ONCE YOU’VE INSTALLED YOUR irrigation system, putting it into operation will not take long. There may be some minor bugs to work out of your system, but most problems you may encounter, if any, will not be major.

Once your system is installed, rushing to turn on valves can create problems. Failure to follow proper procedures can result in damaged equipment, flash floods in your home, and similar unwanted experiences. What is the right way to turn on your system? There is a recommended step-by-step procedure that varies a bit depending on the type of irrigation system installed.

If you are using a simple system, such as a garden hose and sprinkler, there are no elaborate procedures to follow. The most that could go wrong is a missing or malfunctioning hose washer (the round washer in the female hose connectors used with hose bibbs and sprinklers). If the washer is bad, just replace it, which doesn’t require tools and is easy to do.

As you move up to more sophisticated systems, the start-up requirements become a little more complex. Don’t let this alarm you — all aspects of the start-up are well within your skill level if you have installed your own system.

Mobile irrigation systems include a simple hose sprinkler and garden hose, a system where the irrigation equipment is mounted on wheels and the irrigation hose is coiled around a reel, and larger systems with irrigation heads mounted on tripods, staked into the ground, or set out on legs.

These systems are easy to bring up to speed. The connection between the hose/pipe and the irrigation head is usually a simple one. The other end of the hose/pipe connects to a water service. Getting this type of system into operation simply involves securing the connections at both ends and turning on the water.

Overhead irrigation systems can be a bit more complicated to make operational on-line because there’s more to go wrong. For example, there are probably several valves, and there may be a quantity of sprinkler heads. The more parts to a system, the greater the likelihood that you may run into problems.

There may be debris in your pipes that can foul filters and clog sprinklers. If your new irrigation system is equipped with filters and sprinkler heads, remove these devices prior to turning on the water. When you first turn on the water to your irrigation system, flush the system completely with the filters and sprinkler heads removed. In the case of overhead systems with perforated pipe, it will not be necessary to remove filters or heads since there are none.

There probably are at least a few valves incorporated into your overhead system. You may not have any problem with them, but it is not uncommon for valves to develop small leaks around the packing nuts surrounding the valve stems. If water is bubbling out around a packing nut, a turn or two of the nut with a wrench should stop the flow. Once you’re sure there are no leaks in your overhead system, you can turn it on.

Underground systems are the most complicated of all standard residential irrigation systems. Often there are several valves involved with an underground system, and some of them are controlled electrically. The control panel alone can present more than just a few problems. Before starting up, decide which nozzle to use. Many systems offer a half-dozen or more nozzles for various watering situations. After selecting the best one for your job, you must learn to aim it properly at the desired site, which can take a little practice.

Quality sprinkler heads can be fitted to a wide selection of nozzles, allowing versatility in your watering patterns. You may find that the sprinklers you’ve installed are not equipped with the nozzles you want. Each system has its own procedure for installing nozzles; refer to the paperwork that comes with your sprinkler heads for specific instructionstions. Following are instructions for replacing nozzles on several popular sprinkler models.

One sprinkler brand requires no tool for changing nozzles. You simply pull up the riser of the sprinkler by grasping the head, unscrew the existing nozzle, and screw in the replacement. The manufacturer advises that the raised dot found on top of the head be aligned with the right edge of the spray arc. (The right edge as established by standing behind the sprinkler’s spray pattern.) The manufacturer also advises to flush out the system first by removing the internal assemblies on each lateral line for the last sprinkler head. The internal assemblies can then be replaced and the arc and radius for each head set.

Another popular type of sprinkler head design requires a special hex-end tool for nozzle installation. The tool is placed into the nozzle opening and pressed downward, forcing the nozzle up and out. A new nozzle is then placed on the riser, and pushed down and in so that a barbed retainer on the underside of the nozzle engages to hold it in place. A small tab is then folded over and snapped into place on top of the sprinkler nozzle. To replace this type of nozzle, the hex-end wrench is used to pry up the identifier tab, which can then be grasped and pulled up and out at a 45-degree angle.

Other sprinkler head models use retainer screws to hold the nozzles in place. For some types, nozzles are removed by loosening the retainers and turning the water on to blow the nozzles out of their risers. For others, needle-nose pliers are required to remove the nozzles. There are many ways to change nozzles, so follow the instructions that come with your equipment.

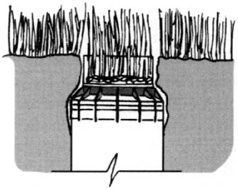

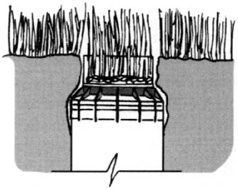

It is possible to buy sprinklers equipped with turf cups, which allow the sprinkler to be concealed with grass. The cup, made of rubber, makes the sprinkler system practically invisible. There are, however, a few tips for installing turf cups.

A rubber turf cup disguises the top of your retractable sprinkler head. Turf is inserted in the cup to blend with the surrounding grass.

The top edge of a turf cup should not be installed higher than the finished grade level of the ground in which its riser is buried. It is recommended that turf cups be installed in grassy areas where reel mowers are used. Once the cup is in place, fill it with an established turf section. It is best to use turf consisting of grass identical to the grass where the sprinkler is located. Don’t attempt to use grass seed in the cup, as the seeds will be washed away when the sprinkler head cycles up and down. According to one manufacturer of a turf cup, you should tend to the new turf (in the cup) for a period of at least two weeks. The company recommends pressing the turf plug into the cup daily for this period of time to establish a root system.

Arc and radius adjustments, like nozzle replacement, vary from system to system. Refer to the instructions provided with your equipment for exact details on how to adjust the arc and radius of your sprinklers. However, I can tell you how this job is done with two types of sprinklers.

With one residential sprinkler head, a special wrench (available from the sprinkler manufacturer) and a screwdriver are needed to adjust the arc and radius. The first step is to lift the riser and to rachet it into alignment so that the arc designator is lined up with the right-hand border of the coverage area. Next, the special wrench, or a screwdriver, is used to turn an adjustment screw counterclockwise, which increases the arc and the discharge rate. The radius is adjusted by holding the arc stationary with the wrench while turning the adjustment screw with a screwdriver.

Another type of sprinkler requires that the nozzle turret be turned to the left stop and then to the right stop, which is also the fixed side of the arc, where it is held while all adjustments are made. A special wrench is also needed to work with this particular type of sprinkler. To increase the arc, the wrench is inserted into an adjustment socket located on top of the sprinkler and turned clockwise. To decrease the arc, the wrench is turned counterclockwise. Radius adjustment with this type of sprinkler is done by changing nozzles.

Controllers can be a bit complicated to set. If you have trouble setting the clock on your VCR, plan to spend some quality time with your controller. Like the other system components discussed, controllers vary substantially. Follow the manufacturer’s instructions. While I can’t give you specific information about the settings on your controller, I can give you a brief rundown on the types of settings you may have to make in order to get your system up and running.

All controllers have a clock and calendar to set. There are usually options for setting automatic watering, semi-automatic watering, manual watering, or watering with a remote sensor, an accessory that measures recent rainfall and controls the irrigation system accordingly.

Most owner’s manuals for controllers are written for the average person to understand. I recommend that you read your manual from cover to cover before making any adjustments or settings. This first reading will familiarize you with your controller.

To ensure desired irrigation results, you must monitor your system. When you first put it into operation, check the water’s arc and radius. Confirm that you are receiving uniform coverage with no wet or dry spots. With a stationary irrigation system, this type of inspection should only be needed once or twice. Mobile systems require more frequent monitoring, since they are never set up in exactly the same way twice.

If you find it necessary to make minor adjustments while monitoring the actions of your irrigation equipment, refer to the manufacturer’s instructions. If you cannot find that information, my advice is to call the manufacturer. If you purchased a quality system, support staff will be available to help. Some irrigation equipment is sensitive, and none of it should be dealt with in a reckless manner. If you do not know what to do or how to do it, my advice is to ask for professional help.