FLOORS

TILING: MEMBRANES FOR

Tile membranes are thin, flexible tile underlayment materials designed to isolate tile installations from problematic substrates, provide for sound abatement, or waterproof and vapor-proof tile installations in wet areas and steam rooms. There are dozens of different types of tile membranes on the market. Please refer to the manufacturer for specific information pertaining to the limitations, benefits, and installation of the membrane selected.

Waterproofing membranes are installed in wet areas and are designed to prevent the migration of water beyond the membrane. They often provide additional benefits, including crack suppression. Tile installed in steam rooms, wet saunas, and steam showers requires the installation of a membrane that is both vapor-proof and waterproof.

Sound isolation membranes are designed to reduce the transmission of impact sounds from hard surface flooring to lower level living spaces. This type of membrane is usually installed in apartment dwellings and condominiums (and behind drywall in home theaters).

Crack isolation and anti-fracture membranes, also called crack suppression membranes, isolate tile installations from tile substrates that are susceptible to stresses that produce horizontal movement. They can absorb movement of as much as 1/8-inch to 3/8-inch. Some membranes are liquid applied to the substrate with a trowel or roller, others are sheet applied. There are even anti-fracture thinset mortars, eliminating the need in some cases, for a separate sheet or liquid applied membrane.

Uncoupling membranes isolate the finished tile installation from the substrate while allowing both to move independently. This type of membrane is typically installed over problematic sub-floors and newly installed or problematic concrete slabs.

Note: Crack suppression and uncoupling membranes are not intended to be a substitution for sound building practices. Tile installations that exceed structural recommendations may see little benefit with the installation of these types of products. Likewise, marginal installations will benefit more from structural reinforcement or repairs. Whenever possible, reinforce weak wall framing and floor joists with wood blocking and install an additional layer of plywood over wood sub-floors if needed.

Membranes used for laying tile include: Roll-on waterproofing and crack prevention membrane (A); multipurpose membrane for uncoupling, waterproofing and vapor management (B); 40-mil thick PVC shower pan liner (C); 40-mil thick (1/16") self-bonding membrane designed for use under floor tile requiring protection from structural movement (D); crack prevention mat (E).

HOW TO INSTALL ISOLATION MEMBRANE

HOW TO INSTALL ISOLATION MEMBRANE

Thoroughly clean the subfloor, then apply thinset mortar with a notched trowel. Start spreading the mortar along a wall in a section as wide as the membrane and 8 to 10 ft. long. Note: For some membranes, you must use a bonding material other than mortar. Read and follow label directions.

Roll out the membrane over the mortar. Cut the membrane to fit tightly against the walls using a straightedge and utility knife.

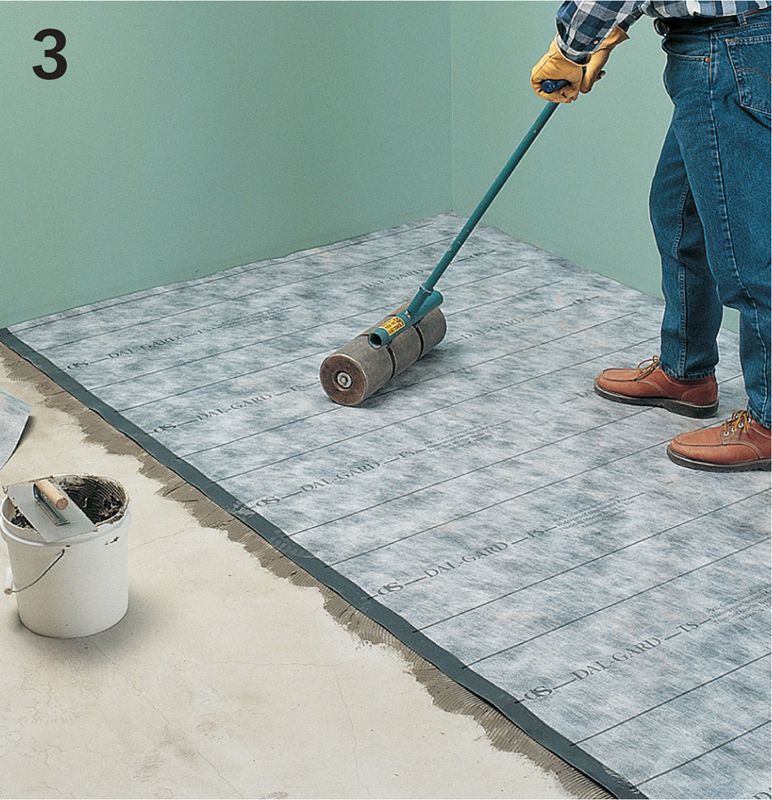

Starting in the center of the membrane, use a heavy flooring roller (available at rental centers) to smooth out the surface toward the edges. This frees trapped air and presses out excess bonding material.

Repeat steps 1 through 3, cutting the membrane as necessary at the walls and obstacles, until the floor is completely covered with membrane. Do not overlap the seams, but make sure they are tight. Allow the mortar to cure for two days before installing the tile.