on account of the risks that an innovation will bring in . . . no training at Annapolis to cultivate the imagination.” For Edison, the debate over whether the Navy Research Laboratory should pursue scientific or practical research was less important than whether it would have all the resources it needed to address the navy’s technological problems. Just as important was Edison’s belief that the navy needed to create an environment that encouraged innovation and risk taking.

THE NAVAL RESEARCH LABORATORY is significant because it was the federal government’s first permanent facility devoted to producing new technological innovations. On a limited basis, the U.S. government had promoted firearms research at its Springfield, Massachusetts, and Harpers Ferry, West Virginia, armories since the early nineteenth century. During the Civil War, Abraham Lincoln created the National Academy of Sciences to advise federal agencies on scientific and technical issues, and the federal government created a few small laboratories in the late nineteenth century that only evaluated private-sector research.

Following the opening of the Naval Research Laboratory in 1923, the U.S. government assumed a greater role in financing technical research. A number of significant technological advances in the twentieth century—including radar, jet engines, atomic energy, digital computers, improvements in vacuum tubes, Global Positioning Systems (GPS), and the Internet—were the result of federal support. The U.S. government assumed the risk of developing many of these technologies to improve the nation’s defense capabilities.

That is the legacy of Edison’s role during the First World War. By advocating industrial preparedness and promoting the Naval Research Laboratory, he encouraged the view that technical research and innovation were vital to national security. Edison’s awareness of the relationship between innovation and security influenced his last major research project in the 1920s: a search for a domestic source of natural rubber.

While Edison worked on his chemical problem, a fire broke out at his West Orange factory complex on the evening of December 9, 1914. The fire began at 5:17 p.m. in the film inspection department, a one-story wood building that stored highly flammable motion picture film. The seventy-two employees of the laboratory and company fire departments were unable to bring the blaze under control, and soon the fire departments of West Orange and the nearby communities of Montclair, South Orange, and Newark sent fire trucks to assist. The firefighting was hampered by a lack of water pressure, which was boosted when West Orange temporarily connected its water main to South Orange. To prevent the laboratory complex from burning, firefighters focused on protecting buildings closest to the lab. Other buildings already ablaze were allowed to burn down.

There was only one fatality: an employee who reentered a burning building to retrieve personal items. Of the twenty-two buildings in the complex—which manufactured phonographs and records, dictating machines, and motion picture equipment—fifteen were destroyed. The value of the buildings and machinery lost was $1.5 million ($34.8 million today).

Edison wasted no time in rebuilding. The next day, workers began removing debris, while Edison and the laboratory staff began making plans to reconstruct the factory complex. His secretary William Meadowcroft reported, “Mr. Edison has been full of vim and ambition to get started up again quickly and there is no need for me to tell you that we have all been on the jump.”

By the first week of January 1915, Edison had resumed production of cylinder phonograph records. Disc record manufacturing began on January 21, and by April the phonograph works had been completely rebuilt.

The charred smoldering ruins of Edison’s West Orange manufacturing complex, destroyed by fire on December 9, 1914. Edison rebuilt the factory within months.