Appendix 2

This appendix gives an idea of the intermetallic compounds/intermediate phases and metallic glasses obtained in various equiatomic and nonequiatomic HEAs. The HEAs have been grouped according the nature of the major intermetallic/intermediate phase observed in them.

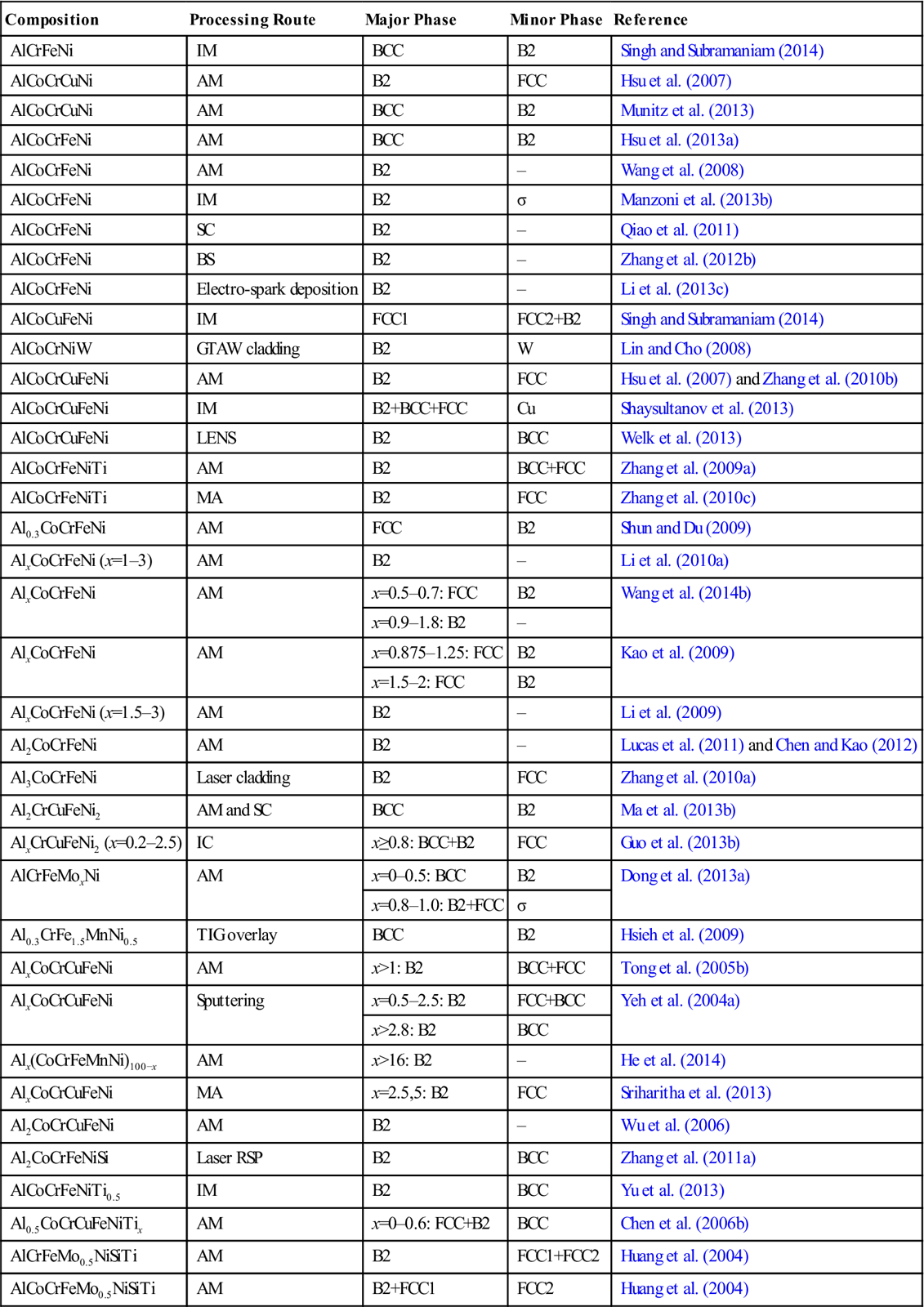

Table A2.1

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| AlCrFeNi | IM | BCC | B2 | Singh and Subramaniam (2014) |

| AlCoCrCuNi | AM | B2 | FCC | Hsu et al. (2007) |

| AlCoCrCuNi | AM | BCC | B2 | Munitz et al. (2013) |

| AlCoCrFeNi | AM | BCC | B2 | Hsu et al. (2013a) |

| AlCoCrFeNi | AM | B2 | – | Wang et al. (2008) |

| AlCoCrFeNi | IM | B2 | σ | Manzoni et al. (2013b) |

| AlCoCrFeNi | SC | B2 | – | Qiao et al. (2011) |

| AlCoCrFeNi | BS | B2 | – | Zhang et al. (2012b) |

| AlCoCrFeNi | Electro-spark deposition | B2 | – | Li et al. (2013c) |

| AlCoCuFeNi | IM | FCC1 | FCC2+B2 | Singh and Subramaniam (2014) |

| AlCoCrNiW | GTAW cladding | B2 | W | Lin and Cho (2008) |

| AlCoCrCuFeNi | AM | B2 | FCC | Hsu et al. (2007) and Zhang et al. (2010b) |

| AlCoCrCuFeNi | IM | B2+BCC+FCC | Cu | Shaysultanov et al. (2013) |

| AlCoCrCuFeNi | LENS | B2 | BCC | Welk et al. (2013) |

| AlCoCrFeNiTi | AM | B2 | BCC+FCC | Zhang et al. (2009a) |

| AlCoCrFeNiTi | MA | B2 | FCC | Zhang et al. (2010c) |

| Al0.3CoCrFeNi | AM | FCC | B2 | Shun and Du (2009) |

| AlxCoCrFeNi (x=1–3) | AM | B2 | – | Li et al. (2010a) |

| AlxCoCrFeNi | AM | x=0.5–0.7: FCC | B2 | Wang et al. (2014b) |

| x=0.9–1.8: B2 | – | |||

| AlxCoCrFeNi | AM | x=0.875–1.25: FCC | B2 | Kao et al. (2009) |

| x=1.5–2: FCC | B2 | |||

| AlxCoCrFeNi (x=1.5–3) | AM | B2 | – | Li et al. (2009) |

| Al2CoCrFeNi | AM | B2 | – | Lucas et al. (2011) and Chen and Kao (2012) |

| Al3CoCrFeNi | Laser cladding | B2 | FCC | Zhang et al. (2010a) |

| Al2CrCuFeNi2 | AM and SC | BCC | B2 | Ma et al. (2013b) |

| AlxCrCuFeNi2 (x=0.2–2.5) | IC | x≥0.8: BCC+B2 | FCC | Guo et al. (2013b) |

| AlCrFeMoxNi | AM | x=0–0.5: BCC | B2 | Dong et al. (2013a) |

| x=0.8–1.0: B2+FCC | σ | |||

| Al0.3CrFe1.5MnNi0.5 | TIG overlay | BCC | B2 | Hsieh et al. (2009) |

| AlxCoCrCuFeNi | AM | x>1: B2 | BCC+FCC | Tong et al. (2005b) |

| AlxCoCrCuFeNi | Sputtering | x=0.5–2.5: B2 | FCC+BCC | Yeh et al. (2004a) |

| x>2.8: B2 | BCC | |||

| Alx(CoCrFeMnNi)100−x | AM | x>16: B2 | – | He et al. (2014) |

| AlxCoCrCuFeNi | MA | x=2.5,5: B2 | FCC | Sriharitha et al. (2013) |

| Al2CoCrCuFeNi | AM | B2 | – | Wu et al. (2006) |

| Al2CoCrFeNiSi | Laser RSP | B2 | BCC | Zhang et al. (2011a) |

| AlCoCrFeNiTi0.5 | IM | B2 | BCC | Yu et al. (2013) |

| Al0.5CoCrCuFeNiTix | AM | x=0–0.6: FCC+B2 | BCC | Chen et al. (2006b) |

| AlCrFeMo0.5NiSiTi | AM | B2 | FCC1+FCC2 | Huang et al. (2004) |

| AlCoCrFeMo0.5NiSiTi | AM | B2+FCC1 | FCC2 | Huang et al. (2004) |

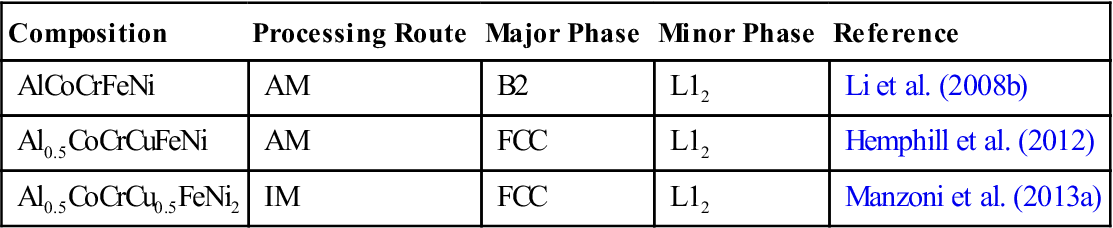

Table A2.2

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| AlCoCrFeNi | AM | B2 | L12 | Li et al. (2008b) |

| Al0.5CoCrCuFeNi | AM | FCC | L12 | Hemphill et al. (2012) |

| Al0.5CoCrCu0.5FeNi2 | IM | FCC | L12 | Manzoni et al. (2013a) |

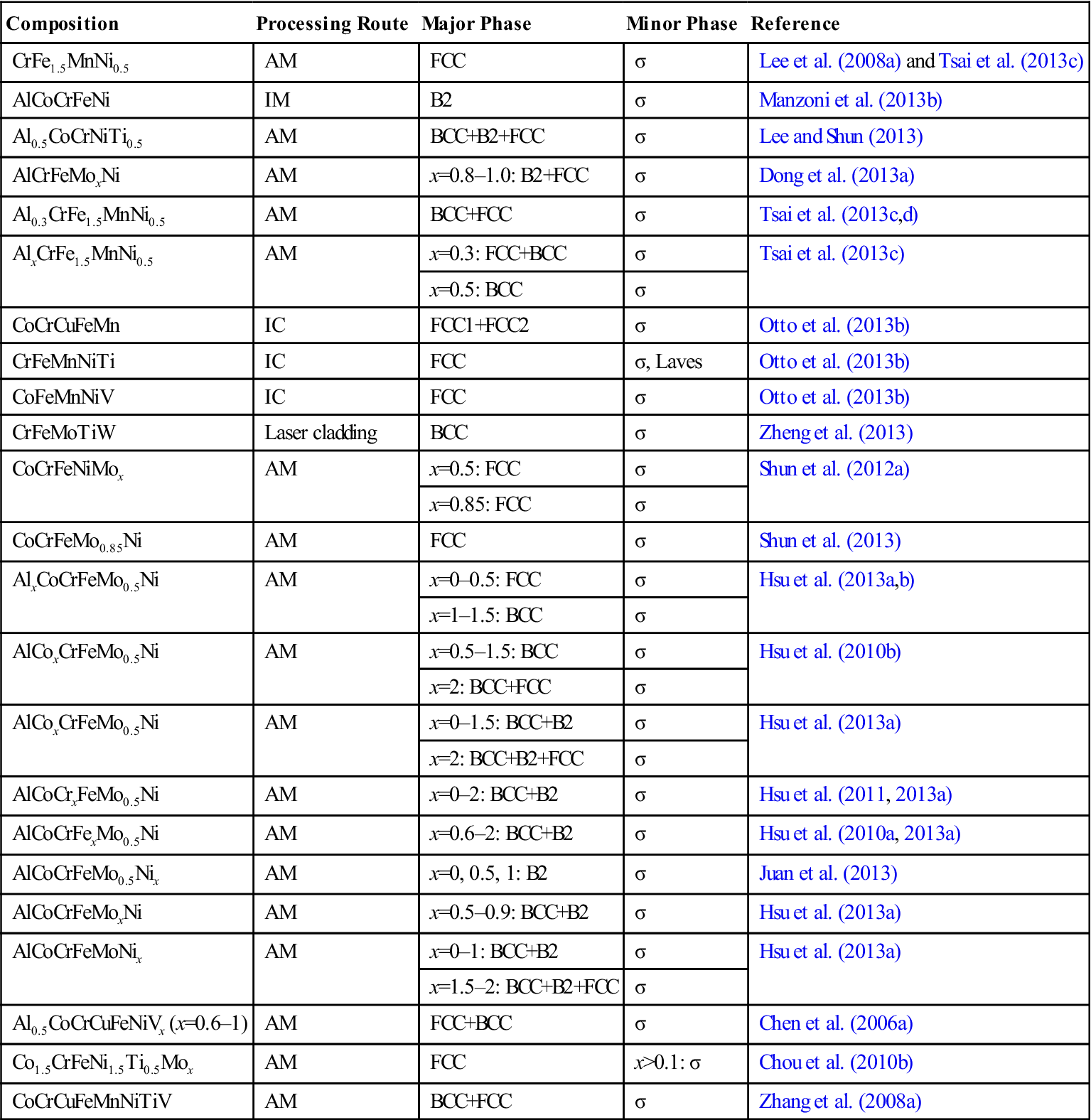

Table A2.3

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| CrFe1.5MnNi0.5 | AM | FCC | σ | Lee et al. (2008a) and Tsai et al. (2013c) |

| AlCoCrFeNi | IM | B2 | σ | Manzoni et al. (2013b) |

| Al0.5CoCrNiTi0.5 | AM | BCC+B2+FCC | σ | Lee and Shun (2013) |

| AlCrFeMoxNi | AM | x=0.8–1.0: B2+FCC | σ | Dong et al. (2013a) |

| Al0.3CrFe1.5MnNi0.5 | AM | BCC+FCC | σ | Tsai et al. (2013c,d) |

| AlxCrFe1.5MnNi0.5 | AM | x=0.3: FCC+BCC | σ | Tsai et al. (2013c) |

| x=0.5: BCC | σ | |||

| CoCrCuFeMn | IC | FCC1+FCC2 | σ | Otto et al. (2013b) |

| CrFeMnNiTi | IC | FCC | σ, Laves | Otto et al. (2013b) |

| CoFeMnNiV | IC | FCC | σ | Otto et al. (2013b) |

| CrFeMoTiW | Laser cladding | BCC | σ | Zheng et al. (2013) |

| CoCrFeNiMox | AM | x=0.5: FCC | σ | Shun et al. (2012a) |

| x=0.85: FCC | σ | |||

| CoCrFeMo0.85Ni | AM | FCC | σ | Shun et al. (2013) |

| AlxCoCrFeMo0.5Ni | AM | x=0–0.5: FCC | σ | Hsu et al. (2013a,b) |

| x=1–1.5: BCC | σ | |||

| AlCoxCrFeMo0.5Ni | AM | x=0.5–1.5: BCC | σ | Hsu et al. (2010b) |

| x=2: BCC+FCC | σ | |||

| AlCoxCrFeMo0.5Ni | AM | x=0–1.5: BCC+B2 | σ | Hsu et al. (2013a) |

| x=2: BCC+B2+FCC | σ | |||

| AlCoCrxFeMo0.5Ni | AM | x=0–2: BCC+B2 | σ | Hsu et al. (2011, 2013a) |

| AlCoCrFexMo0.5Ni | AM | x=0.6–2: BCC+B2 | σ | Hsu et al. (2010a, 2013a) |

| AlCoCrFeMo0.5Nix | AM | x=0, 0.5, 1: B2 | σ | Juan et al. (2013) |

| AlCoCrFeMoxNi | AM | x=0.5–0.9: BCC+B2 | σ | Hsu et al. (2013a) |

| AlCoCrFeMoNix | AM | x=0–1: BCC+B2 | σ | Hsu et al. (2013a) |

| x=1.5–2: BCC+B2+FCC | σ | |||

| Al0.5CoCrCuFeNiVx (x=0.6–1) | AM | FCC+BCC | σ | Chen et al. (2006a) |

| Co1.5CrFeNi1.5Ti0.5Mox | AM | FCC | x>0.1: σ | Chou et al. (2010b) |

| CoCrCuFeMnNiTiV | AM | BCC+FCC | σ | Zhang et al. (2008a) |

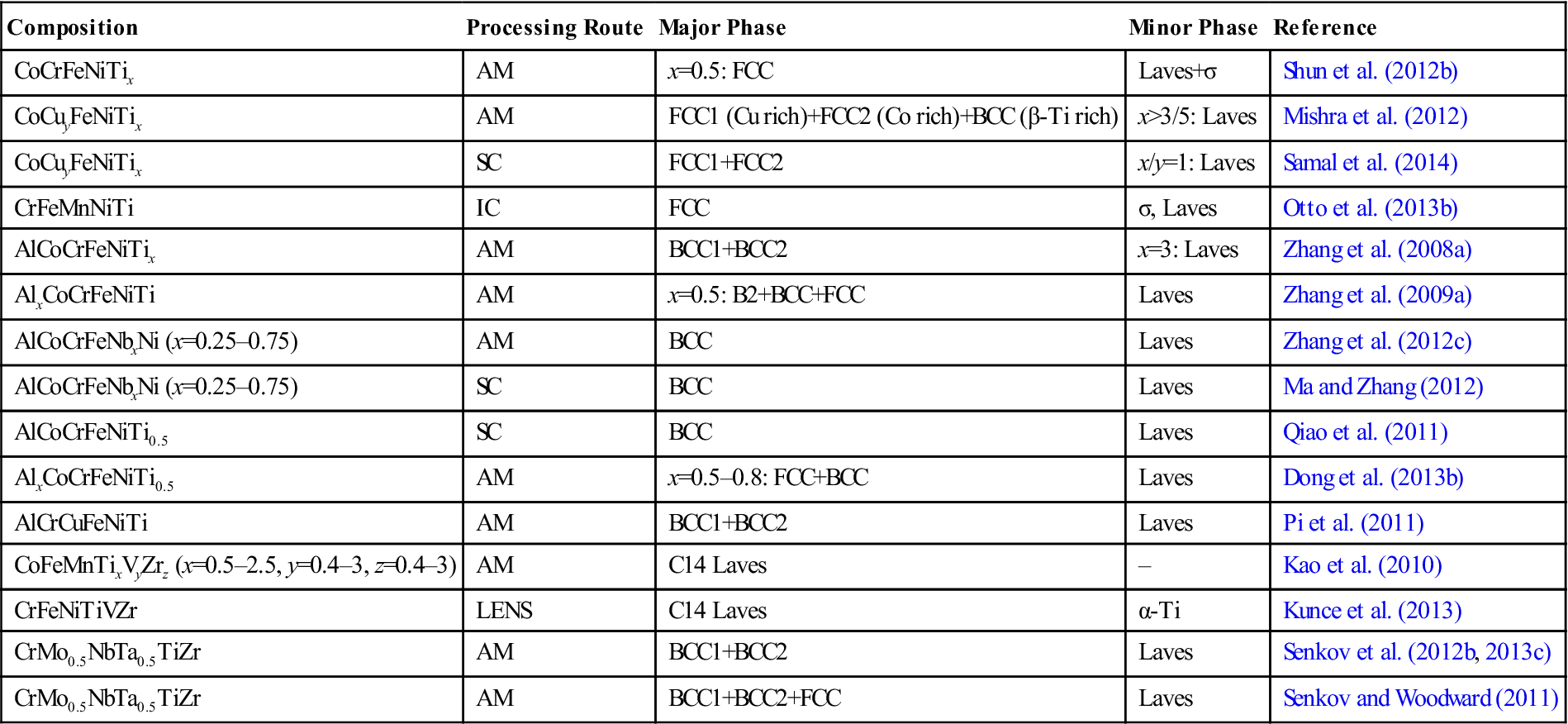

Table A2.4

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| CoCrFeNiTix | AM | x=0.5: FCC | Laves+σ | Shun et al. (2012b) |

| CoCuyFeNiTix | AM | FCC1 (Cu rich)+FCC2 (Co rich)+BCC (β-Ti rich) | x>3/5: Laves | Mishra et al. (2012) |

| CoCuyFeNiTix | SC | FCC1+FCC2 | x/y=1: Laves | Samal et al. (2014) |

| CrFeMnNiTi | IC | FCC | σ, Laves | Otto et al. (2013b) |

| AlCoCrFeNiTix | AM | BCC1+BCC2 | x=3: Laves | Zhang et al. (2008a) |

| AlxCoCrFeNiTi | AM | x=0.5: B2+BCC+FCC | Laves | Zhang et al. (2009a) |

| AlCoCrFeNbxNi (x=0.25–0.75) | AM | BCC | Laves | Zhang et al. (2012c) |

| AlCoCrFeNbxNi (x=0.25–0.75) | SC | BCC | Laves | Ma and Zhang (2012) |

| AlCoCrFeNiTi0.5 | SC | BCC | Laves | Qiao et al. (2011) |

| AlxCoCrFeNiTi0.5 | AM | x=0.5–0.8: FCC+BCC | Laves | Dong et al. (2013b) |

| AlCrCuFeNiTi | AM | BCC1+BCC2 | Laves | Pi et al. (2011) |

| CoFeMnTixVyZrz (x=0.5–2.5, y=0.4–3, z=0.4–3) | AM | C14 Laves | – | Kao et al. (2010) |

| CrFeNiTiVZr | LENS | C14 Laves | α-Ti | Kunce et al. (2013) |

| CrMo0.5NbTa0.5TiZr | AM | BCC1+BCC2 | Laves | Senkov et al. (2012b, 2013c) |

| CrMo0.5NbTa0.5TiZr | AM | BCC1+BCC2+FCC | Laves | Senkov and Woodward (2011) |

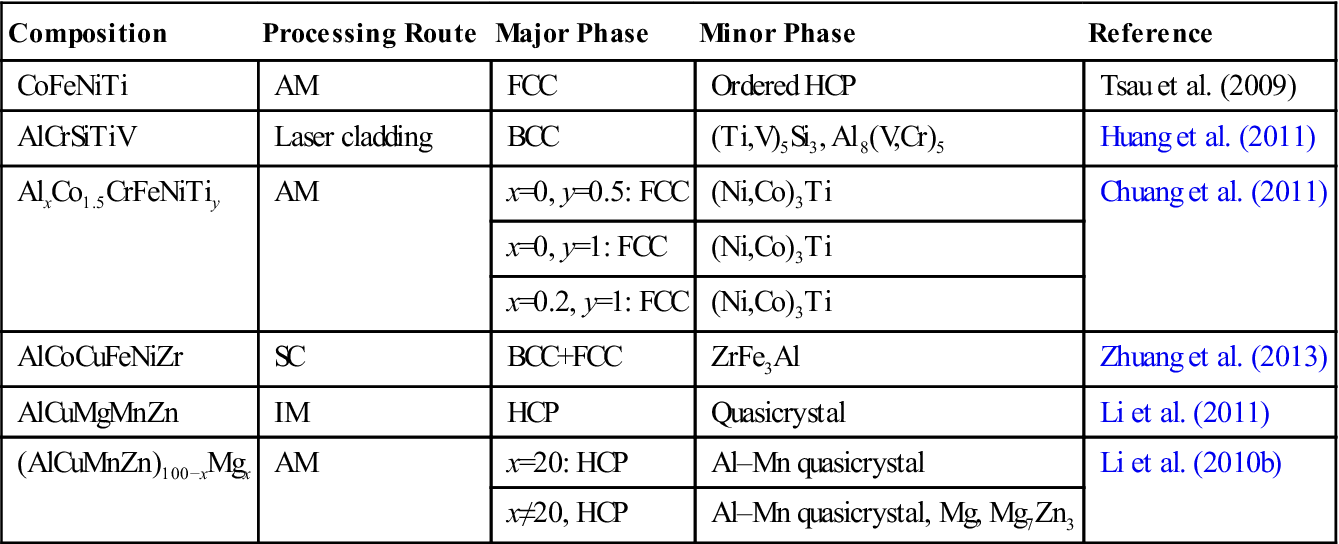

Table A2.5

Other Intermetallic Compounds in HEAs

| Composition | Processing Route | Major Phase | Minor Phase | Reference |

| CoFeNiTi | AM | FCC | Ordered HCP | Tsau et al. (2009) |

| AlCrSiTiV | Laser cladding | BCC | (Ti,V)5Si3, Al8(V,Cr)5 | Huang et al. (2011) |

| AlxCo1.5CrFeNiTiy | AM | x=0, y=0.5: FCC | (Ni,Co)3Ti | Chuang et al. (2011) |

| x=0, y=1: FCC | (Ni,Co)3Ti | |||

| x=0.2, y=1: FCC | (Ni,Co)3Ti | |||

| AlCoCuFeNiZr | SC | BCC+FCC | ZrFe3Al | Zhuang et al. (2013) |

| AlCuMgMnZn | IM | HCP | Quasicrystal | Li et al. (2011) |

| (AlCuMnZn)100−xMgx | AM | x=20: HCP | Al–Mn quasicrystal | Li et al. (2010b) |

| x≠20, HCP | Al–Mn quasicrystal, Mg, Mg7Zn3 |

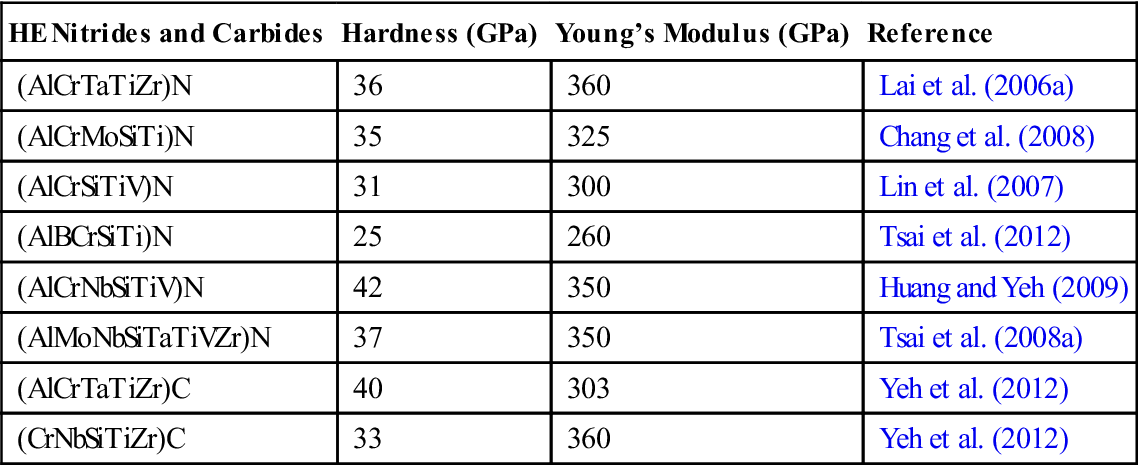

Table A2.6

Typical Strong HE Nitride and HE Carbide Films

| HE Nitrides and Carbides | Hardness (GPa) | Young’s Modulus (GPa) | Reference |

| (AlCrTaTiZr)N | 36 | 360 | Lai et al. (2006a) |

| (AlCrMoSiTi)N | 35 | 325 | Chang et al. (2008) |

| (AlCrSiTiV)N | 31 | 300 | Lin et al. (2007) |

| (AlBCrSiTi)N | 25 | 260 | Tsai et al. (2012) |

| (AlCrNbSiTiV)N | 42 | 350 | Huang and Yeh (2009) |

| (AlMoNbSiTaTiVZr)N | 37 | 350 | Tsai et al. (2008a) |

| (AlCrTaTiZr)C | 40 | 303 | Yeh et al. (2012) |

| (CrNbSiTiZr)C | 33 | 360 | Yeh et al. (2012) |

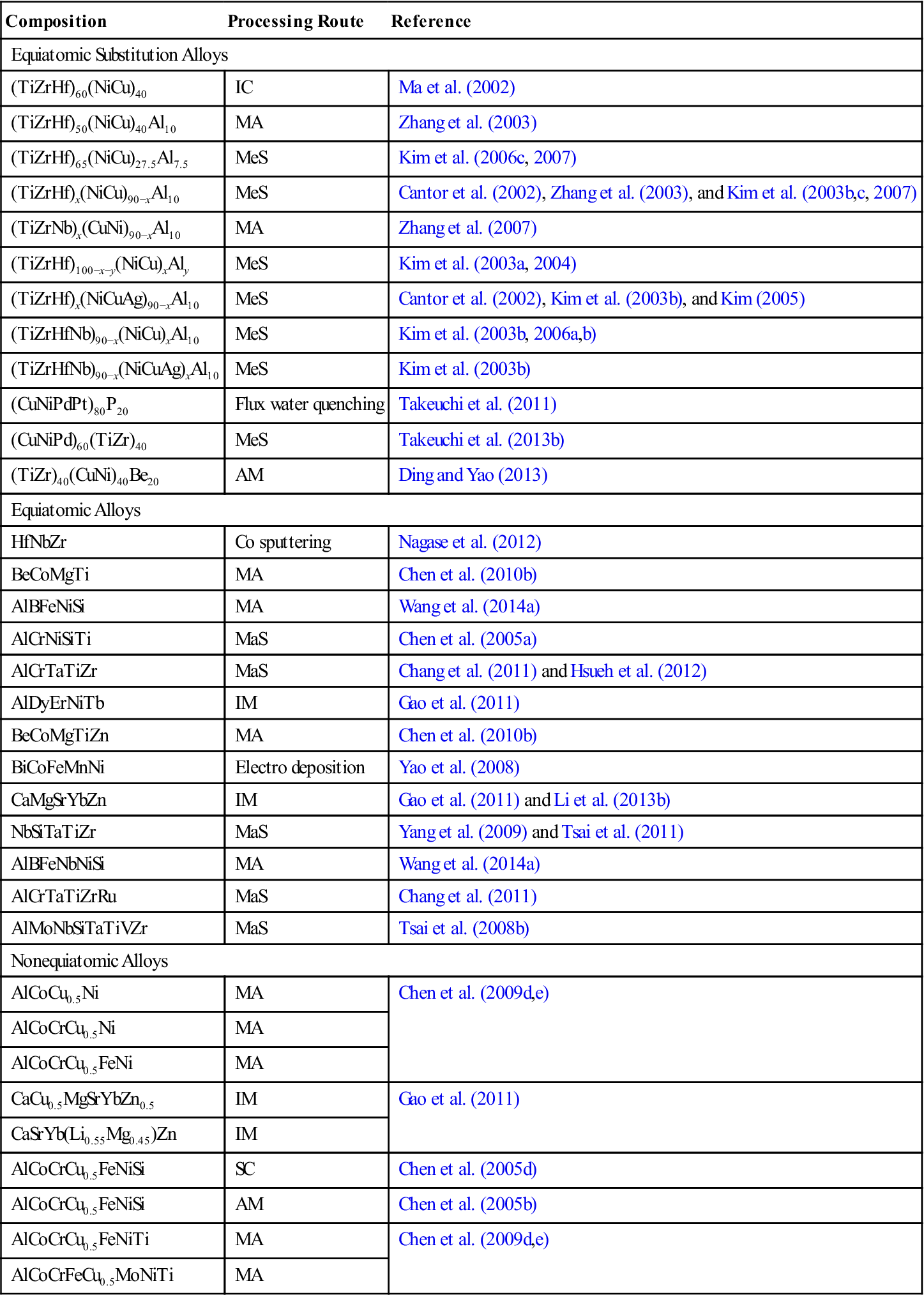

Table A2.7

| Composition | Processing Route | Reference |

| Equiatomic Substitution Alloys | ||

| (TiZrHf)60(NiCu)40 | IC | Ma et al. (2002) |

| (TiZrHf)50(NiCu)40Al10 | MA | Zhang et al. (2003) |

| (TiZrHf)65(NiCu)27.5Al7.5 | MeS | Kim et al. (2006c, 2007) |

| (TiZrHf)x(NiCu)90−xAl10 | MeS | Cantor et al. (2002), Zhang et al. (2003), and Kim et al. (2003b,c, 2007) |

| (TiZrNb)x(CuNi)90−xAl10 | MA | Zhang et al. (2007) |

| (TiZrHf)100−x−y(NiCu)xAly | MeS | Kim et al. (2003a, 2004) |

| (TiZrHf)x(NiCuAg)90−xAl10 | MeS | Cantor et al. (2002), Kim et al. (2003b), and Kim (2005) |

| (TiZrHfNb)90−x(NiCu)xAl10 | MeS | Kim et al. (2003b, 2006a,b) |

| (TiZrHfNb)90−x(NiCuAg)xAl10 | MeS | Kim et al. (2003b) |

| (CuNiPdPt)80P20 | Flux water quenching | Takeuchi et al. (2011) |

| (CuNiPd)60(TiZr)40 | MeS | Takeuchi et al. (2013b) |

| (TiZr)40(CuNi)40Be20 | AM | Ding and Yao (2013) |

| Equiatomic Alloys | ||

| HfNbZr | Co sputtering | Nagase et al. (2012) |

| BeCoMgTi | MA | Chen et al. (2010b) |

| AlBFeNiSi | MA | Wang et al. (2014a) |

| AlCrNiSiTi | MaS | Chen et al. (2005a) |

| AlCrTaTiZr | MaS | Chang et al. (2011) and Hsueh et al. (2012) |

| AlDyErNiTb | IM | Gao et al. (2011) |

| BeCoMgTiZn | MA | Chen et al. (2010b) |

| BiCoFeMnNi | Electro deposition | Yao et al. (2008) |

| CaMgSrYbZn | IM | Gao et al. (2011) and Li et al. (2013b) |

| NbSiTaTiZr | MaS | Yang et al. (2009) and Tsai et al. (2011) |

| AlBFeNbNiSi | MA | Wang et al. (2014a) |

| AlCrTaTiZrRu | MaS | Chang et al. (2011) |

| AlMoNbSiTaTiVZr | MaS | Tsai et al. (2008b) |

| Nonequiatomic Alloys | ||

| AlCoCu0.5Ni | MA | Chen et al. (2009d,e) |

| AlCoCrCu0.5Ni | MA | |

| AlCoCrCu0.5FeNi | MA | |

| CaCu0.5MgSrYbZn0.5 | IM | Gao et al. (2011) |

| CaSrYb(Li0.55Mg0.45)Zn | IM | |

| AlCoCrCu0.5FeNiSi | SC | Chen et al. (2005d) |

| AlCoCrCu0.5FeNiSi | AM | Chen et al. (2005b) |

| AlCoCrCu0.5FeNiTi | MA | Chen et al. (2009d,e) |

| AlCoCrFeCu0.5MoNiTi | MA | |

AM, arc melting; IM, induction melting; IC, injection casting; SC, suction casting; BS, Bridgman solidification; MeS, melt spinning; LENS, laser engineered net shaping; MA, mechanical alloying; MaS, magnetron sputtering.