Drywall is a broad category of building materials that covers many types of panels with various purposes, including common gypsum-based wallcovering panels as well as specialty wallcoverings and tile backers.

Up until the 1930s, interior walls were created by troweling wet plaster onto wood or metal lath that had been nailed to the wall framing members. The finished wall required three coats of plaster, each of which had to be permitted to dry or set. The first generation of drywall panels replaced the lath and the heavy “scratch” coat of plaster. Today, even when a traditional plaster wall finish is desired, special blue-papered drywall panels are anchored to the framing to form the base of the wall instead of a hand-troweled scratch coat. This reduces labor and drying time greatly. Since the end of World War II, the typical drywall panel wall requires no finish layer of plaster. Only minor surface corrections are required, including the filling of seams and covering of fastener dimples with joint compound. Eliminating hand-troweled finishes saves time, labor, and money.

Drywall usually consists of a strong paper skin adhered to a gypsum core. The finish-ready face paper wraps around to the back of the panel at the sides, where it overlaps the coarser, more rigid paper used on the back. For handling purposes, sheets of drywall are joined at the ends by removable strips of tape. To facilitate finishing, panels are typically tapered at the long edges. The shallow depression formed where panels meet is easily covered with tape and filled with joint compound for a flat surface that appears continuous. The short, butt-end joints are not recessed and are more challenging to finish.

Drywall is a broad category of building materials that covers many types of panels with various purposes, including common gypsum-based wallcovering panels as well as specialty wallcoverings and tile backers.

Types of Panels

Types of Panels

Standard drywall is used for most walls and ceilings in dry, interior areas. It comes in 4-ft.-wide panels in lengths ranging from 8 ft. to 16 ft. and in thicknesses of 1/4", 3/8", 1/2", and 5/8". There are also 54"-wide panels for horizontal installations on walls with 9-ft. ceilings.

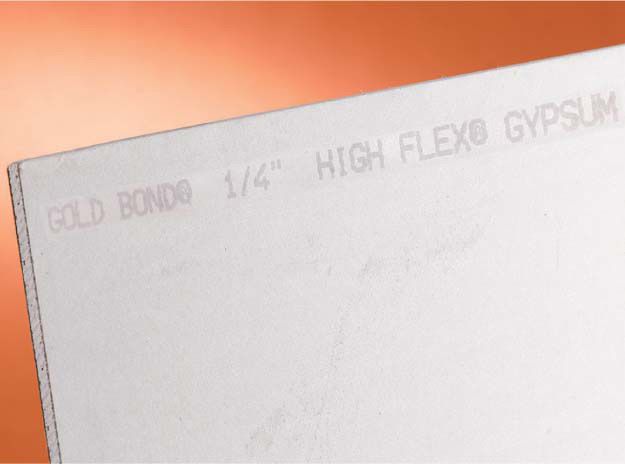

Flexible drywall, specially made for curved walls, is a bendable version of standard 1/4"-thick drywall. It can be installed dry or dampened with water to increase its flexibility.

Fire-resistant drywall has a dense, fiber-reinforced core that helps contain fire. Thicknesses are 1/2", 5/8", and 3/4". Most fire-resistant drywall is called “Type X.” Fire-resistant panels are generally required in attached garages, on walls adjacent to garages, and in furnace and utility rooms.

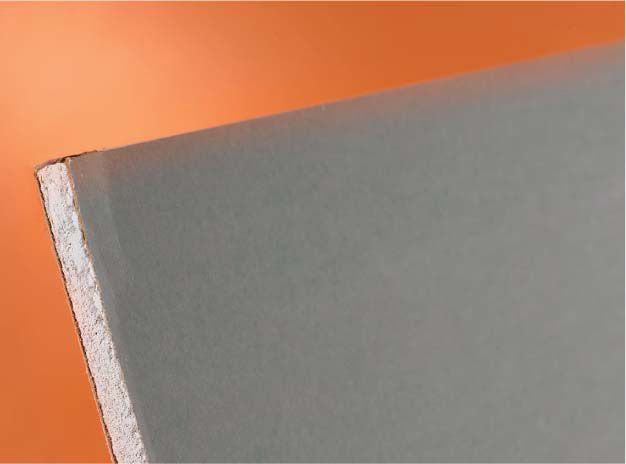

Moisture-resistant drywall, commonly called “greenboard” for the color of its face paper, is designed for areas of high humidity and is used most often in bathrooms, behind kitchen sinks, and in laundry rooms.

Abuse-resistant drywall withstands surface impacts and resists penetrations better than standard drywall. It’s available in 1/2" regular and 5/8" fire-resistant types.

Decorative drywall products include prefinished vinyl-coated panel systems, decorative corner treatments, prefabricated arches, and drywall panels that look like traditional raised-panel paneling.

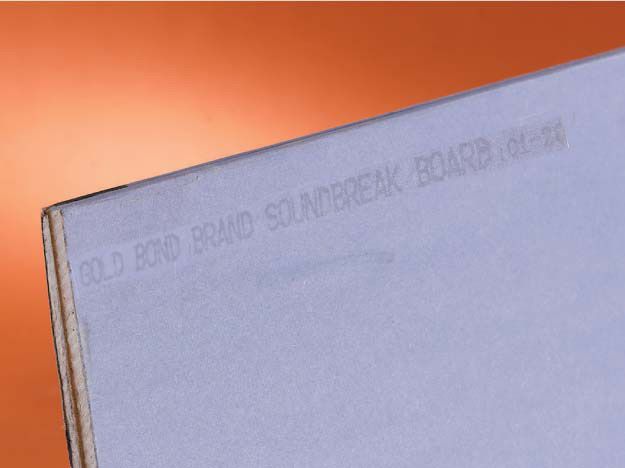

Sound-resistant drywall products have up to eight times as much sound-deadening capability as standard drywall. These products are good for home theaters.

Plaster-base drywall, sometimes called “blueboard,” is used with veneer plaster systems instead of a traditional hand-troweled scratch coat. Panels have two layers of paper—a blue-colored face paper that’s highly absorptive over a moisture-resistant paper to protect the gypsum core.

Mold-resistant drywall is a specialty board designed for areas that are regularly damp, have high humidity, or that are otherwise susceptible to mold and mildew growth.