CHAPTER I

BLACKSMITHS’ TOOLS

THEIR PRESERVATION.

In continuing the construction of blacksmith’s tools from Vol. II. some general directions for their care and preservation will not be out of order, as even the best tools soon become useless if they are not well cared for. The following valuable hints on their preservation will be appreciated by every mechanic who has a desire to make his tools last as long as possible, and who wishes to have them always in good condition:

WOODEN PARTS.—The wooden parts of tools, such as stocks of planes and the handles of chisels, are often made to have a nice appearance by French polishing, but this adds nothing to their durability. A much better plan is to let them soak in linseed oil for a week and rub them with a cloth for a few minutes every day for a week or two. This produces a beautiful surface and exerts a solidifying and preservative action on the wood.

IRON PARTS.—Rust Preventatives—1. Caoutchouc oil is said to have proved efficient in preventing rust, and it has been used by the German army. It only requires to be spread with a piece of flannel in a very thin layer over the metallic surface and allowed to dry up. Such a coating will afford security against all atmospheric influences and will not show any cracks under the microscope after a year’s standing. To remove it, the article has simply to be treated with caoutchouc oil again and washed after twelve to twenty-four hours.

2. A solution of India rubber in benzine has been used for years as a coating for steel, iron and lead, and has been found a simple means of keeping them from oxidizing. It can be easily applied with a brush and as easily rubbed off. It should be made about the consistency of cream.

3. All steel articles can be perfectly preserved from rust by putting a lump of freshly burnt lime in the drawer or case in which they are kept. If the things are to be moved, as a gun in its case, for instance, put the lime in a muslin bag. This is especially valuable for specimens of iron when fractured, for in a moderately dry place the lime will not need renewing for many years, as it is capable of absorbing a large amount of moisture. Articles in use should be placed in a box nearly filled with thoroughly slaked lime. Before using them rub well with a woolen rag.

4. The following mixture forms an excellent brown coating for preserving iron and steel from rust: Dissolve two parts crystallized iron of chloride, two of antimony of chloride and one of tannin in four of water, and apply with sponge or rag and let dry. Then another coat of paint is applied, and again another, if necessary, until the color becomes as dark as desired. When dry it is washed with water, allowed to dry again and the surface polished with boiled linseed oil. The antimony chloride must be as nearly neutral as possible.

5. To keep tools from rusting, take one-half ounce camphor, dissolve in one pound melted lard; take off the scum and mix in as much fine black lead (graphite) as will give it an iron color. Clean the tools and smear with this mixture. After twenty-four hours rub clean with a soft linen cloth. The tools will keep clean for months under ordinary circumstances.

6. Put one quart freshly slaked lime, one-half pound washing soda and one-half pound soft soap in a bucket, and sufficient water to cover the articles; put in the tools as soon as possible after use, and wipe them next morning, or let them remain until wanted.

7. Soft soap, with half its weight in pearlash, one ounce of mixture in one gallon of boiling water, is in everyday use in most engineers’ shops in the drip-cans used for turning long articles bright in wrought-iron and steel. The work, though constantly moist, does not rust, and bright nuts are immersed in it for days, till wanted, and retain their polish.

8. Melt slowly together six or eight ounces of lard to one ounce of resin, stirring until cool; when it is semi-fluid it is ready for use. If too thick it may be further let down by coal oil or benzine. Rubbed on bright surfaces ever so thinly, it preserves the polish effectually and may readily be rubbed off.

9. To protect metal from oxidation, polished iron or steel, for instance, it is requisite to exclude air and moisture from the actual metallic surface; therefore, polished tools are usually kept in wrappings of oil-cloth and brown paper, and thus protected they will preserve a spotless face for an unlimited time. When these metals come to be of necessity exposed, in being converted to use, it is necessary to protect them by means of some permanent dressing, and boiled linseed oil, which forms a lasting covering as it dries on, is one of the best preservatives, if not the best. But in order to give it body, it should be thickened by the addition of some pigment, and the very best, because the most congenial of pigments, is the ground oxide of the same metal, or, in plain words, rusted iron reduced to an impalpable powder, for the dressing of iron and steel, which thus forms the pigment of oxide paint.

10. Slake a piece of quicklime with just enough water to crumble in a covered pot, and while hot add tallow to it, and work into a paste, and use this to cover over bright work; it can be easily wiped off.

11. Olmstead’s varnish is made by melting two ounces of resin in one pound of fresh, sweet lard, melting the resin first and then adding the lard and mixing thoroughly. This is applied to the metal, which should be warm, if possible, and perfectly clean; it is afterward rubbed off. This has been well proved and tested for many years and is particularly well suited for Danish and Russian oil surfaces, which a slight rust is apt to injure very seriously.

Rust Removers.—1. Cover the metal with sweet oil, well rubbed in, and allow to stand for forty-eight hours; smear with oil applied freely with a feather or with a piece of cotton wool after rubbing the steel. Then rub with unslaked lime reduced to as fine a powder as possible.

2. Immerse the article to be cleaned for a few minutes, until all the dirt and rust are taken off, in a strong solution of potassium cyanide, say about one-half ounce in a wineglass of water; take it out and clean it with a toothbrush with a paste composed of potassium cyanide, castile soap, whiting and water mixed into a paste of about the consistency of thick cream.

Bench Tools.

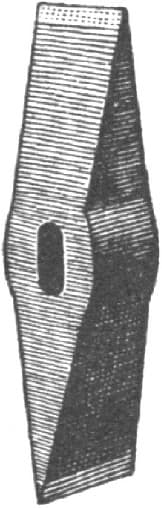

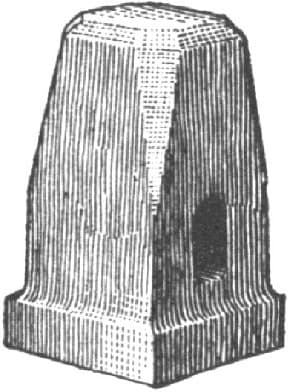

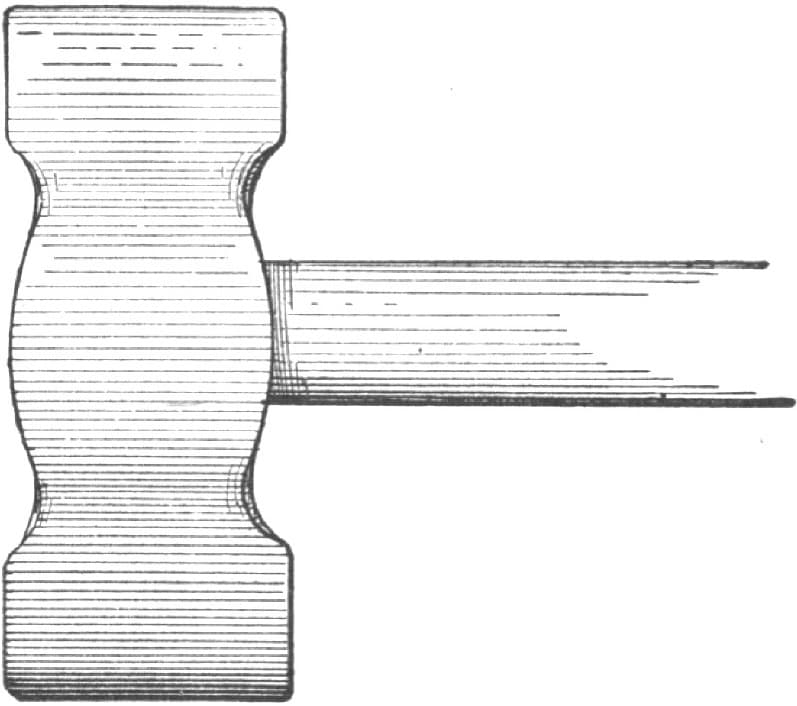

The tool shown in Fig. 1 is very convenient where there is much bundle iron to open, as it is made heavy enough so that any ordinary band can be easily cut with it at one blow. It has an eye large enough to admit a small sledge handle, and the handle should be made of good hickory with some surplus stock near the eye, as it is liable to get many bruises from careless handling and mis-blows. It should have a little less blunt edge than a cold chisel and be tempered a “pigeon-blue,” if it is made of good steel; but if it is made of the fancy brands the temper must be a matter of experiment.

Fig. 1—Hatchet for Opening Bundle Iron. Made of 15/8 square Steel

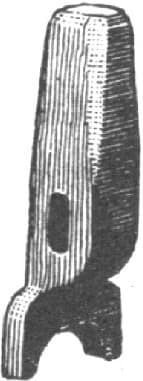

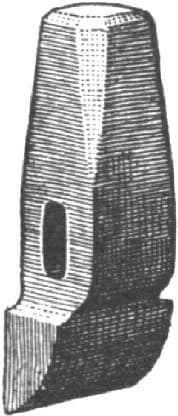

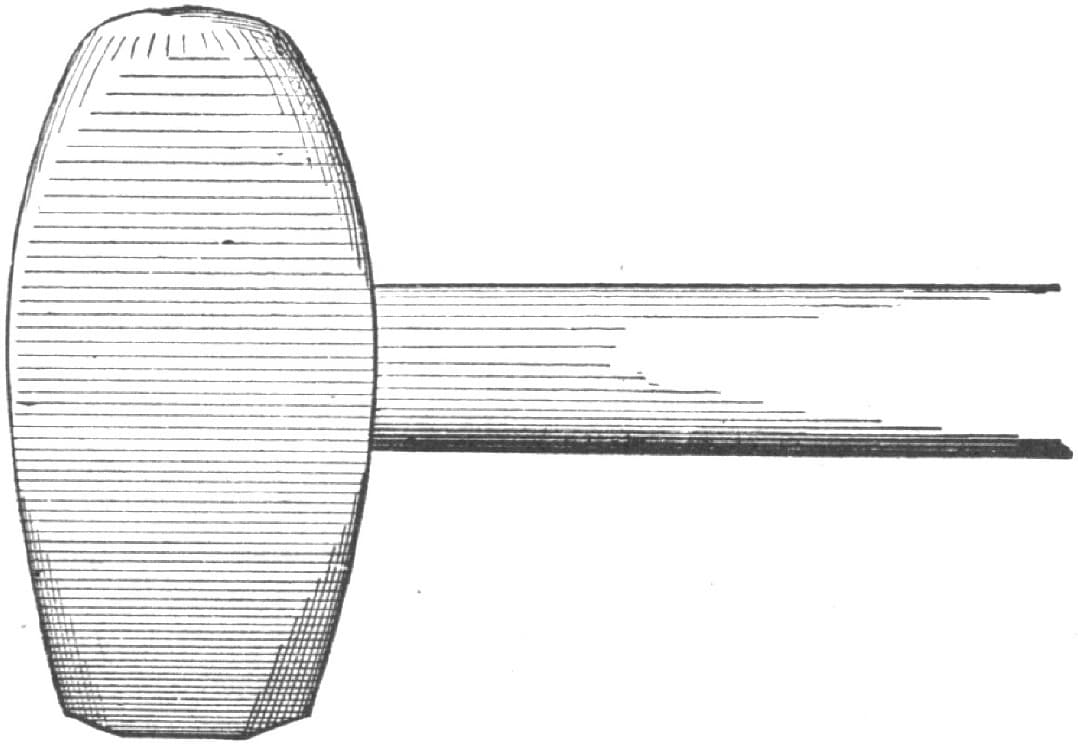

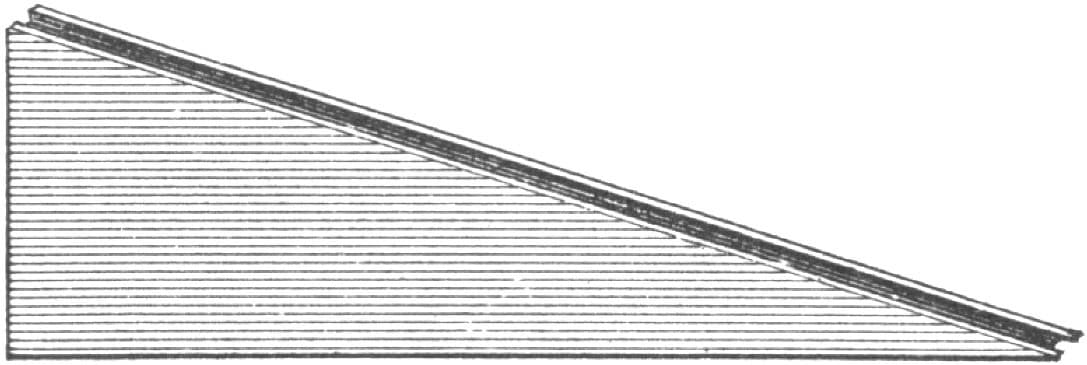

Fig. 2—Collaring Tool for Shouldering Down Round Iron. Made of 11/4 square Steel

For shouldering down round iron or steel to form a collar or neck, there is no tool that is any better than that shown in Fig. 2. The concave should be of a size to fit the circumference of the bar to be worked or larger. The cut does not show the cutting part quite plainly; the edge all the way around the hollow should be flat on the inside and rounded out on the other side the same in section as Fig. 8.

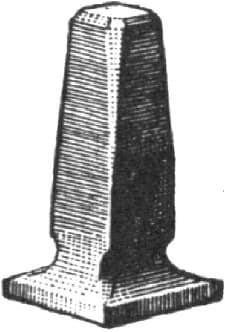

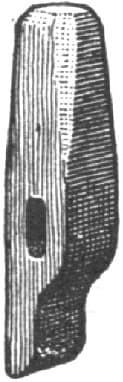

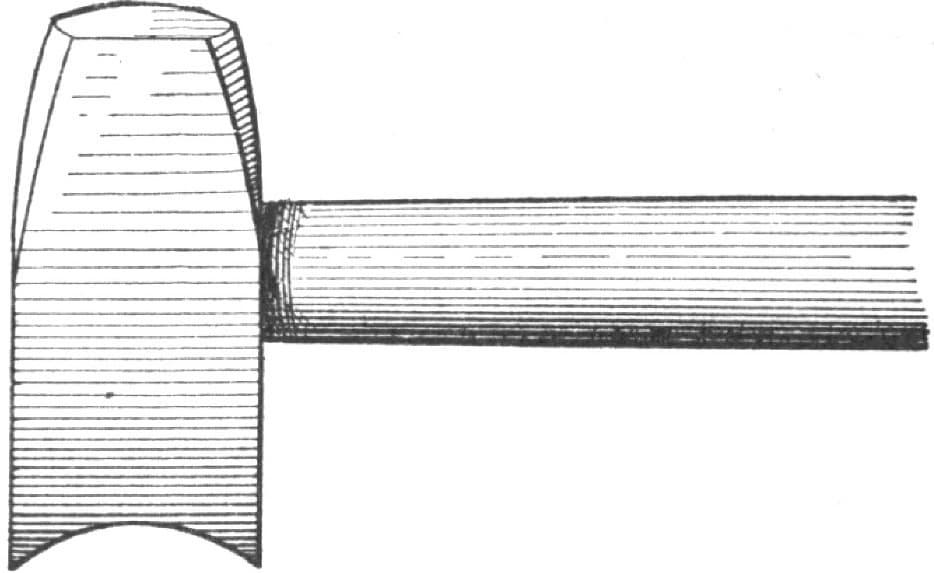

Fig. 3—Light Flatter for Finishing Flat Iron. Made of 13/4 square Steel. Face 21/2 inches square

Fig. 3 is simply a good handy size for a light flatter. It is about 51/2 inches high. There is a great advantage in having a flatter light, not only because it is easier handled, but because it is more efficient. When a flatter is too heavy in proportion to the weight of the sledge it absorbs more force than it gives down. It kicks. It spends its elasticity in reacting against the sledge, instead of letting the blow through it and delivering it to the work on the other side. It is all nonsense to suppose that big flatters are best on big work. It is not the work that governs the size of hand tools, it is the power of the men who are to deliver the blows.

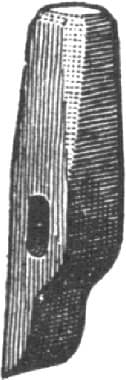

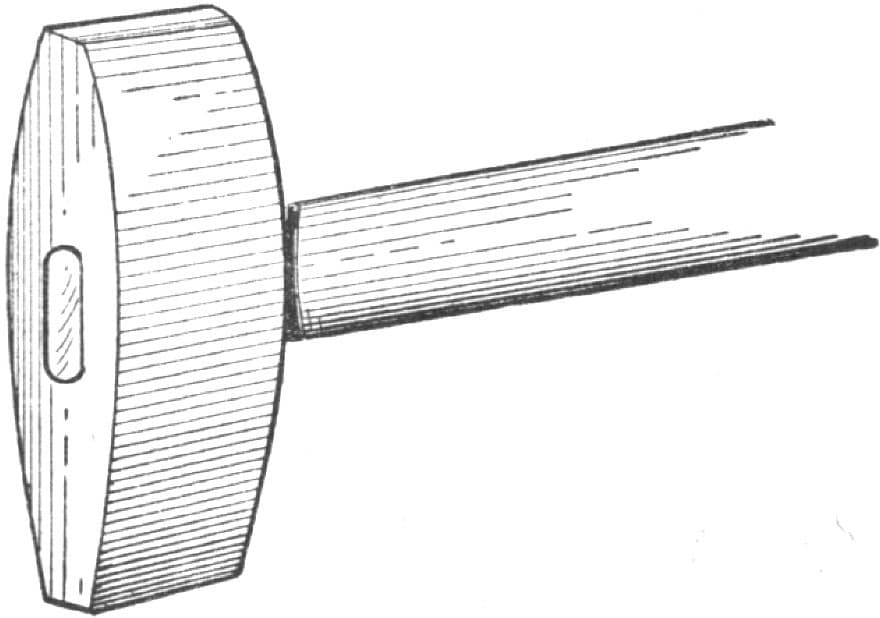

Fig. 4—Round-cornered Set Hammer. Made of 13/4 square Steel

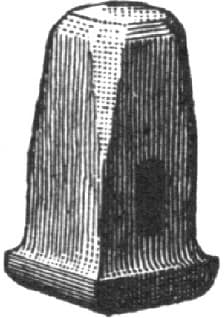

Fig. 5—Heavy Flatter for Straightening Cold Iron. Made of 2-inch square Steel

Fig. 4 is a tool that does not feel as good in the hand, and is not quite as nice to handle. It some way does not hang as well as a flatter, but it is a tool that should be used in the formation of all inside corners, for it is a deadly enemy to cold shuts and broken fibers, which are the vital seeds of death in any work of iron in which they find lodgment.

Fig. 6—Large Siding-Down Tool. Made of 11/2 square Steel

The heavy flatter, Fig. 5, for straightening cold iron, is made very strong, and a sledge must be used with it proportionate to its weight. There is not such particular need of activity, spring, and haste in getting a blow on cold iron as there is on hot, and blows that count in bending or straightening, are slow and solid. Steel rails are straightened under a press. If this flatter is not made very strong it will soon crystallize and break in the weakest place across the eye.

Fig. 7—Small Siding-Down Fuller. Made of 11/4 square Steel

Fig. 8—Small Siding-Down Chisel. Made of 11/4 square Steel

The tools, Figs. 6, 7, 8, are for the purpose of siding-down work or making offsets, leaving good shoulders standing up, without having to use the backing hammer. There is a tendency to make tools heavier than is necessary simply to perform the office in blacksmithing that the jointer plane does in carpentering. The carpenter jacks off the rough stock and then smooths up with his “jointer.” In dressing tools a heavy large-faced hammer is used by some first-class tool dressers. I have known them to call it the “jineter.” The siding-down tool, Fig. 8, need not be wider than a man can sink an eighth of an inch into hot iron or steel at a blow. When the impression is deep enough, or if, in crossing wide iron, it gets crooked sidewise, the wider bitted one shown in Fig. 6 can be used to make the impression straight and uniform, and afterwards the siding-down fuller, Fig. 7, may be used. On a large amount of work these tools suffice; but where there is much wide iron to work it will pay to have a wide fuller, the width, say two and one-half inches, of Fig. 6.

Blacksmith Tongs.

The blacksmith who will do his work well and quickly, whether on carriage work or the ordinary work of the country shop, must be well supplied with tongs, and they well made. It is no uncommon thing to see a man working at the forge depending upon two or three tongs for holding all kinds of work. If the jaw opens too wide it is heated and a blow from the hammer closes it; if too narrow the same operation is gone through to open it; this makeshift business costs dear, and brands the workman as a botch.

A complete list of tongs for one man might not be a complete list for another, as some workmen are particular as regards specialties, but an assortment that comprises those that should be on every bench consists of two pairs of tongs for 1/8-inch iron, two pairs for 1/4-inch iron, two pairs for 3/8-inch iron, two pairs for 1/2-inch iron, and one pair for each succeeding one-eighth of an inch up to 11/4 inches and above that a pair for each succeeding quarter inch up to the limit of size.

Blacksmiths, as a rule, prefer to make their own tongs. For these they should use Lowmoor or Burden’s “best.” Drill all holes, instead of punching, and be careful to see that the face of the jaws are parallel when closed to the required size; jagging or otherwise roughing the face of the jaw is an unnecessary operation, for if the tongs work easily and true, as they should, they will hold the iron without extra pressure. If the jaws wobble or twist the fault is at the joint and should be corrected. The blacksmith who stands all day at the forge working with poor tongs will find, when night comes, the hand that held the tongs is much more wearied than the one that held the hammer.

How to Make a Pair of Common Tongs.

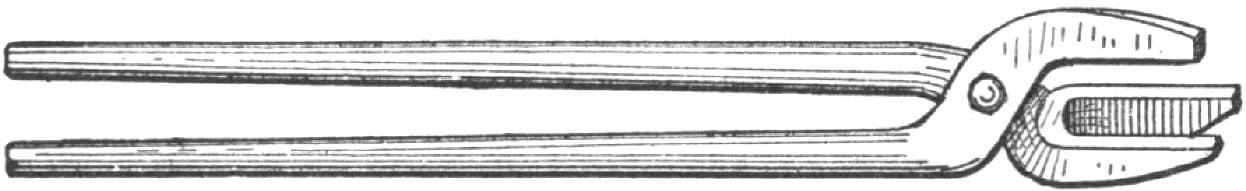

I will describe my method of making a pair of common tongs, which is so simple that any blacksmith can follow it. I take a piece of 1/2 × 11/4 inch iron, 14 inches long, and draw down the ends as shown in Fig. 9. Fig. 10 shows a side view. Then split as shown in Fig. 11 and draw the handles to the proper shape. Punch the holes, rivet, and the tongs are completed and can be shaped to suit your own notion. —By J. M. W.

How to Make a Pair of Common Tongs. Fig. 9—Shape to which “J. M. W.” would Draw the Iron

Tools for Farrier Work.

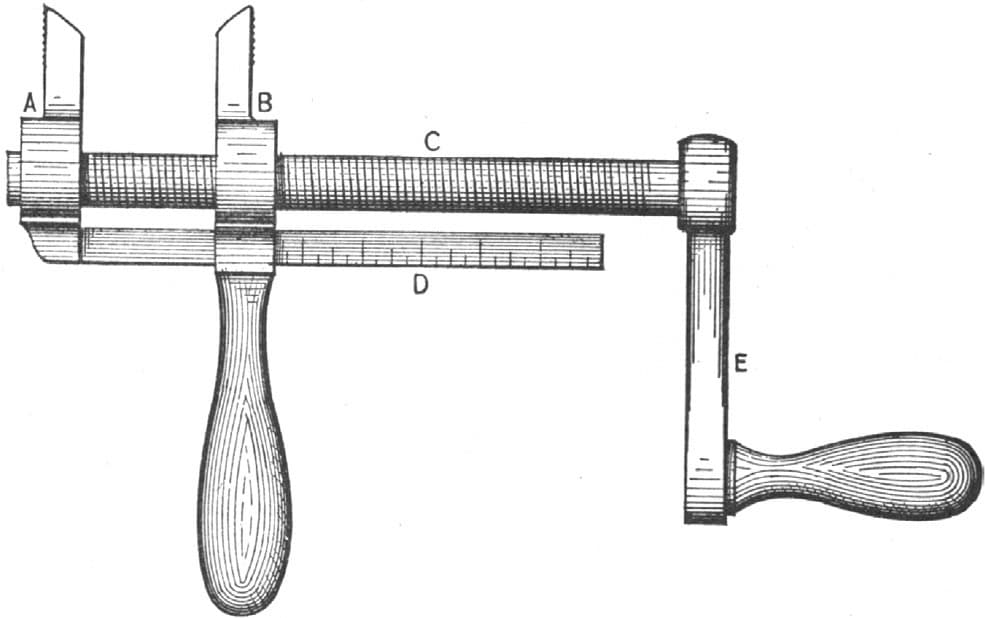

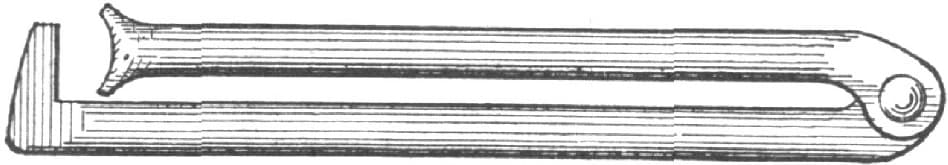

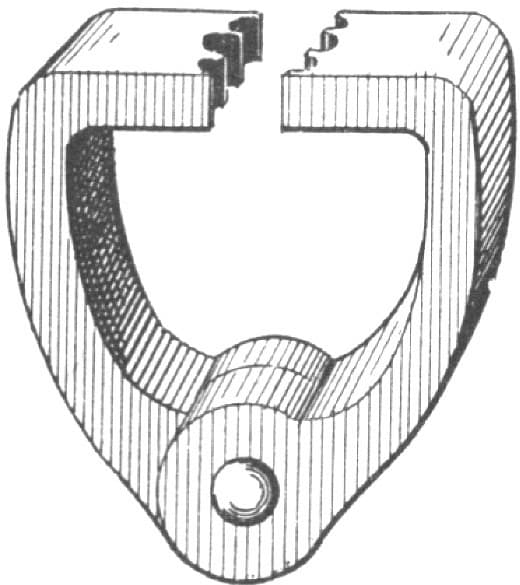

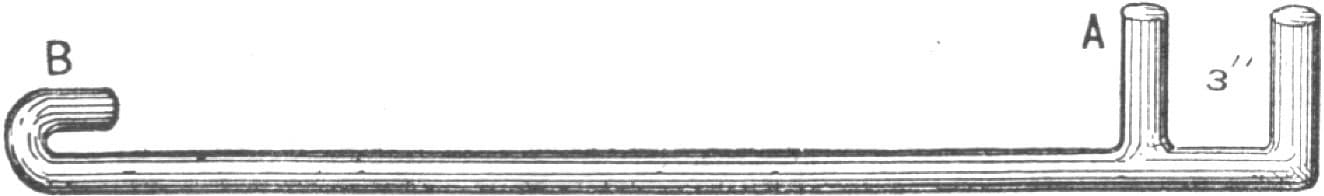

Fig. 12 shows a shoe-spreader. To make it take 3/4 or 7/8-inch square Norway iron, shoulder and turn down as shown at A and B. Fig. 13 shows a side view of B of Fig. 12. For C use three-fourths rod with thread up to the jaw A and riveted through it. File notches in points so that they will not slip. This tool is very useful and can be used to spread a shoe that has been on two or three weeks, or when only one side is nailed. D, of Fig. 12, is marked in inches, so that one can tell the exact distance the shoe has been spread.

Fig. 10—Side View of Fig. 9

Fig. 11—How the Iron is Split

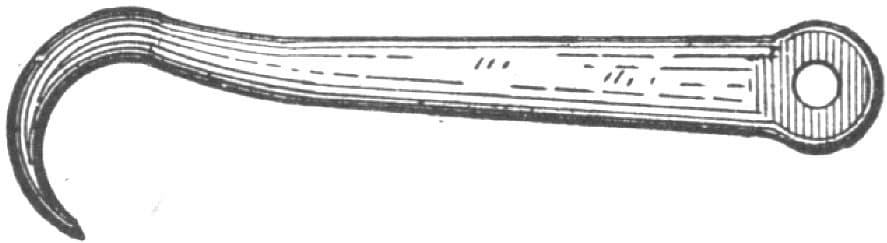

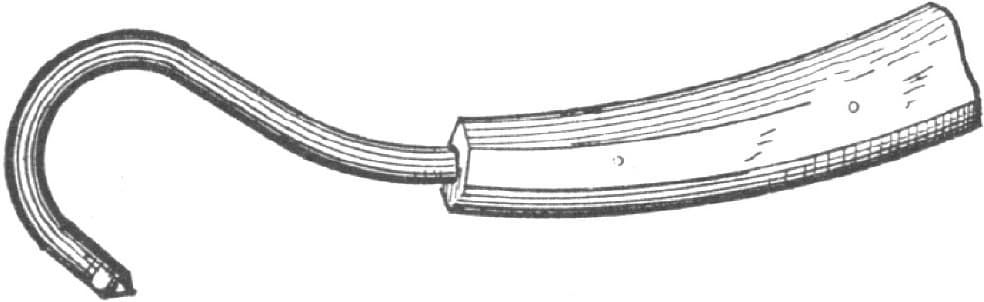

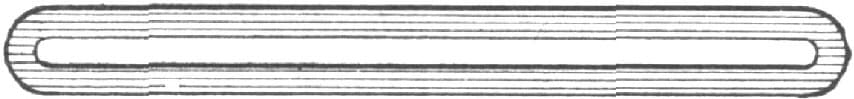

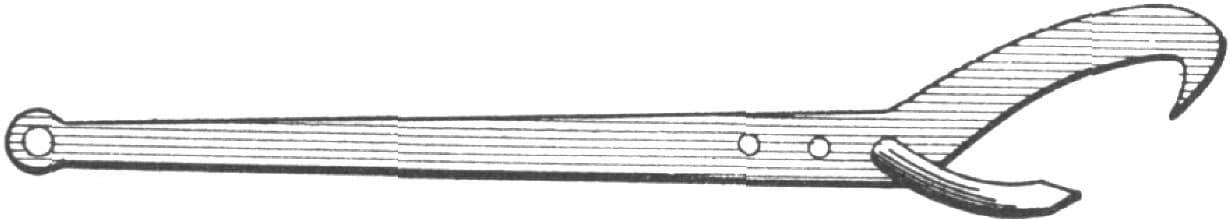

Fig. 14 shows a farrier’s pick for removing dirt and gravel. It is made of 1/2-inch steel and has a hole in the end that it may be hung on box.

Fig. 12—Shoe Spreader Complete

Fig. 15 is a farrier’s corn-cutting tool. It is made of 1/4-inch round steel and has the point ground to a sharp diamond tip. It is worth its weight in gold to any horseshoer. The handle is that of a farrier’s broken knife.

Fig. 13—Side View of B, Fig. 12

As every blacksmith is acquainted with the clinch block it does not need illustrating. I have mine made rounded to fit the shoe and with a groove to fit outside of the crease in the shoe, and runs up the side of the shoe, the idea being to hold nails that are sunk too deep for corn block.

Fig. 14—Farrier’s Pick

Fig. 15—Farrier’s Corn-Cutting Tool

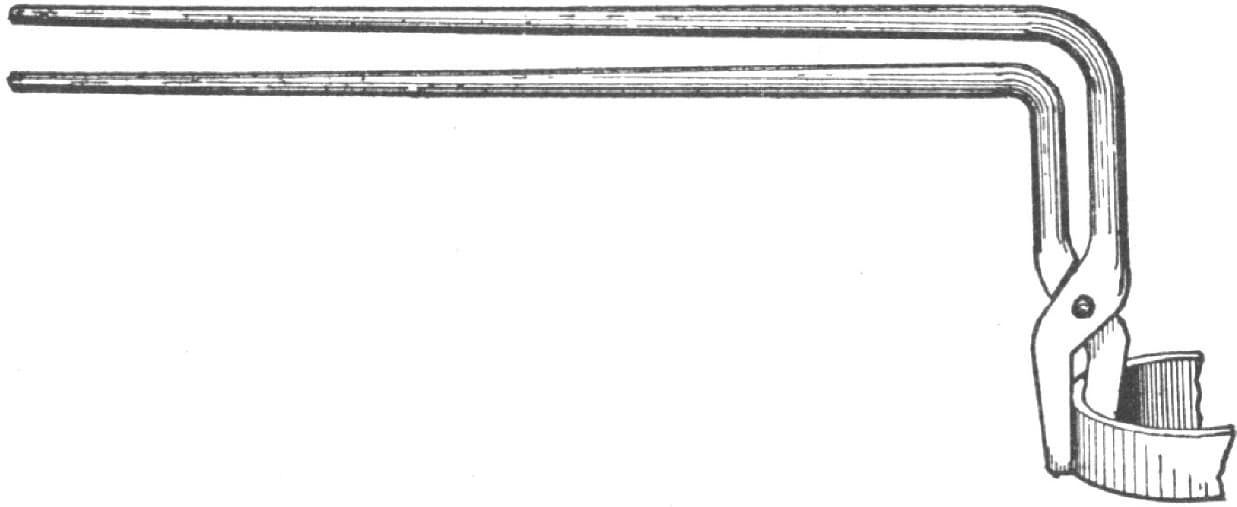

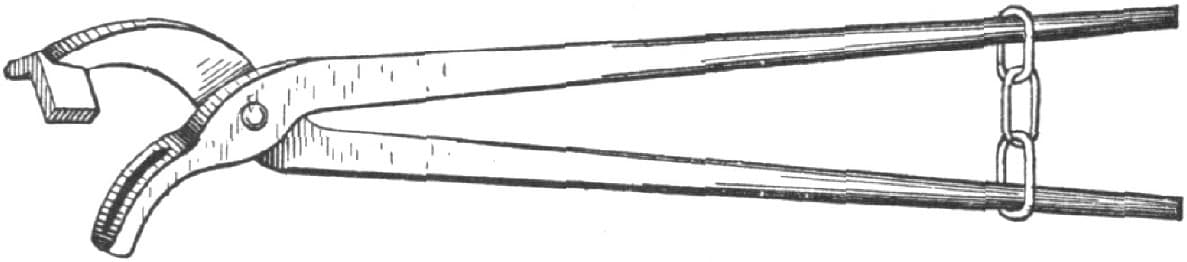

Fig. 16 shows a pair of fire-tongs made like the ordinary fire-tongs but having the handles bent four or five inches above the jaws. These tongs are to be used in cases where it is desirable to keep the hands away from the fire. Especially are they handy to use in handling wagon tires.

Fig. 16—Handy Tongs for Handling Wagon Tires

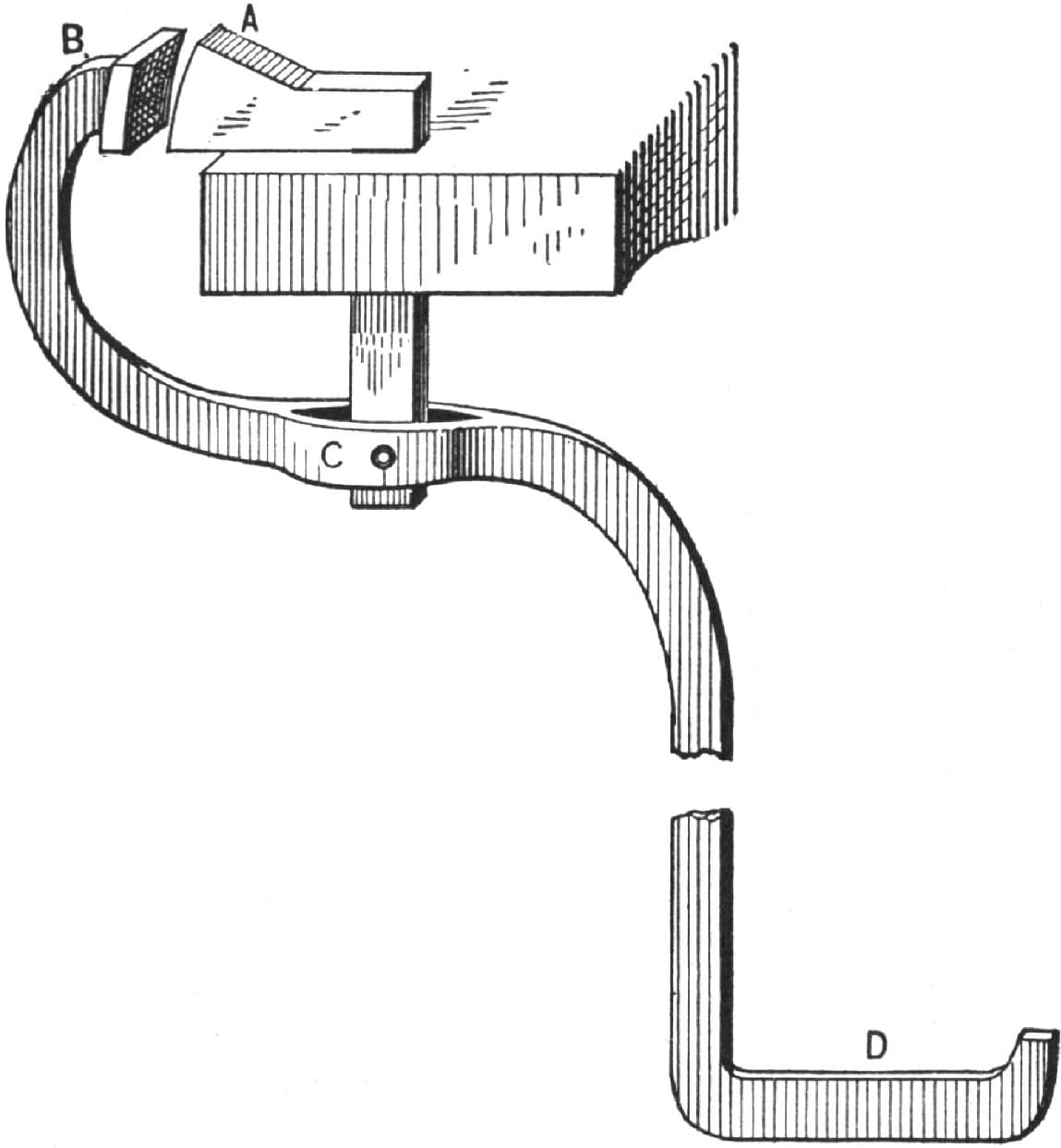

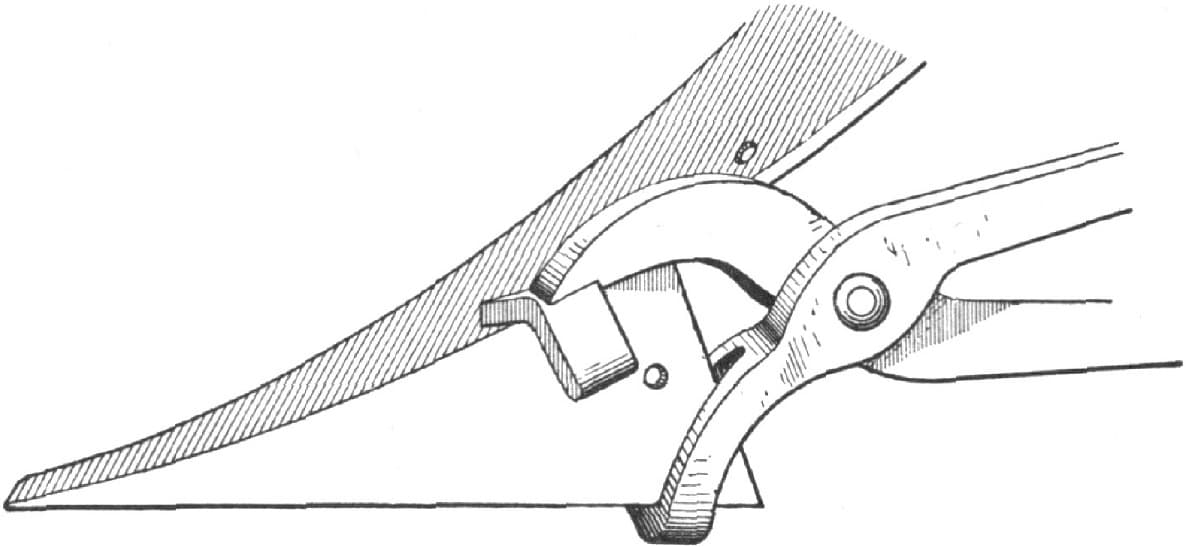

Fig. 17 shows tool used in sharpening toe calks. The part A is made of tool steel, and is swaged same as an ordinary bottom swage, raised at A, and slightly rounded, so that the toe of the shoe will stand out. The part B, C, D is made of one by one-fourth inch iron, and to the shape shown in Fig. 17. It should be long enough so that the smith can keep his heel on the floor and place his toe on D. No weights are necessary to raise the jaw B. This tool has the merit of simple construction. Of course it is intended for use on end of the anvil.

Fig. 17—Tool used in Sharpening Toe Calks

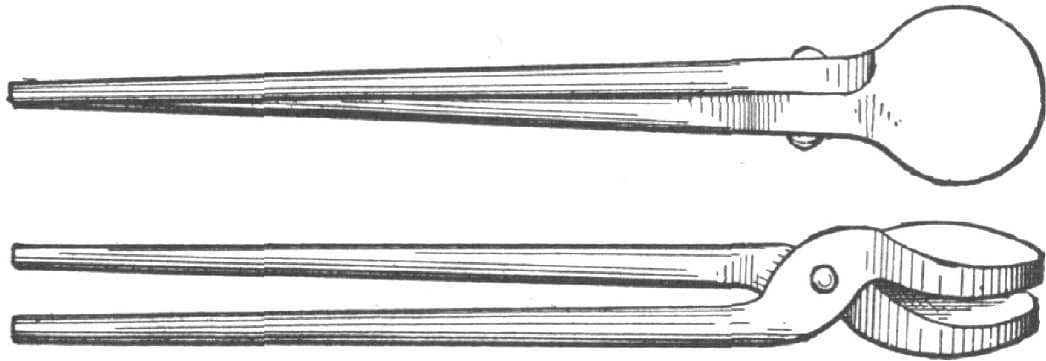

Fig. 18 shows a pair of tongs that come very handy for holding horseshoes. These are so well known as to need no explanation.

Fig. 18—Tongs for Holding Horseshoes

Fig. 19 shows a handy yoke puller. It is made of 3/8-inch round iron and hinged and riveted. One point is turned up to fit in hole of yoke, the other is rounded to fit clip, as seen in cut.

Fig. 19—Yoke Puller

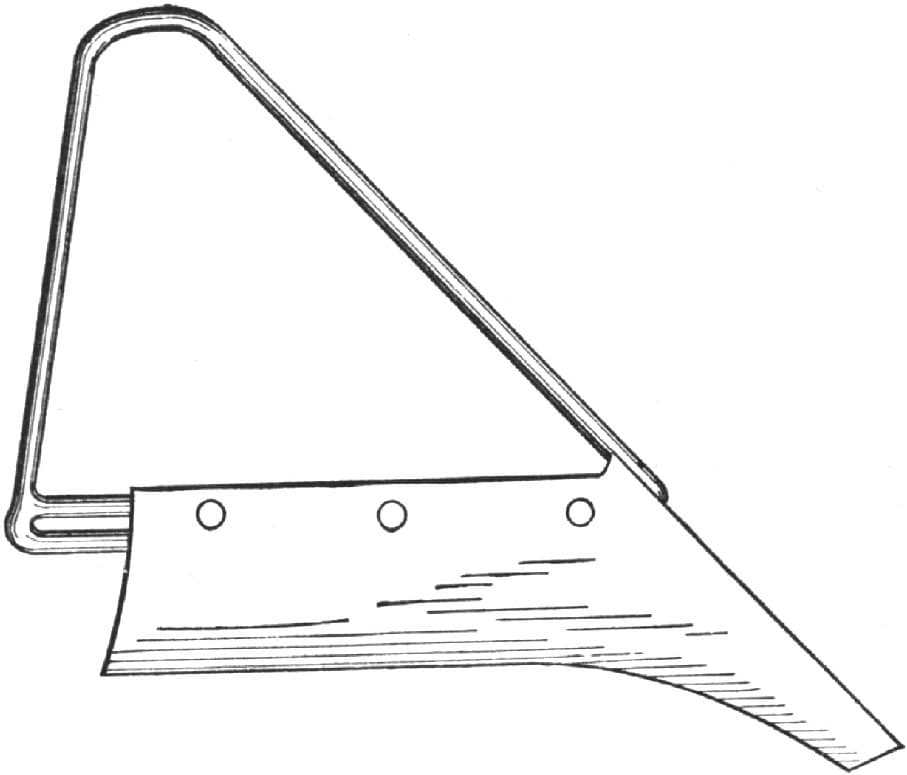

The plow clamp shown in Fig. 20 is made of 3/4 × 7/16 horseshoe bar, turned and welded. It fits the share edgewise.

Fig. 20—Plow Clamp

The space is for 5/16 bolt, and bolts to share with cam. The bolts keep the share from springing when being sharpened.

Fig. 21—Tongs for Holding Cultivator Shovels

Fig. 21 shows the tongs I use for holding cultivator shovels. The under piece has forks that pass on either side of the casting on the shovel or ball tongue. The upper jaw is similar to that of ordinary tongs, except that it is a little shorter than the forks. The handles are bent a little so that the ball tong point stands nearly straight.

Fig. 22—Horn for Welding Ferrules

Fig. 22 shows a horn for welding ferrules and small bands, also for rounding the same. It is made to fit anvil and is one and one-half inches at bottom and tapers to a point. The length of horn is eight inches.

Fig. 23—Light Riveting Hammer

Fig. 23 shows a light riveting hammer. It is made of five-eighths steel. Draw and make like ordinary hammer, except that the handle should be very light and elastic. This hammer is very handy in riveting light castings, light welds, etc.

Fig. 24—Light Plow Hammer

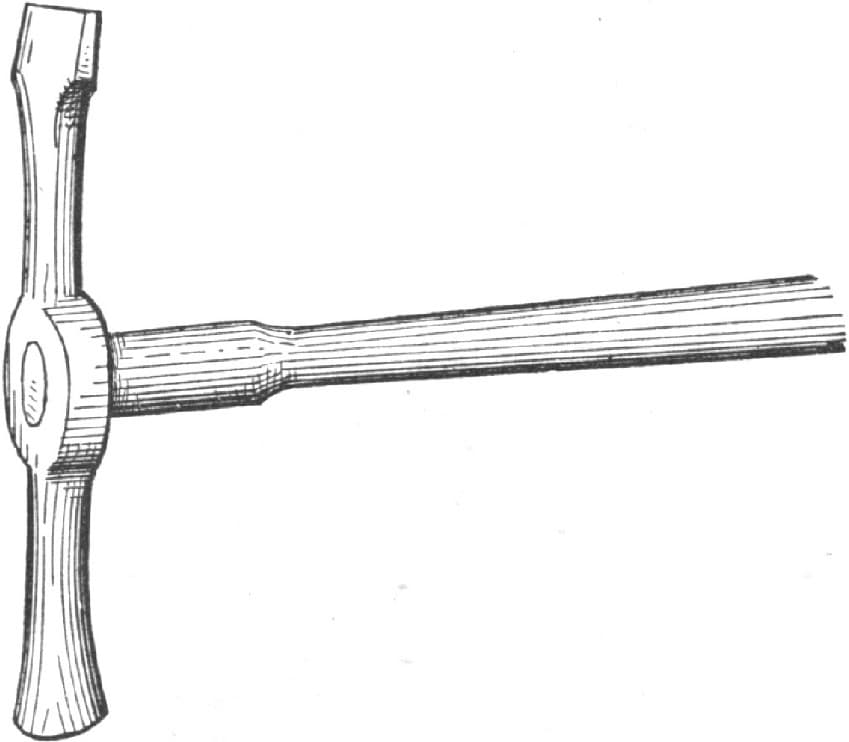

A plow hammer is seen in Fig. 24. It weighs two pounds, and has the pene set lengthwise with the handle and enables the smith to weld in throat of plow.

Fig. 25—Turning Hammer

Fig. 25 shows a turning hammer with two faces; one is made rounding for concaving shoes, it is also handy for drawing any kind of iron. It weighs from two and one-half to three pounds.

Fig. 26—Round Chisel

Fig. 26 shows a round chisel. It is made similar to the ordinary handle chisel, except that it is made round in two sizes—1 and 13/4 inches—for cutting holes in wagon plates, roller plates, etc.

Fig. 27—Hoop Set-Hammer

A hoop set-hammer is seen in Fig. 27. It is made lighter than the ordinary set-hammer and tapering on sides only. It is used for band hoops or any kind of band drawing.

Fig. 28—Singletree Clip Wedge

Fig. 28 shows a singletree clip wedge. It is made of 1/2 × 2-inch iron with a groove on bevel side, and is used to draw tight single and doubletree clips. In putting them on, slip on clip, drive in wedge tight down, and cool, drive out the wedge and the job is done.

Fig. 29—Vise Tool for Holding Short Bolts

Fig. 29 shows a vise tool for holding short bolts. It is made of 2 × 21/2-inch iron bent square, and has three grooves cut for three sizes of bolts, shouldered off, and riveted at bottom. This tool is handy in cutting threads on plow, or any short bolts, or in working nuts on same.

Fig. 30—Heavy Wrench or Bending Tool

Fig. 30 shows a heavy wrench or bending tool. This tool is so common among our smiths as to need no description.

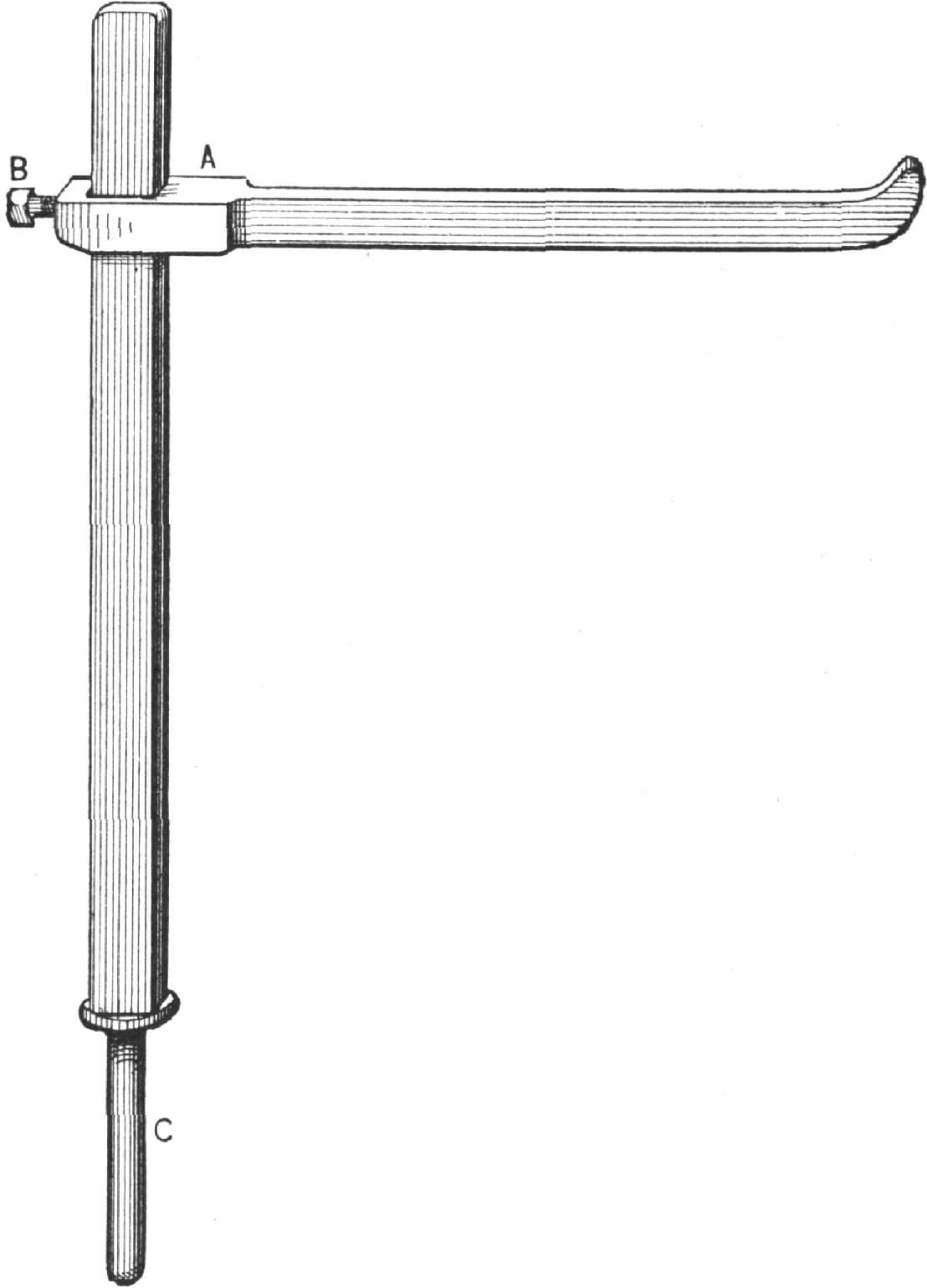

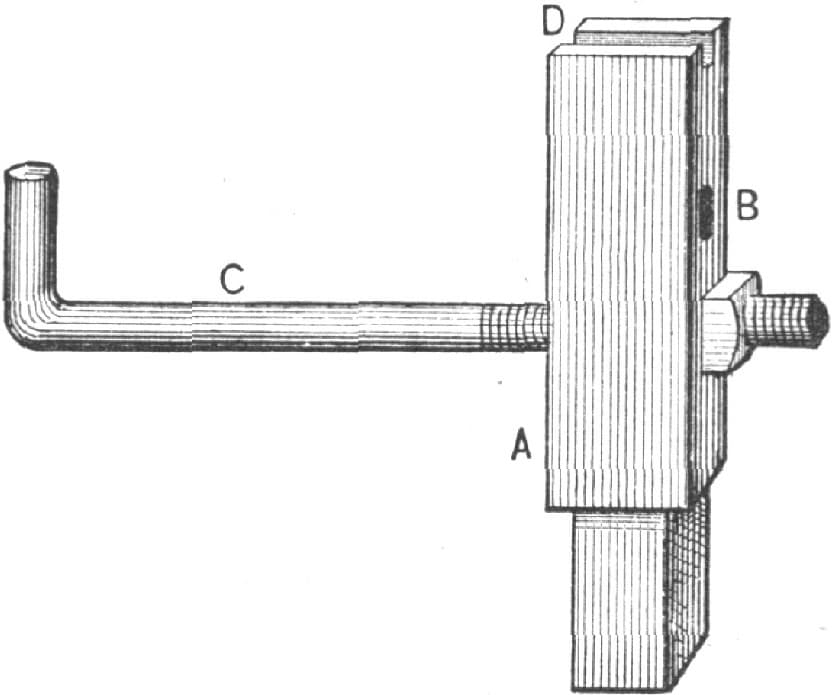

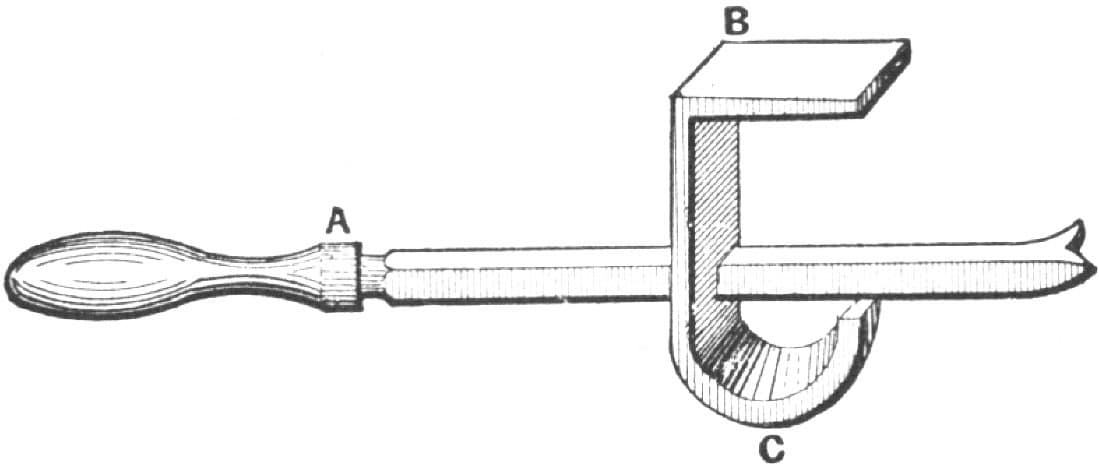

Fig. 31—Forge Crane

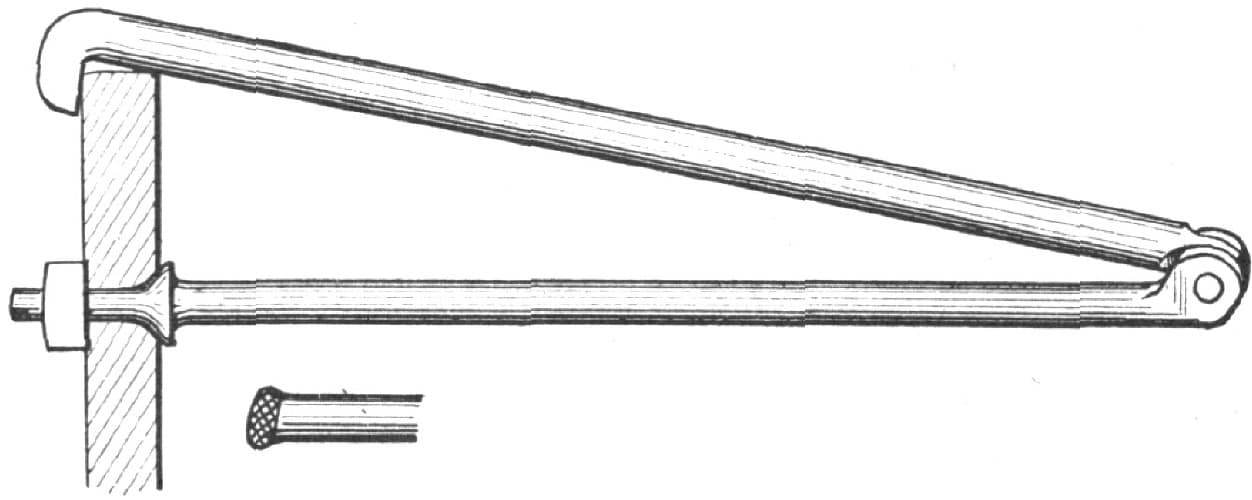

Fig. 31 shows a forge crane. The upright post is made of 11/2 × 1/2-inch iron and shouldered at C; draw around to five-eighths or three-fourths; place collar on at shoulder. Bore a hole close to the forge to receive C. The crane is made of inch square iron and should slide easily, and is held in position by the set-screw at B. The upright should extend seven or eight inches above the forge. If there is no floor in the shop then drive or set a post level with the dirt. Blacksmiths will find this to be a great labor-saving tool.

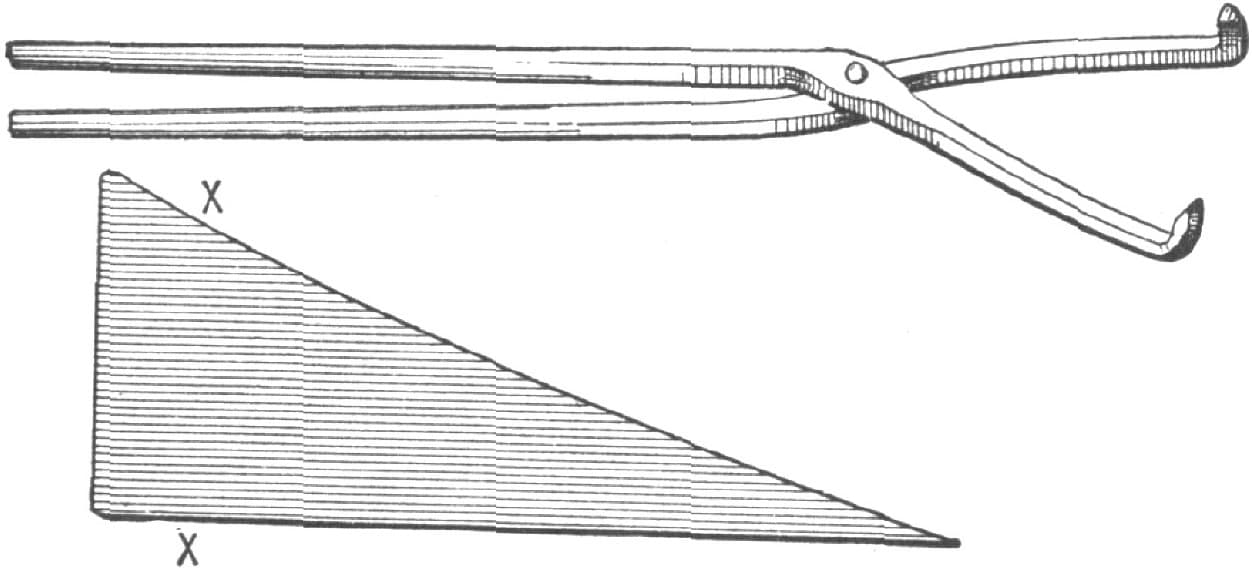

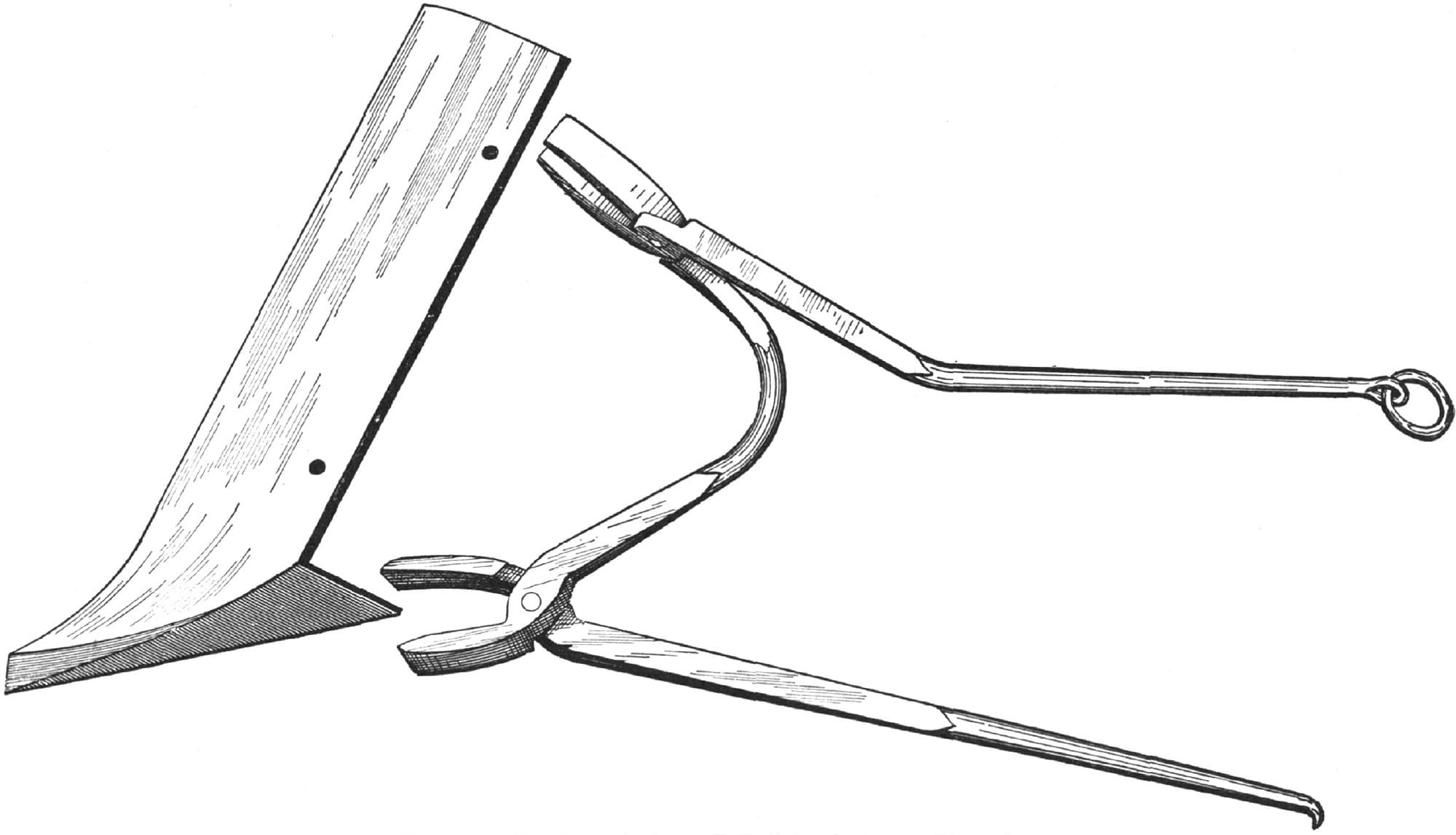

Fig. 32—Tongs for Plowshare

Fig. 32 shows a pair of handy tongs for plowshares. The jaws are made to fit top and bottom of share, being turned to fit the bevel as shown at x x of share. These tongs are used in either welding or sharpening.

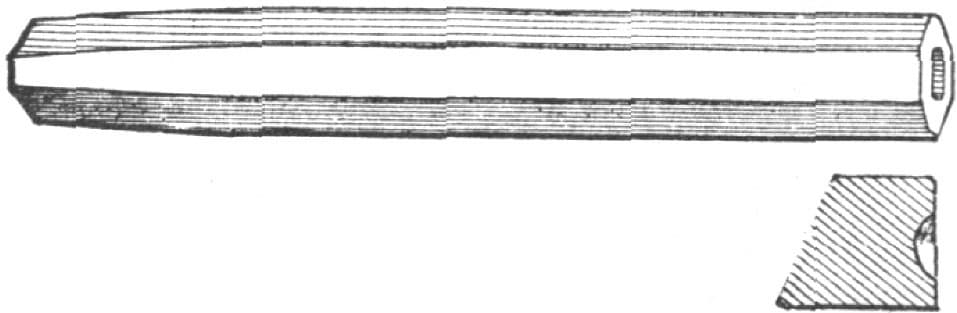

Fig. 33—Tool for Making Round Clips

Fig. 33 shows a clip for making round clips. It is made to fit the anvil and can be made in any size. C is the gauge, B the hole, and D the groove in top. Cut the iron to the right length for clip wanted, cut threads on both ends, heat and run through the hole B, gauge by C, and bring the end over to D, tap down gently until true.

Fig. 34—Tool for Rounding Rivet Heads

Fig. 34 shows a tool for rounding rivet heads. It is made of one-half inch steel shaped like a punch. Make a tool to the shape that you want the head of the rivet to be when finished. Heat the steel and place it in the vise, then drive the special tool, or rivet head, into the steel until it is sunk enough. Then dress up and temper to a light blue.—By REX.

A Tool for Holding Plow Bolts.

I will try to give a description of a handy tool for holding plow bolts.

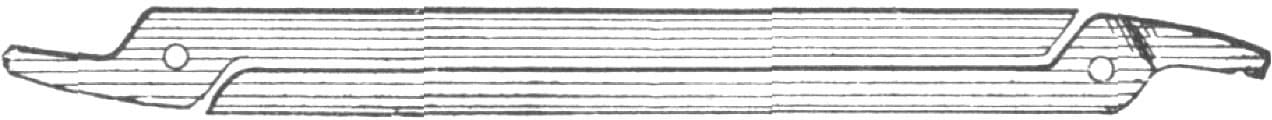

The piece A shown in Fig. 35 is made of 3/8 or 1/2-inch iron, and is about 20 inches long. It has holes in it into which the piece B can be inserted and moved forward or backward so as to catch any bolt. The piece B is made of steel with a rounded end to fit in the hole in A. The other end is made like a cold chisel in order to catch the bolt. Fig. 36 represents the tool ready for use.—By A. G. BUNSON.

A Tool for Holding Plow Bolts. Fig. 35—Showing how the two Pieces are made

Fig. 36—Showing the Tool completed

Tongs for Holding Plow Points.

I have a pair of tongs for holding plow points while sharpening or laying, that are simple, easily made, and I like them far better than any other tongs for the purpose that I ever saw. I forged them from a one and a quarter inch square bar just like ordinary straight jawed tongs. The edges are about two inches long (not longer), quite heavy, with one-half inch handles. After they were finished I heated them and then caught them edgewise in the vise and bent them, just at the rivet, to an angle of nearly forty-five degrees, and I find they never slip or work off, but answer every purpose.—By EARLES J. TURNER.

A Tool for Holding Plow Bolts.

A handy little tool which I use to prevent plow bolts from turning when the wrench is on the nut is shown in Fig. 37. The tool is one that will be appreciated by every smith who does plow work. It is made of 5/8-inch round iron, but having steel at one end which is cross-cut as shown in the illustration.—By H. H. K.

Fig. 37—Tool made by “H. H. K.” for holding Plow Bolts

A Tool for Holding Slip-Shear Plows in Sharpening.

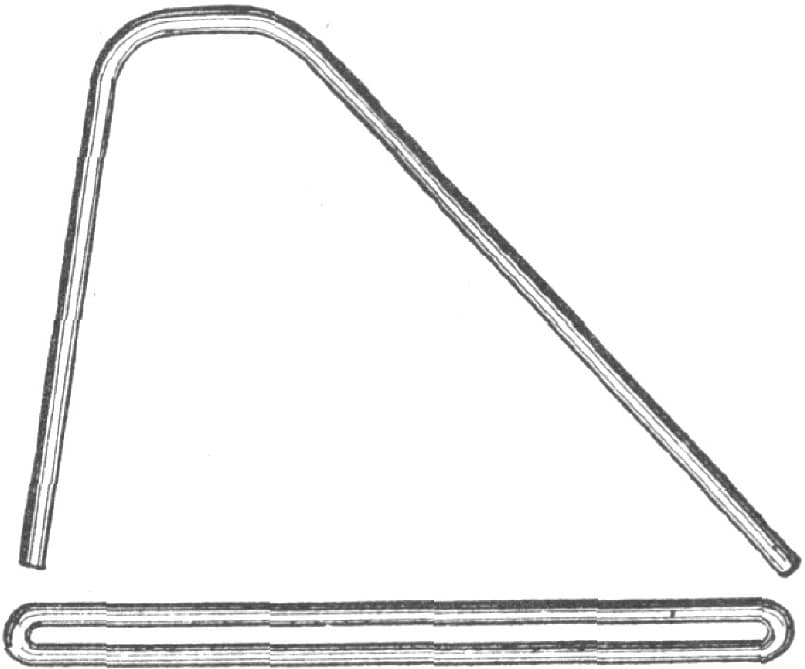

To make a tool for holding slip-shear plows in sharpening them, take 5/8-inch round iron, cut off two pieces, making each 21/2 feet long, and bend one in the middle and weld the ends as shown in Fig. 39, so that a plow bolt will fit in and slip along. I then bend the other piece as shown in the cut, then weld the ends of this piece to those of the other, and the tool is finished as shown in Fig. 40. In Fig. 41 the tool is shown fastened to a plowshare with plow bolts. This tool will hold either right or left-hand plows.—By A. G. B.

A Tool for holding Slip-Shear Plows in sharpening. Fig. 38—Showing how the two Pieces are shaped

Fig. 39—Showing the Tool as finished

Fig. 40—Showing the Tool fastened to a Plowshare

Making a Plow Bolt Clamp.

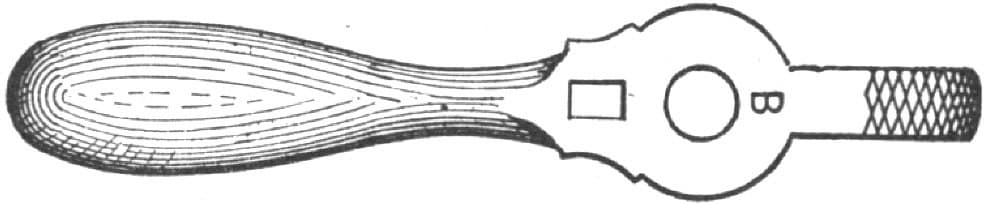

To make a plow bolt clamp take a piece of steel 14 inches long, and 5/8-inch square; make a two-pronged claw to fit the bolt-head on one end and draw the other to go into the wooden handle marked A, Fig. 41. Then draw a piece of 13/4 × 1/2 inch iron to an edge and bend two inches to a right angle at B. Punch a square hole to fit the steel, two inches from the bend.—By G. W. P.

Fig. 41—A Plow-Bolt Clamp as made by G. “W. P”

Tongs for Holding Plow Bolts.

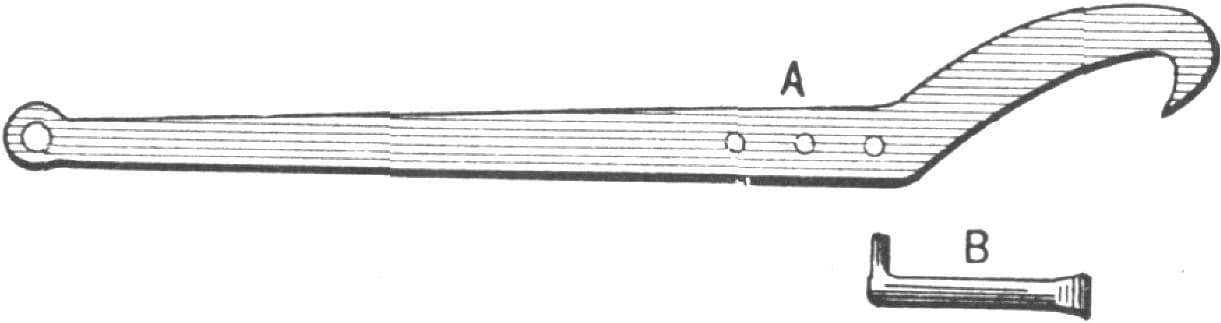

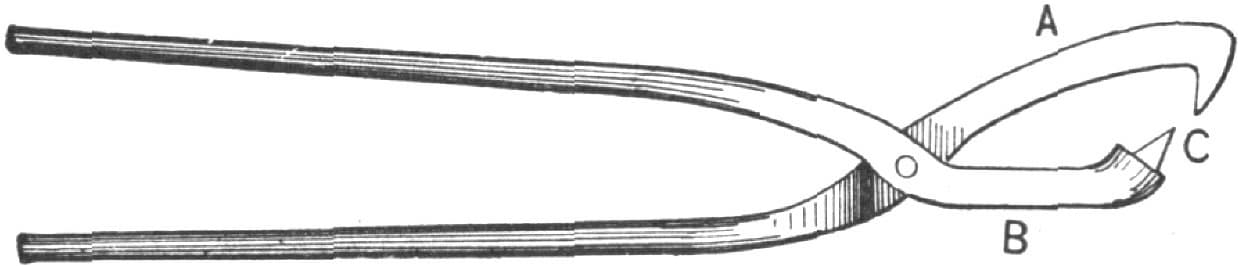

This is a very handy tool and one which no shop should be without. With this tool a bolt in the lay can be held with one hand while the other is free to remove the burr. I consider it the only successful tool ever invented for this purpose.

The jaw A, Fig. 42, is five inches in length, while B is four and one-half inches long. The point C is made of steel and welded to B, and must be tempered hard. It is made with a sharp point like a chisel or screw point. The handles are two feet long and of five-eighths inch iron. The jaws are of three-fourths inch square iron.

To remove a bolt from a plow-lay with this tool place the point C on the bolt head, and let the jaw A come in any convenient place on the other side of the lay, grip tightly and the bolt will be held tight while the nut is being removed. If the nut be rusted on and hard to turn, then with a sharp chisel cut across the bolt head same as a screw head. Then place C in the cut and the bolt cannot turn. You will seldom have to do this.—By E. K. WEHRY.

Fig. 42—Iron Tongs for holding Bolt Heads, as made by E. K. Wehry

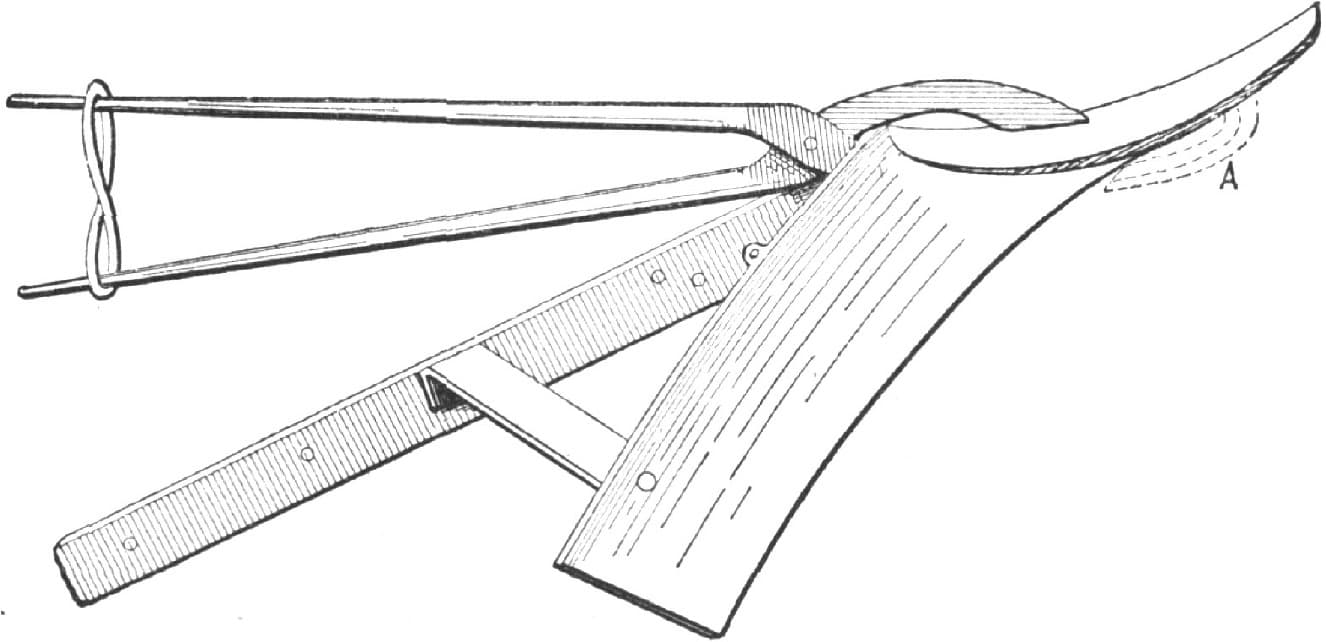

How to Point a Plow.

My plan for pointing a plow is as follows: Make a pair of blacksmith’s tongs, somewhat heavier than ordinary tongs, let one jaw be two inches and the other one five inches long. Make the long jaw very heavy and shaped as shown in Fig. 43; then take a piece of suitable steel and cut out a point the desired shape, and, after shaping and filing the edges, place it on the plow lay and clamp it with the tongs, as shown in Fig. 44; then take a light heat on the point and bend it under, as shown by the dotted lines. Make the point of such a length that when bent under it will lap on the original point from one to two inches. Then take a thin piece of soft iron and place it between the lap at A in Fig. 44—this is to make the point heavier and to cause it to weld better—then take a welding heat on the point, after which the tongs may be taken off and the job finished up. This plan is a great advantage over the old way of drilling the point and share, and riveting the point to hold it in place while taking the first heat. It not only saves time and labor, but it makes a stronger and neater job.—By H. L. C.

Fig. 43—Pointing a Plow, as Done by “H. L. C.” The Tongs

Fig. 44—Showing the Clamping and Bending Processes

Hints for Plow Work.

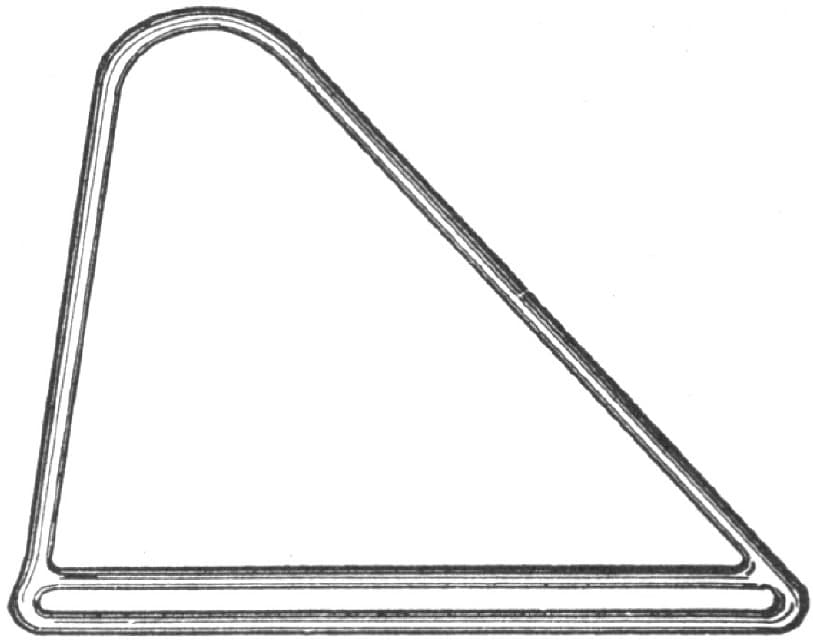

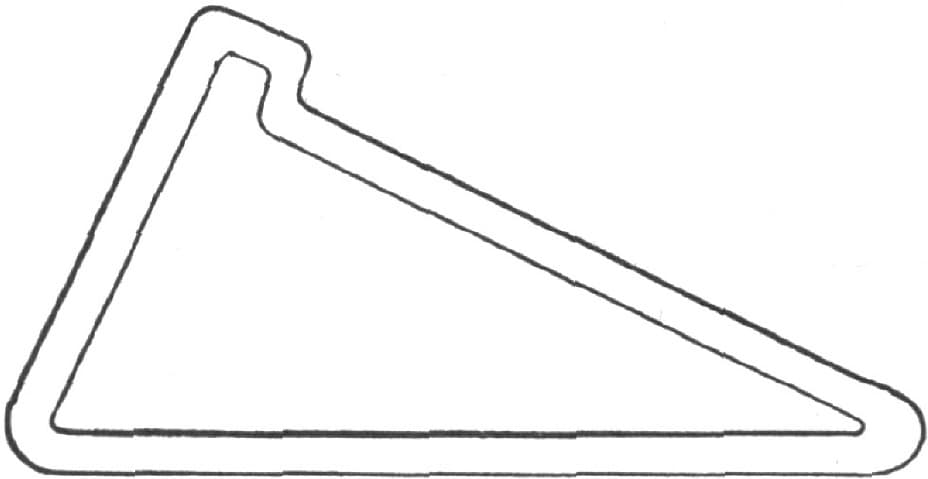

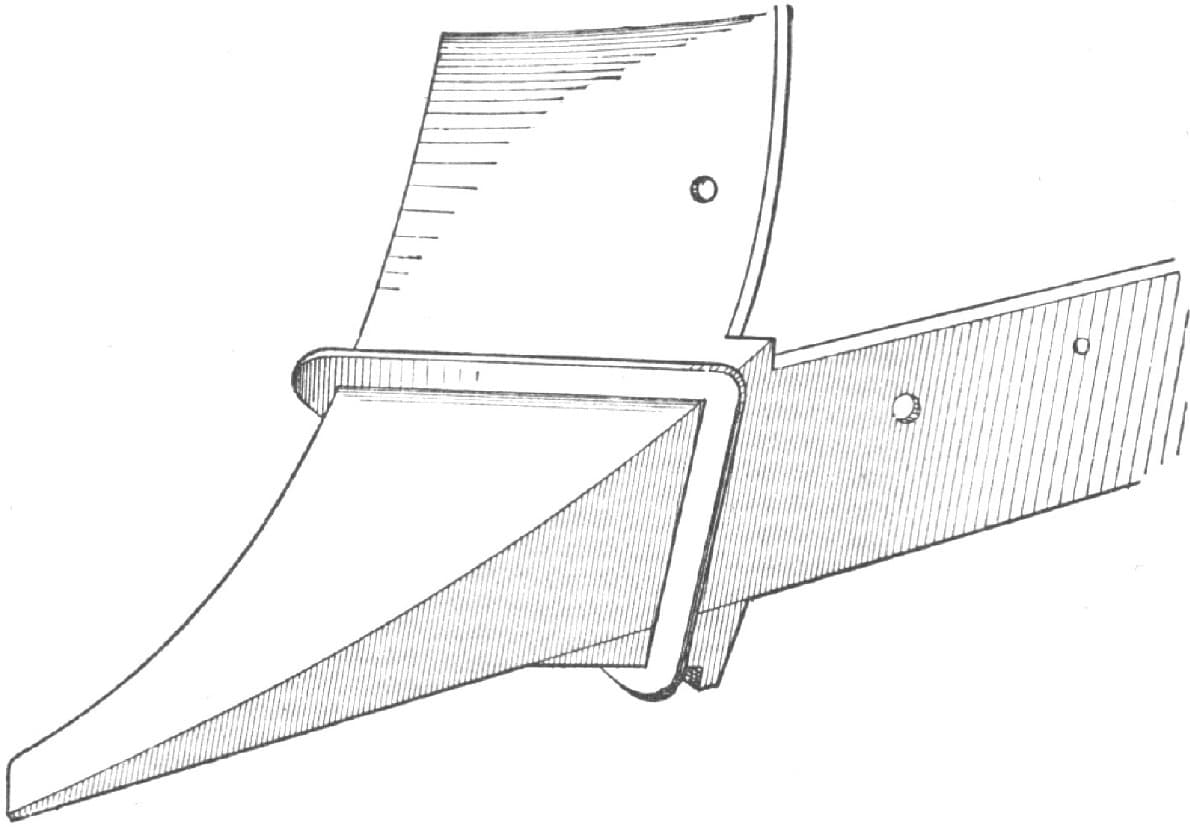

Some of the plow manufacturers send out lays that are so badly welded that after being sharpened once or twice they fall away from the landside, and then the farmer blames the blacksmith. For the benefit of smiths who have to handle such plows I give a few hints which may prove valuable. Fig. 45 represents the tongs I use in sharpening lays when there is danger that they will be loosened. Fig. 46 shows how the tongs are used on a slip lay so that the lay and landside will be held together until the welding has been done up to the tongs. Fig. 48 represents a whole landside lay or bar lay. In welding these I use a triangle shown in Fig. 47 and a wedge shown in Fig. 49.—By G. W. PREDMORE.

Hints for Plow Work. Fig. 45—Showing Tool used in sharpening Lays

Fig. 46—Showing how the Tongs are used

Fig. 47—The Triangle used in Welding

Fig. 48—A Landslide or Bar Lay

Fig. 49—The Wedge used in Welding

A Tool for Holding Plowshares.

A device invented by me for holding plowshares, which I think is one of the best tools in use for holding plowshares when sharpening or pointing them, is shown by Fig. 50. It consists of two pairs of tongs welded together, one holding the bar and the other holding the wing. The tongs holding the wing should have round jaws. When taking hold of the share the handles come together within three inches or so, and the ring on one of the handles is then slipped over the other.—By G. B.

Fig. 50—Tool made by “G. B.” for holding Plowshares