CHAPTER II

BOLT AND RIVET CLIPPERS

A Bolt and Rivet Clipper.

Cutting off bolts and rivets with a cold chisel is not very convenient in a shop where only one man is working: for instance, a blacksmith shop in a small town. Very good bolt and rivet clippers are now manufactured, but many blacksmiths cannot afford to pay eight or ten dollars for a bolt clipper, and so they have some one to hold a hammer or bar on one side of the bolt while the smith cuts from the other side with a dull chisel, and now and then hits his hand, or the end of the bolt flies in his eye or in the eye of the man that holds the bar. Then very often the end of the bolt goes through a window, and before they get through with their job the smith is very mad.

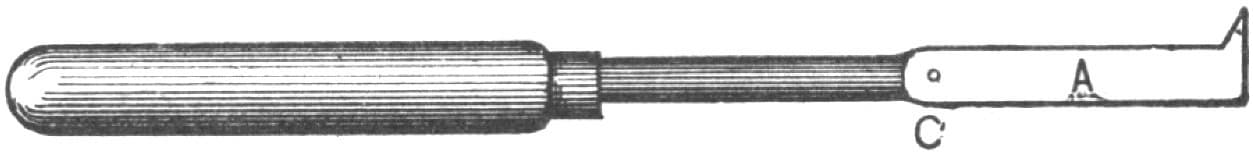

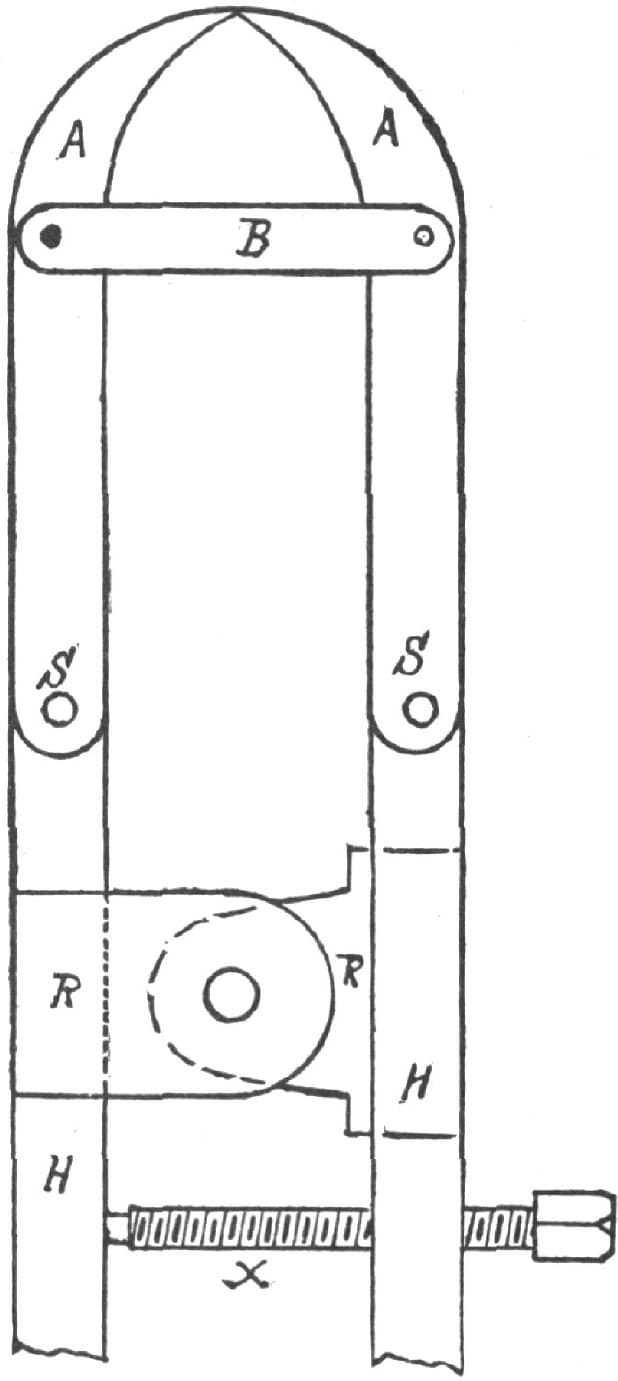

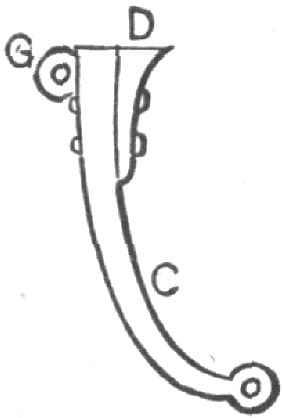

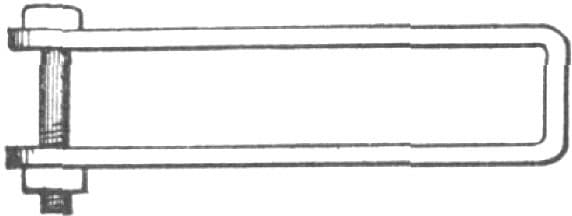

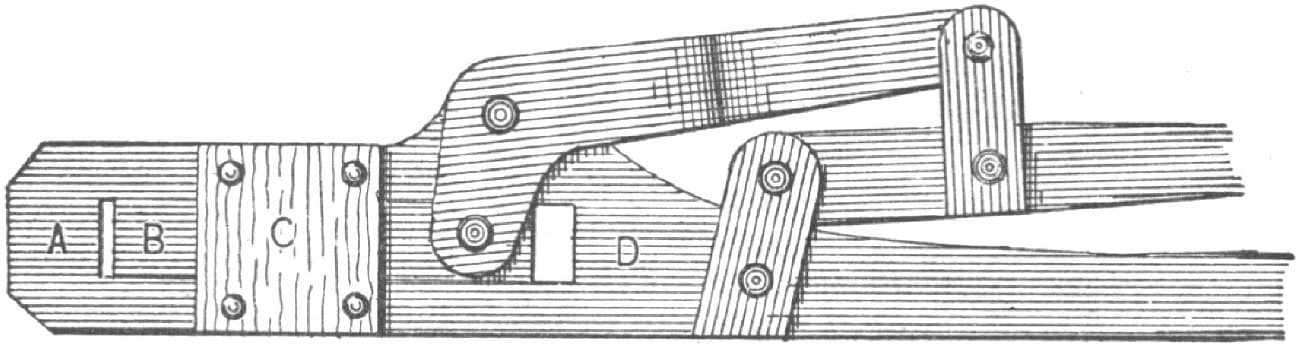

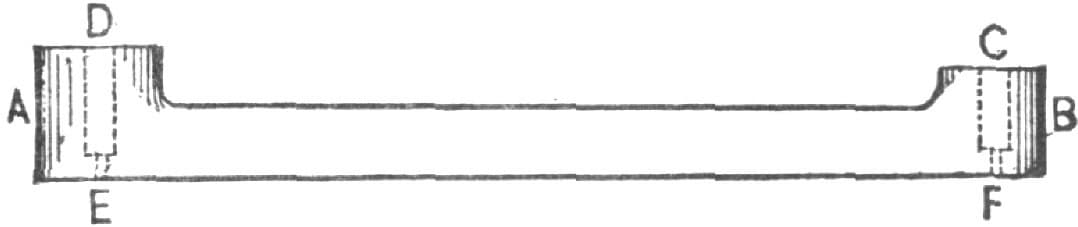

Fig. 14a—Showing how the Knife is made for Bolt and Rivet Clipper

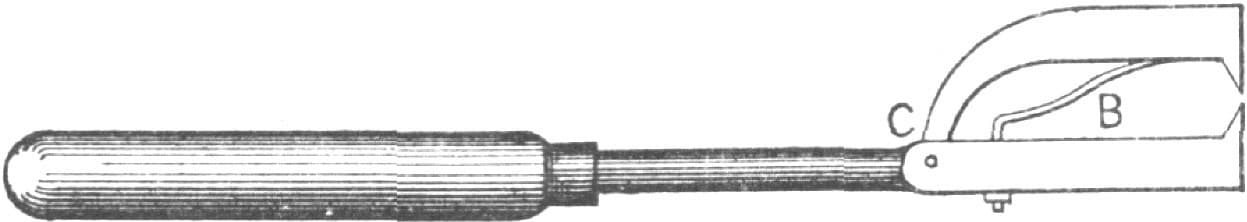

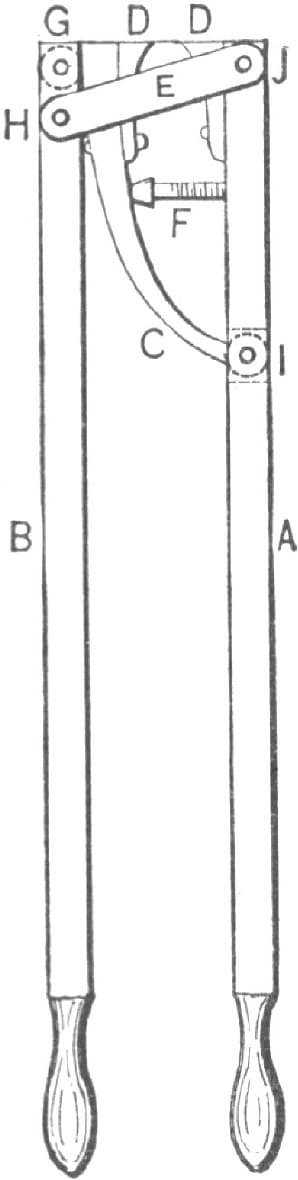

About three years ago I made a good and cheap bolt clipper, which is shown in the accompanying illustrations, Figs. 14a to 17. It is made as follows: A piece of steel 1/2 × 1 inch and 6 inches long is welded to a 3/4-inch round rod 12 inches long, and the end of the steel is turned up half an inch for a nipper or knife, as at A in Fig. 14a. In Fig. 15 the two jaws or nippers are together. B, in Fig. 15, is a spring used to raise one jaw when the tool is applied to a rivet. The upper jaw works loosely in a slot hole at C. A small hole is punched six inches from the end for the spring. A nut is used to fasten the spring. In Fig. 16 the purchase lever is shown. This is made of inch-square iron and 12 inches of 3/4-round iron, or just as the lower handle is made.

Fig. 15—Showing the two Jaws together

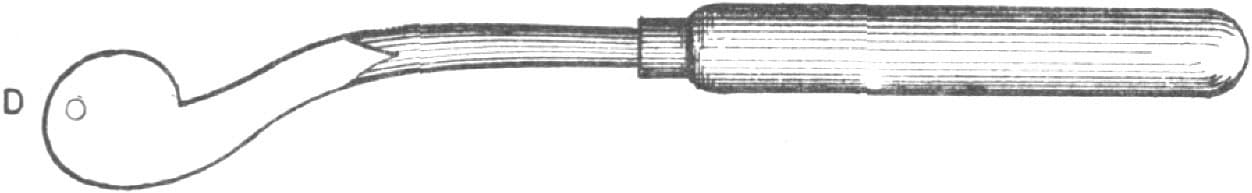

Fig. 16—The Purchase Lever

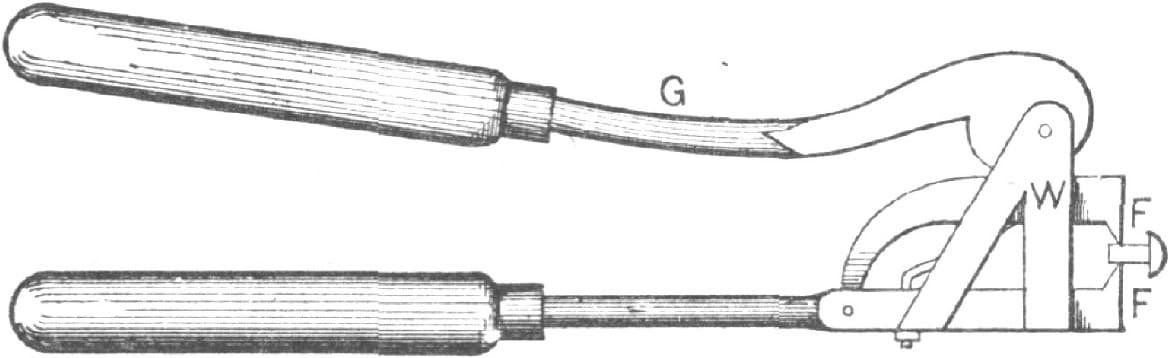

Fig. 17—Showing the Clipper completed

A 1/2-inch round hole is punched in one side at D, as in Fig. 16. In Fig. 17 the clipper is shown as it appears when put together and ready to be applied to a bolt.

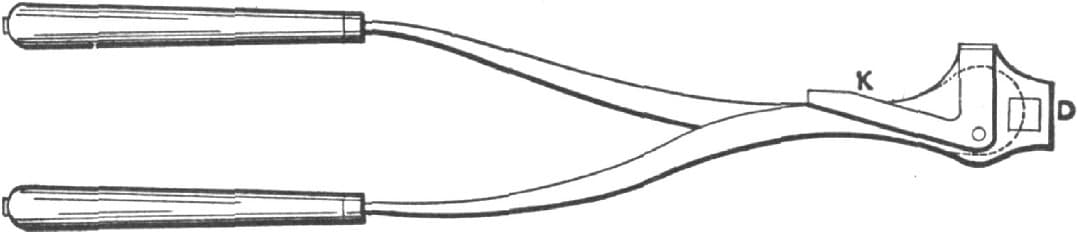

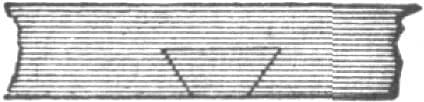

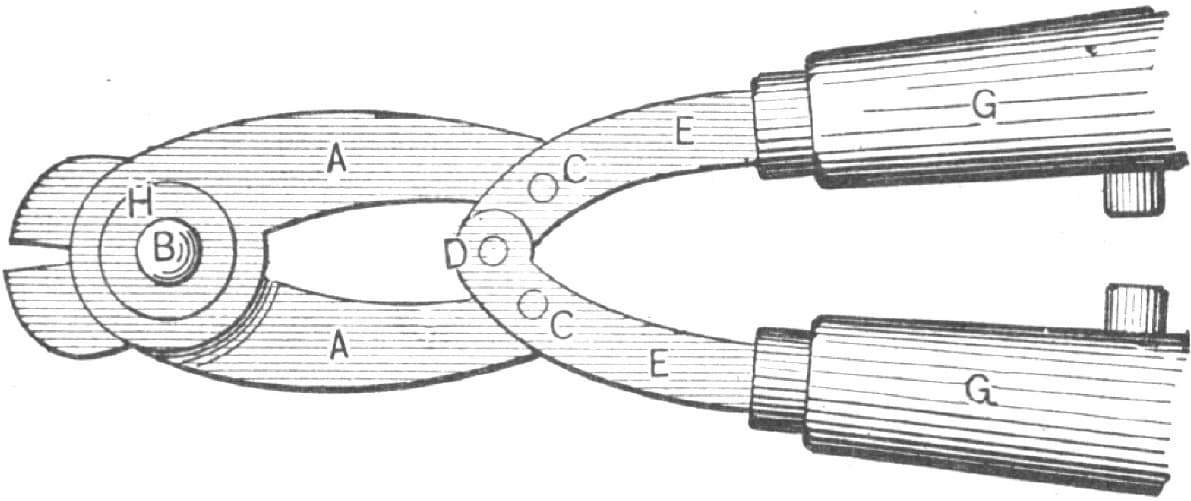

Fig. 18—Cut Nippers as made by Steel Square

Fig. 17 is a side view of the clipper. The jaws, F, F, must be close to the piece W. When you press down the lever the lower side of the head commences to press down. This clipper can be made in half a day and will answer for most jobs.—By E. H. WEHRY.

Cut Nippers.

I send you a sketch, Fig. 18, of a pair of cut nippers I invented. They are not patented, nor will they be. Three-eighths-inch iron can be cut with them with ease.

A A are steel cutters down to joints S S, and they may be made of any shape to suit. At B there are two links bolted to the cutter, one on each side. The joint R R would be difficult to forge, so it is made of malleable iron, and is bolted on the side of the handle H. There are two of these made with a shoulder on the inside. The right-hand part is bolted on the edge of the other handle H, is the same thickness as the handle and sets in between the other two, being held by a bolt. A set screw, as shown, stops the handles H H at the right point. The handles may be of any length desired—By STEEL SQUARE.

Bolt Clipper.

I inclose sketches illustrating a bolt clipper which may be made by any good blacksmith in four hours’ time. Fig. 19 represents the tool complete, while the other sketches represent details of construction. For the parts shown in Fig. 21 take a piece of spring steel 21/4 inches wide by 1/4 inch thick and flatten out about 21/2 inches wide at B. That will leave the part 3/16 of an inch thick. Punch holes as shown at A and B. Shape a small piece of steel as indicated by C in the same cut and place it on the end. Take a light heat and weld it fast in that position. That will keep the end from pushing out. The square hole marked O in Fig. 21 is made large enough to pass it over the nuts. The part shown in Fig. 20 is made of cast-steel and sharpened in the parts shaded as shown at H. The construction of the guard is shown in Fig. 22. It is to be bent at the dotted lines, giving it the shape indicated by Fig. 23. It is then ready to clinch into the holes provided for it as shown in A and B of Fig. 21. The bolt uniting the two parts should be made of cast-steel 5/16 inch in diameter. The entire length of the tool should be 15 inches. Made of these dimensions leverage enough will be afforded to clip bolts 3/16 to 5/16 inches in diameter.—By D. H. E.

Fig. 19—The Bolt Clipper complete

Fig. 20—Portion of Bolt Clipper. Elevation, Sectional View and Details of “D. H. E.’s” Bolt Clipper

Fig. 21—Another part of Bolt Clipper

Fig. 22—Shows how the Guard is Constructed

Fig. 23—Shows Shape of Guard

A New Bolt Clipper.

I enclose a sketch, Fig. 24, of a bolt clipper which is a handy tool and unlike any I have seen in other shops. The handles are of wood, and are about two feet long. The band or clamp prevents the twisting of the knives to one side when they close on the bolt. The plate shown in the sketch is duplicated on the other side. This arrangement enables me to get a leverage near the hinge or heel.

This tool can be used for bolts ranging in size from the smallest up to half inch.—By R. D. C.

A Handy Bolt Cutter.

I enclose sketches of a bolt cutter of my own make, which I will describe as well as I can. I think the tool may be of some benefit to some of my brother smiths. It saves labor and is easily made. To make it I first take a bar of iron 7/8-inch square and cut off two pieces, each two feet long, for the levers A and B shown in the engravings, Figs. 25 and 26. In making the lever A, I first square up the end where the hole, G, is made. I then punch, six inches below the hole G, another hole, I, to receive the bow C. The lever B is of the same length as A and has on the upper end at G a coupling made the same as a joint on a buggy top brace. This coupling connects the lever B and bow C. The hole in the coupling and the hole shown at H, Fig. 27, are one inch apart from center to center. I next take a piece of steel 3/4-inch square to make the bow. I first stave it up on one end to put the ear on it for the coupling G, then I put an eye in it to fit in the long holes shown at I, and bend it so that the knife D will fit closely against it when the two are put together. To forge the knife I take a piece of 3/4-inch good cast-steel. I dress up the knives, harden them and then rivet one on the lever A and the other on the bow C, using two rivets in each one. The plates E, are made of 17/8-inch by 3/8-inch iron, the holes in them being four inches apart from center to center. The holes are 3/8 inch. The plates are placed as indicated by the lines in Fig. 26, and are held in position by steel rivets inserted in the holes H and I. The set screw F is used to prevent the edges of the knives from striking together. The jaws must be open about three-quarters of an inch when the levers are straight. In this tool the cutting is done, not by pressing the levers together but by pulling them apart.

Fig. 24—A New Bolt Clipper as made by “R. D. C.”

Fig. 25—A Handy Bolt Cutter. The Bow

Fig. 26—The Bolt Cutter as completed

Fig. 27—Side View of Bolt Clipper made by “C. N. S.”

Fig. 28—Showing the Piece F, used in the Bolt Clipper

I can cut with it all bolts from 1/2-inch down.—By L. G.

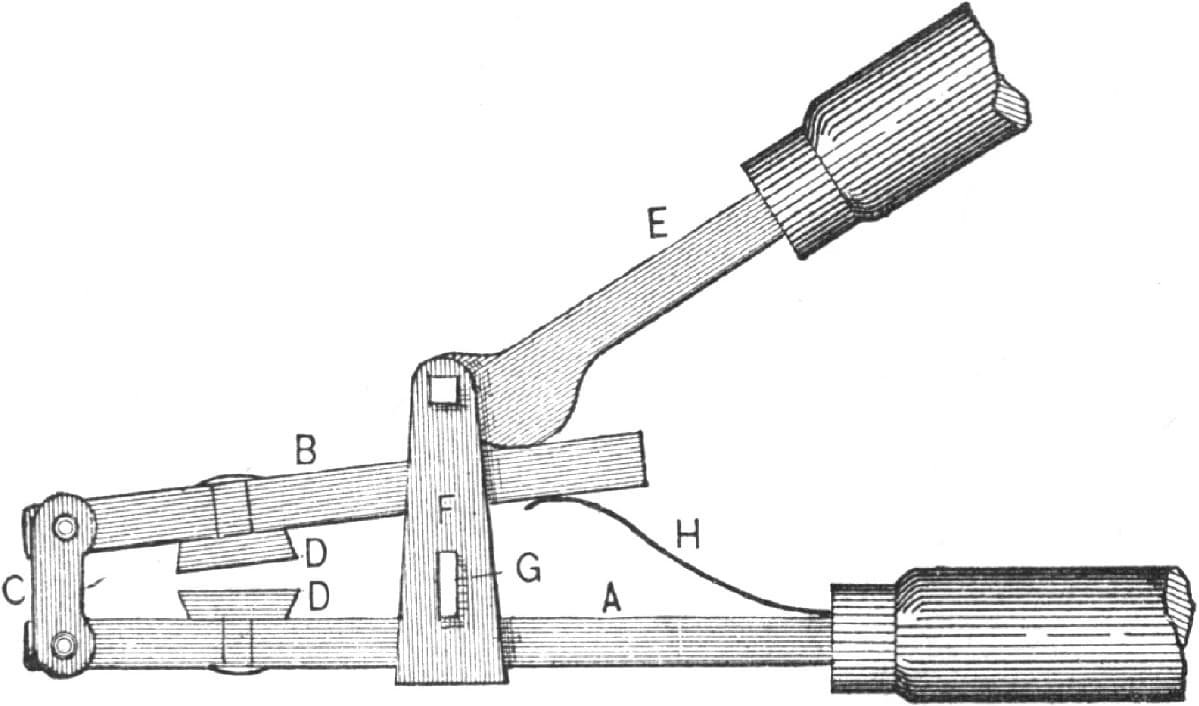

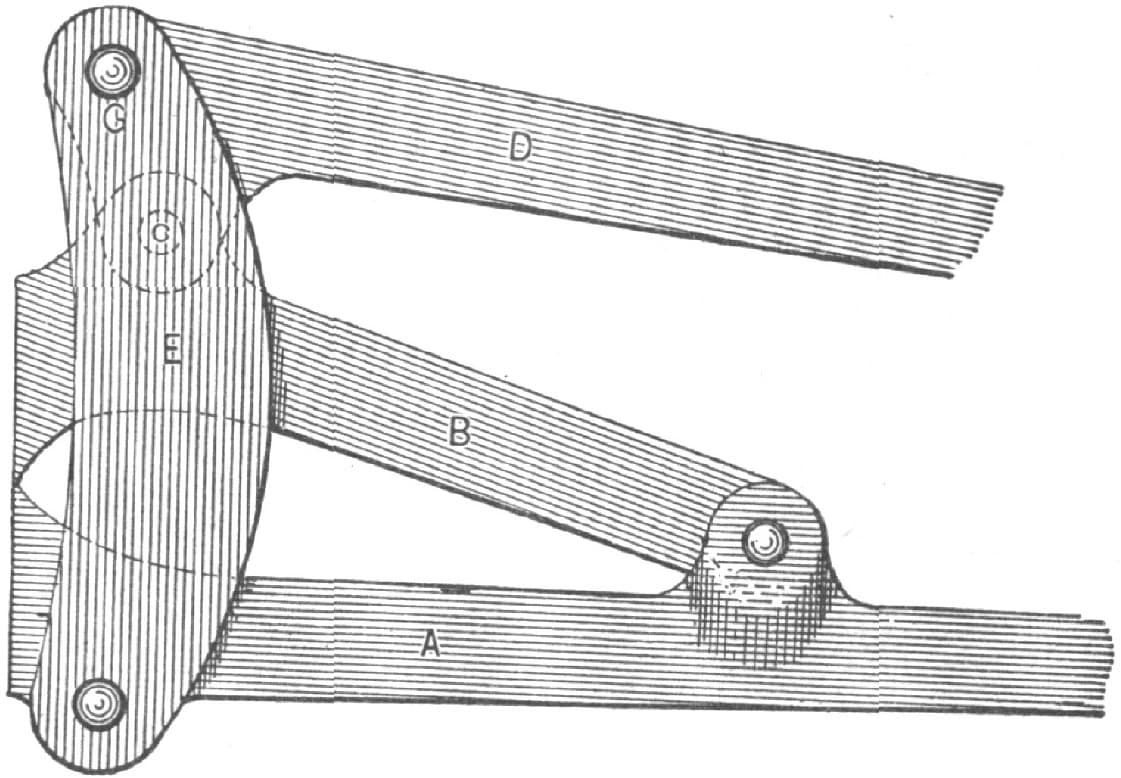

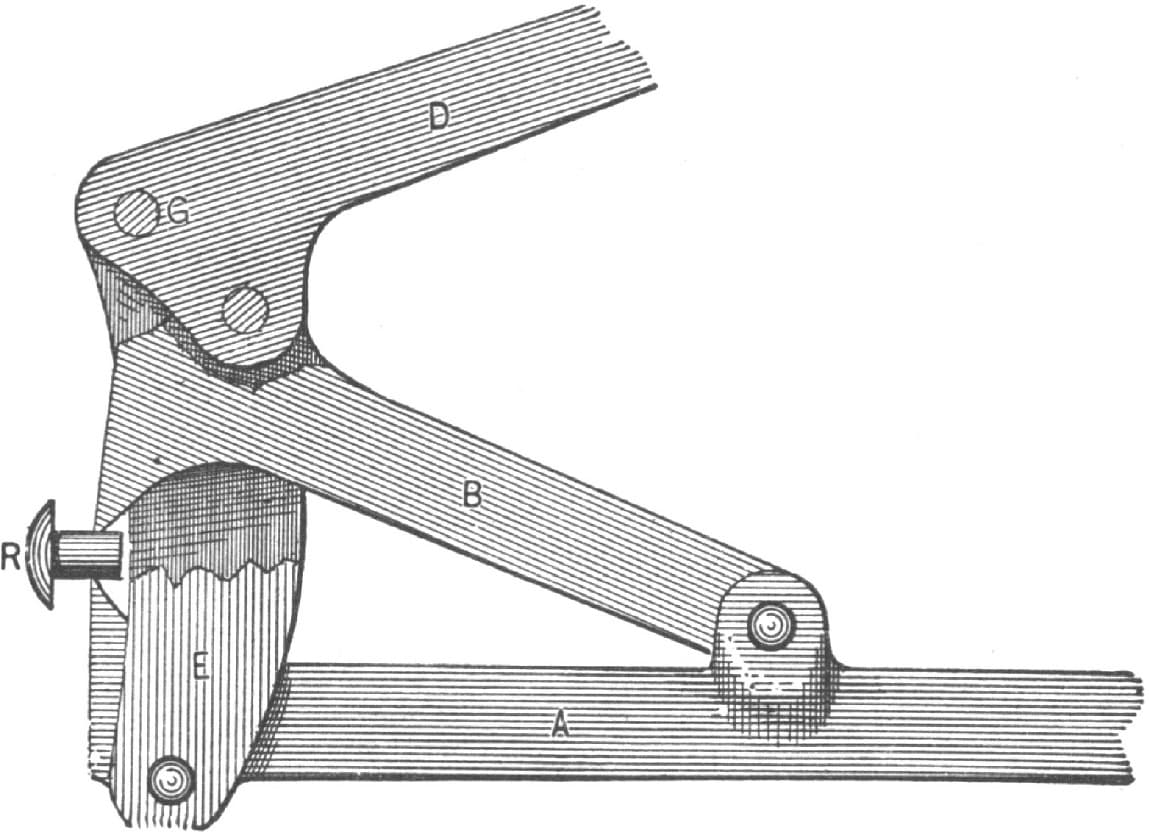

Making a Bolt Clipper.

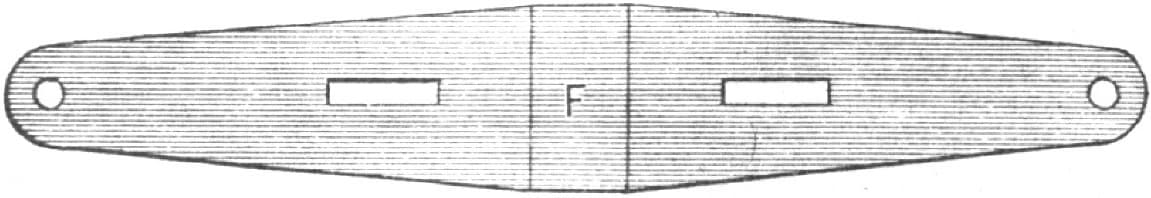

I have made a bolt clipper which, in my opinion, is equal to any of the patent ones in the market. In Fig. 27 of the illustration, A denotes the long handle made of 3/4-square iron; B is the other piece, C is the double hinge, D D are the knives, E the purchase lever, F the piece that holds the purchase lever in place. In Fig. 28 the piece F is shown ready to bend, and in Fig. 29 it is shown bent. G is a key for fastening the piece F on the piece E or the main lever. It is also used to keep the knives apart. H, in Fig. 27, is the spring used to open the jaws. The piece shown in Fig. 30 is one of those that form the hinge, one goes on one side and one on the other, being fastened together with two rivets. Fig. 31 shows how the knives are put on the handle.—By C. N. S.

Fig. 29—Showing the Piece F Bent

Fig. 30—Showing one of the Pieces used for the Hinge

Fig. 31—Showing how the Knives are Fastened to the Handle

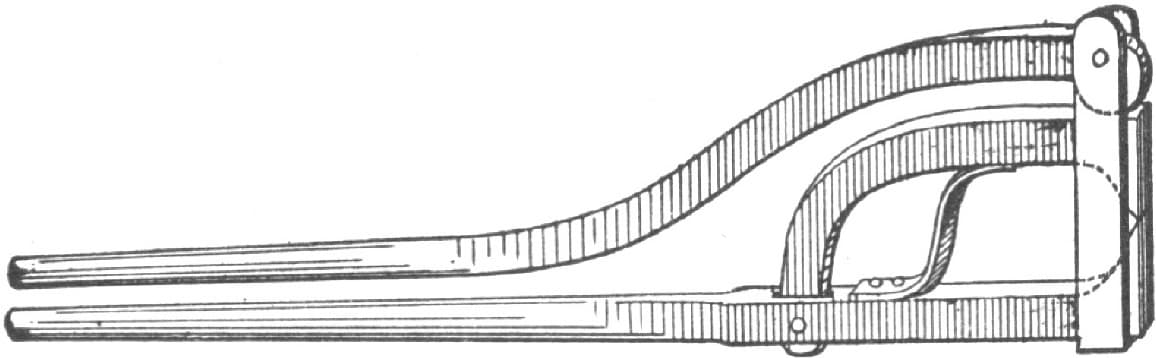

Tool for Cutting Rivets.

I send you sketches of a pair of cut-nippers, Figs. 32 and 33. They are adapted to cutting bolts and rivets up to 1/4-inch in diameter. The jaws do not project, so as to cut long wire, and whatever is cut must be inserted end ways. When finished the tool is 10 inches long, and weighs 14 ounces. [The portions represented in the engravings are full size, the handles being broken at the points indicated, to save space. The plate E is represented partially broken away in Fig. 33, so as to show clearly the method of construction.—ED.] A is the fixed jaw or leg, having a pivoted jaw, B. A lever, D, is pivoted to B, at C. Two plates, E, on each side of the jaws, are pivoted to A, at F, and to D, at G; D is moved outwards, a rivet, at R, put in, and D is closed, cutting off the rivet, the operation being obvious. The plate, E, must be 1/3 of an inch thick, and riveted to A and D, on both sides, with at least 3/16 rivets, as the strain is very great. If well made and carefully used, one of these cut-nippers will last a long time. I have used one seven years, and it is in good condition yet, though I have averaged to iron fifty sleighs a year, and they have done all the cutting, besides all my other work, where they could be used.—By O. F. F.

Fig. 32—“O. F. F.’s” Rivet Cutter

Fig. 33—Another View of “O. F. F.’s” Rivet Cutter

Rivet Cutter.

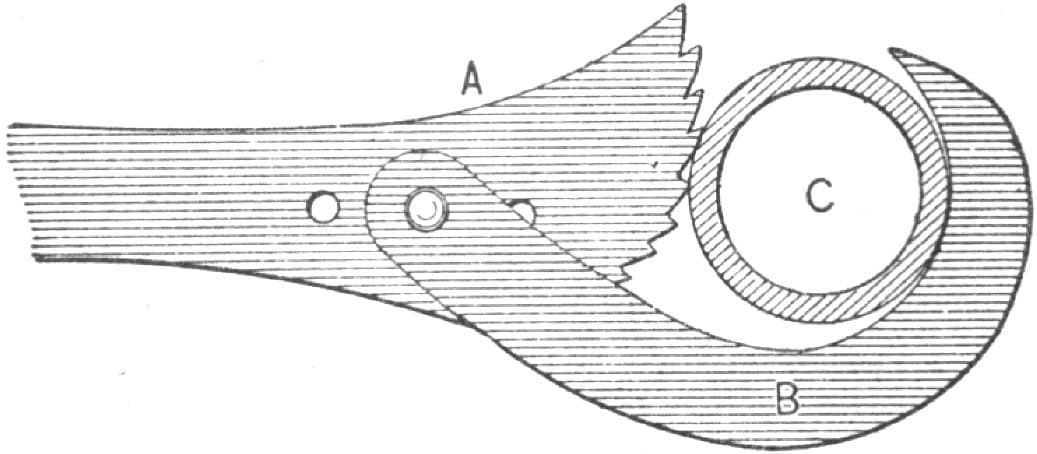

I have a tool which will cut a rivet or bolt one-half inch in diameter very easily. It is very handy and useful in cutting points of bolts, in ironing wagons, buggies, etc. In my sketch, Fig. 34 represents the tool nearly closed. The part marked A is one shear or knife, which is a piece of steel (best) welded on the iron frame or body, and beveled from the opposite side so as to make an edge. The part marked B, is the main or sliding shear, made of the best steel. It also has a beveled edge the same as A. C is a plate, and there is one on each side so as to hold the shear or knife, B, to its place. These plates can be fastened on either with rivets or small bolts as desired. D is the main frame or body of the tool, which is iron. Fig. 35 is a top view with a portion of the outer jaw removed, showing the points or edges of shears or knives, A and B, and the method of securing the plates referred to.—By CYRUS G. LITTLE.

Fig. 34—Showing Rivet Cutter Closed

Fig. 35—Sectional View of Rivet Cutter showing Edges of Shears

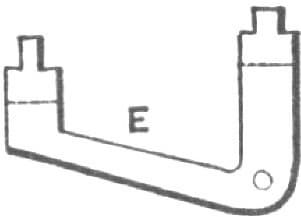

Tools for Making Rivets—Pipe Tongs.

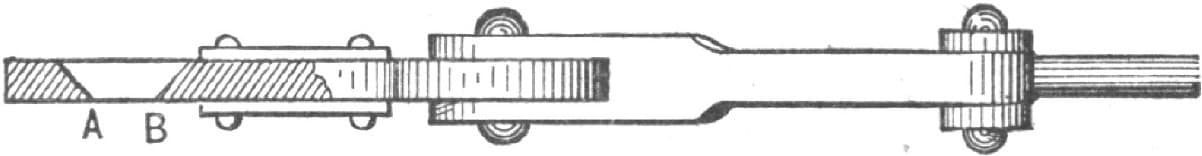

I send you a sketch, Fig. 36, of a handy rivet-making tool. The hole at A is just deep enough to make the required length of rivet; the wire is cut off long enough to make the body and head, and is riveted with a button rivet set; the lower part of the tool is bowed as you see and naturally holds the two jaws a little open. The vise jaws grip at C C, the two flanges, D, resting on top of the vise jaws: as the vise is opened or shut the jaws of the tool open and release or close and grip the rivet.

Fig. 36—Rivet-making Tool

I also send you a sketch, Fig. 37, of, I think, the best form of pipe tongs. The jaw B points to jaw A. Moving A in the direction of arm causes pipe C to be very firmly gripped. —By “SOUTHERN BLACKSMITH.”

Fig. 37 Best form of Pipe Tongs

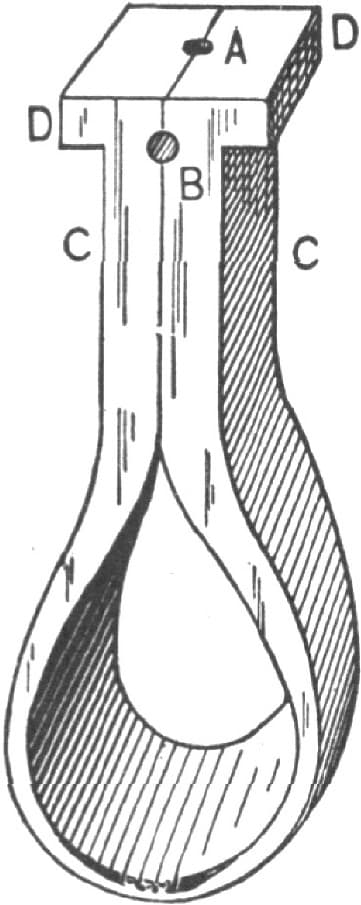

A Tool for Making Rivets.

The accompanying illustration, Fig. 38, represents a tool which is very convenient for making the rivets that are used to fasten the brass on the plow share and the bar, and also the frog when wooden stock plows are made. The tool will make rivets of two lengths, namely, 11/2-inch and 1-inch. I used 3/8-inch round Norway iron for rivets because it is the only kind fit for that purpose. Rivets made of common iron will always break if they are put in hot.

Fig. 38—A Tool designed by “L. G.” for making Rivets

I make the tool as I would an ordinary heading tool, but am careful to get the ends A B, high enough where the holes are. The end A is for the 11/2-inch rivets and the other end is for the 1-inch rivets; A is made two inches high, and B is an inch and a half high. The ends are laid with steel on the tops, and I then take a 3/8-inch bit the size of the round iron used and bore holes at C and D, so that they lack but half an inch more to come through the piece, and then bore through the rest of the way with a 3/16-inch bit at E and F. This is to facilitate the driving out of the rivets after they are made. The iron should be cut long enough to allow for a head. After making the rivets I drive them out with a small punch. If a little oil is used in the tool they will come out easier.—By L. G.

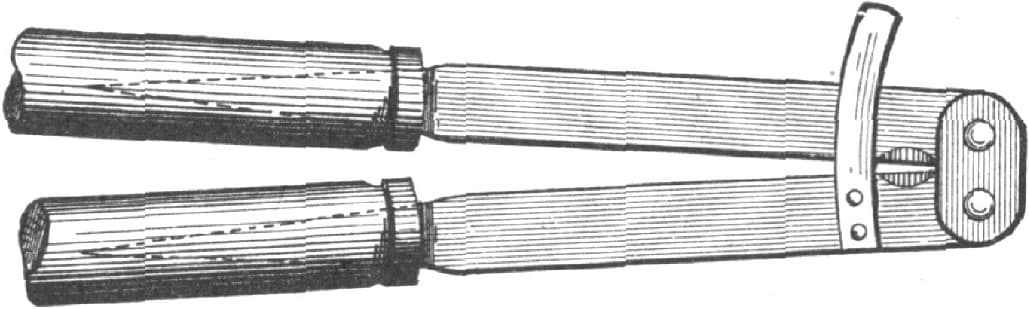

Making a Bolt Clipper.

I have a bolt clipper that will cut easily bolts of half an inch or smaller ones. It is made as follows:

I first make a pattern of tin. For the jaws, which are marked A A in the accompanying illustration, Fig. 39, I used a piece of bar iron, 3/8 × 3 inches, cutting off two pieces about 10 inches long, then forming them according to the pattern and welding on a piece of steel for the cutting edge. The hole B is made 5/8-inch in diameter. The holes C C and D are 1/2-inch in diameter. The distance from the hole B to C C is 6 inches, from C C to D it is 11/4 inches, and from C to C is 11/2 inches. The handles G G are made of iron 5/8 × 11/2 inches and are joined at D. The jaws, A A, are joined to the handles at C C. The other parts of the handles, G G, are of wood, about three feet long, with ferrules on the ends. The total length of the handles, measuring from D, is 31/2 feet. The washer, H, is 2 inches in diameter, and is forged to a thin edge around the outside. I put one on each side. The rivets should be of steel.—By W. R.

Fig. 39—Bolt Clipper made by “W. R.”

How to Make a Bolt and Rivet Cutter.

I have made a bolt and rivet cutter that works spendidly, and will tell how it is made.

Take a piece of square iron, twenty-four inches long, for the bottom piece. In the end weld a piece of tool steel for a cutter. This should be 3/4 inch so as to have solid steel cutters. In the bottom piece, seven inches from the end, punch a hole with a flat punch and round down from above the hole.

The other jaw is made from the same kind of iron with steel welded on the end for cutter. The upper handle can be made from round or square iron whichever is handiest. The spring can be made from any piece of old spring, and is put on with two small rivets. The end piece can be made from 3/4-inch stake iron. It is in one piece and bent so as to fit around the lower jaw. Fig. 41 shows the cutter complete and will give a good idea as to how it is made. I think that some of the boys will find this cutter very useful. It is powerful and will cut easily small bolts and pieces of iron. It is also, as will be seen by the engraving, simple in construction and not difficult for any smith to make.—By C. V. MARSH.

Fig. 41—Showing C. V. Marsh’s Bolt and Rivet Cutter complete