ELECTRICAL GROUNDING IN METAL CONDUIT

ELECTRICAL GROUNDING IN METAL CONDUITElectrical wiring that runs in exposed locations must be protected by rigid tubing called conduit. For example, conduit is used for wiring that runs across masonry walls in a basement laundry and for exposed outdoor wiring. THHN/THWN wire (opposite page) normally is installed inside conduit, although UF or NM cable can also be installed in conduit.

There are several types of conduit available, so check with your electrical inspector to find out which type meets code requirements in your area. Conduit installed outdoors must be rated for exterior use. Metal conduit should be used only with metal boxes, never with plastic boxes.

At one time, conduit could only be fitted by using elaborate bending techniques and special tools. Now, however, a variety of shaped fittings are available to let a homeowner join conduit easily.

ELECTRICAL GROUNDING IN METAL CONDUIT

ELECTRICAL GROUNDING IN METAL CONDUIT

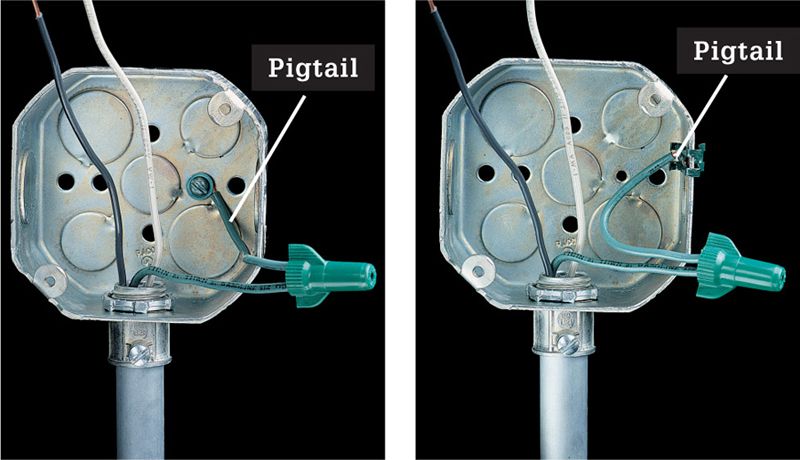

Install a green insulated grounding wire for any circuit that runs through metal conduit. Although code allows the metal conduit to serve as the grounding conductor, most electricians install a green insulated wire as a more dependable means of grounding the system. The grounding wires must be connected to metal boxes with a pigtail and grounding screw (left) or grounding clip (right).

FILL CAPACITY

FILL CAPACITYConduit 1/2" in diameter can hold up to six 14-gauge or 12-gauge THHN/THWN wires (A), five 10-gauge wires (B), or two 8-gauge wires (C). Use 3/4" conduit for greater capacity.

METAL CONDUIT

METAL CONDUIT

EMT is lightweight and easy to install. IMC has thicker galvanized walls and is a good choice for exposed outdoor use. Rigid metal conduit provides the greatest protection for wires, but it is more expensive and requires threaded fittings. EMT is the preferred metal conduit for home use.

PLASTIC CONDUIT

PLASTIC CONDUIT

Plastic PVC conduit is allowed by many local codes. It is assembled with solvent glue and PVC fittings that resemble those for metal conduit. When wiring with PVC conduit, always run a green grounding wire.

WORKING WITH CONDUIT

WORKING WITH CONDUIT

Conduit types used most in homes are EMT (electrical metallic tubing), IMC (intermediate metallic conduit), RNC (rigid nonmetallic conduit), and flexible metal conduit. The most common diameters by far are 1/2" and 3/4", but larger sizes are stocked at most building centers.

Nonmetallic conduit fittings typically are solvent welded to nonmetallic conduit, as opposed to metal conduit, which can be threaded and screwed into threaded fittings or attached with setscrews or compression fittings.

A thin-wall conduit bender is used to bend sweeps into EMT or IMC conduit.

HOW TO MAKE NONMETALLIC CONDUIT CONNECTIONS

HOW TO MAKE NONMETALLIC CONDUIT CONNECTIONS

Cut the rigid nonmetallic conduit (RNC) to length with a fine-tooth saw, such as a hacksaw. For larger diameter (1 1/2" and above), use a power miter box with a fine-tooth or plastic cutting blade.

Deburr the cut edges with a utility knife or fine sandpaper such as emery paper. Wipe the cut ends with a dry rag. Also wipe the coupling or fitting to clean it.

Apply a coat of PVC cement to the end of the conduit and to the inside walls of the coupling (inset). Wear latex gloves to protect your hands. The cement should be applied past the point on the conduit where it enters the fitting or coupling.

Insert the conduit into the fitting or coupling and spin it a quarter turn to help spread the cement. Allow the joint to set undisturbed for 10 minutes.