By 1942 heavy tank design had advanced considerably since the German manufacturing firm Henschel and Son began development of a 30-tonne Durchbruchwagen (“breakthrough vehicle”) in 1937. While Germany had been on the strategic offensive between 1939 and 1942, lighter armored vehicles such as the 23-tonne Panzer III (main) and 25-tonne Panzer IV (infantry support) had proved sufficient in the maneuver and exploitation roles. Combat on the Eastern Front, however, necessitated tanks and self-propelled guns of increasing size and firepower as the Germans and Soviets both attempted to maintain an edge in the arms race. As Germany’s military stance steadily transitioned to the defensive the continued modification and modernization of existing armored vehicle types would not be a sustainable, long-term solution. An entirely new vehicle design was needed.

Henschel’s 57-tonne Tiger I had proved an effective counter to the Soviet T-34, and the heavier KV-1 and British designs, but by mid-war its boxy design was already six years old. The German authorities knew they would eventually need a more modern replacement and Henschel, and their rival Porsche, were subsequently tasked with its development. On May 26, 1942, the German Ordnance Department’s Waffenprüfamt 6 (Weapons Proving Office) determined that the replacement for the Tiger I should be able to achieve 40kph, have a main armament capable of penetrating 100mm of rolled homogeneous armor (RHA) from 1,500m, and possess front and side armor of 150mm and 80mm respectively. Under Waffenprüfamt 6’s office head, Oberst Friedrich-Wilhelm Holzhäuer, and chief designer, Heinrich Ernst Kniepkamp, development soon got underway for what would become the heaviest operational tank of the war.

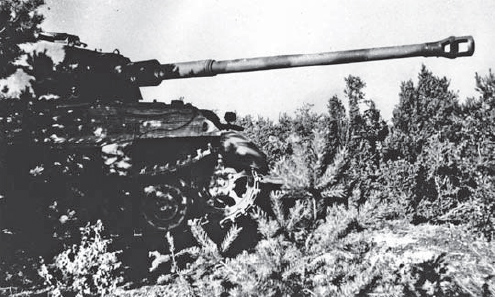

A Tiger II with a production turret (as evidenced by the two-piece barrel), with its Bosch headlight on the glacis and Zimmerit on the hull. The Tiger II was at its best when used as a “sniper,” given open terrain and infantry support nearby; the surrounding foliage would provide good concealment for such a position. (DML)

Henschel expanded on their 45-tonne VK (Vollketten, “fully tracked”) 45.01 (H), essentially a heavier version of the Panzer IV mounting the experimental 75mm/ 50mm Waffe 0725; this relied on the Gerlich Principle where a skirted round was fired through a tapering barrel to increase velocity, distance, and hitting power. To assist penetration the projectile’s tip comprised very hard, dense tungsten-carbide, but as this material was also used to create armor machining tools, limited stockpiles forced the cancellation of the weapon.

Porsche’s VK 45.02 (P) proposal was based on their previous attempt to secure the Tiger I contract. The vehicle’s weak engine and suspension, high ground pressure, and an over-engineered gasoline/electrical drivetrain – which relied on copper and other materials that would be in short supply for wartime mass production – sealed its fate. Intended to incorporate Rheinmetall-Borsig’s new 88mm Flak 41 L/74 antiaircraft gun, it was found to require a breech/counterweight that was too long to fit into turrets designed to house the shorter main armament of the Tiger I. Although Ferdinand Porsche held Hitler’s favor, his efforts to produce the Tiger II were canceled on November 3, 1942, in favor of the competition’s improved prototype.

As part of this Tigerprogram, Henschel’s updated VK 45.03 (H) possessed the long 88mm KwK 43 main gun coupled with sloped armor that resembled a bulked-up medium Mark V Panther. To simplify future maintenance and supply, the Tiger II also included transmission, track, engine cooling system, and other components that were interchangeable with the proposed Panther replacement. Hitler’s calls for thicker armor and improved maneuverability meant that work on the prototype was slower than anticipated as the vehicle’s side panels had to be strengthened during production to compensate for the added weight.

Since the 1800s Henschel had been a producer of locomotives, and they were therefore in a position to build a host of combat-related armored vehicles, trucks, aircraft, and artillery in the lead-up to, and during, World War II. Their factory complex at Kassel comprised locomotive and gun production, a foundry, and an armored vehicle assembly works where some 8,000 employees worked in two 12-hour shifts. Instead of an assembly line where skilled laborers assembled components in a sequential manner, Henschel organized production as a series of nine Taktzeiten (cycle times), “Takt” for short, where large vehicle sections were completed in a defined period before being moved along the line. Bombed some 40 times – often severely, as in a massive RAF raid on October 22/23, 1943 – the company continued to operate in at least a partial capacity until it was overrun by American ground forces on April 4, 1945.

In October 1943, 176 Tiger IIs (including three prototypes) were scheduled to be built at Henschel’s factory between November and January 1944. The following month the run of the new tank was expanded by an additional 350, and the order was finally increased to 1,500 vehicles. As Henschel (and Porsche) did not possess the ability to construct the raw turrets and hulls, these were provided by Friedrich Krupp AG (Aktiengesellschaft, “corporation”), which along with Dortmund Hörder Hutten Verein (DHHV) and Škoda Works of Czechoslovakia produced main armor components. Turrets would then go to the Kassel-based Wegmann and Company for final assembly before being sent to Henschel for mounting.

As Porsche’s design requirement for a 1,900mm turret ring proved too small for the 88mm main armament, Krupp designed one with a 2,000mm diameter to provide a stable platform and accommodate both Porsche’s and Henschel’s lengthy main armaments with minimal modifications. As Porsche had prematurely created 50 turrets for their VK 45.02 (P) prototype the first Tiger II chassis were so crowned. Externally the “pre-production” turret possessed a curved mantlet (similar to Panther D and A models), which proved resilient, but low impacts could damage the turret ring or deflect a round into the much thinner hull roof. This design shortcoming, and the rather involved construction process, caused the cessation of further such “pre-production” turrets on December 7, 1943. Krupp created the remaining “series production” versions, which featured a Saukopf (pig head) mantlet that minimized impact-related jamming of the main gun, and could accommodate many of Porsche’s turret components with little or no alteration. Its more simplified armor configuration also resulted in greater internal space so that it held 86 main gun rounds instead of the 80 in Porsche’s design.

A Zimmerit-covered Tiger II with its turret traversed slightly to provide better access to the engine compartment. A Büssing-NAG 4500 truck with a 3-tonne crane assists with the removal of the 700hp engine for an overhaul. A 2-tonne jib crane with its tripod base fitted into the turret “Pilz” sockets could be used for lighter jobs. (DML)

The Tiger II’s interior and crew positions adhered to conventional German tank layout, with the forward compartment housing the driver and radio operator/bow machine gunner behind the glacis on the left and right, respectively. The driver had an adjustable seat, which could be raised to allow his head to protrude through his open hatch to improve visibility when driving in non-combat environments. Both crewmen had their own hatches and were separated by the vehicle’s drivetrain and radio equipment.

The central fighting compartment comprised the turret, which, because of the vehicle’s lengthy barrel, needed to be long and roomy to accept the breech’s recoil and function as a counterweight. An attached platform/“basket” enabled the turret to rotate as a complete entity with its component parts and floor, which improved safety and operating efficiency. The gunner sat to the left, just ahead of the commander, with the loader to the breech’s right. Because of the turret’s size it limited the commander’s downward visibility from the cupola when “buttoned up.” As the Tiger II’s transmission and drive wheels were at its front, a universal joint needed to be run under the turret basket to the rear-mounted engine, which increased the vehicle’s height by 0.5m, and added to its weight as more armor was needed to cover the difference.

Although the Tiger II had a 17-month production run few significant changes were made to the basic design. Some vehicles in the first two series (420500 and 420530) had deep fording submersion kits attached, but these were not used outside of testing. In January 1944 flat fenders were replaced with curved ones, straight exhaust pipes were bent to keep exhaust fumes from entering the engine, and a device was added to heat the cooling water to improve starting in wintry conditions. In May, a new type of track was introduced that minimized uneven wear and helped prevent it from climbing over the drive sprocket when in motion. Factory-applied Zimmerit anti-magnetic paste was used on all four series runs until September 9, 1944, when it was mistakenly believed to catch fire following projectile impacts, and was discontinued. Because the vehicle’s great weight placed considerable stress on gaskets, seals, and sockets, such components were improved to prevent leaks and breakdowns.

A Tiger II “series production” turret with its attached basket. Unlike that of the IS-2 this design allowed for the entire fighting compartment to traverse. With greater crew comfort and reduced risk of injuries, the odds of getting the first look/first hit/first kill against enemy armor were improved. (DML)

Tiger II with a “pre-production” (Porsche) turret. The curved mantlet could create a “shot trap” by redirecting incoming rounds down into the more thinly armored upper hull. Appearing fully equipped (minus side skirts and cupola armament), the vehicle is probably en route to operational status. (DML)

Three “Pilz” sockets were welded to the turret’s roof to anchor the tripod of a 2-tonne jib crane that was used to help move heavier vehicle components. In July, four track link hangers were mounted to the turret’s sides, and retro-fitted to existing vehicles, and in the following month the 20-tonne jack was no longer issued. Starting in November 1944, Wegmann received 20 Tiger IIs for conversion into Befehlswagen (command vehicles) housing either an FuG 8 (SdKfz 267) or an FuG 7 radio (SdKfz 268), but these did not re-enter combat until February and March 1945. To prevent rain from obscuring the gunner’s view, small shields were fitted over the sight’s turret opening, starting in January 1945.

When production of the “heavy” KV-1 (named for Marshal Kliment Voroshilov) began in 1939 it was found to have excellent firepower and armored protection when compared to contemporary armored vehicles. Intended as a complement to the more agile “medium” T-34, it was dogged by engine, transmission, and suspension problems. Unable to keep pace in a headlong offensive operation, and often stranded by bridges that could not support its 45-tonne weight, its reliability shortcomings, high production cost, and essentially identical armament to the T-34 made the design increasingly extraneous. A change would be needed, but with the Germans threatening to take Leningrad in the autumn of 1941, the nearby State Plant No. 100 was forced to halt production of the T-34 and KV-1, and join the great industrial migration to relocate in the east. The KV-1’s poor combat performance the following year at Kharkov and in the Crimea was the final straw. To avoid the disruption of immediately halting KV-1 production, it was decided to reorganize the vehicles into independent, infantry support tank regiments until a replacement could be produced. By doing this tank brigades would have a more homogeneous composition of T-34s and light armored vehicles.

Once resettled as the Chelyabinsk State Plant No. 100 (ChKZ), the company merged with remnants of related new arrivals such as the Izhora Works No. 187/35, State Plant No. 185 (S. M. Kirov), and State Plant No. 183 (formerly Kharkov Locomotive Works), which specialized in plate armor, heavy armored vehicles, and engines, respectively. To coordinate these armored vehicle production facilities, each was subordinated to the Chelyabinsk Tractor Plant (ChTZ), which had recently transitioned to tank manufacturing. Safely away from the advancing German front lines, and steadily able to overcome quality control issues resulting from the move and integration, the overall organization of seven relocated factories was designated the Chelyabinsk Heavy Machine Plant No. 100 (ChZTM). It was one of the few factories with cranes big enough to lift heavier armored vehicles, and production progressed along a 1km-long main assembly line that was supported by an auxiliary line at designated intervals. To maximize output, workers repeated simple tasks, and all section components remained in one location. Due to the complex’s specialized purpose and massive proportions it soon garnered the nickname “Tankograd” (“Tank City”).

In March 1942 State Plant No. 185’s Special Construction Bureau-2 (SKB-2) commenced work on the KV-1’s replacement. As with other tank factory design bureaus, ultimate authority rested with the chief designer, Nikolai Shashmurin, who was responsible for day-to-day operations. Under Deputy Chief Zhozef Kotin and his factory chief – who was responsible for meeting production goals – machinists, engineers, and other technicians began work on the KV-13 “universal tank,” which was to take on the roles of both the T-34 and KV-1. To minimize weight, while maintaining maneuverability, the turret and much of the hull were to be cast to economize internal space and strengthen key vehicle sections.

A Landser from Panzergrenadier Division Grossdeutschland inspects a “broken-nose” IS-2, which has suffered a penetration above the driver’s position causing an internal explosion and damaging the suspension. The hole in the turret side is a small-arms firing port, minus its plug. Behind vehicle “23” two more IS-2s have also been immobilized; the original photograph may have been altered to make these two appear closer. (DML)

Production run: November 1943–March 1945 (17 months)

Vehicles produced: 492 (inc. three prototypes)

Combat weight: 69.8 tonnes (with “series” turret)

Crew: five (commander, gunner, loader, driver, radio/bow MG operator)

Dimensions

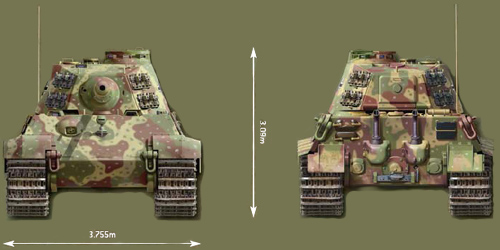

Length (hull / overall): 7.62m / 10.286m

Width (without aprons / with aprons): 3.65m / 3.755m

Height: 3.09m

Ground clearance: 0.5m

Armor (degrees from vertical)

Glacis (upper / lower): 150mm @ 50° / 100mm @ 50°

Hull side (upper / lower): 80mm @ 25°/ 80mm @ 0°

Hull rear: 80mm @ 30°

Hull roof: 40mm @ 90°

Hull bottom (front / rear): 40mm / 25mm @ 90°

Turret face: 180mm @ 10°

Turret mantlet: 150mm (Saukopf)

Turret side: 80mm @ 21°

Turret rear: 80mm @ 20°

Turret roof: 40mm @ 78°

Cupola side: 150mm @ 0°

Armament

Main gun: 88mm KwK 43 L/71 (22 turret/64 hull) (typically 50 percent Pzgr 39/43 and 50 percent Sprgr 43)

Sight: Turmzielfernrohr 9d articulated monocular (2.5×/5×)

Secondary: 2 × 7.92mm MG 34 (coaxial; bow); additional 7.92mm MG (antiaircraft) (5,850 rounds)

Main gun rate of fire: 5–8rpm

Turret rotation (360°): 10 sec @ 3,000 engine rpm; 19 sec @ 2,000; 77 sec by hand

Communications

Internal: Bordsprechanlage B intercom

External: FuG 5 10-watt transmitter/USW receiver (wireless telegraphy and radio telephony stationary ranges were 6km and 4km, respectively; an FuG 2 (USW receiver only) was less common, and had a comparable range)

Motive power

Engine: Maybach HL 230 P30 12-cylinder (water-cooled) 23l (gasoline)

Power/to weight: 600hp (sustained) @ 2,500rpm; 700hp (max.) @ 3,000rpm (10hp/tonne)

Transmission: Maybach OLVAR EG 40 12 16 B; eight forward, four reverse gears

Fuel capacity: 860l in seven tanks

Performance

Ground pressure (hard / soft): 1.03 kg/cm2/ 0.76kg/cm2

Maximum speed (road / cross-country): 41.5kph / 20kph

Operational range (road / cross country): 170km/ 120km

Fuel consumption (road / cross country): 5.1l/km / 7.2l/km

Fording: 1.8m

Step climbing: 0.8m

Climbing, degrees: 35°

Trench crossing: 2.5m

As the Soviet offensive continued its seemingly inexorable northward advance, by February 3 warmer temperatures and thawing terrain were hampering movement. The commander of one of seven German vehicles that took part in a counterattack to help stabilize the situation southwest of Arnswalde, SS-Untersturmführer Karl Brommann maneuvered his Tiger II near Sammenthin. Although making progress throughout the day, at 0700hrs on February 4 he ran into heavy enemy antitank fire that, when combined with a similar event four days previously, immobilized his vehicle. With Soviet forces threatening to overrun the area three Tiger IIs were brought in to tow Brommann’s stricken vehicle back to Arnswalde’s central square during the night. From there it was to be withdrawn for servicing.

The Tiger IIs deployed by 503rd Heavy SS Panzer Battalion had been shipped directly from the factory and so Brommann’s vehicle would have appeared new, save for any damage from combat or having to maneuver across terrain that could not adequately support its weight. It had a factory-applied “ambush” color scheme, which after early January 1945 was a dark yellow (RAL (Reich Committee for Delivery Terms and Quality Assurance) 7028) basecoat. A hard-edged chocolate brown (RAL 8017) and olive green (RAL 6003) were applied as the vehicle’s primary pattern. Small dark yellow (RAL 7028), gray white (RAL 9002), or light gray (RAL 7035) spots were added to the green and brown sections, and olive green to the yellow parts. Internally, the vehicle was painted dark yellow (RAL 7028) as supplies of beige (RAL 1001) dwindled. The turret floor and lower hull were often left in their red oxide primer (RAL 8012), which by war’s end encompassed the entire interior as construction times were reduced. Although Brommann’s vehicle “221” (the numbers denoting 2nd Panzer Company/2nd Platoon/first vehicle) did not have its number displayed on the turret (unlike the vehicles of 1st Panzer Company, which had them as three black-outlined digits), it did have a Balkan cross. Spare track sections stored on the turret sides acted as additional armor protection. A water-soluble white paint was used to whitewash the vehicles when operating in winter conditions.

The specifications and illustrations are of a Tiger II Ausf B of 2nd Panzer Company, 503rd Heavy SS PanzerBattalion, February 1945 (common to vehicles 269–72,350–55, and 362–90).

Rear view of an early model IS-2 with a post-November 1943 rear hull (as evidenced by the engine access ports). Probably immobilized, judging by the surrounding debris, this camouflaged vehicle has its tow cables unhitched and its external fuel and oil tanks are missing. Note the lack of a turret bulge to the cupola’s left, indicating a narrow mantlet. (DML)

Within two months a promising prototype was unveiled, but its high speed and horsepower were considerably negated by an underperforming transmission. SKB-2’s assistant bureau head (Nikolai Dukhov) and chief designer Shashmurin conducted work on a second replacement design, but the outcome was again mixed. The resulting KV-1S “fast” tank resembled a T-34 turret atop a KV-1 frame, and although it had an improved transmission, numerous structural changes such as weighting armor to the frontal arc at the expense of the rest of the vehicle led to considerable delays.

When the recently fielded, and captured, heavy German Tiger I was evaluated in January 1943, Soviet authorities quickly reevaluated their present heavy tank development program. On February 24 the State Defense Committee (GKO), with General Staff approval, issued decree No. 2943ss (“ss” meaning “completely secret”) ordering State Plant Nos 185 (S. M. Kirov) and 100 to develop two new heavy tank prototypes based on the KV-13 that would be capable of dealing with the latest enemy threat. As the 76.2mm L/41 ZiS-5 and 122mm U-11 howitzer were already in production and showed promise against heavier enemy armor, Development Projects “Object 233” and “Object 234” were respectively started.

On September 4, 1943, GKO ordered State Plant No. 100, and its subcontractors UZTM and State Plant No. 200, to improve upon the existing solution. In an effort to distance himself from his disgraced father-in-law, Voroshilov, and gain political favor, Kotin named the new vehicle type “Iosef Stalin.” As part of “Bureau IS” (formerly SKB-2), Dukhov favored a design using the KV-13’s hull, armor configuration, and suspension, and the T-34’s 76.2mm F-34 or the KV-1’s ZiS-5. After an unsuccessful attempt to mount a 122mm S-31 main gun into the existing turret, he settled for the smaller-caliber air defense gun M-1939 which was reworked as the D-5T 85mm L/51.6. As with the KV-1S-derived KV-85 (“Object 239”), this IS-85/IS-1 (“Object 237”) was also produced in limited numbers from October 1943 to January 1944 as an interim solution. In light of the 85mm gun’s sub-par performance against the heavier German Tiger and Panther tanks fielded at Kursk, focus turned to the 122mm U-11 howitzer.

To maintain high production numbers Soviet designers relied on existing gun types as much as possible for their artillery and armored needs. While this simplified production and logistics, the only options for improving a main gun’s velocity, accuracy, and penetrative potential were to lengthen its barrel or improve ammunition. Although the 100mm gun outperformed the 122mm A-19 Model 1931 field gun in penetrative capability, weight, and rate of fire, the former was not available in great numbers. By incorporating recoil absorbers and parts from the U-11 howitzer, Kotin’s team mated the A-19’s barrel to a 122mm howitzer M-30 carriage to produce the D-25T. After successful field testing, “Object 240” was christened the “IS-2” on October 31, 1943, and became operational the following April. To make use of existing IS-1s, Plant No. 100 converted several vehicles to accept the D-25T as “IS-2s,” with the remainder being used for training and other non-combat functions.

With a tank’s battlefield life generally brief, the IS-2’s designers continued with what had made the T-34 so successful: loose tolerances, simplicity, and ruggedness. Such attributes facilitated mass production and maintenance, and made for a vehicle that could be produced without unduly taxing current manufacturing capabilities. Crew comfort was a secondary concern, and even though the IS-2 had one fewer crewman than the KV-1, the interior was cramped. With only the driver occupying the forward control compartment, the duties of radio/machine-gun operator were taken over by the commander and driver, respectively. To keep from degrading the glacis’ integrity and anti-ballistic shape, aside from the driver’s vision port, the bow machine gun was rigidly fixed into the hull’s forward right side. Electrically fired, the weapon provided little more than suppressive fire along the vehicle’s axis. With the tank having only two hatches located in the turret, the driver was in a particularly dangerous position should quick extraction be needed.

The remaining crewmen were stationed in the central fighting compartment with the gunner and commander positioned along the left of the breech and the loader/coaxial machine-gun operator to the right. Crew efficiency was hampered by the lack of a turret basket, so, to keep the trio from having to negotiate hull components when traversing, each was provided with a suspended seat. As loading the heavy ammunition in such an environment would be difficult, it was stored with the propellant sections in metal, floor-mounted boxes (often covered by a rubber floor mat), while the projectiles were distributed in racks along the turret bustle. F-1 hand grenades and pistol flares were also carried, and the machine guns were mounted for easy removal should the crew be forced to fight outside their vehicle.

An early-model ChKZ-produced IS-2 near Riga on August 10, 1944. Its D-25T gun has a “German style” muzzle brake (as opposed to the TsAKB style that soon became standard) and a screw-type breech block. (DML)

An early-chassis IS-2 with a partially open driver’s visor to help with visibility during operation. A late-war 12.7mm DShK 1938 heavy machine gun is mounted on the cupola of vehicle “35” for antiaircraft use. The splash guard across the glacis minimized the damage caused by small-arms rounds and shrapnel. (DML)

The engine and drivetrain took up the rear compartment, which negated having to run a universal joint along the bottom of the vehicle as on the Tiger II. This allowed for a shallower hull that reduced the vehicle’s overall height and silhouette. IS-2s had 190- and 245-liter fuel cells in the crew compartment, and one of 85 liters near the motor and transmission. As a reserve, four unconnected 90-liter external cells (three diesel fuel/one oil) were added to the hull’s side.

Production run: April 1944–June 1945 (15 months)

Vehicles produced: 4,392 (+ 107 IS-1s)

Combat weight: 46.08 tonnes (53 percent armor weight)

Crew: four (commander, gunner, loader, driver)

Dimensions

Length (hull / overall): 6.77m / 9.83m

Width: 3.07m

Height: 2.73m

Ground clearance: 470mm

Armor (degrees from vertical)

Glacis (upper / lower): 120mm @ 60°/ 120mm @ 30°

Hull side (upper / lower): 90mm @ 15°/ 90mm @ 0°

Hull rear (upper / lower): 60mm @ 49°/ 60mm @ 41°

Hull roof: 30mm @ 90°

Hull bottom: 20mm @ 90°

Turret mantlet: 100mm (round)

Turret side: 90mm @ 18°

Turret rear: 90mm @ 30°

Turret roof: 30mm @ 85–90°

Cupola (side / top): 90mm @ 0° / 20mm @ 90°

Armament

Main gun: 122mm (121.92mm) Model 1943 D-25T L/43 (28 rounds – typically 20 OF-471/OF-471N (HE) and 8 BR-471 (APHE))

Sight: TSh-17 articulated telescope (4×); MK-IV periscope

Secondary: 3 × 7.62mm DT MGs (2,331 rounds for hull, coaxial, and turret rear)

Main gun rate of fire: 2–3rpm

Communications

Internal: TPU-4-BisF intercom

External: 10-R; later 10-RK (W/T and R/T stationary ranges were 24km and 16km, respectively)

Motive power

Engine: 12-cylinder (water cooled) 38.9l (diesel) (V-2-IS or V-2-K)

Power/to weight: V-2-IS: 600hp @ 2,300rpm (13hp/tonne) or V-2-K: 520hp @ 2,200rpm (11.3hp/tonne)

Transmission: Synchromesh (clutch synchronizer), eight forward, two reverse gears

Fuel capacity: 790l (520l + 3 × 90l external tanks)

Performance

Ground pressure: 0.81 kg/cm2

Maximum speed (road / cross-country): 37kph / 19kph

Operational range (road / cross-country): 150km (230km with external tanks) / 120km (185km)

Fuel consumption (road / cross-country): 3.5l/km / 4.3l/km

Fording: 1.3m

Step climbing: 1m

Climbing, degrees: 36°

Trench crossing: 2.5m

By February 8, 1945, Soviet forces had encircled Arnswalde, and armored spearheads were pushing ahead to reach Kolberg and cut off German defenders around Danzig. North of Reetz Forty-Seventh Army’s 70th Guards Heavy Tank Regiment and 397th Rifle Division seemed to have a clear path to achieve this goal as German defenses remained largely fluid. As part of this mix of T-34/85s, trucks, infantry, and artillery, IS-2s were diverted westward to counter a German armor and infantry probe coming out of Ziegenhagen.

After having finished transitioning from KV-1s to IS-2s the previous October many of these crewmen were still getting used to their mounts as they maneuvered through the village of Klein Silber. Although infantry provided small-arms support from the surrounding buildings, a lack of effective communication with the IS-2s resulted in the lead vehicle stumbling into the path of a German Tiger II. Before the Soviet crew could react it was struck between the turret and glacis by an 88mm Pzgr Patr 39/43 and disabled. Anticipating being struck again for good measure those crewmen who could baled out and made their way back to friendly lines.

At this stage of the war the vehicle retained its original green color, over which splattered mud and dust has provided a degree of camouflage. By 1945 Soviet efforts to camouflage armored vehicles beyond their Green “83020 4BO” (basic) security paint jobs steadily declined. For winter, a water-soluble whitewash Type B paint was generally available, and applied by the crew or at the Maintenance Company. As camouflage paint patterns were seldom used, foliage could be substituted. With combat occurring in an increasingly urbanized environment, unit identification became a priority to avoid confusion, and prevent mistaken targeting by friendly ground and air elements. After 1942 this fluctuated among several variations to prevent the enemy from emulating them, such as a white triangle (red during the winter) surrounding a yellow circle. Tactical identification for IS-2 units could be allocated for specific missions by their parent corps or higher commands. IS-2s of 70th Guards Heavy Tank Regiment, like the vehicles of many of the heavy tank regiments, do not appear to have displayed identification numbers on their turrets.

The specifications and illustrations are of a 5th-series IS-2 of 70th Guards Heavy Tank Regiment, February 1945.

In February 1944 the Central Scientific Research Institute No. 40 determined that the IS-2’s original “stepped” glacis would need 20–30mm of additional armor to effectively resist German 75mm and 88mm armor-piercing rounds. As a solution a single, 60-degree slab of armor provided the required extra strength without an increase in thickness or weight, which necessitated the changing of the driver’s plug visor to a simple vision slit. Within four months State Plant No. 200 and UZTM were producing the straightened glacis in, respectively, a cast or welded capacity. Externally welded handrails were also added to assist mounted infantry.

During March a wedge-type breech block was incorporated into the D-25T to facilitate loading, but it did little to improve the system’s dismal rate of fire. To vent some of the propellant gas, minimize excessive post-firing smoke caused by poor-quality propellants, and reduce recoil the initial “T”-shaped, single-chamber muzzle brake was temporarily replaced by a more reliable German-style, dual-chamber variety. This, however, restricted vision through the TSh-17 articulated (jointed) telescopic gunsight as it was mounted too close to the breech. State Plant No. 9 in Gorky solved the problem by mounting it further to the left, which meant subsequent turrets had an accommodating bulge beside the cupola and a widened mantlet. The loader’s PT4-17 periscopic sight was upgraded to a MK-IV, and a TsAKB (Central Artillery Design Bureau)-designed muzzle brake, which reduced recoil by up to two-thirds, was incorporated as standard. A rear hinge bracket/lock was added to hold the gun in its rear-facing traveling position, and from January 1945, IS-2s were equipped with an external, cupola-mounted 12.7 × 108mm DShK 1938 machine gun for use against ground and air targets.