Tools & Materials

Tape measure

Felt-tipped pen

Tubing cutter (or miter box or hacksaw)

Utility knife

Channel-type pliers

Vinyl or latex gloves

Plastic pipe

Fittings

Emery cloth

Plastic pipe primer

Solvent glue

Rag

Protective equipment

Cut rigid ABS, PVC, or CPVC plastic pipes with a tubing cutter or with any saw. Cuts must be straight to ensure watertight joints.

Rigid plastics are joined with plastic fittings and solvent glue. Use a solvent glue that is made for the type of plastic pipe you are installing. For example, do not use ABS solvent on PVC pipe. Some solvent glues, called “all-purpose” or “universal” solvents, may be used on all types of plastic pipe.

Solvent glue hardens in about 30 seconds, so test-fit all plastic pipes and fittings before gluing the first joint. For best results, the surfaces of plastic pipes and fittings should be dulled with emery cloth and liquid primer before they are joined.

Liquid solvent glues and primers are toxic and flammable. Provide adequate ventilation when fitting plastics, and store the products away from any source of heat.

Plastic grip fittings can be used to join rigid or flexible plastic pipes to copper plumbing pipes.

Solvent welding is a chemical bonding process used to permanently join PVC pipes and fittings.

Primer and solvent glue are specific to the plumbing material being used. Do not use all-purpose or multipurpose products. Light to medium body glues are appropriate for DIYers as they allow the longest working time and are easiest to use. When working with large pipe, 3 or 4 inches in diameter, buy a large-size can of cement, which has a larger dauber. If you use the small dauber (which comes with the small can), you may need to apply twice, which will slow you down and make connections difficult. (The smaller can of primer is fine for any other size pipe, since there’s no rush in applying primer.) Cement (though not primer) goes bad in the can within a month or two after opening, so you may need to buy a new can for a new project.

HOW TO CUT RIGID PLASTIC PIPE

HOW TO CUT RIGID PLASTIC PIPE

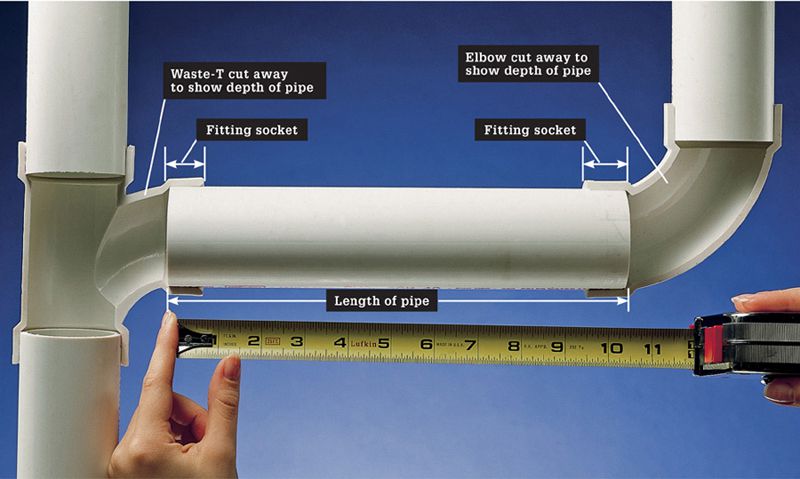

Find the length of plastic pipe needed by measuring between the bottoms of the fitting sockets (fittings shown in cutaway). Mark the length on the pipe with a felt-tipped pen.

Plastic tubing cutters do a fast, neat job of cutting. You’ll probably have to go to a professional plumbing supply store to find one, however. They are not interchangeable with metal tubing cutters.

The best cutting tool for plastic pipe is a power miter saw with a fine tooth woodworking blade or a plastic-specific blade.

A ratcheting plastic-pipe cutter can cut smaller diameter PVC and CPVC pipe in a real hurry. If you are plumbing a whole house you may want to consider investing in one. They also are sold only at plumbing supply stores.

HOW TO SOLVENT-GLUE RIGID PLASTIC PIPE

HOW TO SOLVENT-GLUE RIGID PLASTIC PIPE

Remove rough burrs on cut ends of plastic pipe, using a utility knife or deburring tool (inset).

Test-fit all pipes and fittings. Pipes should fit tightly against the bottom of the fitting sockets.

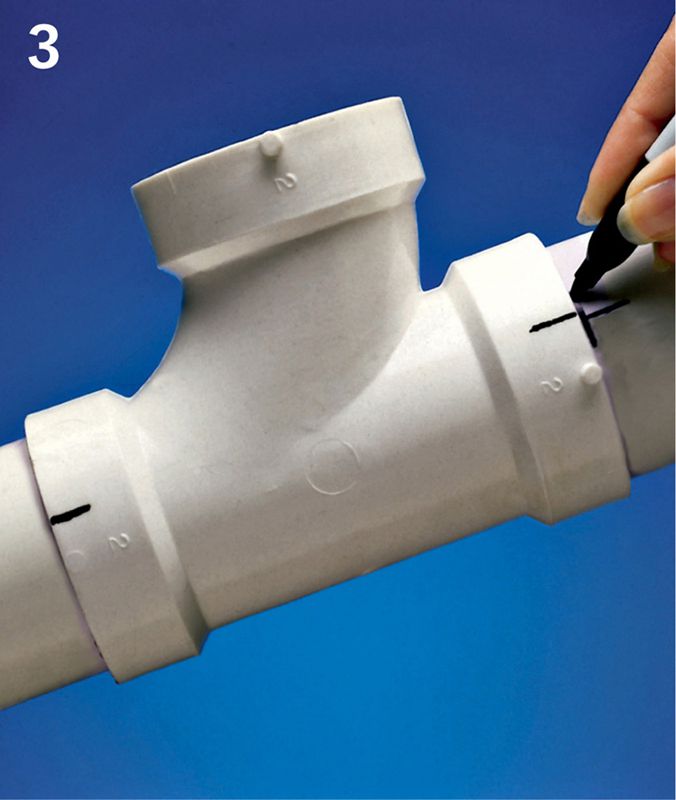

Mark the depth of the fitting sockets on the pipes. Take pipes apart. Clean the ends of the pipes and fitting sockets with emery cloth.

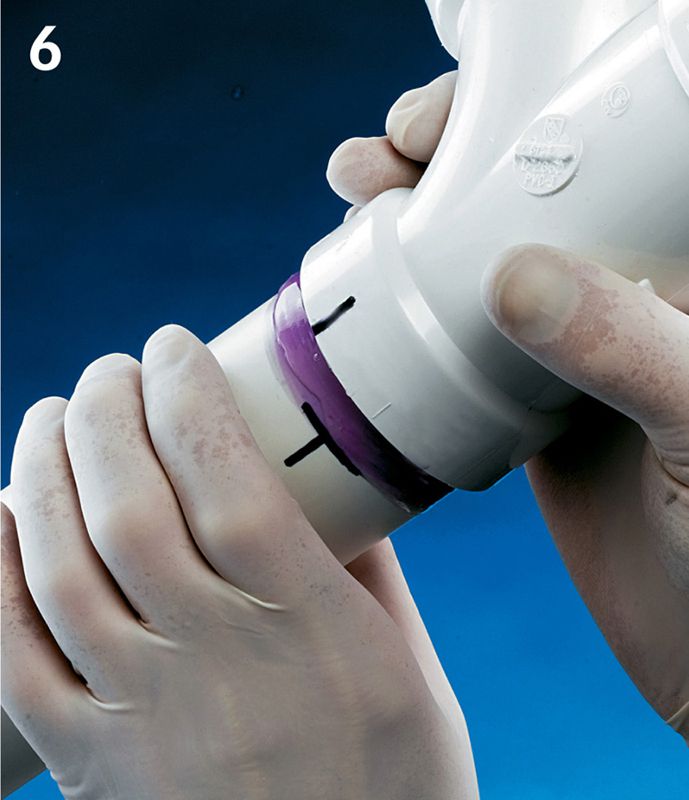

Apply a light coat of plastic pipe primer to the ends of the pipes and to the insides of the fitting sockets. Primer dulls glossy surfaces and ensures a good seal.

Solvent-glue each joint by applying a thick coat of solvent glue to the end of the pipe. Apply a thin coat of solvent glue to the inside surface of the fitting socket. Work quickly: solvent glue hardens in about 30 seconds.

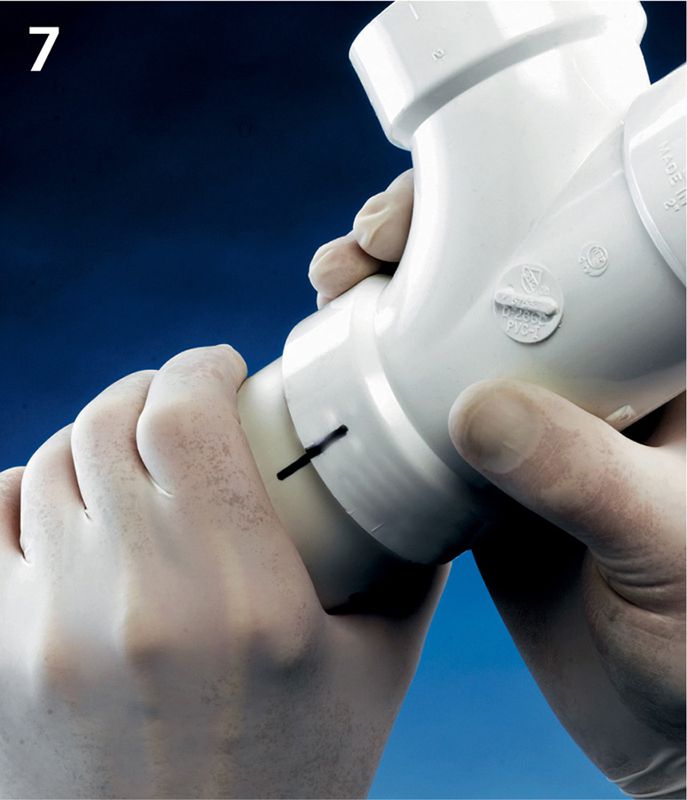

Quickly position the pipe and fitting so that the alignment marks are offset by about 2". Force the pipe into the fitting until the end fits flush against the bottom of the socket.

Spread solvent by twisting the pipe until the marks are aligned. Hold the pipe in place for about 20 seconds to prevent the joint from slipping.

Wipe away excess solvent glue with a rag. Do not disturb the joint for 30 minutes after gluing.