CHAPTER VIII

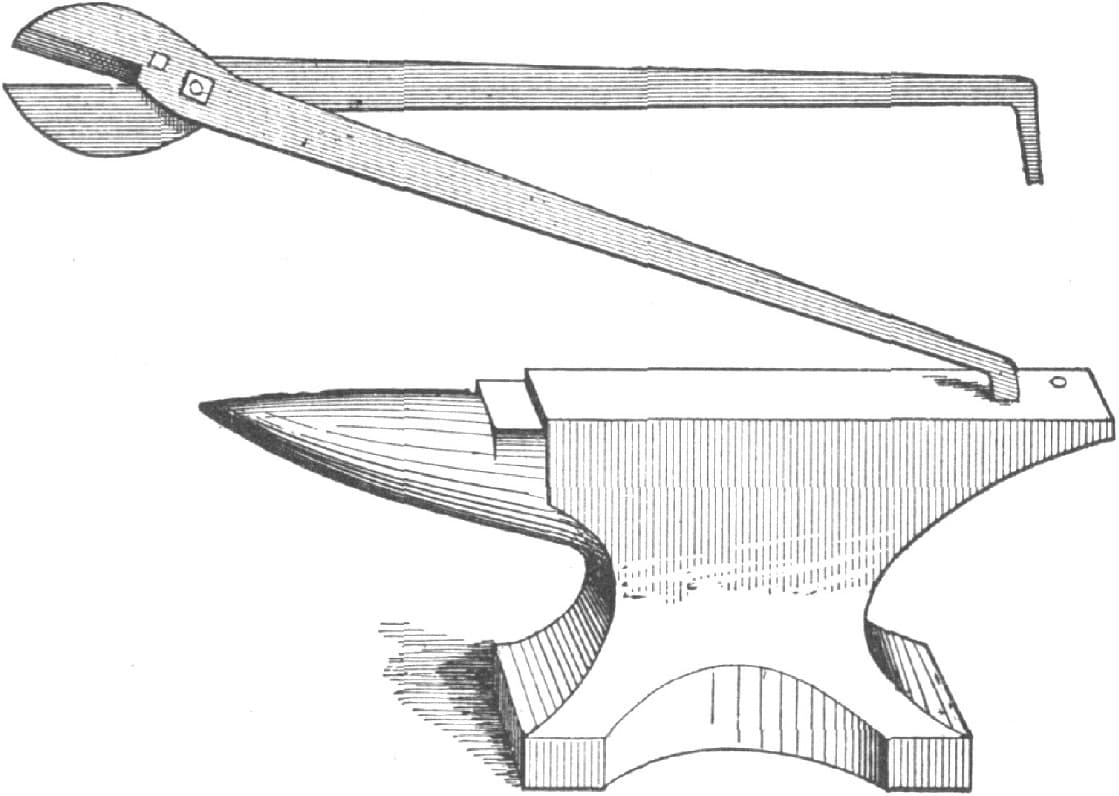

BLACKSMITHS’ SHEARS

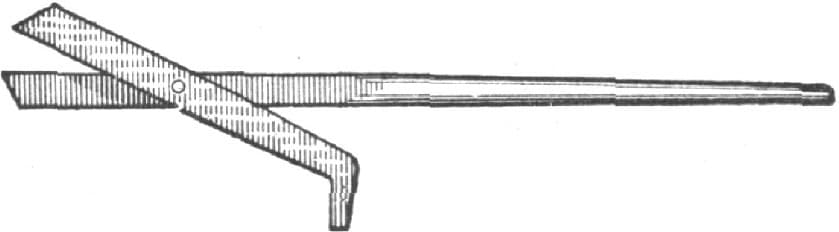

I enclose a sketch, Fig. 221, of a pair of shears to be used in the square hole of the anvil. They are very useful and cheap. Any blacksmith can make them. Use good steel and make the blades eight inches long, measuring from the rivet. Make the short blade with a crook, as shown in the illustration, to go in the anvil, and have the long blade extend back about two and a half feet to serve as a handle. With these shears I can cut quarter-inch iron with ease and cut steel when it is hot. —By A. J. T.

Fig. 221—Blacksmiths’ Shears

Shear for Cutting Round and Square Rods.

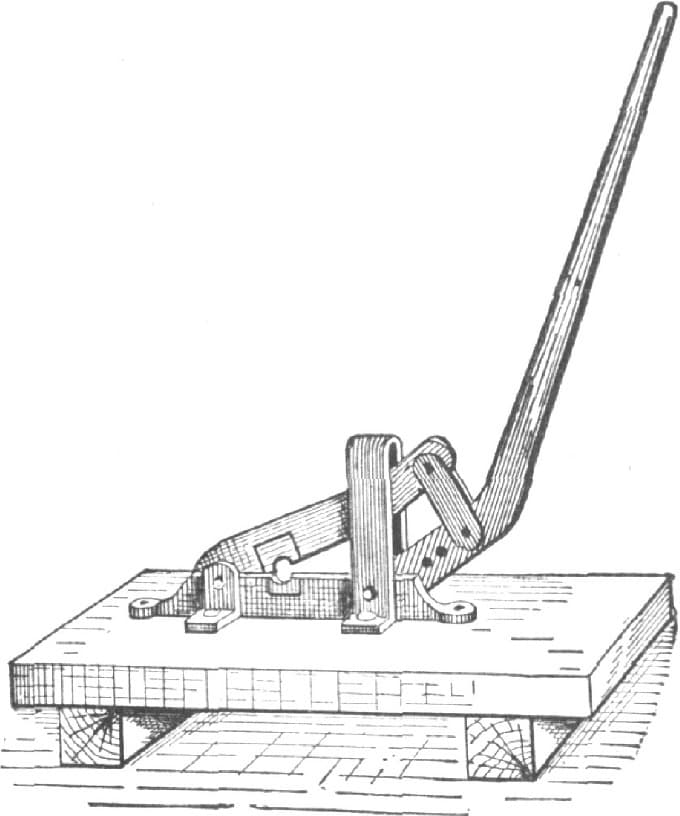

I would like to give a description of a shear for cutting round and square iron constructed by me. The inclosed sketch, Fig. 222, is an attempt to represent it. The lower member of the shear is a bar an inch thick, three inches wide and fourteen inches long, and is furnished with a steel face at that part where the cutting is done. The upper member is of the same general description, except that it is seventeen inches long. The lower blade is fastened to the bench at the back part by cleats, as shown in the drawing. A guide for the upper blade, just wide enough in the opening to allow of easy play, is made to serve a like purpose for the front part. The handle of the shear is hinged to the lower blade, and is connected also with the upper one by the link shown in the sketch. The handle is five feet long and is one by three inches in size down to a taper. Three holes are provided in it for connecting the link attached to the upper blade, thus opening the shear more or less as may be required. With this shear I can cut round or square iron up to seven-eighths in size.—By SOUTHERN BLACKSMITH.

Fig. 222—Shear for Cutting Round and Square Rods

Cheap Shears for Blacksmiths’ Use.

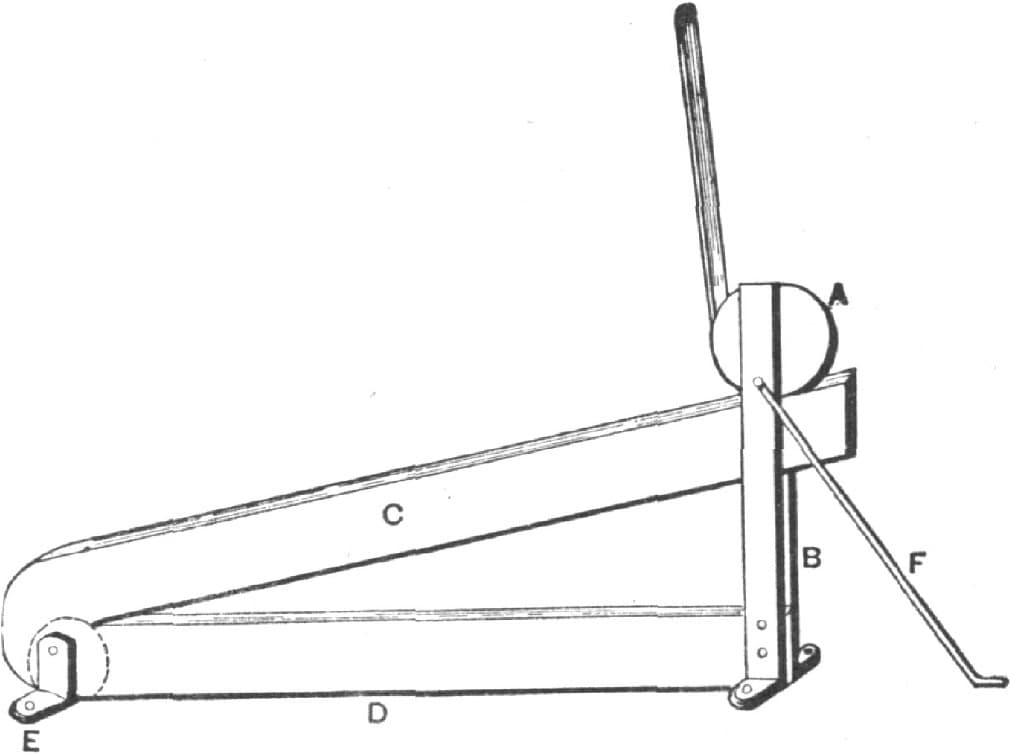

I inclose a sketch, Fig. 223, of a cheap shears for smiths’ use, and submit the following directions for making: The under jaw, D, should be 10 inches long, 3 inches wide and 1 inch thick. The upper jaw must be 13 inches long, but otherwise the same as the lower jaw, except where it couples with the latter. Then it must be forged by the dotted lines. The coupling at E is made with a 7/8-inch cast-steel bolt, which takes a brace on each side of the shears, this brace taking one half-inch bolt at the foot through the bench. The braces at the other end take two bolts through the bench. That next to the lower jaw takes two half-inch rivets through the same and a 3/4-inch cast-steel bolt at the top through the the cam. The upper jaw is brought up by two strips of sole leather connected to the cam A by two bolts. The two braces, F (only one of which is shown in the cut), are 1/2-inch round and take a 3/8 bolt at the foot. The material for jaws should be 5/8 × 3 inch Swede’s iron with the same amount of cast steel or English blister laid on the cutting side, and when finished should have just bevel enough to give a good edge. E and B are made of Swede’s iron 1/2 × 3 inches. The cam, A, is the same thickness as the jaw and finished with 1 inch round for a lever 3 feet long. The jaws should be brought to a low straw color in tempering. The cam must be finished smooth and the bearings kept well oiled.

Fig. 223—Cheap Shears for Blacksmiths

Then you have a pair of shears at a nominal cost that will last a lifetime and work better than most of the shears in the market. It is a good plan to use a guard with the shears; let it bolt on to the bench, rising 3/8 of an inch above the edge of the lower pair, and then run parallel with the jaw to the other end, where it is secured by another bolt. The brace, B, which rivets to lower jaw, must have an offset of one inch to come flush with the inside of the jaw.—By J. M. W.

Blacksmiths’ Shears.

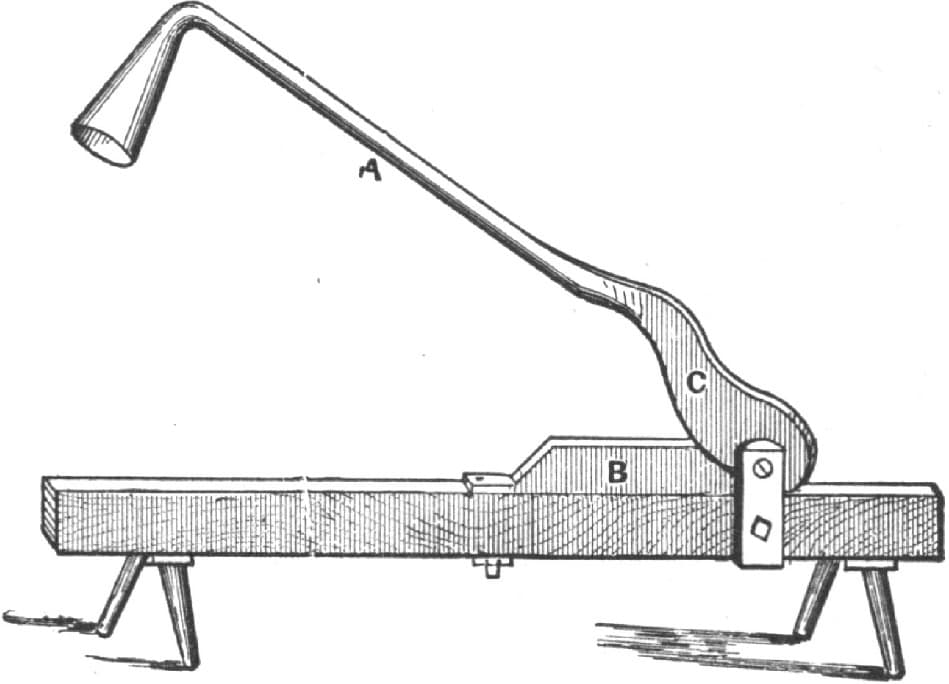

I send a sketch, Fig. 224, of shears made by myself. They are cheap and I have found them very convenient. The engraving from my design requires no explanation. A glance at it will be sufficient for any smith who understands his trade. I will, however, give some of the dimensions. A is 13/4 round, B 9 × 3/4 and C 61/2 × 3/4 inch. The main point in making is to get the edges to come together as in the common shears.—By J. J.

Fig. 224—Blacksmith’s Shears

Shears for the Anvil.

I send you a sketch, Fig. 225, of a very handy tool, a pair of shears for the anvil. Any blacksmith that understands his trade can make them. They are good for trimming cultivator shovels when they have just been painted and they will take the place of a helper on many jobs where striking is needed. The cutting jaws are 4 inches long, 3 inches wide and 3/4 inch thick, and bevel to the edge and to the back. One jaw has a square hole for a square shoulder bolt. The handles are two feet long. I use them on hot iron or steel and they cut sheet iron cold.—By G. W. P.

Fig. 225—Shears for the Anvil