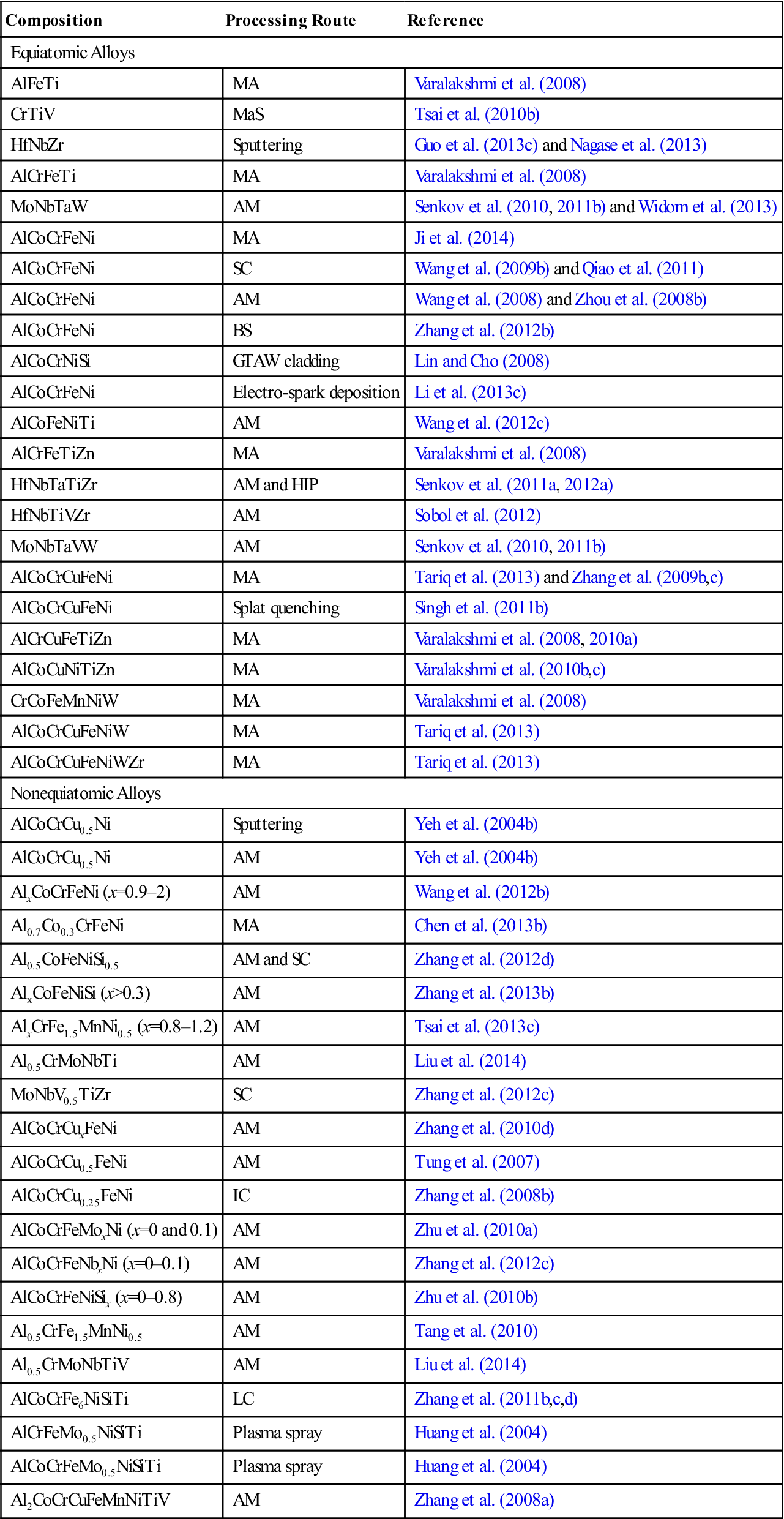

Appendix 1

This appendix gives an idea of the structures of various equiatomic and nonequiatomic HEA solid solutions. The HEAs have been grouped according to their structures.

Table A1.1

| Composition | Processing Route | Reference |

| Equiatomic Alloys | ||

| AlFeTi | MA | Varalakshmi et al. (2008) |

| CrTiV | MaS | Tsai et al. (2010b) |

| HfNbZr | Sputtering | Guo et al. (2013c) and Nagase et al. (2013) |

| AlCrFeTi | MA | Varalakshmi et al. (2008) |

| MoNbTaW | AM | Senkov et al. (2010, 2011b) and Widom et al. (2013) |

| AlCoCrFeNi | MA | Ji et al. (2014) |

| AlCoCrFeNi | SC | Wang et al. (2009b) and Qiao et al. (2011) |

| AlCoCrFeNi | AM | Wang et al. (2008) and Zhou et al. (2008b) |

| AlCoCrFeNi | BS | Zhang et al. (2012b) |

| AlCoCrNiSi | GTAW cladding | Lin and Cho (2008) |

| AlCoCrFeNi | Electro-spark deposition | Li et al. (2013c) |

| AlCoFeNiTi | AM | Wang et al. (2012c) |

| AlCrFeTiZn | MA | Varalakshmi et al. (2008) |

| HfNbTaTiZr | AM and HIP | Senkov et al. (2011a, 2012a) |

| HfNbTiVZr | AM | Sobol et al. (2012) |

| MoNbTaVW | AM | Senkov et al. (2010, 2011b) |

| AlCoCrCuFeNi | MA | Tariq et al. (2013) and Zhang et al. (2009b,c) |

| AlCoCrCuFeNi | Splat quenching | Singh et al. (2011b) |

| AlCrCuFeTiZn | MA | Varalakshmi et al. (2008, 2010a) |

| AlCoCuNiTiZn | MA | Varalakshmi et al. (2010b,c) |

| CrCoFeMnNiW | MA | Varalakshmi et al. (2008) |

| AlCoCrCuFeNiW | MA | Tariq et al. (2013) |

| AlCoCrCuFeNiWZr | MA | Tariq et al. (2013) |

| Nonequiatomic Alloys | ||

| AlCoCrCu0.5Ni | Sputtering | Yeh et al. (2004b) |

| AlCoCrCu0.5Ni | AM | Yeh et al. (2004b) |

| AlxCoCrFeNi (x=0.9–2) | AM | Wang et al. (2012b) |

| Al0.7Co0.3CrFeNi | MA | Chen et al. (2013b) |

| Al0.5CoFeNiSi0.5 | AM and SC | Zhang et al. (2012d) |

| AlxCoFeNiSi (x>0.3) | AM | Zhang et al. (2013b) |

| AlxCrFe1.5MnNi0.5 (x=0.8–1.2) | AM | Tsai et al. (2013c) |

| Al0.5CrMoNbTi | AM | Liu et al. (2014) |

| MoNbV0.5TiZr | SC | Zhang et al. (2012c) |

| AlCoCrCuxFeNi | AM | Zhang et al. (2010d) |

| AlCoCrCu0.5FeNi | AM | Tung et al. (2007) |

| AlCoCrCu0.25FeNi | IC | Zhang et al. (2008b) |

| AlCoCrFeMoxNi (x=0 and 0.1) | AM | Zhu et al. (2010a) |

| AlCoCrFeNbxNi (x=0–0.1) | AM | Zhang et al. (2012c) |

| AlCoCrFeNiSix (x=0–0.8) | AM | Zhu et al. (2010b) |

| Al0.5CrFe1.5MnNi0.5 | AM | Tang et al. (2010) |

| Al0.5CrMoNbTiV | AM | Liu et al. (2014) |

| AlCoCrFe6NiSiTi | LC | Zhang et al. (2011b,c,d) |

| AlCrFeMo0.5NiSiTi | Plasma spray | Huang et al. (2004) |

| AlCoCrFeMo0.5NiSiTi | Plasma spray | Huang et al. (2004) |

| Al2CoCrCuFeMnNiTiV | AM | Zhang et al. (2008a) |

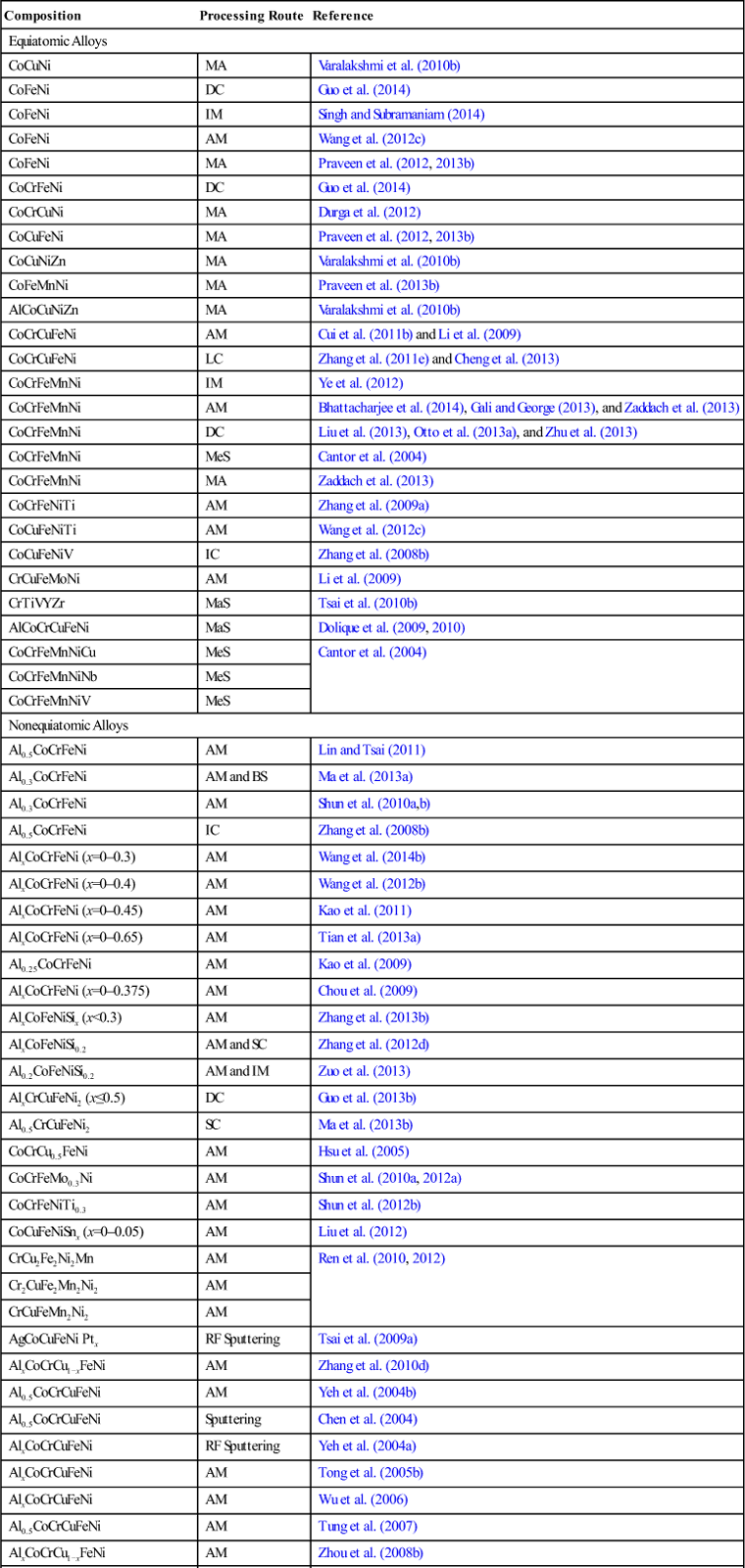

Table A1.2

| Composition | Processing Route | Reference |

| Equiatomic Alloys | ||

| CoCuNi | MA | Varalakshmi et al. (2010b) |

| CoFeNi | DC | Guo et al. (2014) |

| CoFeNi | IM | Singh and Subramaniam (2014) |

| CoFeNi | AM | Wang et al. (2012c) |

| CoFeNi | MA | Praveen et al. (2012, 2013b) |

| CoCrFeNi | DC | Guo et al. (2014) |

| CoCrCuNi | MA | Durga et al. (2012) |

| CoCuFeNi | MA | Praveen et al. (2012, 2013b) |

| CoCuNiZn | MA | Varalakshmi et al. (2010b) |

| CoFeMnNi | MA | Praveen et al. (2013b) |

| AlCoCuNiZn | MA | Varalakshmi et al. (2010b) |

| CoCrCuFeNi | AM | Cui et al. (2011b) and Li et al. (2009) |

| CoCrCuFeNi | LC | Zhang et al. (2011e) and Cheng et al. (2013) |

| CoCrFeMnNi | IM | Ye et al. (2012) |

| CoCrFeMnNi | AM | Bhattacharjee et al. (2014), Gali and George (2013), and Zaddach et al. (2013) |

| CoCrFeMnNi | DC | Liu et al. (2013), Otto et al. (2013a), and Zhu et al. (2013) |

| CoCrFeMnNi | MeS | Cantor et al. (2004) |

| CoCrFeMnNi | MA | Zaddach et al. (2013) |

| CoCrFeNiTi | AM | Zhang et al. (2009a) |

| CoCuFeNiTi | AM | Wang et al. (2012c) |

| CoCuFeNiV | IC | Zhang et al. (2008b) |

| CrCuFeMoNi | AM | Li et al. (2009) |

| CrTiVYZr | MaS | Tsai et al. (2010b) |

| AlCoCrCuFeNi | MaS | Dolique et al. (2009, 2010) |

| CoCrFeMnNiCu | MeS | Cantor et al. (2004) |

| CoCrFeMnNiNb | MeS | |

| CoCrFeMnNiV | MeS | |

| Nonequiatomic Alloys | ||

| Al0.5CoCrFeNi | AM | Lin and Tsai (2011) |

| Al0.3CoCrFeNi | AM and BS | Ma et al. (2013a) |

| Al0.3CoCrFeNi | AM | Shun et al. (2010a,b) |

| Al0.5CoCrFeNi | IC | Zhang et al. (2008b) |

| AlxCoCrFeNi (x=0–0.3) | AM | Wang et al. (2014b) |

| AlxCoCrFeNi (x=0–0.4) | AM | Wang et al. (2012b) |

| AlxCoCrFeNi (x=0–0.45) | AM | Kao et al. (2011) |

| AlxCoCrFeNi (x=0–0.65) | AM | Tian et al. (2013a) |

| Al0.25CoCrFeNi | AM | Kao et al. (2009) |

| AlxCoCrFeNi (x=0–0.375) | AM | Chou et al. (2009) |

| AlxCoFeNiSix (x<0.3) | AM | Zhang et al. (2013b) |

| AlxCoFeNiSi0.2 | AM and SC | Zhang et al. (2012d) |

| Al0.2CoFeNiSi0.2 | AM and IM | Zuo et al. (2013) |

| AlxCrCuFeNi2 (x≤0.5) | DC | Guo et al. (2013b) |

| Al0.5CrCuFeNi2 | SC | Ma et al. (2013b) |

| CoCrCu0.5FeNi | AM | Hsu et al. (2005) |

| CoCrFeMo0.3Ni | AM | Shun et al. (2010a, 2012a) |

| CoCrFeNiTi0.3 | AM | Shun et al. (2012b) |

| CoCuFeNiSnx (x=0–0.05) | AM | Liu et al. (2012) |

| CrCu2Fe2Ni2Mn | AM | Ren et al. (2010, 2012) |

| Cr2CuFe2Mn2Ni2 | AM | |

| CrCuFeMn2Ni2 | AM | |

| AgCoCuFeNi Ptx | RF Sputtering | Tsai et al. (2009a) |

| AlxCoCrCu1−xFeNi | AM | Zhang et al. (2010d) |

| Al0.5CoCrCuFeNi | AM | Yeh et al. (2004b) |

| Al0.5CoCrCuFeNi | Sputtering | Chen et al. (2004) |

| AlxCoCrCuFeNi | RF Sputtering | Yeh et al. (2004a) |

| AlxCoCrCuFeNi | AM | Tong et al. (2005b) |

| AlxCoCrCuFeNi | AM | Wu et al. (2006) |

| Al0.5CoCrCuFeNi | AM | Tung et al. (2007) |

| AlxCoCrCu1−xFeNi | AM | Zhou et al. (2008b) |

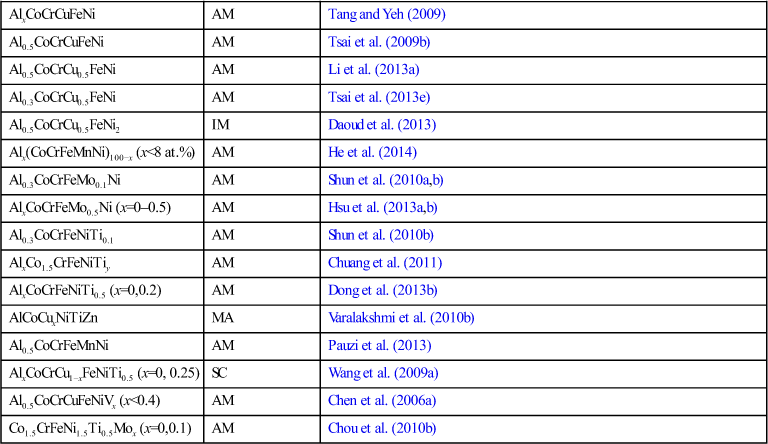

| AlxCoCrCuFeNi | AM | Tang and Yeh (2009) |

| Al0.5CoCrCuFeNi | AM | Tsai et al. (2009b) |

| Al0.5CoCrCu0.5FeNi | AM | Li et al. (2013a) |

| Al0.3CoCrCu0.5FeNi | AM | Tsai et al. (2013e) |

| Al0.5CoCrCu0.5FeNi2 | IM | Daoud et al. (2013) |

| Alx(CoCrFeMnNi)100−x (x<8 at.%) | AM | He et al. (2014) |

| Al0.3CoCrFeMo0.1Ni | AM | Shun et al. (2010a,b) |

| AlxCoCrFeMo0.5Ni (x=0–0.5) | AM | Hsu et al. (2013a,b) |

| Al0.3CoCrFeNiTi0.1 | AM | Shun et al. (2010b) |

| AlxCo1.5CrFeNiTiy | AM | Chuang et al. (2011) |

| AlxCoCrFeNiTi0.5 (x=0,0.2) | AM | Dong et al. (2013b) |

| AlCoCuxNiTiZn | MA | Varalakshmi et al. (2010b) |

| Al0.5CoCrFeMnNi | AM | Pauzi et al. (2013) |

| AlxCoCrCu1−xFeNiTi0.5 (x=0, 0.25) | SC | Wang et al. (2009a) |

| Al0.5CoCrCuFeNiVx (x<0.4) | AM | Chen et al. (2006a) |

| Co1.5CrFeNi1.5Ti0.5Mox (x=0,0.1) | AM | Chou et al. (2010b) |

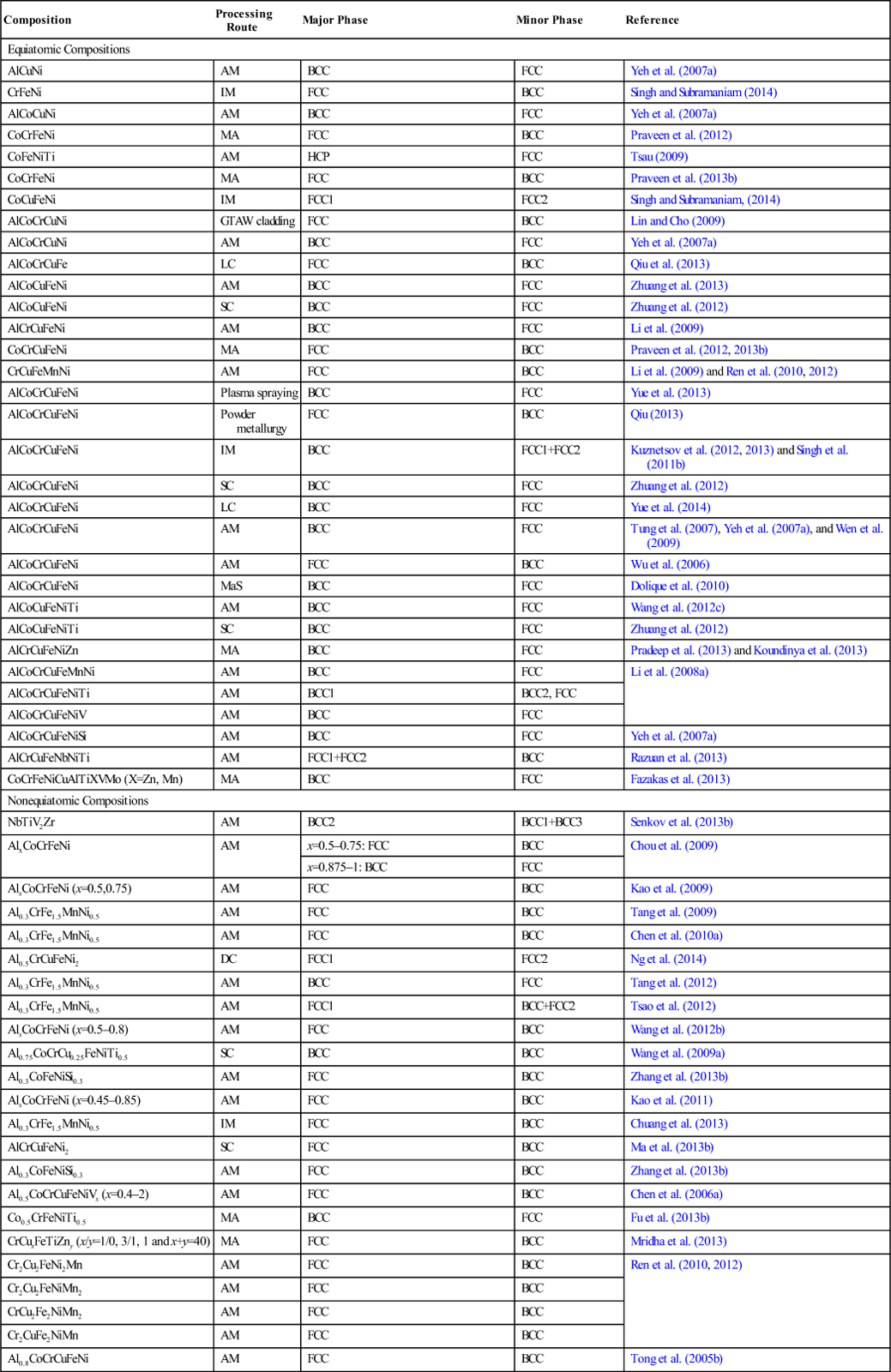

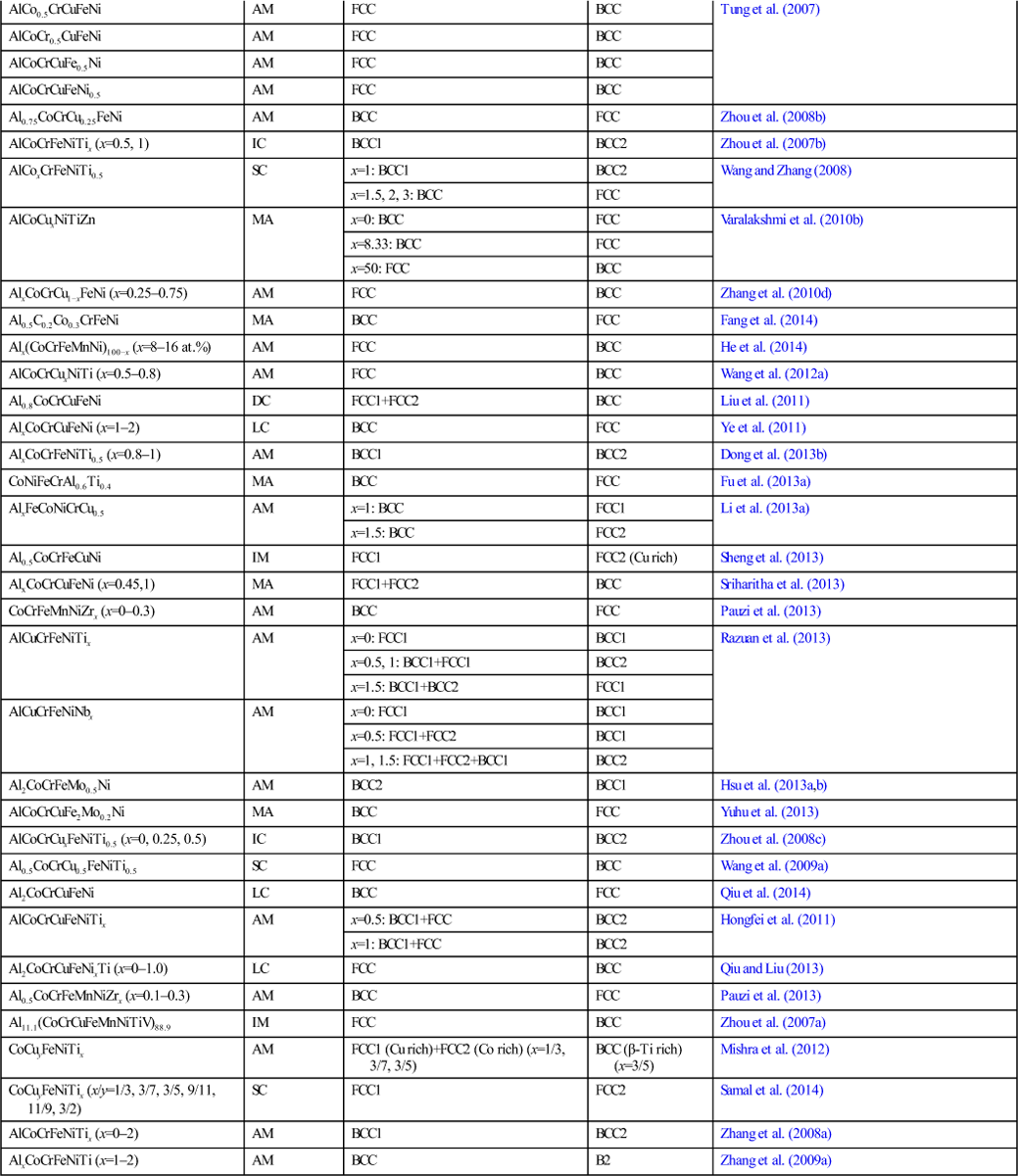

Table A1.3

HEAs Showing More Than One Solid Solution

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| Equiatomic Compositions | ||||

| AlCuNi | AM | BCC | FCC | Yeh et al. (2007a) |

| CrFeNi | IM | FCC | BCC | Singh and Subramaniam (2014) |

| AlCoCuNi | AM | BCC | FCC | Yeh et al. (2007a) |

| CoCrFeNi | MA | FCC | BCC | Praveen et al. (2012) |

| CoFeNiTi | AM | HCP | FCC | Tsau (2009) |

| CoCrFeNi | MA | FCC | BCC | Praveen et al. (2013b) |

| CoCuFeNi | IM | FCC1 | FCC2 | Singh and Subramaniam, (2014) |

| AlCoCrCuNi | GTAW cladding | FCC | BCC | Lin and Cho (2009) |

| AlCoCrCuNi | AM | BCC | FCC | Yeh et al. (2007a) |

| AlCoCrCuFe | LC | FCC | BCC | Qiu et al. (2013) |

| AlCoCuFeNi | AM | BCC | FCC | Zhuang et al. (2013) |

| AlCoCuFeNi | SC | BCC | FCC | Zhuang et al. (2012) |

| AlCrCuFeNi | AM | BCC | FCC | Li et al. (2009) |

| CoCrCuFeNi | MA | FCC | BCC | Praveen et al. (2012, 2013b) |

| CrCuFeMnNi | AM | FCC | BCC | Li et al. (2009) and Ren et al. (2010, 2012) |

| AlCoCrCuFeNi | Plasma spraying | BCC | FCC | Yue et al. (2013) |

| AlCoCrCuFeNi | Powder metallurgy | FCC | BCC | Qiu (2013) |

| AlCoCrCuFeNi | IM | BCC | FCC1+FCC2 | Kuznetsov et al. (2012, 2013) and Singh et al. (2011b) |

| AlCoCrCuFeNi | SC | BCC | FCC | Zhuang et al. (2012) |

| AlCoCrCuFeNi | LC | BCC | FCC | Yue et al. (2014) |

| AlCoCrCuFeNi | AM | BCC | FCC | Tung et al. (2007), Yeh et al. (2007a), and Wen et al. (2009) |

| AlCoCrCuFeNi | AM | FCC | BCC | Wu et al. (2006) |

| AlCoCrCuFeNi | MaS | BCC | FCC | Dolique et al. (2010) |

| AlCoCuFeNiTi | AM | BCC | FCC | Wang et al. (2012c) |

| AlCoCuFeNiTi | SC | BCC | FCC | Zhuang et al. (2012) |

| AlCrCuFeNiZn | MA | BCC | FCC | Pradeep et al. (2013) and Koundinya et al. (2013) |

| AlCoCrCuFeMnNi | AM | BCC | FCC | Li et al. (2008a) |

| AlCoCrCuFeNiTi | AM | BCC1 | BCC2, FCC | |

| AlCoCrCuFeNiV | AM | BCC | FCC | |

| AlCoCrCuFeNiSi | AM | BCC | FCC | Yeh et al. (2007a) |

| AlCrCuFeNbNiTi | AM | FCC1+FCC2 | BCC | Razuan et al. (2013) |

| CoCrFeNiCuAlTiXVMo (X=Zn, Mn) | MA | BCC | FCC | Fazakas et al. (2013) |

| Nonequiatomic Compositions | ||||

| NbTiV2Zr | AM | BCC2 | BCC1+BCC3 | Senkov et al. (2013b) |

| AlxCoCrFeNi | AM | x=0.5–0.75: FCC | BCC | Chou et al. (2009) |

| x=0.875–1: BCC | FCC | |||

| AlxCoCrFeNi (x=0.5,0.75) | AM | FCC | BCC | Kao et al. (2009) |

| Al0.3CrFe1.5MnNi0.5 | AM | FCC | BCC | Tang et al. (2009) |

| Al0.3CrFe1.5MnNi0.5 | AM | FCC | BCC | Chen et al. (2010a) |

| Al0.5CrCuFeNi2 | DC | FCC1 | FCC2 | Ng et al. (2014) |

| Al0.3CrFe1.5MnNi0.5 | AM | BCC | FCC | Tang et al. (2012) |

| Al0.3CrFe1.5MnNi0.5 | AM | FCC1 | BCC+FCC2 | Tsao et al. (2012) |

| AlxCoCrFeNi (x=0.5–0.8) | AM | FCC | BCC | Wang et al. (2012b) |

| Al0.75CoCrCu0.25FeNiTi0.5 | SC | BCC | BCC | Wang et al. (2009a) |

| Al0.3CoFeNiSi0.3 | AM | FCC | BCC | Zhang et al. (2013b) |

| AlxCoCrFeNi (x=0.45–0.85) | AM | FCC | BCC | Kao et al. (2011) |

| Al0.3CrFe1.5MnNi0.5 | IM | FCC | BCC | Chuang et al. (2013) |

| AlCrCuFeNi2 | SC | FCC | BCC | Ma et al. (2013b) |

| Al0.3CoFeNiSi0.3 | AM | FCC | BCC | Zhang et al. (2013b) |

| Al0.5CoCrCuFeNiVx (x=0.4–2) | AM | FCC | BCC | Chen et al. (2006a) |

| Co0.5CrFeNiTi0.5 | MA | BCC | FCC | Fu et al. (2013b) |

| CrCuxFeTiZny (x/y=1/0, 3/1, 1 and x+y=40) | MA | FCC | BCC | Mridha et al. (2013) |

| Cr2Cu2FeNi2Mn | AM | FCC | BCC | Ren et al. (2010, 2012) |

| Cr2Cu2FeNiMn2 | AM | FCC | BCC | |

| CrCu2Fe2NiMn2 | AM | FCC | BCC | |

| Cr2CuFe2NiMn | AM | FCC | BCC | |

| Al0.8CoCrCuFeNi | AM | FCC | BCC | Tong et al. (2005b) |

| AlCo0.5CrCuFeNi | AM | FCC | BCC | Tung et al. (2007) |

| AlCoCr0.5CuFeNi | AM | FCC | BCC | |

| AlCoCrCuFe0.5Ni | AM | FCC | BCC | |

| AlCoCrCuFeNi0.5 | AM | FCC | BCC | |

| Al0.75CoCrCu0.25FeNi | AM | BCC | FCC | Zhou et al. (2008b) |

| AlCoCrFeNiTix (x=0.5, 1) | IC | BCC1 | BCC2 | Zhou et al. (2007b) |

| AlCoxCrFeNiTi0.5 | SC | x=1: BCC1 | BCC2 | Wang and Zhang (2008) |

| x=1.5, 2, 3: BCC | FCC | |||

| AlCoCuxNiTiZn | MA | x=0: BCC | FCC | Varalakshmi et al. (2010b) |

| x=8.33: BCC | FCC | |||

| x=50: FCC | BCC | |||

| AlxCoCrCu1−xFeNi (x=0.25–0.75) | AM | FCC | BCC | Zhang et al. (2010d) |

| Al0.5C0.2Co0.3CrFeNi | MA | BCC | FCC | Fang et al. (2014) |

| Alx(CoCrFeMnNi)100−x (x=8–16 at.%) | AM | FCC | BCC | He et al. (2014) |

| AlCoCrCuxNiTi (x=0.5–0.8) | AM | FCC | BCC | Wang et al. (2012a) |

| Al0.8CoCrCuFeNi | DC | FCC1+FCC2 | BCC | Liu et al. (2011) |

| AlxCoCrCuFeNi (x=1–2) | LC | BCC | FCC | Ye et al. (2011) |

| AlxCoCrFeNiTi0.5 (x=0.8–1) | AM | BCC1 | BCC2 | Dong et al. (2013b) |

| CoNiFeCrAl0.6Ti0.4 | MA | BCC | FCC | Fu et al. (2013a) |

| AlxFeCoNiCrCu0.5 | AM | x=1: BCC | FCC1 | Li et al. (2013a) |

| x=1.5: BCC | FCC2 | |||

| Al0.5CoCrFeCuNi | IM | FCC1 | FCC2 (Cu rich) | Sheng et al. (2013) |

| AlxCoCrCuFeNi (x=0.45,1) | MA | FCC1+FCC2 | BCC | Sriharitha et al. (2013) |

| CoCrFeMnNiZrx (x=0–0.3) | AM | BCC | FCC | Pauzi et al. (2013) |

| AlCuCrFeNiTix | AM | x=0: FCC1 | BCC1 | Razuan et al. (2013) |

| x=0.5, 1: BCC1+FCC1 | BCC2 | |||

| x=1.5: BCC1+BCC2 | FCC1 | |||

| AlCuCrFeNiNbx | AM | x=0: FCC1 | BCC1 | |

| x=0.5: FCC1+FCC2 | BCC1 | |||

| x=1, 1.5: FCC1+FCC2+BCC1 | BCC2 | |||

| Al2CoCrFeMo0.5Ni | AM | BCC2 | BCC1 | Hsu et al. (2013a,b) |

| AlCoCrCuFe2Mo0.2Ni | MA | BCC | FCC | Yuhu et al. (2013) |

| AlCoCrCuxFeNiTi0.5 (x=0, 0.25, 0.5) | IC | BCC1 | BCC2 | Zhou et al. (2008c) |

| Al0.5CoCrCu0.5FeNiTi0.5 | SC | FCC | BCC | Wang et al. (2009a) |

| Al2CoCrCuFeNi | LC | BCC | FCC | Qiu et al. (2014) |

| AlCoCrCuFeNiTix | AM | x=0.5: BCC1+FCC | BCC2 | Hongfei et al. (2011) |

| x=1: BCC1+FCC | BCC2 | |||

| Al2CoCrCuFeNixTi (x=0–1.0) | LC | FCC | BCC | Qiu and Liu (2013) |

| Al0.5CoCrFeMnNiZrx (x=0.1–0.3) | AM | BCC | FCC | Pauzi et al. (2013) |

| Al11.1(CoCrCuFeMnNiTiV)88.9 | IM | FCC | BCC | Zhou et al. (2007a) |

| CoCuyFeNiTix | AM | FCC1 (Cu rich)+FCC2 (Co rich) (x=1/3, 3/7, 3/5) | BCC (β-Ti rich) (x=3/5) | Mishra et al. (2012) |

| CoCuyFeNiTix (x/y=1/3, 3/7, 3/5, 9/11, 11/9, 3/2) | SC | FCC1 | FCC2 | Samal et al. (2014) |

| AlCoCrFeNiTix (x=0–2) | AM | BCC1 | BCC2 | Zhang et al. (2008a) |

| AlxCoCrFeNiTi (x=1–2) | AM | BCC | B2 | Zhang et al. (2009a) |

AM, arc melting; IM, induction melting; IC, injection casting; SC, suction casting; BS, Bridgman solidification; MeS, melt spinning; LENS, laser engineered net shaping; LC, laser cladding; MA, mechanical alloying; MaS, magnetron sputtering.