CHAPTER I

ANCIENT AND MODERN HAMMERS

A trite proverb and one quite frequently quoted in modern mechanical literature is, “By the hammer and hand all the arts do stand.” These few words sum up a great deal of information concerning elementary mechanics. If we examine some of the more elaborate arts of modern times, or give attention to pursuits in which complicated mechanism is employed, we may at first be impressed that however correct this expression may have been in the past, it is not applicable to the present day. But if we pursue our investigations far enough, and trace the progress of the industry under consideration, whatever may be its nature, back to its origin, we find sooner or later that both hammer and hand have had everything to do with establishing and maintaining it. If we investigate textile fabrics, for instance, we find they are the products of looms. In the construction of the looms the hammer was used to a certain extent, but back of them there were other machines of varying degrees of excellence, in which the hammer played a still more important part, until finally we reach a point where the hammer and hand laid the very foundation of the industry.

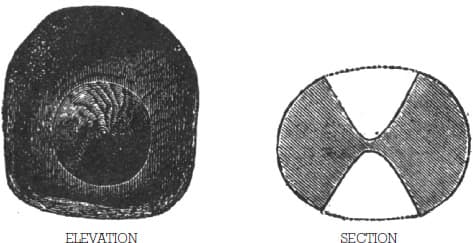

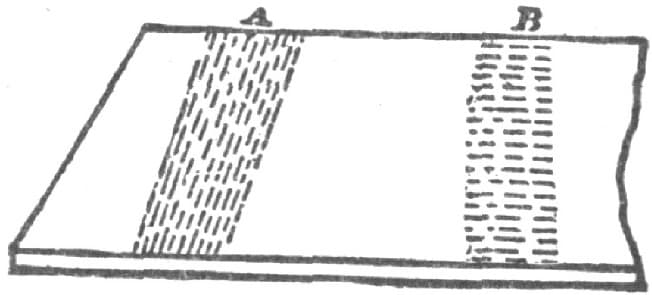

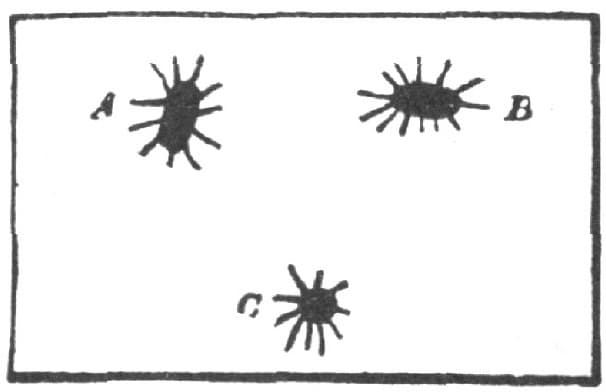

FIG. 1—A TAPPING HAMMER OF STONE

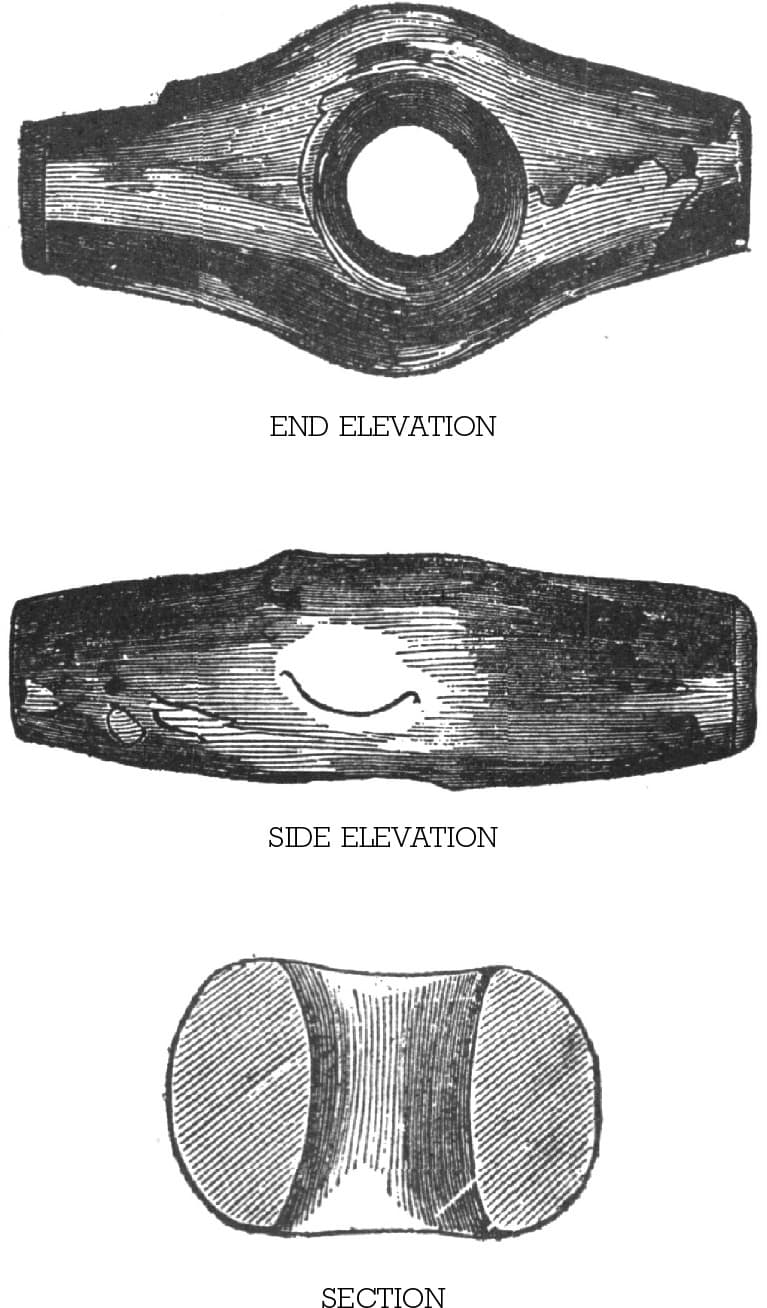

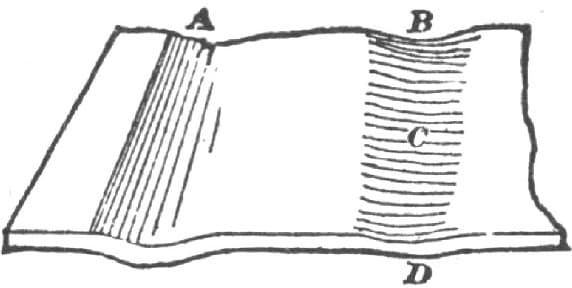

FIG. 2—PERFORATED HAMMER HEAD OF STONE

It would be necessary to go back to this point in order to start anew in case by some unaccountable means our present equipment of machinery should be blotted out of existence. The wonderful mechanism of modern shoe factories, for another example, has superseded the cobbler’s hammer, but on the other hand the hammer and hand by slow degrees through various stages produced the machinery upon which we at present depend for our footwear. And so it is in whatever direction we turn. The hammer in the hands of man is discovered to be at the bottom of all the arts and trades, if we but go back far enough in our investigation. From an inquiry of this kind the dignity and importance of the smith’s art is at once apparent. While others besides him use hammers, it is to the smith that they all must go for their hammers. The smith, among all mechanics, enjoys the distinction of producing his own tools. A consideration of hammers, therefore, both ancient and modern, becomes a matter of special interest to blacksmiths of the present day as well as to artisans generally.

The prototype of the hammer is found in the clinched fist, a tool or weapon, as determined by circumstances and conditions, that man early learned to use, and which through all the generations he has found extremely useful. The fist, considered as a hammer, is one of the three tools for external use with which man is provided by nature, the other two being a compound vise, and a scratching or scraping tool, both of which are also in the hand. From using the hand as a hammer our early inventors must have derived the idea of artificial hammers, tools which should be serviceable where the fist was insufficient. From noting the action of the muscles of the hand the first idea of a vise must have been obtained, while by similar reasoning all our scraping and scratching tools, our planes and files, our rasps, and, perhaps, also some of our edged tools, were first suggested by the finger nails. Upon a substance softer than itself the fist can deal an appreciable blow, but upon a substance harder than itself the reaction transfers the blow to the flesh and the blood of nature’s hammer, much to the discomfort of the one using it. After a few experiments of this kind, it is reasonable to suppose that the primitive man conceived the idea of reinforcing the hand by some hard substance. At the outset he probably grasped a rounded stone, and this made quite a serviceable tool for the limited purposes of the time. His arm became the handle, while his fingers were the means of attaching the hammer to the handle. Among the relics of the past, coming from ages of which there is no written history, and in time long preceding the known use of metals, are certain rounded stones, shaped, it is supposed, by the action of the water, and of such a form as to fit the hand. These stones are known to antiquarians by the name of “mauls,” and were, undoubtedly, the hammers of our prehistoric ancestors. Certain variations in this form of hammer are also found. For that tapping action which in our minor wants is often more requisite than blows, a stone specially prepared for this somewhat delicate operation was employed, an illustration of which is shown in Fig. 1. A stone of this kind would, of course, be much lighter than the “maul” already described. The tapping hammer, a name appropriate to the device, was held between the finger and the thumb, the cavities at the sides being for the convenience of holding it. The original from which the engraving was made bears evidence of use, and shows traces of having been employed against a sharp surface.

The “maul” could not have been a very satisfactory tool even for the work it was specially calculated to perform, and the desire for something better must have been early felt. To hold a stone in the hollow of the hand and to strike an object with it so that the reaction of the blow should be mainly met by the muscular reaction of the back of the hand and the thinnest section of the wrist is not only fatiguing, but is liable to injure the delicate network of muscles found in these parts. It may have been from considerations of this sort that the double-ended mauls also found in the stone age were devised. These were held by the hand grasping the middle of the tool, and were undoubtedly a great improvement over the round mauls. Experience, however, soon suggested that in even this form there was much wanting. It still lacked energy to overcome reactions, the office which the wooden handle so successfully performs. Experiments were, therefore, early made in the direction of a more suitable handle than the unassisted arm and of a proper connection between the hammer and the handle. The first attempts were doubtless in the use of withes, by which handles were attached to such of the double-ended mauls as may have seemed suitable for the purpose. This means of fastening the handle is seen to the present day among half-civilized nations, and in some cases is even practised by blacksmiths to whom are available other and more modern means. Evidences of a still further advance are, however, found at almost the same period, for in the geological records of the stone age are met double mauls with holes through their centers for the insertion of a handle. In some instances these holes are found coned, and are almost as well adapted for the reception of hammer handles as the best tools of modern times. An illustration of one of these primitive tools is presented in Fig. 2.

From this it will be seen that the advance toward a perfect hammer in the earliest periods was important as well as rapid. All the preliminary experimenting to the development of a perfect tool was done by men who lived and worked before history commenced to be written. What remained to be done by the fraternity was entirely in the direction of more suitable material, and in the adaptation of form to meet special requirements. While principles were thus clearly established at an early day, very slow progress seems to have been made in applying them and in perfecting the hammer of the modern artisan. Between the “maul” of the savage of the stone age and a “Maydole” hammer, what a gulf! From the “tapping hammer” of stone, illustrated in Fig. 1, to a jeweler’s hammer of the present day, what a change! Between the double-faced perforated stone hammer, shown in Fig. 2, and the power forging hammers of modern practice, what a series of experiments, what a record of progress, what a host of inventors! In whatever direction we turn and from whatever standpoint we view the hammer there are clustered around it facts and legends, historical notes and mechanical principles, to the consideration of some of which a portion of our space may be well devoted.

To trace the origin of the hammer, commencing with its prototype, the human fist, and advancing step by step through the stone age, where fragments of rocks were made to do roughly the work that better tools afterwards performed, and so down the ages until the finished hammer of the present day is reached, would read like a romance. Like a pleasing story it would, perhaps, be of very little practical value, however entertaining the narrative might be, and, therefore, we shall not follow the development of the hammer too minutely. We desire to interest our readers, but we also hope to do more than simply amuse them.

The hammer has been justly called the king of tools. It has been sung by poets, and made the central figure of graphic scenes by some of the world’s most noted writers. Sir Walter Scott has turned it to good account in some of his stories. The poet of modern history, however, is yet to come; but when his day appears there will be much of suggestive incident from which he can fashion his song. Some of the most beautiful and delicate works that has ever been produced by the hand of man has been wrought by the hammer, and the skillful hammerman is well worthy of admiration. The fabled hammer of Thor is scarcely an exaggeration of the giant tools in actual use today in scores of iron works, and it would appear that the mythology makers of ancient times really saw visions of the coming ages, when they wove the wonderful stories that were a part of the religion of our ancestors.

We are very apt to look upon the hammer as a rude instrument. We overlook the scientific principles involved in its construction and use, and pay too little attention to the materials of which it is fashioned and the forms in which it is made. We frequently look upon it merely as an adjunct to other tools, and forget that it is entitled to consideration as a sole independent and final tool. In some handicrafts, and these, too, involving a high class of finished work—the hammer is the only tool employed. That great artistic skill in the use of the hammer as a finishing tool can be acquired is manifest from the many beautiful specimens of répoussé work to be seen in silversmiths’ shops. The details of the ornamentation are not only minute, but they so harmonize as to give elegance and expression to the whole, exclusive of the form of the articles themselves. A glance into the art stores in any of the cities will reveal specimens of hammered work of this sort, or of duplications of them, made by electroplating or by stamping with dies. The excellence, and, consequently, the value of these copies depends upon the closeness of imitation to the original; and as they are for the most part very clever specimens in this particular, they serve as illustrations in point almost as well as the originals. Those of our readers who are interested in the capabilities and possibilities of the hammer will be interested in an examinanation of some of these pieces of work. They are mostly of brass and copper, and in both originals and copies the tool marks are faithfully preserved. The esteem in which they are held may be judged from the statement that a piece of work of this kind about half the size of one of these pages sometimes fetches as much as $25, while shields of a larger size frequently sell for three and four times this sum. Choice originals are cherished in museums and are beyond the reach of money to buy. Other examples of hammer work might be mentioned, for example, the ancient wrought-iron gates, hinges and panels, representations of which are frequently met in art books. The suits of mail, and choice armor, most of which the ancient warriors were wont to clothe themselves in, are also examples in point. As marvelous as these examples of ancient work may seem, we think there are modern applications of the hammer that are quite as wonderful.

THE HAMMER.1

* * * The hammer is generally known as a rude instrument, but as a matter of fact it is in some of its uses a very refined one, requiring great care and skill in its use. * * *

Time forbids that I should refer to more than a few prominent forms of hammers. The carpenter’s mallet has a large rectangular head, because, as his tools are held in wooden handles, he must not use a hard substance to drive them with, or he will split the handles. Wood being light, he must have a large head to the mallet in order to give it weight enough.

THE STONE-MASON’S MALLET.

The stone-mason uses a wooden mallet, because it delivers just the kind of dull blow that is required. His mallet head is made circular, because his tools are steel, and have no wooden handles, and he is able to use the whole circumference, and thus prevent the tools from wearing holes in the wooden mallet face. The handles of both these mallets are short, because they will strike a sufficiently powerful blow without being used at a great leverage. On the other hand, the stone-breaker’s hammers have long handles, to avoid the necessity of stooping. The pattern-maker’s hammer is long and slender; long, that it may reach down into recesses and cavities in the work, and slender, because, being long, it has weight enough without being stout. Now, take the blacksmith’s sledge, and we find the handle nearer to the pene, or narrow end, than it is to the broad-faced end, while the pavior’s sledge has the handle in the middle of its length. If we seek the reason for these differences, it will readily occur to us that the blacksmith’s helper or striker delivers most of his blows in a vertical direction, and uses mainly the face and not the pene of the hammer, and by having the eye, and therefore the handle, nearest to the pene end, the face end naturally hangs downward, because, as held by the handle, the face end is the heaviest, and, as a result, he needs to make but little, if any effort, to keep the face downward. The pavior’s work, however, lies near the ground, and he uses both faces, his hammer not requiring a pene. Hence the handle is placed central, balancing both faces equally.

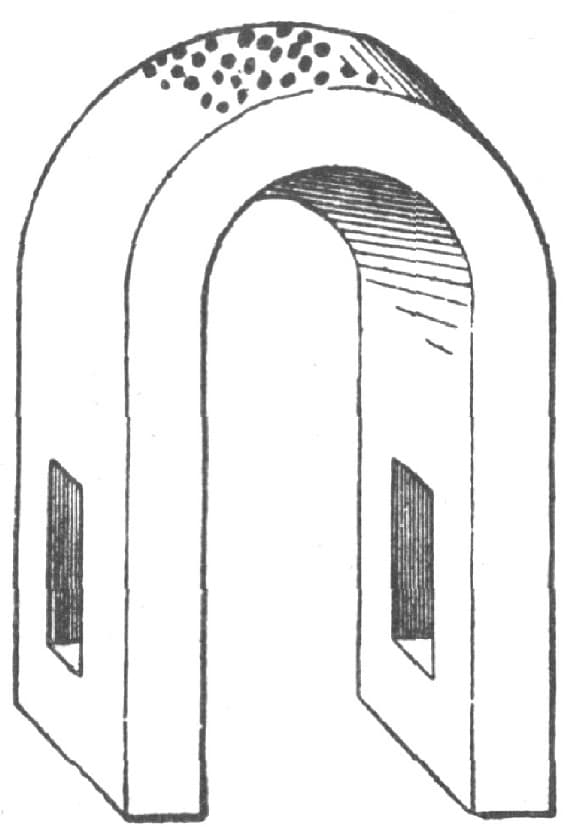

FIG. 3—AN ILLUSTRATION OF THE PROCESS OF STRETCHING WITH THE HAMMER

THE MACHINIST’S HAMMER.

The machinist’s hammer is also made heavier on the face than on the pene end, so that the face which he uses the most will hang downward without any special effort to keep it so. His chipping hammer, which he also uses for general purposes, weighs in the heaviest kinds 13/4 pounds, and the handle should be 15 inches long. He wields it for heavy chipping, with all the force he can command, obeying the law that it is velocity rather than weight that gives penetration. Thus, supposing a hammer weighing 100 pounds is traveling at a velocity of ten feet per second, and the power stored up in it is 1,000 foot-pounds. Another hammer, weighing one pound and traveling 1,000 feet per second, would also have stored up in it 1,000 foot-pounds. Hence the power is equal in the two, but the effects of their blows would be quite different. If they both struck a block of iron we should find that the effects of the quick moving hammer would sink deeper, but would spread out less sidewise, giving it a penetrating quality; while the slow-moving one would affect the iron over a wider area and sink less deeply. To cite an important operation in which this principle must be recognized: Suppose we have a wheel upon a shaft, and that the key is firmly locked between the two. In driving it out we know that, if we take a heavy hammer and strike slow, moving blows we shall spread the end of the key riveting it up and making it more difficult to drive out; so we take a hammer having less weight and move it quicker.

USES OF THE HAMMER.

In whatever form we find the hammer, it is used for three purposes only, namely, to crush, to drive and to stretch. And the most interesting of these operations are stretching and driving. The gold-beater, the blacksmith, the sawmaker, the plate straightener and the machinist, as well as many others, employ the hammer to stretch; while the carpenter, the machinist, and others too numerous to mention, use the hammer to drive. Among the stretching operations there are many quite interesting ones. Here in Fig. 3, for example, is a piece of iron, two inches wide, and an inch thick, bent to the shape of the letter u. This piece of wire is, you observe, too short to fit between the jaws, and I will now bend the piece and close the jaws by simply hammering the outside of the curved end with a tack hammer. The proof that the blows have bent the piece is evident, because the piece of wire now fits tightly instead of being loose, as before the hammering. The principle involved in this operation is that the blows have stretched the outer surface, or outside curve, making it longer and forcing the jaws together. If we perform a similar operation upon a straight piece of metal, the side receiving the blows will actually rise up, becoming convex and making the other side concave, giving us the seeming anomaly of the metal moving in the opposite direction to that in which the blows tend to force it. This process is termed pening, because, usually, the pene of the hammer is used to perform it. It is sometimes resorted to in order to straighten the frame-work of machines, and even to refit work that has worn loose.

STRAIGHTENING PLATES AND SAWS.

Straightening thin metal plates and saws form very interesting examples of the stretching process, and are considered very skillful operations. Some few years ago I was called upon to explain the principles involved in this kind of straightening, and having no knowledge of the subject, I visited a large saw factory to inquire about it. I was introduced to one of the most skillful workmen, and the object of my visit was made known to him. He informed me that it was purely a matter of skill, and that it was impossible to explain it.

“I will show you how it is done,” said he, and taking up a hand-saw blade, he began bending it back and forth with his hands, placing them about eight inches apart upon the blade.

“What do you do that for?” I asked.

“To find out where it is bent,” he replied.

* * * * *

I spent two hours watching this man and questioning him, but I left him about as much in the dark as ever.

Then I visited a large safe-making factory, knowing that the plates for safes required to be very nicely straightened. The foreman seemed very willing to help me, and took me to the best straightener in the shop, who duly brought a plate for a safe door and straightened it for me. Then he brought another, and as soon as he stood it on edge and began to sight it with his eye, I asked him why he did that.

“Because the shadows on the plate disclose the high and the low patches.”

“In what way?” I asked.

“Well, the low patches throw shadows,” he replied, and the conversation continued about as follows:

“When you have thus found a low place, what do you do?”

“I hammer it out.”

I sighted the plate and made a chalk mark inclosing the low spot, and he laid the plate upon the anvil and struck it several blows.

“Why did you strike the plate in that particular spot?” I asked.

“Because that is where I must hit it to straighten it.”

“Who told you that this particular spot was the one to be hammered?”

“Oh! I learned some years ago.”

“But there must be some reason in selecting that spot, and that is what I wanted to find out.”

“Yes, I suppose there is a reason for it, but if it had been a different kind of hollow place I wouldn’t have hit it there at all.”

“Why not?”

“Because I should have had to hit it somewhere else.”

And so it went on, until finally I got some pieces of twisted plate, one with a bulge on one edge, another with a bulge in the middle, and he straightened them while I kept up my questions. But still the mystery remained, nor did I seem any nearer to a solution; so I abandoned the attempt.

About six months after this I met by chance, an Eastern plate straightener, and on relating this experience to him he offered to go into the shop and explain the matter.

We went, and taking up a plate one-eighth inch thick, two feet wide and four long, he laid one end on an anvil and held up the other with his left hand, while with his right hand he bent or rather sprung the plate up and down, remarking as he did so:

“Now you just watch the middle of this plate, and you will see as I swing it the middle moves most, and the part that moves most is a loose place. The metal round about it is too short and is under too much tension. Now, if I hammer this loose place, I shall stretch it and make it wide, so I hammer the places round about it that move the least, stretching them so that they will pull the loose place out. Now, with a very little practice you could take out a loose place as well as I can, but when it comes to a thick plate the case is more difficult, because you cannot bend the plate to find the tight and loose places, so you stand it on edge, and between you and the window, the light and shades show the high and low patches just as a landscape shows hills and valleys.”

I selected several examples of twisted and crooked plates and he straightened them for me, explaining the reasons for each step in the process, and as this forms one of the most interesting operations performed by the hammer, I may as well speak somewhat in detail of hammers, the way they are used, and the considerations governing their application to the work.

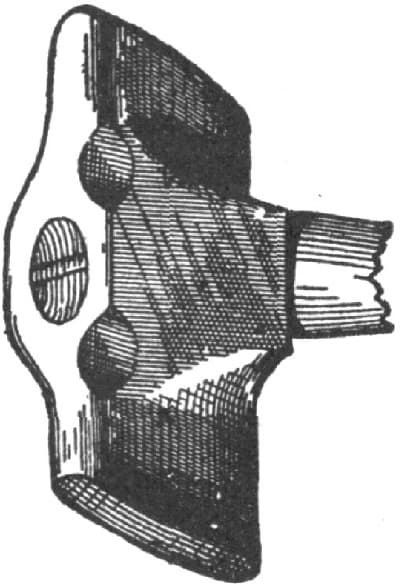

FIG. 4—THE LONG CROSS FACE HAMMER

Fig. 4 represents what is called the long cross-face hammer, used for the first part of the process, which is called the smithing. The face that is parallel to the handle is the long one, and the other is the cross-face. These faces are at a right angle one to the other, so that without changing his position the operator may strike blows that will be lengthways in one direction, as at A, in Fig. 5, and by turning the other face toward the work he may strike a second series standing as at B. Now, suppose we had a straight plate and delivered these two series of blows upon it, and it is bent to the shape shown in Fig. 6, there being a straight wave at A, and a seam all across the plate at B, but rounded in its length, so that the plate will be highest in the middle, or at C. If we turn the plate over and repeat the blows against the same places, it will become flat again.

FIG. 5—SHOWING HOW THE CROSS-FACE HAMMER OPERATES IN TWO DIRECTIONS

FORM OF HAMMER FOR STRAIGHTENING SAWS.

To go a little deeper into the requirements of the shape of this hammer, for straightening saws, I may say that both faces are made alike, being rounded across the width and slightly rounded in the length, the amount of this rounding in either direction being important, because if the hammer leaves indentations, or what are technically called “chops,” they will appear after the saw has been ground up, even though the marks themselves are ground out, because in the grinding the hard skin of the plate is removed, and it goes back to a certain and minute extent toward its original shape. This it will do more in the spaces between the hammer blows than it will where the blows actually fell, giving the surface a slightly waved appearance.

FIG. 6—ANOTHER ILLUSTRATION OF THE STRAIGHTENING PROCESSS

The amount of roundness across the face regulates the widths, and the amount of roundness in the face length regulates the length of the hammer marks under any given force of blow. As the thicker the plate the more forcible the blow, therefore the larger dimensions of the hammer mark. *

* * This long cross-face is used again after the saws have been ground up, but the faces are made more nearly flat, so that the marks will not sink so deeply, it being borne in mind, however, that in no case must they form distinct indentations or “chops.”

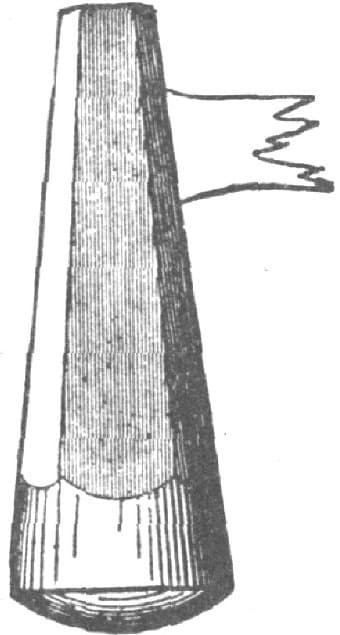

In Fig. 7 we have the twist hammer, used for precisely the same straightening purposes as the cross-face, but on long and heavy plates and for the following reasons:

FIG. 7—THE TWIST HAMMER

When the operator is straightening a short saw he can stand close to the spot he is hammering, and the arm using the hammer may be well bent at the elbow, which enables him to see the work plainly, and does not interfere with the use of the hammer, while the shape of the smithing hammer enables him to bend his elbow and still deliver the blows lengthways, in the required direction. But when a long and heavy plate is to be straightened, the end not on the anvil must be supported with the left hand, and it stands so far away from the anvil that he could not bend his elbow and still reach the anvil. With the twist hammer, however, he can reach his arm out straight forward to the anvil, to reach the work there, while still holding up the other end, which he could not do if his elbow were bent. By turning the twist hammer over he can vary the direction of the blow, the same as with the long cross-face. * * *

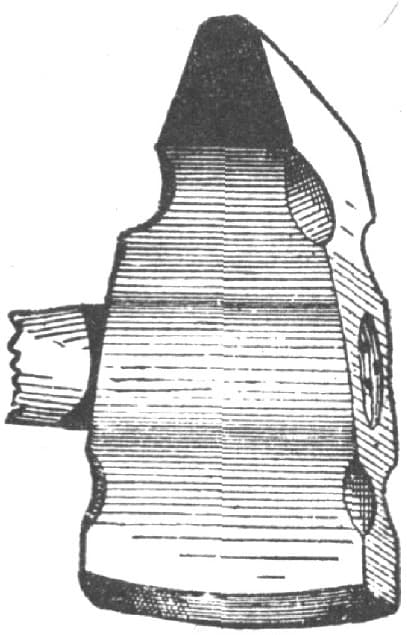

FIG. 8—THE DOG-HEAD HAMMER

Both of these hammers are used only to straighten the plates, and not to regulate their tension, for you must understand that a plate may be flat and still have in it unequal strains; that is to say, there may exist in different locations internal strains that are not strong enough to bend the plate out of truth, as it is, but which will tend to do so if the slightest influence is exerted in their favor, as will be the case when the saw is put to work. When a plate is in this condition it is said to have unequal tension, and it is essential to its proper use that this be remedied.

The existence of unequal tension is discovered by bending the plate with the hands, as has been already mentioned, and it is remedied by the use of the dog-head hammer, shown in Fig. 8, whose face is rounded so that the effects of its blow will extend equally all around the spot struck. It will readily be understood that the effects of the blow delivered by the smithing, or by the twist hammer, will be distributed as in Fig. 7, at A B, while those of the dog-head will be distributed as in Fig. 9, at C, gradually diminishing as they pass outward from the spot struck; hence the dog-head exerts the more equalizing effect.

FIG. 9—SHOWING THE DIFFERENCE IN THE EFFECTS OF TWIST AND DOG-HEAD HAMMER BLOWS

USE OF THE DOG-HEAD HAMMER.

Now, while the dog-head is used entirely for regulating the tension, it may also be used for the same purposes as either the long cross-face, or the twist hammer, because the smith operates to equalize the tension at the same time that he is taking down the lumps; hence he changes from one hammer to the other in an instant, and if after regulating the tension with the dog-head he should happen to require to do some smithing, before regulating the tension in another, he would go right on with the dog-head and do the intermediate smithing without changing to the smithing hammer. Or, in some cases, he may use the long cross-face to produce a similar effect to that of the dog-head, by letting the blows cross each other, thus distributing the hammer’s effects more equally than if the blows all lay in one direction.

_____________

1 [From a lecture delivered before the Franklin Institute, by Joshua Rose, M. E., Philadelphia.]