A blower draws in air through the air intake (1) while a fuel pump (2) maintains a constant supply of fuel oil. The mixture is ignited by a high-voltage spark as it enters the combustion chamber (3) and heats water.

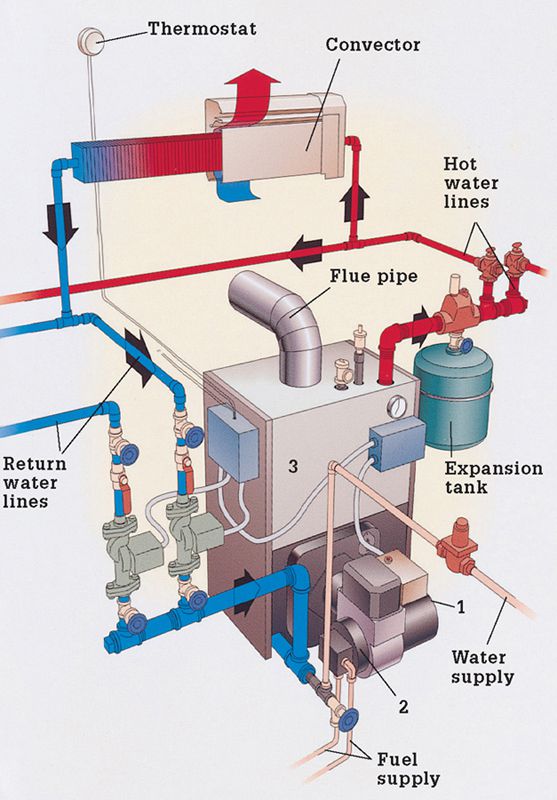

Hot water and steam systems, also known as hydronic systems, feature a boiler that heats water and circulates it through a closed network of pipes to a set of radiators or convectors. Because water expands and contracts as it heats and cools, these systems include expansion tanks to ensure a constant volume of water circulating through the pipes.

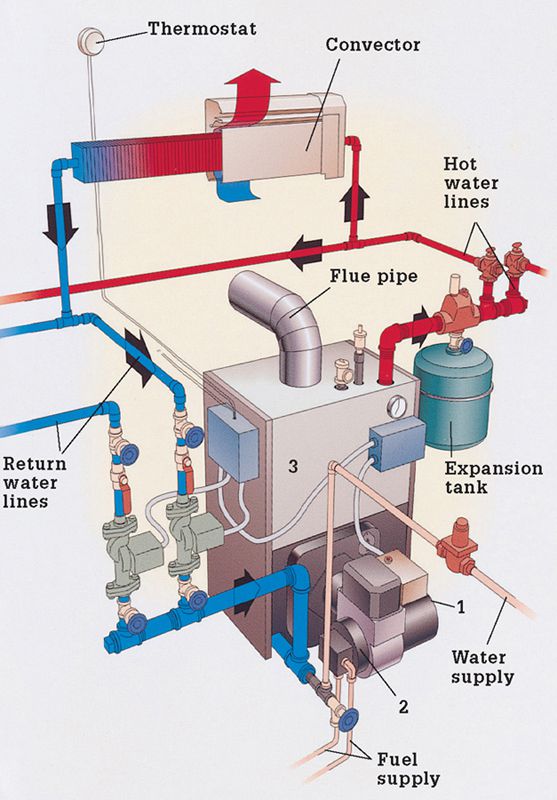

Hot water and steam systems warm the surrounding air through a process called convection. Hot water radiators (photo 1) are linked to the system by pipes connected near the bottom of the radiator. As water cools inside the radiator, it is drawn back to the boiler for reheating. The radiators in steam systems (photo 2) have pipes connected near the top of the radiator. These radiators can be very hot to the touch. Convectors (photo 3) are smaller and lighter and may be used to replace hot water radiators, or to extend an existing hot water system.

Although the delivery of hot water or steam to the rooms in your house is considered a closed system, some air will make its way into the system. Steam radiators have an automatic release valve that periodically releases hot, moist air. Hot water radiators contain a bleed valve that must periodically be opened to release trapped air. It is usually necessary to bleed convector systems using a valve near the boiler.

Today’s hot water and steam systems are often fueled by natural gas. Older systems may use fuel oil. Fuel oil systems require more frequent maintenance of the filter and blower.

A blower draws in air through the air intake (1) while a fuel pump (2) maintains a constant supply of fuel oil. The mixture is ignited by a high-voltage spark as it enters the combustion chamber (3) and heats water.

Hot-water radiators circulate heated water through pipes. As it cools, water is drawn back to the boiler for reheating.

Steam radiators operate at a higher temperature. Steam cools in the radiators, returns to a liquid state, and then flows back to the boiler.

Space-saving hot water convectors work on the same principle as radiators, but use thin sheet-metal fins to transfer heat to the air.

DRAINING & FILLING A SYSTEM

DRAINING & FILLING A SYSTEMSediment gradually accumulates in any water-based system, reducing the system’s efficiency and damaging internal parts. Draining the boiler every season reduces the accumulation of sediment. Be aware that draining the system can take a long time, and the water often has an unpleasant odor. This doesn’t indicate a problem. Drain the system during warm weather, and open the windows and run a fan to reduce any odor.

Start by shutting off the boiler and allowing the hot system to cool. Attach a garden hose to the drain at the bottom of the boiler (photo 1), and place the other end in a floor drain or utility sink. Open a bleed valve on the highest radiator in the house (page 338).

When water stops draining, open a bleed valve on a radiator closer to the boiler. When the flow stops, locate the valve or gauge on top of the boiler, and remove it with a wrench (photo 2).

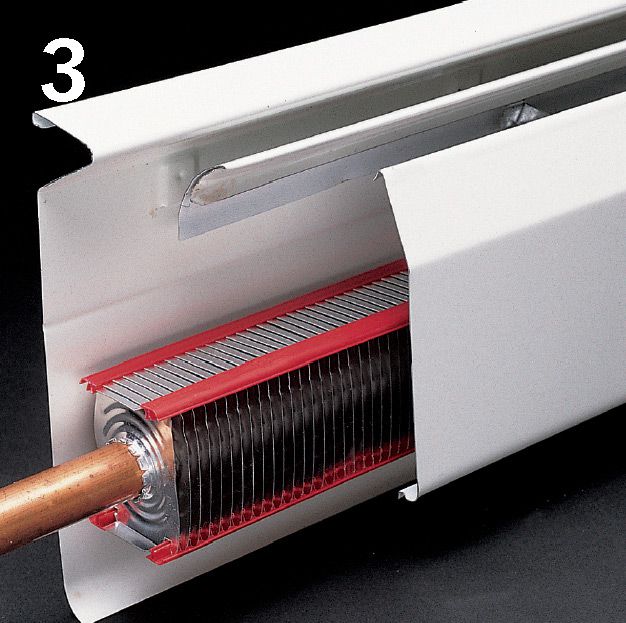

Make sure the system is cool before you add water. Close the drain valve on the boiler. Insert a funnel into the gauge fitting and add rust inhibitor, available from heating supply dealers (photo 3). Check the container for special instructions. Reinstall the valve or gauge in the top of the boiler, close all radiator bleed valves, and slowly reopen the water supply to the boiler.

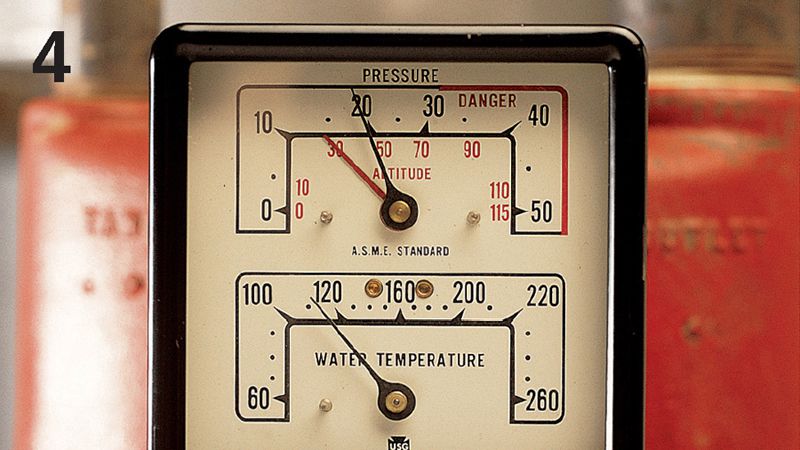

When the water pressure gauge reads 5 psi, bleed the air from the radiators on the first floor, then do the same on the upper floors. Let the boiler reach 20 psi before you turn the power on (photo 4). Allow 12 hours for water to circulate fully, then bleed the radiators again.

Use a garden hose to drain water from the boiler. Keep the drain end of the hose lower than the drain cock on the boiler.

If the valve or gauge on top of the boiler is attached to a separate fitting, hold the fitting still with one wrench while removing the valve or gauge with another.

Using a funnel, add a recommended rust inhibitor to the boiler through the valve or gauge fitting.

The boiler should reach a pressure of 20 psi before you turn the power back on.