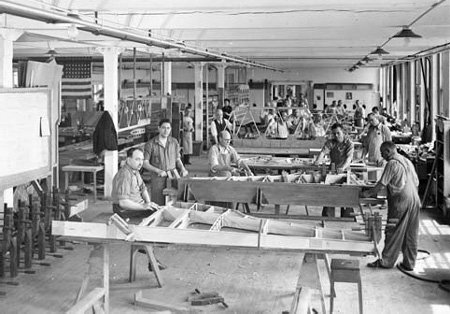

During World War II, Steinway & Sons was directed to put pianos aside and make troop-carrying aircraft. This photograph from 1943 shows workers in the factory putting together the tail assembly for the CG-4A glider. Courtesy of LaGuardia and Wagner Archives.

The piano being the kind of beast it is, it’s largely an instrument that is imaginative. In fact, nothing, really, should work in the piano at all. I mean, you have a bunch of materials that are largely incongruous—materials that really don’t fit with one another—iron and wood and felt. These are all materials that are essentially in conflict with one another and, of course, this Western imagination has created an illusion that they are perfectly harmonious.

—David Rubin, manager, Concert and

Artists department, Steinway & Sons

IN 1942, WHEN VERNE EDQUIST was eleven years old and had yet to learn the rudiments of piano tuning at the Ontario School for the Blind, and as ten-year-old Glenn Gould was starting his studies at the Toronto Conservatory, a piano both men would grow intimately familiar with was being built in fits and starts five hundred miles to the south in Astoria, Queens.

That this collection of wood, wire, metal, and glue eventually became an elegant and ravishing ebony beauty was something close to a miracle, as it was built during the period just after America entered World War II, when the government began to commandeer factories of all kinds for the war effort: Steinway & Sons was directed by the government to build components for combat gliders. It was an extraordinary request. Not only was Steinway & Sons unaccustomed to adapting to new routines, especially those it hadn’t invented itself, but by the 1940s it was making the world’s finest musical instruments. To be asked now to switch over to mass-producing wooden airplane parts required a seismic shift in the corporate mind-set. And it was a mind-set that had been fixed in bedrock a century earlier.

IN 1836, HEINRICH Engelhard Steinweg, a cabinetmaker by trade, cobbled together a piano in the kitchen of his home in the town of Seesen, Germany. From then on, what set Steinway & Sons apart was a combination of rigor, wile, and inventive risk.

Steinweg’s first bold move, in 1850, was to sell a prospering piano company, uproot himself and his family, and, at the age of fifty-three, sail to America. He took most of his children with him, leaving the eldest, C. F. Theodore, behind to run what little remained of the family business. Many years later, family members guessed that the reason for the wholesale move to America was purely economic: Germany was in a recession, a rigid tariff structure was bogging business down, and the free-enterprise promise of America was too enticing to resist.

The first thing the Steinwegs did when they arrived in New York was fan out across the city. Although the Steinwegs had already been running a productive factory in Germany for some years, in order to learn about American manufacturing techniques Heinrich and his sons took jobs at different piano factories in New York. And they had plenty to choose from: Every major city on the Eastern Seaboard could claim at least a few piano makers. In New York alone there were nearly two dozen. Charles and William worked for William Nunns & Co., a prominent piano maker whose instruments were known for their high-quality cabinetry. Henry Junior went to work for James Pirsson, who had invented a double piano that was not unlike a tandem bicycle. And Heinrich made soundboards for a manufacturer named Leuchte, earning six dollars a week. (Had he bothered to learn English and worked for an American, he could have earned double that.) Piano building was evolving in Europe, but much more slowly than in America. When it came to innovation in piano building, the Steinwegs soon discovered, America was the place to be. It was American piano makers who were changing the way pianos were built, breaking major new ground with plate and action design and stringing techniques. Three years later, in 1853, equipped with an insider’s understanding of the process of building a piano in America, the family regrouped, Americanized their name, and formed Steinway & Sons.

The experience had been especially beneficial for Henry Junior, a curious young man who lifted the lid of every piano he saw, looking for new ideas. It was he who introduced an innovation that would eventually be adopted by piano manufacturers around the world, and would ultimately change the way piano music would be heard and played. Henry’s idea called for a single cast-iron frame that could hold the 230 heavy-gauge piano wires in tune under tremendous tension—as much as forty-six thousand pounds, or twenty tons. The single metal plate allowed for this much greater string tension, which in turn allowed the use of bigger, heavier—and thus louder—strings that produced a larger, brighter, bolder sound than had been heard in Europe. Moreover, the single plate held the strings in tune for a longer period. With this innovation came bigger sound and bigger concert halls.

It was Henry who was awarded the company’s first patents, for improvements to grand piano action. And Henry completely rearranged the way that the strings on a piano had traditionally been placed by innovating an “overstringing” technique in which the bass strings, instead of running parallel to the others, were strung over them diagonally in a second layer. This arrangement allowed for the use of longer strings that were capable of producing greater contrasts between loud and soft as well as a richer, more complex tone. The result was an instrument unlike any heard before. The 350-pound cast-iron plate was the essential innovation that led to Steinway & Sons’ rise to the top of the highly competitive business of piano building in the nineteenth century.

The unprecedented stream of innovations ended abruptly with Henry’s death in 1865, of tuberculosis, at age thirty-four. “Mr. Steinway had reduced the manufacture of pianofortes to a science,” read the brief obituary in the New York Times, “and it is probable that few men ever lived who were better acquainted with the construction of the instrument.” His brother Charles died a month later, of typhoid fever, at age thirty-six.

Heinrich placed William in charge of the company, and William in turn implored C. F. Theodore, the lone holdout in Germany, to come to New York. While back in Germany, Theodore had designed and built pianos of his own, and when he arrived in the United States in late 1865, he picked up where Henry had left off. Between 1868 and 1885 he was awarded fortyfive patents for various aspects of piano design and manufacture. It was when Theodore and William paired up, combining Theodore’s engineering genius with William’s entrepreneurial skills, that the company began to take off.

William started at Steinway at age eighteen as a “bellyman,” installing soundboards, but his legacy would be that of marketing genius. Before the birth of the concert-management industry, Steinway’s concert department was actually a production operation that booked performances for pianists. The company did this not because it wanted to but because no one else did it, and Steinway wanted to expose the superiority of the Steinway piano to as wide an audience as possible. So the company set out to get the best pianists of the day to play Steinways before large audiences. In 1860 Henry had come up with the idea of shipping a Steinway grand to Franz Liszt. The plan fizzled, but the Steinway brothers knew that if the company could lure a famous musician to play on a Steinway, it could increase the value of the brand. Around 1870, fighting for recognition among other, better-known piano makers—Chickering, Mason & Hamlin, Baldwin—the company started the “Endorsement Program.” The motivation was simple: Since no members of the Steinway family were themselves concert-ready pianists, they reached out to those who were.

In 1872, William broke new ground when he brought Anton Rubinstein, the eminent Russian pianist, to the United States for a 215-concert tour. All the performances, which Rubinstein played over the course of a grueling 239 days, were on Steinways. The company kept six pianos in constant rail transit to accommodate each of the concerts, and a Steinway technician traveled with each piano to keep it tuned and regulated.

William also carried out an intensive brand-awareness campaign. He solicited letters from well-known musicians including Berlioz, Wagner, and Saint-Saëns to provide testimonials to the perfection of the Steinway piano. He was a pioneer in using newspaper advertisements to promote a product, and ultimately succeeded in convincing an entire tier of American society that unless a girl could play the piano, she wasn’t likely to get far in life. William pried the piano from its roots as an amusement for the idle wealthy and replanted it as a mark of respectability for all households. William likewise pioneered the idea early on of building a network of dealers who were given exclusive rights to sell Steinway pianos. Every dealer in a major city maintained a “piano bank” of concert grands for touring Steinway artists to choose from.

In 1864, the company opened an elegant showroom next to Union Square on East Fourteenth Street in Manhattan. Two years later, directly behind the store, the company inaugurated Steinway Hall, a two-thousand-seat theater, which went on to become the city’s cultural center and home to the New York Philharmonic until Carnegie Hall opened in 1891. Steinway Hall was much more than a concert hall: It was a brilliant marketing device that took concertgoers to their destination only after they had passed through the ornate, white-marble showroom filled with square, upright, and grand pianos. The main showroom remained at Union Square until 1925, when a new, still more elaborate sales headquarters opened on West Fiftyseventh Street, with a more modest concert hall on the third floor.

The emphasis on marketing continued long after William’s death in 1896. In the early 1900s, the advertising phrase that would come to define Steinway for nearly a century came in a flash to Raymond Rubicam, then a young advertising copywriter. Upon learning that a Steinway piano had been used by nearly every great pianist and most of the great composers since Wagner, Rubicam scribbled the words “The Instrument of the Immortals” on a notepad. And in a series of national advertisements, he linked the phrase with portraits of great pianists: Rubinstein, Hofmann, Rachmaninoff. Throughout the early part of the twentieth century, even at times when the overall production of pianos decreased, that one line helped propel the steady rise of Steinway & Sons. And the phrase “The Instrument of the Immortals” eventually took its place alongside other famous advertising slogans like “Breakfast of Champions” and “I’d Walk a Mile for a Camel.”

William’s son Theodore took over the company in 1927, and had the misfortune of presiding over it when the Great Depression hit. Theodore was not much of a businessman to begin with, and the mid-1930s were the worst years in the history of the company, as it was beset not just by the general economic downturn but by radio’s rise in popularity. Piano manufacturing in general fell sharply, and dozens of firms failed. At Steinway & Sons, sales were so dismal that the factory was nearly shut down. Running the company during those years all but killed Theodore: He drank heavily and developed a multitude of health problems.

It was into this state of affairs in 1937, around the time that Glenn Gould was getting his first piano lessons from his mother, that Theodore’s son Henry Z. wandered into the family business. The affable and pragmatic twenty-two-year-old was the great-grandson of Henry Engelhard Steinway, the founder, and grandson of William, the marketing genius. He returned to New York after graduating from Harvard, with no clear prospects for a career. After a summer of lazing about, he told an interviewer years later, he thought to himself, “Well, what the hell, I’ll try Steinway for a while.” He entered an apprenticeship program for young Steinways that sent him from department to department over the course of a few years, earning the Depression-era minimum wage of ten dollars a week. By the end of his first year he had acquired a working knowledge of every facet of piano construction.

Henry was certainly no craftsman; as an apprentice, it took him a full week to build the same case that a seasoned Steinway workman would make in eight hours. And he was definitely no artist. Of course, he had taken piano lessons starting at age six, as his father fervently believed that if you were a Steinway, you should play the piano. Theodore played, as did every other Steinway in his generation, and he raised his children to believe they were part of something special—“this whole piano thing,” as Henry Z. once described it. But he hated practicing and knew that his talents lay elsewhere. He was an intuitive businessman and took quickly to the rhythms of the business: sales, lumber procurement, factory administration, and relations with Steinway dealers and pianists. And he showed a particular talent for labor relations. It was Henry Z. who would come to guide the company through the second half of the twentieth century, a time of retrenchment and renewed postwar growth. And it was he who would make the acquaintance of Glenn Gould, and in the process navigate his way through one of the company’s most difficult partnerships with any artist in its long history.

No sooner had Henry Z. begun his corporate ascent than new setbacks befell the company. World War II brought havoc to Steinway & Sons. In 1942, the War Production Board, which regulated “nonessential” industrial activities, restricted piano manufacturers’ production of new instruments. And recognizing the potential that piano factories offered for necessary war work, the government conscripted the piano industry to build aircraft parts. A scarcity of metal made wood the centerpiece of airplane design. With its piano production shut down, Steinway & Sons leased one of its factory buildings to an aircraft maker that manufactured a troop-carrying combat glider called the CG-4A. Steinway & Sons signed on as subcontractor for the woodwork. Stacks of spruce that Steinway had carefully selected for its soundboards were used instead to make parts for the CG-4A: the wings, underbodies, and tail assemblies, as well as the nose, where the pilot sat, and the benches for the crews. In the process, the company had to move the pianos and other inventory out to an annex to make room for the glider parts. And where Steinway workers had once been artisans bending layered strips of maple into the elegant arch of a grand piano, they were now carving huge sheets of plywood into wings for a mammoth glider designed to carry combat-ready troops silently across enemy lines.

Indeed, in 1942, as America built momentum with its manufacturing might, factories across the country were ordered to stop making vacuum cleaners and washing machines and instead manufacture gun turrets and canteens. Still, it was one thing to convert a home-appliance factory and quite another to commandeer a piano manufacturer—especially if that piano manufacturer was Steinway & Sons, which for the past nine decades had been producing exquisite musical instruments. Steinway workers felt a distinct sense of calling, and they considered themselves members of a rarefied community. Workers in the Steinway factory, even those without an ounce of musical talent, would say that it was easy to get hooked on pianos. Even after spending all day at the factory making pianos for as little as seventy-five cents an hour, they would go home and talk pianos with their families. This was especially true in families with more than one generation at the plant.

The Astoria factory was home to more than a thousand workers—men who were too old for the army, and immigrants from Italy, Ireland, and Germany. In fact, there were so many German workers that for a time German was the predominant language heard inside the factory. Many of them had been at Steinway for decades, and most lived within a few blocks of one another. By Christmas of 1942 they were building glider components, and as the tasks changed, the face of the workforce changed as well. Hundreds of women were brought in, and the factory had to be reconfigured with new bathrooms because until then the Steinway & Sons workforce had been exclusively male.

The gliders, it turned out, were nose-heavy and not altogether airworthy, not because they were poorly manufactured but because they were poorly designed. The huge all-purpose wooden boxes the gliders were shipped in ended up being more useful than the planes: Henry Z. Steinway later heard the story of a military unit that received a shipment of gliders, took them out of their crates, burned the planes, and slept in the crates. But it wasn’t only gliders that distracted Steinway’s workers during the war years. Soon after the government finally ended its aircraft program, and in an effort to get the company through the aftereffects of the Depression years, Steinway & Sons turned to making an item that was increasingly in demand: caskets. Its workers and technicians churned out a full range of coffins made from some of the choicest wood that was stored in the Steinway lumberyards, hundreds of thousands of feet of spruce, maple, walnut, poplar, and mahogany.

It was in the fog of those lost years during World War II that CD 318, the piano that Glenn Gould would one day come to cherish, came into being. Piano production had not been completely halted during the war years. Steinway was given permission to make a thousand or so vertical pianos, the solid, war-rugged, homely, and practical forty-inch instruments that came to be called “G.I. uprights.” Those pianos, some painted olive drab, others gray, were designed with a simple, heavy block case. They were shipped out in special packing containers to military bases, many of them overseas, along with instruction manuals and tuning tools in the unlikely event that there was a soldier who knew how to use them. And other pianos, already in the works when Pearl Harbor was attacked in December 1941, managed to inch along to completion.

The piano that would eventually become CD 318 started out as W 905, a factory designation it most likely received when the rim was first bent to form the distinctive outline of a concert grand. Since a piano moves through a factory for many months before receiving its serial number, there needed to be a means of marking a piano while it was still under construction. For that purpose, Steinway & Sons used letters, cycling through the alphabet on a regular basis. W had first come around in 1897, was used again in 1918, and now returned in 1942 when work commenced on the 905th piano of the year. Surely it was part of the piano’s improbable fate that work on it began when it did, because its construction began just before the piano-making prohibition went into effect.

Even in the best of times, building a concert grand is a slow process, although workers at Steinway were never idle. If they stopped working on one piano because it was waiting for glue to dry or for lacquer to cure, they started on another. Over the years Steinway’s concert grands had become a particular source of pride for the company. The Steinway Model D, as it is recognized today, was first conceived by C. F. Theodore Steinway in 1883. The first such piano, with a rosewood case, was finished in 1884 and sold to a man named M. D. Stevens of New York in June 1885. Each Model D that emerged from the factory thereafter was a masterpiece of thousands of separate parts that were glued, pressed, planed, machined, hammered, and screwed into place. Workers marveled (and complained) that a concert grand Model D’s twelve thousand parts—D for damn big, they’d commonly say—felt more like fifty thousand.

The process of manufacturing a piano like W 905 had changed little in the nearly one hundred years since Henry Steinway started the company. Despite a few advances in manufacturing techniques, in the 1940s the creation of a grand piano was as labor-intensive as it ever had been. The multitude of parts and processes required the involvement of some 250 workers, including specialists in mechanical engineering, design, carpentry, cabinetmaking, wood finishing, metallurgy, tuning, and voicing. The plate department ran on steam power and elbow grease, and the soundboards were shaped by careful craftsmen who used hand planes, chisels, mallets, saws, and calipers. The individual handcrafting of each piano remains a source of great pride to Steinway even as it has witnessed the success Yamaha enjoys with its assembly-line process. Eventually, in the 1970S, Henry Z. gave credit to the Japanese for helping to boost sales of modern grand pianos by bringing large quantities of them into the country. But the tradition at Steinway, which carried into the late twentieth century, was to value handwork and individual craftsmanship, and to make the workers feel that they were part of a brotherhood of craftsmen as well as members of the Steinway family.

Joe and Ralph Bisceglie, brothers who both worked at Steinway for nearly four decades, typified the tradition of loyalty and longevity among Steinway’s factory workers. It was workers like the Bisceglie brothers that Henry Z. knew he could depend on for consistency and craftsmanship—Astoria boys whose parents had come from Italy through Ellis Island, who started at Steinway after high school and never left. Employees like the Bisceglies knew that if you worked at Steinway long enough and hard enough, Henry Z. took care of you. “Even if you got in trouble with Steinway and he fired you, it was like a slap on the wrist . . . and he hired you back,” said Joe Bisceglie, who eventually rose to the level of senior factory technician. “We had guys hired fifteen different times after they were let go. Because I guess even Steinway himself realized, where would you go? If you worked on pianos all your life, where else could you go?”

Most of Steinway’s craftsmen took enormous pride in the work they did. Many, from the tone regulators to the bellymen, signed their names and the date somewhere inside each piano they worked on, especially the concert grands. Often the signatures would be made in pencil on the side of the lowest A, the first key on the piano. And sometimes a worker signed his name so far inside the piano that it would never be seen unless the instrument was taken apart for repair. A factory worker once recounted the story of walking past an old man, a second- or third-generation factory employee, weeping as he repaired an old piano. He had found the signature of his father—then dead for forty years—inscribed deep inside the instrument.

For all its manufacturing rigor, Steinway & Sons never produced a formal blueprint for building its first Model D. Henry and C. F. Theodore made a few scale drawings, but for the most part, instead of a piano being built from blueprints or any other sort of written instructions, the specifications were handed down from each generation of craftsmen to the next, over many decades of building pianos. They were simply built, then refined; then more were built. Throughout the years, each foreman carried a small notebook in his back pocket and wrote down every detail of how things were done. In this way, the specifications, such as they were, were passed down from foreman to foreman.

To Henry Z., in the business of piano making, craft came before science. General Motors had hundreds of engineers who made detailed drawings of every screw that went into a car before a model went into production. “In the piano business it works the other way around,” he once observed. “You start with a piano and say, oh, we’ll make this here . . . make this plate a little longer here . . . move this one inch, and so on.” So it was that W 905 evolved.

Under normal circumstances, producing a Steinway concert grand like W 905 could take the better part of a year. Add to that the preproduction process and it could be more like two years. The moisture-laden lumber, some of it containing up to 80 percent water, has to be dried, first out in the air and then in a kiln, for anywhere from nine months to five years depending on where in the piano the wood is going. Work can’t begin until the moisture content falls to around 6 percent. The drier the wood, the less likely it is to change dimensions after being installed in a piano. Steinway has always spent a great deal of money on its wood, yet fully half of the dried lumber is rejected because it has an imperfection, like a knot or an uneven grain pattern, which are the marks of a weaker spot in the wood.

One unique aspect of piano construction that Steinway patented and is still in use today is the building of the piano’s inner and outer rims, which give a grand its sensual curves. Eighteen rock-hard layers of maple, each twenty-two feet long and still fairly moist so it can be forced into one sinewy shape, are first coated with glue and stacked into layers; then glued into a single form of wood and wrestled onto a giant, gracefully curved, piano-shaped vise; locked into place with clamps; then put in a darkened, climate-controlled “rim-bending” room and cured for several weeks.

As the rim is curing and the wood is growing accustomed to its new shape, other parts are being built, including the soundboard, the acoustical centerpiece of the instrument. The soundboard serves the essential purpose of amplifying the sound that’s created when a hammer hits a slender string, making it capable of reverberating through a huge concert hall. The soundboard is a large wooden diaphragm with a long strip of laminated maple called the bridge, which is much like the bridge on a violin, running from one side to the other. Over that bridge, at high tension, are stretched more than two hundred strings that constitute the tone-generating element of the piano. When the piano is played, the strings pass over the bridge, which transfers the energy into the soundboard, which in turn repeats the vibratory motions of the strings and sets in vibration much more air than the strings would on their own, thus intensifying the sound. The more faithfully a soundboard performs this function, the better its quality. On a Model D like W 905, the soundboard was built to withstand the combined downward force of nearly one thousand pounds. W 905’s soundboard was made of close-grained quarter-sawn spruce, a lightweight yet strong wood that is considered the very best—some would say the only—wood for soundboards because its long parallel fibers make it flexible enough to vibrate freely and project sound while remaining strong enough to support the weight of the piano’s strings. The soundboard panel is composed of approximately twenty boards that are glued together along their lengths and bow out slightly in the center. First the ribs—long, narrow strips of spruce—are glued to the underside of the soundboard so that the board is distorted into a slight crown, which increases its ability to project sound waves into the air. Then the bridge is doweled and glued to the top of the soundboard. The factory workers, of course, were constructing piano W 905 for a ghost. No one could have imagined that the musician who would eventually fall in love with this specific piano was at the time a ten-year-old boy living in Toronto who was already particular to the point of obsession, not just about the music he would play but about the instrument he would play it on. They couldn’t know that this child possessed a sense of touch so uncannily sensitive that he could feel the tiniest bit of unevenness in the action. And those Steinway factory workers in the early 1940s had no way of knowing that the main appeal of W 905 would, for this extremely tactile young musician up in Toronto, lie in its action.

The action on a modern grand is a marvelously complex device. A self-contained mechanism that includes not just the keyboard but all the levers and hammers behind the keys, the action translates the downward pressure of the finger on the key to the corresponding hammer, propelling the hammer to strike the strings. The action is composed of felt, leather, spring wire, wood, and small pieces of metal, which work together to accomplish an array of different functions simultaneously. The action not only sets the hammers in motion but, because it is a lever mechanism, it is able to do so in a way that makes the hammers move farther and faster than the keys do in order to reach the strings. Once a key is depressed, it is the action’s job to see to it that the hammer travels independently over the last fraction of its path and rebounds immediately after striking the strings, even if the key is still depressed. Simultaneously, the dampers—pieces of felt glued to a small block of wood resting above the string—are sent into motion, preventing the strings from unintentionally vibrating once the key has been released. As if that wasn’t enough to worry about, the overeager hammer must be prevented from bouncing back up to the strings as a result of its own momentum. At the same time, the action has to allow for the fact that the pianist might want to restrike a note without having to lift his finger entirely off the key, so the part that propels the hammer—called a jack—must return to its original position, ready to strike again. Meanwhile, the damper that has been sitting over the strings, preventing them from vibrating, must rise so the strings can sound cleanly, but must fall back promptly to cut off the sound when the key is released.

Steinway didn’t invent the piano action. That was the work of Bartolomeo Cristofori in the early 1700s. Cristofori is often credited with inventing the modern piano as we know it, and Cristofori’s main achievement was inventing the action. Before the eighteenth century, stringed keyboard instruments were extremely limited in terms of how the strings could be made to vibrate. On a harpsichord, strings are plucked by a quill, which produces the same volume no matter how firmly the key is struck. On a clavichord—another early keyboard instrument that was in use during the fifteenth century—the strings were struck with a small metal blade that was embedded in the back of each key. The musician could control the volume of individual notes, but there wasn’t much volume to control: As soon as the clavichordist removed his finger from the key, the sound would evaporate.

Cristofori’s innovation was to build an instrument that he described as an arpicembalo che fa il piano e il forte, a harpsichord that plays soft and loud. It was eventually shortened to pianoforte. Cristofori’s instrument was exceptionally sophisticated. Instead of using quills to pluck the strings, tiny leather-covered hammers struck them head-on. Cristofori’s invention also contained a rudimentary escapement mechanism that let the hammers fall away quickly. In fact, the fifty-four keys on Cristofori’s pianoforte performed all the functions of a modern piano with one exception: the “repetition,” which allows a note to be restruck before the key returns to its original position. This shortcoming was eventually corrected in the early 1800S by a French piano maker, Sebastien Erard, who came up with what is called the double-escapement mechanism, which permitted a note to be repeated even if the pianist’s finger had not yet fully released the key. The double escapement eventually became the standard action on grand pianos, employed by every manufacturer, including, of course, Steinway & Sons.

Because piano actions are so complex, many piano makers didn’t bother to build their own, and instead would buy the action from an outside supplier. But Steinway, with its long tradition of craftsmanship, would never stoop to outsourcing. The actions for all of Steinway’s grands—including the hammers— were created in the New York factory.

Recognizing that a pianist can give full expression to a piece only if there exists a proper harmony between the pianist and the keyboard, many Steinway workers still regard assembling the action as one of the most rewarding aspects of building a piano. A professional pianist is likely to care most about the piano’s action, because that is what controls its responsiveness and relative lightness—or heaviness—of touch. Roughly speaking, a piano’s action is light when its keys fall easily under the fingers, and heavy when a noticeable downward thrust is required. The action, in short, is what makes a piano playable or not to an individual musician. Steinway’s workers were constantly reminded of this when famous artists came through the factory to play pianos that were just being finished, to see which ones “spoke to their fingers.” And it was frequently the action that determined that outcome.

While its action was being built, W 905 underwent belly work, finishing, and stringing. Bellying is one of many customfitting operations in the manufacture of a piano, involving the precise and careful joining of the soundboard, the cast-iron plate, and the rim. After that process the soundboard assembly is affixed to the rim. Borrowed, perhaps, from the vernacular of the violin maker, the term belly refers to the shape of the soundboard and the bridges and rim that surround it. To some historians, the rounded shape of the violin and piano soundboards resembles a belly. But anyone who watches a bellyman do his job can see immediately where the process gets its name, as a bellyman must lie on his stomach on top of the soundboard to do his work, all the while teetering on the rim of the piano.

After the belly work was finished, W 905 was strung and then chipped, or given its first rough tuning, the first job Verne Edquist had when he started doing factory work. Then the action and the keyboard were installed. Next came the final process to the finish, done by the rubbing department: a pumice stone and oil are rubbed on the lacquered case parts to remove the rough coating and give the piano a satin finish.

Like many pianos built during the war, W 905 kept getting delayed. Work was done in the hours that could be captured between the manufacture of glider parts, packing crates, helicopter floors, rifle stocks, and army-issue uprights. Piano parts often lay scattered around the factory until someone was free to assemble them.

Finally W 905’s action was pieced together, and the piano underwent the action and tone regulating that would bring its mechanism and sound to their peak. Regulating the action requires the technician to delicately and precisely adjust the thousand or so moving parts in the keyboard mechanism in order to ensure maximum evenness for the pianist, which in turn translates to maximum control. If a pianist is struggling against an uneven action, it hampers his ability to phrase a piece just as he wants it.

The process of fine-tuning W 905’s action entailed fitting the keys, hammers, and dampers into the newly strung piano, and making sure that the hammer rebounded instantly after coming into contact with the strings so that the strings had ample opportunity to vibrate for as long as the key was held down. Each hammer on W 905 was made to rise and hit the three strings squarely, and the keys were then leveled. The damper felts were matched to the strings, and the levers that controlled each of the dampers were adjusted. Finally, the technician adjusted the spring tension and aligned the many small parts for each note. In a process called the action weigh-off, every key was then calibrated so that they all would have a consistent feel. The technician placed brass weights on each key, meant to simulate the downward pressure of a pianist’s finger, and then inserted lead underneath each key covering until the pressure needed to depress a key was the same across the entire span of eighty-eight keys. When he was done, every key would contain varying amounts of lead, but each would fall with approximately fifty grams of downward pressure.

Then came the instrument’s tone. Compared to the rich resonance of a finished piano, an instrument that is still under construction sounds terrible. Some notes buzz while others fade too fast, and they don’t project the way they should—they don’t seem loud enough. This is where the tone regulator comes in. His job is to transform a piano from a mass of moving parts into a musical instrument with the complexity, beauty, and magic of a Steinway grand.

Tone regulating—the term was later gussied up and changed to “voicing”—was a coveted job at Steinway. Workers strove, and were indeed encouraged, to progress from the physical labor of case, rim, and belly work—to say nothing of the noxious fumes from the glue—to the more nuanced work that involved making the instrument more musical. Voicing a piano in the final stages of construction, after the action weigh-off, is a simple process with complex repercussions. It has nothing to do with tuning—although most voicers have received training in tuning—and everything to do with the quality of sound and the evenness of volume that is produced by each note. It is perhaps the most subjective part of the piano-building process, performed by a technician with well-trained ears and hands. Voicing requires that the technician subtly alter the texture of the hammer felt (each hammer in a piano is covered with one or two layers of compressed wool felt), which is critical to forming each piano’s distinctive sound and personality. A voicer makes adjustments to the hammer’s resiliency by driving a small row of needles into its felt. This separates the fibers and makes the tone mellower, rounder, or more open. Needling the felt on certain parts of the hammer can even make the tone stronger and louder. The ultimate goal of voicing is to give a pianist access to the widest possible dynamic range—from the softest, creamiest whisper to a brassy, hard-edged, crashing fortissimo—all emanating from the same hammer. Like a skilled acupuncturist, a master voicer knows how to get these different effects through either shallow or deep needling of the felt, or, if he wants to increase the brilliance of a note, by applying lacquer to it. It is a delicate process: Overneedling or overlacquering can ruin a set of hammers, and in turn the tone of the piano.

It is the voicer who ensures that the piano’s sound is as powerful as it can be without destroying its capacity for softness and warmth. The process can take several days. As Ralph Bisceglie explained, “You’re working with eighty-eight notes and you’ve got to do the same operations on each one.” And overnight, after a full day of meticulous needling, everything changes with the small heaves and sighs of the wood.

Any technician knows that a bad voicing job can ruin a set of hammers, but there is also great pride to be had in voicing— because it is in the voicing that a piano maker can have a real influence on the instrument. Voicing gave employees who loved music a chance to indulge their passion, allowing them to impose a little of their own musicality on a piano. The sound of a piano can vary dramatically, depending on what the voicer has done. A piano voiced in a mellow tone for the music room of a typical home, for instance, can be swallowed up in a concert hall. And what one person might perceive as mellow, another might hear as weak. This subjectivity—this unquantifiable sense that guides the essential voicing process—is part of what makes each piano distinct, while at the same time it is what creates the characteristic “Steinway sound.”

Although every Steinway was made the same way, from the same materials and by the same workers to the same specifications, each piano that emerged from the factory, mysteriously enough, felt and sounded different. Some ended up sounding small or mellow, fine for chamber music. Some were so percussive that a full-strength orchestra could not drown them out. On some, the keys moved almost effortlessly. On others the pianist’s hands and arms got a workout. W 905 ended up with an exceptionally light touch, an action so delicate it would eventually attract the attention of the highly demanding Glenn Gould.

W 905 was actually a twin. When work started on Glenn Gould’s future piano, construction on another concert grand— W 902—had already begun. As was often the case with Model D’s, the pianos would travel through the manufacturing process together. Both ended up as especially fine instruments—which could have been due to the crew of artisans that put them together, so starved for concert pianos to build as they spent the war years on the relatively artless work of airplane parts. Perhaps they lavished their finest craftsmanship on those two pianos. But something else set W 905 apart that might have had more to do with the materials that went into it. Perhaps it was the wood that gave the piano its personality. No matter how carefully Steinway workers selected or prepared each batch of lumber, it’s a fact that in the forest, some trees get more sunlight than others, and some get more moisture. Perhaps the trees that became W 905 received more sunlight, giving the wood more resonance. Or maybe it was the quality of that particular batch of hammer felt. Steinway used a yellow-tinted wool that was thicker and more refined than conventional felt. As with everything else in a piano, the quality of the wool affects the tone. For years the wool used for Steinway pianos came from South African merino sheep, known for producing wool fiber that in turn produced dense felt that was also highly resilient, the best combination for hammer felt. Makers of this high-quality felt tried to avoid fibers that came from the underside of the sheep, because although they were longer and technically more desirable, those fibers also carried a higher urine content. But who can say whether that was the felt that was used on W 905? During World War II, like so many other materials basic to piano manufacturing, felt was scarce. For all anyone knows, the felt for W 905 could have been pieced together from scraps.

And who could say what effect the unpredictable, out-of-rhythm construction process of the war years had on both W 905 and W 902? Both pianos were officially declared finished on the same day: March 30, 1943. Yet as the war dragged on, they entered a protracted state of limbo. When Steinway & Sons moved its partly finished pianos out of the factory and into a warehouse to make way for glider parts, the pianos must certainly have been moved as well. No doubt they were then neglected for many months. And they weren’t the only instruments to be affected by the on-again, off-again business of piano manufacturing during wartime. In all of 1944, only one concert grand was shipped from the Astoria factory, in contrast to a prewar high of sixty-three in 1929. In 1945, W 905 was one of ten concert grands to leave the factory, having been given the serial number 317194. This number did not signify that W 905 was necessarily the 317,194th piano built, but that it was the 317,194th piano to be assigned a serial number. W 902 got the serial number 317193. The number 317195 was assigned to one of the wartime pianos, a forty-inch, olive-drab upright that was shipped out to an officers’ mess in Kansas.

When the two pianos finally emerged from the Steinway factory in Astoria in 1945, it was against all odds. By early 1945, having managed to end up as pianos and not glider parts or, worse, caskets, W 902 and W 905 were both taken off the showroom floor and selected for service as part of the Concert and Artists fleet. This was a relatively easy decision, because there were fewer pianos to choose from. The Steinway & Sons logo above the keyboard, which included the company’s famous lyre, was replaced by larger letters that read, simply, STEINWAY. Finally, the two nine-foot grands, relatively anonymous behemoths up to now, were officially assigned their CD designations: 317 and 318. CD 317 would end up staying at Steinway & Sons on Fiftyseventh Street for twelve more years before it was sold in 1957— and moved just a block away—to Helen Hobbs Jordan, the famous music teacher who lived next door to Carnegie Hall. CD 318 spent approximately a year at Steinway & Sons before it was crated up, loaded onto a train, and shipped to the T. Eaton Company in Toronto, where it was placed in the company’s small fleet of pianos that were reserved for professional concerts and recitals.

Unlike some pianos that become instant favorites, no one singled out CD 318 as an exceptional instrument; its hidden virtues and native inclinations would eventually be teased out, over a period of many years, by the right combination of pianist and technician. As it was played by touring concert artists, CD 318’s hammer felt gradually wore down and required periodic reshaping or softening, and the parts of its action required continual adjustment and readjustment. Joe Bisceglie, who would one day, many years later, find himself face to face with Glenn Gould’s piano when it was in dire need of repair, compares a concert-grand piano to a finely tuned racing engine: There’s a point at which it’s ready to run flat out, and only the constant attention of a master mechanic can keep it there. For CD 318, that genius would turn out to be Verne Edquist.