1

THE RACE CAR

WHEN THIS project began in 2003 there were two approved chassis manufacturers—Panoz G-Force and Dallara. A race team cast their lot with one or the other. A multiyear development for a newer and safer vehicle saw Dallara emerge as the sole supplier of the Indy chassis starting with the 2013 season. The approved “package” that they offer includes optional equipment, aerodynamic variables, and spare parts. Over the one hundred years of Indy racing the car has gotten far lighter, lower, and sleeker. Even the driver’s helmet and faceplate are now shaped to offer as little air resistance as possible. Comfort is but a minor consideration. The car is meant to knife through the air with just enough “downforce” to keep the powerful rear wheels in contact with the asphalt and provide the front wheels with the precise amount of “bite” for high-speed steering and handling. Vast effort has been expended in pursuit of the racer’s “holy grail”—a perfectly balanced race car.

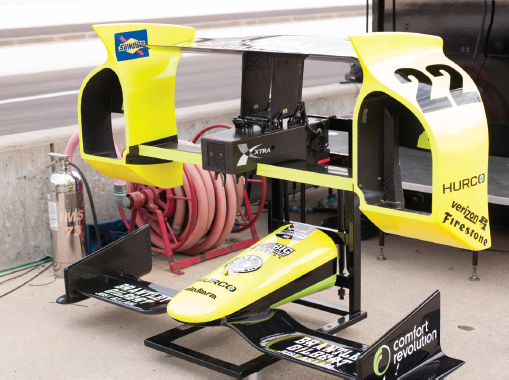

The car is already in place on the starting grid but the team has removed one of the sidepod panels to work on the car.

Carbon fiber will conduct electricity but not very efficiently. The metallic foil seen on the underside of the panel is to provide a good electrical “ground” for the radios, transponders, and other electronic gear.

The nose and tail sections are seen mounted on a stand behind the pit wall. They stand in reserve. Each provide a “one piece” renewal of a damaged part. Teams endlessly practice such substitution. Dallara estimates that if the front wing assembly, which is made of carbon fiber, were made of steel, it would be more than three times the weight. It would reduce “lap speed” at Indy by 1.5 mph.

The race cars, in the interest of reducing weight, leave the battery and starter motor back at the pit. At the beginning of the race or in the event that the car stalls during a stop, the starter is right at hand. The long probe is geared at the very end and meshes with gears in the transmission. Danny Sullivan, in a separate chapter, recounts a fortunate occasion where he is able to “jump start” his stalled (and speeding) race car.

Fuel Bladder. This unit is not fabricated by Dallara, but comes from a separate supplier. The technology is similar to that used in helicopters. Dallara builds a whole range of race cars and what is shown may or may not be “IndyCar” specific. Certain configurations feature a “buckeye” fill port on each side of the car for use on tracks that pit to different sides. Fuel capacity in IndyCars during the span of years covered by this project have ranged from 30 gallons of methanol down to the current capacity of 18.5 gallons of E85. “Baffles” in the tank control the sloshing brought on by the g-forces. The “pickup” strives to make every drop of fuel in the tank available to the racer. Drivers are constantly reminded to “reset the fuel indicator” at the end of a pit stop for more accurate “end of race” and “scheduled stop” strategy.

Here is the “buckeye” on a 2015 car. It’s obviously on the left side, closest to the pit wall. Safety is designed into the entire fuel system in several ways. The port snaps shut and locks as the fill probe is removed. In the event of a wreck, the supply line from the tank to the engine stops pumping.

Jacob of A. J. Foyt Racing is using a mini-grinder to shave down a chassis component so that it joins its adjacent part with almost no gap. The tiniest mismatch between parts can affect aerodynamic efficiency. If the part is on the topside of the car where it is visible it will have its vinyl “skin” attached.

The car is constantly assembled and reassembled for repair, maintenance, and a dozen other reasons. Here’s a look at the “underside.” The driver’s cockpit has its own floor, and that’s not what is shown here. Air is directed under the car into what are known as “tunnels.” Part of the race strategy involves “tuning” the airflow in that area under the speeding car for maximum effect. The “ground effect” bargain is well known. Get it right, and the car will “stick” to the course in the corners. Overcorrect in that direction, and the “drag” will slow the car on the straights.

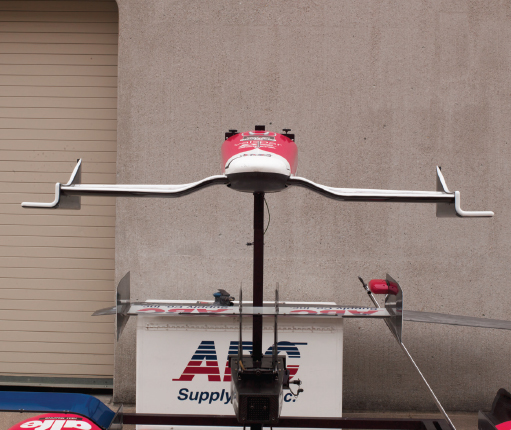

The nose assembly here demonstrates the idea that IndyCar racing is more like NASA than NASCAR.

The “livery” on Oriel Servia’s #32 Rahal-Letterman-Lanigan car has a special #THANKSDAVE message honoring the Late Night host’s retirement from TV.

This is a rare opportunity to see the axle, wheel hub, brake rotor, wishbones, and other parts of the suspension. The wishbones are steel alloy covered with a skin of carbon fiber and resin.

A. J. Foyt Racing has removed the entire rear section of the car to get at the innards.

Here the mechanic from the Schmidt-Peterson team is holding the ultra-lightweight carbon-fiber brake rotor covers. They take a good bit of abuse as tires are changed. Small ends can crack or break off and a constant chore is to epoxy them back to perfection. Each weighs in the neighborhood of eight ounces.

The seatback (as well as the steering wheel) is removable to allow the driver easier access to the cockpit. He (or she) will ease down into the custom molded seat; the helmet and “head and neck” protector (one brand is called the HANS Device) would already be in place. This piece becomes the “coaming” of the race car. There is padding both behind the driver’s helmet and also along the right side. When racing on ovals the powerful centrifugal force pushes the driver mainly to the right.

The “T” car. Here the letter next to the #4 identifies the car as Panther Racing’s “backup” racer. It was identical to the main entrant in every way. Rules permitting, it could be put into service to replace a damaged car. There is a quilted black drape shielding the day’s “aero setup” from the prying eyes of rival teams. IRL rules have now outlawed such “black magic” gamesmanship, in the years after this photo was taken.

The unit being installed above the air intake port is the housing that contains the “car cam.” The camera transmits the video (and sometimes audio) information, in real time, to both a dedicated recorder as well as to the broadcasting team. Its point of view is usually the same as that of the driver, but some cameras can be diverted to a rear view.

When the technology was first introduced, live cameras would be installed only on the cars of a few top drivers, presumably because they were more likely to be in the race until the finish. Cars not so selected would be mounted with a “dummy cam” so that everyone shared the extra aerodynamic “drag” that the unit would cause.

The car cam had an ingenious method of self-cleaning the lens. The aperture, which was no larger than a pea, could be totally obliterated by a single drop of moisture, oil, insect, or (most likely) a flying, sticky blob of tire rubber. Thus, a spool of clear tape was threaded in such a way that it became the “leading edge.” As the broadcast production crew saw fit, the tape could be advanced an inch or so, moving the obstruction away and clearing the view.

Interior of camera unit without housing.

This savvy “over the wall” tire changer keeps a spare wheel nut loosely clipped to his belt. If one is dropped or gets away during a pit stop he’s ready.

Paoli wrench: This air-driven workhorse (made in Italy) does one thing very well: It engages with the wheel nut to mount or dismount a wheel and tire. It may seem as if it has been carelessly “cast aside” as the tire changer acts out his meticulous ballet, but the designer knew the abuse the tool was likely to see. The precision of the front “teeth” is shielded by a sturdy steel “collar.” An experienced hand can send it safely skidding across the pavement when the task has been completed.

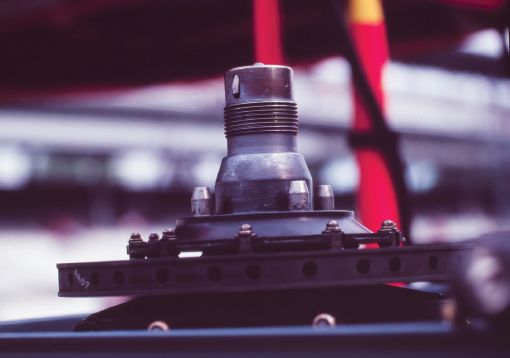

Looking down at the brake rotor, showing wheel hub that receives the nut.

Signboard: Reset Fuel #21. There is always a chance that modern telecommunication methods can fail or malfunction. Here is an “in your face” reminder. Accounting for every drop of fuel is essential. Races are won or lost depending on how well fuel use is calculated.

Buckeye on white Toyota. The Buckeye is designed to mate perfectly with the fuel probe before a drop of the gravity-fed fuel is allowed to pass. Obviously, the driver is inches away from the operation. A fireman is closely engaged with the race team during each pit stop. He holds a canister of pressurized liquid, which he can direct to even the suspicion of a small spill. (It can be difficult to see an alcohol flame.) In the event of an actual fire, the crew is well trained in fire suppression. Extinguishers are at hand just over the pit wall. A two-inch fire hose is fully pressurized and ready; one hose serves two adjacent pits.

Transporters, of necessity, use every bit of storage space as they truck from race to race. Here, the lift gate retrieves the car from one of the storage bays in the “attic.”

This is a rear brake duct backing plate for the 2003 generation IndyCar from Panoz G-Force (other side shown below). It’s extremely light and quite rigid. The reverse side shows embedded metal “taps” for connecting screws or bolts. Each has a bit of “wiggle room” for a snug, secure fit.

|

Q&A WITH SIMON MARSHALL CHIEF DESIGNER, PANOZ G-FORCE |

|

Marshall spoke with me in October 2003 and again in February 2004.

Q: CAR CHANGES FOR NEXT YEAR (2004)?

They’ve taken away some downforce from us in a very efficient area, which is the “underbody.” They’ve reduced the diffuser height in the back of the car, which is the driving force behind sucking the air into the under-wing area.

Q: EFFICIENT? BECAUSE YOU WISH THEY WOULDN’T TAKE THAT AWAY FROM YOU?

Yes, it gives a lot of downforce with a small amount of drag, whereas other features on the car—even the wings—are not that efficient.

Q: WHY WOULD ONE SPECULATE THAT THEY (THE IRL) WOULD DO THAT?

Oh, because they know that the cars always seem to be going faster and faster, and I think—you see they regulate the speed at the tracks with different wing angles and different “gurney” or “wicker” heights—and they can take five miles per hour off the cars if they feel we’re going a bit too quick. You’ve gotta have Indy as being the fastest track just for P/R reasons, and um, the insurers do not like them going over 230 miles per hour.

Q: INSURANCE?

Well yes, someone has to insure all these people sitting in the stands. These things have gone out—into the stands before. Someone has got to pay someone an awful lot of money.

Money. It just comes down to cash at the end of the day. So they’ve taken some efficient downforce on the car, knowing that for us to put it back, we have to look in different areas to put it back.

Q: THEY KNOW YOU’LL WORK AROUND THIS?

They know we will. It’s just, every year, they have to “take away” from us—and we try to get it back.

Q: WE’LL SEE A WHOLE NEW “SHELL” OF A CAR NEXT YEAR?

The rear wings’ll be the same, because they’re mandated. Everything else will change.

Q: CAN YOU POINT OUT THE DIFFERENCES BETWEEN THE IRL AND FORMULA ONE?

In essence, a hell of a lot more money. That’s all it would take, is more money. They (Toyota) are putting their car together in Cologne at the moment. They are currently campaigning that car in F-1. It takes a thousand people to put that car on the track. That’s for two drivers, and they’re up against Ferrari and Williams. They’ve all got in excess of $100,000,000 to spend on the car.

Q: HERE IN THE IRL THERE ARE ABOUT A HUNDRED PEOPLE BEHIND EVERY DRIVER.

Well there’s a few of us doing the designing and building of it [laughs]. The teams have, uh . . . well I suppose Ganassi’s got tons of those people, a hundred, I’d say.

Q: REALLY, ONLY TWO CHASSIS MANUFACTURERS?

The third one that’s been approved is Falcon Cars, which was a hurriedly put- together outfit. They swung a deal with the IRL to be the third manufacturer. The teams aren’t stupid—they could see what was a good bet, and what isn’t. And no one signed up for their car; therefore they went away, even before they even produced a car. This series can’t support any more than two—because of markups on the parts.

Q: CAN YOU DESCRIBE VISUAL DIFFERENCES BETWEEN G-FORCE AND DALLARA, BESIDES THE SHAPE OF THE AIR INTAKE PORTS?

We’ve both got lumps over the front dampers. They’ve got a bulbous piece in front of the windshield, and a lower nose, and a “pull-rod” system—a pull rod on the front suspension. Of course we’ve got a push rod on our suspension.

Q: TEAM PENSKE IS USING BOTH CHASSIS. DOES ANY DIFFERENCE SHOW UP IN THEIR PERFORMANCE?

I think, at the moment, that the two cars are so close that it’s hard to actually call between them. Which has ended up in this series being good for both us and Dallara this year. Also the engines are fairly close, although that has changed and “swung around” during the season. Recently it’s swung around into Chevy’s favor because they’ve just got a new engine now, which they got “passed” somehow. It was approved, somehow. It wasn’t meant to be, but they were looking so bad before—it’s not in the IRL’s interest to make Chevy look bad. Chevy puts a lot of money into the series, as do Toyota and Honda—they need to get lots of positive press out of it. At the end of the year, everyone can do some pretty good ads saying how great they are.

Q: WHAT CAN YOU SAY ABOUT THIS TEXAS TRACK (TEXAS MOTOR SPEEDWAY)?

You can’t really pull ahead easily on this sort of track and with the cars in this configuration. The guys “behind” find it easier to, kind of, “pull alongside,” but once they get alongside they can’t get past because of the increased drag. You fall back behind in the “slipstream.” So the cars are going to rush around here “slipstreaming” each other, but in a pack, which will make it exciting. A bit dangerous, but . . .

[Kenny Brack was badly hurt that day, a day marked by several wrecks.]

Q: IS THIS TEXAS TRACK UNIQUE IN ITS AERO QUALITIES?

It’s fairly unique. It’s got such high banking. The teams can take off a lot of downforce and drag here. You don’t want the drag. If you take off too much downforce, to try to lose drag, you end up sliding, slightly in the corner, and reducing speed in the corner. And then your “lap time” doesn’t improve. It’s faster down the straights and slower in the corners.