The green and pleasant landscape of modern Britain has been crafted, moulded and sculpted by successive generations seeking to make a living. And for millennia a significant part of the pressure upon the land has been people’s need for fuel. Competing with the need for the arable land on which crops are grown and the pastureland by which livestock are fed, was the need for combustible plant material with which to cook food, brew beer and stave off the winter chill. People had to make choices: harvest peat or firewood or harvest food. Over time they found a variety of ways to combine land uses to maximize the yields of each of these essential components of life.

Britain has long been an extensively populated set of islands. The degree of population pressure on the land has fluctuated as different peoples have arrived, moved around and departed; famine, plague and war have each taken their toll, but these were followed by periods of quiet prosperity, when numbers have risen again. When Britain’s population fell, fields that had been left to revert to scrub grew into woodland. When there were more mouths to feed, areas of marsh were drained to create needed pasture. Sometimes fuel was abundant and gathered rather casually; at other times it was scarce and carefully managed. These changing needs have been etched onto the landscape. The big shift in how Britain’s homes were fuelled also played out in the surrounding woods, fields, moors, fens and heaths.

So what was the old order? What fuel was used to cook porridge, roast beef, bake pies, dry out sodden socks and warm toes before the advent of coal?

Choosing what to burn

It helps to begin with an understanding of how to make a fire. Different fuels burn in different ways, producing not just varying levels of heat, but a range of forms and shapes of it. Some fires release their energy in short, concentrated bursts, others do so over a longer, slower period. Flames from a coal fire tend to be small and uniform, peat rarely produces any recognizable flame, instead burning with a hot, smouldering glow, while a bundle of dry twigs can generate long, lazy tongues of wavering flame. But much depends on exactly what you’re burning. Turves, which are cut from the very top layer of a peat deposit where plants are still growing, can behave quite unlike each other if they have been harvested from different areas, even when they were taken from the same moorland. Rye straw and barley straw have their own idiosyncrasies, quite distinct from those of wheat. Oak and pine are as different to burn as chalk and cheese. A hard black Welsh anthracite or ‘stone coal’ from Pembrokeshire combusts in a markedly different way from a softer, tarry, more bituminous sample extracted from the rocks around Newcastle.

Fuel can be treated in a number of ways to alter its nature and behaviour within the fire. Unit size is of particular importance: small chopped sticks burn differently to whole logs; coal dust and large lump coal are poles apart. For some fuels, orientation is crucial. A bundle of neatly aligned straw bound a couple of times along its length can sustain a concentrated flame where a similar amount of loose jumbled material would flash and dissipate into ash and dust and unburnt residue in no time.

Drying is particularly important for peat, which can easily contain 75 per cent water when first cut. But even anthracite coal burns better if it has had time out of the rain. And there are a whole host of controlled heating and burning processes that can turn fuels into more efficient versions of themselves. Wood can be transformed into ‘white coal’, or kiln-dried wood, or – continuing the metamorphosis – into charcoal, where the wood has been charred in an oxygen-depleted environment, driving out all moisture and impurities. Coal too can be cooked, or ‘coked’, into coke, where once again controlled burning removes unwanted matter, leaving behind a purer, hotter-burning fuel.

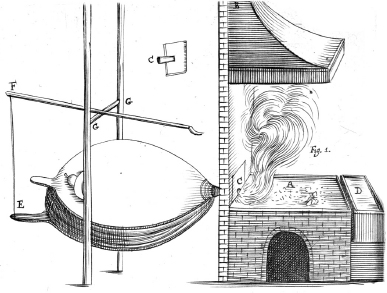

The permutations are almost endless, a fact that allows us humans to use fire in a myriad of ways to achieve a large range of effects. The blacksmith’s forge offers an ideal demonstration of the possibilities. Working with coal, for example, you can create a fairly shallow fire, packed down flat on top, which is suitable for tempering, or hardening, a blade. In contrast, welding, or joining two pieces of metal together, demands a deep and narrow fire. For the highest heats, you can pack the right sort of coal – a rock that is bituminous but low in sulphur and phosphorus – into such a shape that it becomes a virtual oven; the fire can be practically contained within this globe of unburnt fuel, which retains most of the heat rather than allowing it to escape upwards with waste gases (otherwise known as smoke). Sometimes, and rather counterintuitively, mixing a little water with small pieces of coal can help to produce this globe of intense heat, by allowing the coal to bind together and form a ‘shell’ around the fire. This is one way in which coal is coked. By gradually moving the coked material towards the centre of the fire and replacing it with new coal, you increase the efficiency and heat at the centre and open up space around the periphery to turn more coal into coke.

We can see this knowledge about forging with coal being committed to print as early as 1677, in Joseph Moxon’s Mechanick Exercises. Moxon finished his opening piece on smithing by declaring that he won’t bother to describe lighting and using a smith’s fire as the technique is too basic to bother with. He does, however, provide a few tips:

you must with the Slice, clap the Coals upon the outside close together to keep the heat in the body of the Fire; and as oft as you find the Fire begin to break out, clap them close again, and with the Washer dipt in Water, wet the out-side of the Fire to damp the outside, as well to save Coals, as to strike the force of the Fire to the inside, that your work may heat the sooner.

Undoubtedly, smiths had been employing these techniques long before Moxon set them down for publication.

Fire management is not just about producing a particular temperature. The size of the physical space held at that temperature is also important – and adjustable. If a smith is working on a nail, then a single, small point of high heat is sufficient. Some work, however, requires heat to be diffused across a much larger area, and although iron will conduct heat along its length, raising the temperature of an entire area rather than overheating a single point is generally preferable. Gradations of heat within the same fire can also be useful in allowing a smith to move swiftly from one operation to another, from large to small work and back again. With skill and knowledge, a fire can be used to shape and bend metal; temper and adjust its hardness, brittleness or spring; divide it; or unite disparate pieces.

‘Smithing’ forge from Joseph Moxon’s Mechanick Exercises (1677).

When we turn our attention from the forge to the kitchen we can see a similar range of options and subtleties at play. Managing the fire in your hearth gave you the power to render foodstuffs digestible, transform liquids into bacteria-free drink, conjure cleanliness out of filth and drive away the chill of northern climes. And just as with the blacksmith’s work, different fuels could be brought into service to perform different functions by dint of the techniques and equipment particular to them. It is possible to boil a kettle upon wood, peat, heather, ling, gorse, dried dung and various types of straw if you are in possession of the right know-how. But each of these materials are just better suited to some jobs than to others.

For instance, dry thistle stalk combusts well, because the seed heads – if they have not blown away in the wind – are packed with oil. They are an excellent form of kindling, and many people in England, Wales, Scotland and Ireland have collected them for this purpose. Yet when Humphrey O’Sullivan watched the women of Callan, in County Kilkenny, Ireland, cut old thistle stalks at the end of 1828 for use as winter fuel, he was struck by the unusual scale of their endeavour, with ‘a bundle or load of them on a poor woman as big as a pig’s sty’. He was witnessing an activity born of desperation and resourcefulness, not of preference. That’s because, as a fuel to boil a kettle or cook a potato, thistle stalks have many drawbacks.

Like all the straws they burn very fast. Hollow stems direct air to the centre of the conflagration, the long, thin proportions producing a rapid draught, not only encouraging impressive flames but blowing ash, burning fragments, and loose, unburnt material up and away from the fire. Naturally this process goes even faster if the stems are standing vertically or placed at a rising angle. Capturing heat from this quick energy release can be tricky, but both fuel and hearth can be adapted to fit this purpose.

If the stalks are first formed into a set of straight, uniform bundles and securely bound, they can then be stacked and placed under a weight. This crushes the hollow stems flat, thus reducing the air flow capacity through them and slowing down the rate of their burn. It also makes the fire easier to handle and reduces the stoking rate. Ideally, you would burn material like thistle inside a firebox where the volatile mixture of gases, ash, cinders and unburnt material can be contained (and, hopefully, burnt again later, unlocking more of the thistles’ energy).

If you didn’t have a purpose-built firebox, and it is highly unlikely any of those women in Callan did, a crude version could be rigged up with a horseshoe-shaped arrangement of stones upon a flat hearth with a cooking pot balanced on top to form a lid. However, you can’t leave the thistles for a moment, they burn quite quickly and continuous stoking is required. Indeed, a huge pile of prepared stalks would be needed to bring just one small pot of water to the boil. Anyone reliant upon thistle fuel will eat only the occasional hot meal and live in an almost completely unheated home – which is why the women of Callan must have been very desperate.

Dung, particularly cattle dung, was pressed into service in parts of Britain where other sources of fuel were scarce, right up until the widespread adoption of coal for domestic use. It was often used by poorer members of rural communities who had commoners’ rights upon areas of rough grazing.

Common land was (and is) not public land, nor was it ‘free’ land for anyone to use as they wished. It was an area held in common by a specific group of people who were permitted to use it in carefully specified ways. In most cases, commoners were the people who rented parcels of land fringing the common. They held the right to graze an agreed number of animals upon the common as well as the right to collect dead vegetation and other resources, including cow pats, from the land.

To be used as a fuel, the dung first had to be dried out. Celia Fiennes (1662–1741), the traveller and memoirist, recorded seeing this in action in 1698 outside the town of Peterborough, where she noticed cow dung ‘upon the walls of the ordinary people’s houses and walls of their outhouses’. She noted that the dung had been ‘plastered up to dry in cakes which they use for firing’. Her visit to Leicestershire revealed the practice in operation there too. She didn’t approve in either location. Around the same time, George Meriton published A York-Shire Dialogue, which contained a short scene where a mother asks her daughter to fetch some dried cow dung fuel: ‘clawt some cassons out o’ th’ hurne’, the mother said, ‘cassons’ being one of the many regional names for this form of fuel. In Buckinghamshire they were traditionally called ‘clatts’ and in Cornwall ‘glaws’.

The custom of burning cassons in this part of the country was captured in the probate inventories of the parish of North Cave in the East Riding of Yorkshire from the mid-sixteenth to the mid-seventeenth centuries. (This period is not particularly special; it is just that the surviving inventories are from this time, and there is no reason to believe things changed quickly before then or after.) In a scattering of the inventories of both the poorer parishioners and the better off, the stocks of cassons ‘on hand’ when the head of household died were recorded. For example, Richard Brigham, who died in 1626, was neither wealthy nor destitute. He called himself a ‘husbandman’, a title which indicated he was farming on a modest scale. He lived in a house with three rooms – many of his neighbours had only one – and among a mix of livestock he had five mares, two colts, two foals and ‘an old nag’, a few cows and fifty pigs plus a similar number of sheep. His will was written in October, a time of year when most people would have been laying up fuel stores for the winter, and included ‘helme baulks’ – meaning ‘bog oak’, or old stumps and logs preserved within peat – as well as ‘other old wood and turfes and cazons’. Thomas Clarke, who died in 1607, had a two-room house and a slightly smaller accumulation of livestock. His ‘backer end’, or outbuildings, contained ‘casens, turves and certain old wood’. Thomas Pinder was just a touch less prosperous than these men, though he still had a two-room house, which he too kept stocked with ‘turves and casons’. None of these men would have been designated as one of ‘the poor’ by their contemporaries. They were almost certainly commoners, fitting Celia Fiennes’s description of the ‘ordinary people’. Their use of cow dung as a fuel may have represented a mixture of tradition and thrift.

Other inventories in the same collection – forty-three in total – referred to ‘the dung’ and ‘manure’. These words described the same resource, cattle dung, but indicated a different use. Cassons were individually dried out for fuel, while manure was left wet and gathered into heaps where it could break down, ready for use as a fertilizer. Rather surprisingly, the local vicar, Thomas Brabes, headed one of the eight households in 1638 that had cassons in their inventory. He was most assuredly one of the better-off members of his community. Among his wealth in the probate records, six rooms were mentioned, as well as such refinements as ‘his library’. He also had a load of manure, a rare example of cassons and manure listed side-by-side.

Most people used the dung of their cattle for either fuel or fertilizer. Few had enough of this material to use it for both. The people of the parish of North Cave were exercising a choice as to whether to use the dung of their livestock as fertilizer or fuel – and, in at least one sacred case, a bit of both.

Dung is a rather curious fuel, in part because it is now a fuel we generally see only among traditional rural populations in hot and remote places. It is also a fuel that can initially be hard for people today to understand because much of the dung produced by modern farming methods is rather unsuitable for stoking a fire. We are accustomed to dung that is wetter, darker-coloured and much more smelly than the dung Richard Brigham and the other residents of the parish of North Cave would have encountered back in 1620. Modern cattle feed is designed to pack in nutrients, in order to produce high milk yields in dairy cows and rapid muscle growth in beef cattle. This super-rich diet has an effect upon the animals’ digestive processes. It is, in the twenty-first century, a common sight to see cows with their own dung splashing down their legs. They live their lives with something akin to permanent diarrhoea.

Brigham’s cows, and those of his neighbours, had to make do with a high-fibre diet rather than a high-nutrient one. Winter feed in particular was poor. Hay – comprised of dried grass and meadow plants, including their nutrient-packed seed heads – was largely reserved for draught animals who needed energy to work; the rest of the livestock typically ate straw, which was much less nutritious, consisting of the dried stems left over from a wheat, barley or rye crop after the grain had been harvested. In some areas where straw was in short supply, overwintering cattle were reliant upon holly branches cut especially as fodder. Their dung was much drier, more fibrous, paler and far more solid than that of a modern cow. A pat could be picked up after a day or two in the field and would hold together. Judging the right moment for gathering one before sticking it to the wall of an outbuilding to dry probably took a little experience, as a pat would need to be dry enough to handle but sticky enough to adhere to the wall. Leaving pats out in the field too long risked getting them trampled on, reduced to mush and crumble. Once properly dry, the dung could be stacked fairly easily until needed.

Personally, I don’t have a great deal of experience burning dung. I have never tried to burn cow dung, though I have idly messed about with dried sheep dung (I was bored when camping). In my very limited experience, it catches easily and smoulders along with little difficulty in a rather hot fashion, but it is often smothered by its own ash, which clings around the burning core and has a distinctly pungent and acidic aroma. You could definitely rustle up a supper on it if you needed to, although I would advise keeping a firm lid on any pot to stop the smell infecting the flavour of your meal.

In nineteenth-century America, a similar resource – the dried dung of wild buffalo herds, also known as ‘buffalo chips’ – was an essential fuel for those heading out across the Great Plains. Frederick Piercy, an artist from Liverpool who accompanied a group of pioneers heading to the West, said the chips were ‘composed of grass, masticated and digested, and dried in the sun’. In his illustrated travelogue The Route from Liverpool to Great Salt Lake Valley, published in parts between 1853 and 1855, he observed: ‘It is a common joke on the plains that a steak cooked on these chips needs no pepper.’

According to Derek E. Earl in his book Forest Energy and Economic Development, dried dung releases about the same amount of energy as peat – a little more than wood does, and more than half of the energy produced by a similar weight of bituminous coal. And, of course, it is typically there for the taking.

If some of the good people of North Cave knew much more than me about the use of cassons in the home, far more were expert in the use of peat and turves. (Rather confusingly, ‘peat’ and ‘turf’ are sometimes used interchangeably, especially in Ireland.) There are more than four times the number of listings of turves than of cassons in the North Cave probate inventories, plus another handful of households that mention turf spades but no turves. This parish included a section of the Wallingfen, a wet and boggy area of thin peat, moss and patches of reed and thin grasses, for which many parishioners had commoners’ rights.

These commons, as we have noted, were not a free-for-all, and turf-cutting was highly regulated. On St Helen’s Eve – the third of May – each attested commoner was permitted to stake a claim for the coming turf-cutting season so long as he (or she, if she were a widow) did so before noon. Once claimed, the turf was permitted to be cut only during the hours of daylight and only until Midsummer’s Day, towards the end of June. No fuel obtained from the fen was to be sold to anyone outside the jurisdiction of the ‘liberties’, which included all of the parishes that had a share of the land. The season’s cutting was further restricted, in an attempt to preserve supplies for the future, to a single turf spade’s deep – in this region, about 12 inches (30 cm) deep.

No one knows when people started cutting peat for fuel. We are equally in the dark about when people began to manage this resource in such an orderly manner. Besides extracting peat, the fens could be used in a variety of ways: as grazing for all sorts of livestock, for hay-making, for fishing and fowling or for the gathering of sedge and reeds for thatch, and of sallows for basket-making. Since digging the place up to get the peat out destroys the potential for most of these other uses, peat-cutting was restricted. The best known of the old peat-cutting areas in England today are the Norfolk Broads. Leases for areas of ‘turbary’ – the local name for fenland set aside for peat-cutting – indicate that people were cutting peat in the Broads in a regulated fashion by 1140.

Between the Norman Conquest in 1066 and the arrival of the Black Death in 1348, the population of the British Isles had risen from under 2 million people to around 4.5 million. Pressure on basic resources was acute. Marginal areas of land were brought into cultivation despite dreadfully poor yields. Peat-digging was confined to small, linear plots, so the cuttings were pushed deeper and deeper to extract much-needed fuel. Modern practice, continuing commercially right up until the Second World War, and a few walls of earth surviving from the medieval ‘broads’ – the open areas of fresh water created by peat diggings – suggest that each small pit was the result of a single season’s campaign by a single digger, perhaps with the help of his family. Looking at the accounts of those involved in the last days of commercial hand-cut peat, we can piece together an understanding of the methods that left behind these traces in the shape of the earth and water bodies.

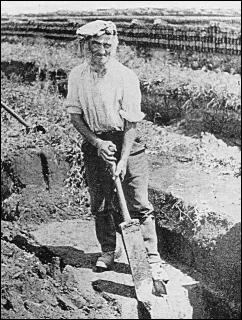

‘Mad Jack’ Darnell was a peat cutter. In the late spring of 1892, he was kind enough to demonstrate his traditional method of turf-cutting for the photographer P. J. Deakin, and these images, along with memories of people who knew Mad Jack or themselves worked in the peat business, were collected in 1999 by Anthony Day, the nephew of the last commercial peat cutter in the area of Wicken Fen, in Cambridgeshire, in his book Fuel from the Fens. During winter, Wicken Fen is very wet. The water table sits not far below the surface, and the waterlogged peat can freeze solid in the cold weather. Mad Jack’s work therefore began in March, when the peat slowly began to thaw and dry, and finished in late August. With a piece of string stretched between two pegs thrust into the ground, he’d mark out a straight line parallel to pits he or others had worked in previous seasons. This new work area was not directly on the side of the old digging, because these diggings had filled with water over the winter. Instead, a strip was left untouched to act as a ‘baulk’, or wall, between the old, now flooded pit, and the new. This had the advantage of leaving Mad Jack room to stack drying turves along the edge of the pit on one side and still have space to run a barrow up and down the length of his workings.

‘Mad Jack’ Darnell demonstrating the procedure for cutting peat for photographer P. J. Deakin in 1892.

The surface vegetation was stripped off, leaving a bare and flat surface, into which the new season’s hole was dug. First an edge was cut into the peat with a turf knife and then the real work began. Cutting into peat requires strength and perseverance. Water slowly seeps from the surrounding bog through the top section of peat, forcing diggers to stop and bail out water on occasion. Peat cutters tried to maintain a relatively standard block size, since this helped in monitoring how the blocks were drying. Extraordinarily straight and even, and about the size of a modern breeze block when first dug, each block of peat was stacked one atop another at the edge of the digging so that it could begin drying as soon as possible. The peat blocks had to be moved and restacked in different formations several times as they dried to permit the sun and wind to do their work. In an essay published by the Highland Society of Scotland in 1803, the Revd Dr John Walker noted: ‘the “flaw” or surface peat affords but a very weak fire, like a parcel of dry sticks or straws, and leaves as few ashes behind … The heather peat, and the springy brown peat, formed by the decay of herbaceous plants, are somewhat better, being a little more lasting. But the solid black peat, formed from wood, and which lies deep, is much preferable to these, and makes the best fuel.’ While his understandings of the origins of the different types of peat would today be refuted scientifically, Professor Walker’s observations about the burning characteristics of peat taken from different depths is sound.

Deep, highly compressed peat burns much more steadily and for a longer period. The processes by which vegetation turns into peat have simply had longer to act, so the peat has a much more even texture and is less likely to contain intact stems or roots. The other reason to dig deep is a desire to maximize upon one’s investment. Given how much better it performed, it is quite likely that deeper peat fetched a higher price at market. Some areas of the fen were subject to common rights but some areas could be leased, with fewer restrictions on where the peat was sold. Regardless, the surface areas claimed for cutting could be quite small. The deeper you dug, the more peat – and potentially profit – you could extract from your section.

Such diggings left behind a landscape of multiple small deep pools divided by walls of untouched peat. From the early fifteenth century onwards, we have evidence of some secondary rounds of peat extraction, conducted by cutting into these walls some time after the initial digging. The method did not survive in England, but something rather like it did continue in the Netherlands into the nineteenth century, when it attracted antiquarian and folklorist interest, and in Ireland in areas where the bog is especially wet. Evidence of the practice in England comes in the main from a set of accounts kept by the owners of Bartonbury Hall in Norfolk. In 1451, for example, a profit of ‘10s [shillings] 0d [pence] for 12 lasts of fen taken in the several pond-waters of the Lord with laggying’ was recorded. Another entry mentioned the peat had been retrieved ‘with a dyday’, a tool identified through the writings of farmer-poet Thomas Tusser more than a century later, when he advised using one to clear out ditches in winter. Several of Bartonbury’s accounting entries also make it clear that the estate’s peat had not been cut in nice organized blocks, as it was ‘sufficient for making 4000 turves’ (my emphasis). Instead, it is likely some baulks were hacked away, with the loose peat being dredged out of the water with the dyday. This wet, broken peaty mass then had to be dried out and pressed into ‘turves’. In Ireland, Humphrey O’Sullivan described similar ‘peat pulp’ which, he said, had ‘been kneaded by human feet … and then made into brickettes by women’s hands’. And lo, bit by bit, the ‘several pond-waters’ became a ‘broad’, as all the little peat divisions were removed.

A fire of smoke and spirit

Using peat as a fuel is a varied business. As Professor Walker pointed out at the beginning of the nineteenth century, its burning quality can vary quite a lot, depending on where it comes from. In addition, the structure of the peat block or turf was determined by the method of extraction.

Turves cut with a spade or other hand tool have a ‘grain’ representing the horizontal layers of year after year of material deposition. The grain is most obvious in mid-level peat, where the plant material has had time to begin to break up and been subject to a fair amount of pressure squeezing down upon it. Surface peat, which has not been subject to so much decomposition or pressure, retains more of the chaotic texture of intertwined stems and roots. Peat dug from deep layers has a grain that is finer, more densely packed and harder to discern; it becomes more obvious during combustion, when the ash maintains the structure of the block until it is disturbed and falls away into a soft, fine powder. Peat that has been dredged up out of the bog water and re-formed into briquettes has no structure whatsoever.

If there is a grain in the peat, the blocks tend to burn along it. Since peat is what might be called a ‘contact burner’ – fire spreads through direct contact – the grain makes a difference. Re-formed briquettes create a sphere or hemisphere of fire, since the initial spark catches on the outside surface and works its way steadily inwards. The fire in its early stages therefore remains largely within the block, with the surrounding, unburnt peat serving as something of an insulation. Hand-cut peat, with its grain running across the original deposit lines of plant fibres, helps to direct the spread of your fire, as it is more likely to ignite the peat within the same deposit layer rather than the peat in the layers above and below. A ‘plate’ of fire is formed. This fire tends to burn to the edges of the block, where it is exposed to the air, releasing heat in a usable fashion.

Once your fire has a good hold – which can take a considerable time with this slow-burning fuel – the burning peat starts to resemble charcoal. It is at this stage that it can successfully be used for cooking or heating water. You will not see any flames, and the heat dissipates very quickly if you move your pot away from direct contact with the fire. So while a pot can be suspended above a peat fire, it needs to be close. Actual boiling is best done with the pot’s sides touching burning turves. If it is moved just a couple of centimetres further away, bringing a pot to the boil is almost impossible; maintaining a simmer is generally the best you might do. The high heat required for baking can be achieved by laying food upon some hot stone or iron surface in the centre of a peat fire, upturning a pot over the food and heaping burning turves around and on top of the pot. However, the need for such close contact places a significant limit on how many cooking vessels can be put into use at any one time.

A pot put to boil over a peat fire – note how the pot is nestled by the turves.

There are two things that people particularly like about peat as a fuel: the smell and the staying power. Peat smoke has a strong, distinctive smell, one that evokes powerful memories of home, especially for those who have moved away from peat-burning districts. Peat smoke translates into flavour wherever it comes into contact with food, particularly dairy produce or other animal fats (and whisky, of course). The smell is a product of chemicals from the peat’s original plant materials, but its prevalence is mostly a function of the slow, cool-burning nature of a peat fire. Whatever calorific value is locked up within the material is released only slowly and at a considerably lower temperature than that of wood, straw or coal. The low temperature of combustion creates a great deal of partly burnt particles that we experience as smoke. In fact, the sheer abundance of fine particulates released by peat makes it one of the most damaging of all fuels for the lungs.

Staying power, unsurprisingly, is also a result of the cool-burning nature of peat. A single turf can burn for over an hour, which means a peat fire requires very little attention, not a small consideration for anyone running a busy household.

The loss of wetlands

Generally, the presence of peat in an area indicated a shortage of wood. Wet, boggy areas are not ideal for most tree growth. It works the other way round too. Where the land is very wet, felling trees that once sucked up excess water can make an area even more boggy, creating an accumulation of peat where once a straggly wood grew.

Before coal there were very many more peaty areas than there are today. Once useable coal supplies became widely available, fewer people were reliant upon peat. The ability and demand to put more land into agricultural production meant many wet areas were rapidly drained. The largest area that is still called ‘the fens’ – nearly 2.485 sq. miles (4,000 sq. km) in Lincolnshire, Cambridgeshire and Norfolk – is today prime cropland with only tattered fragments of wetland and peat formation surviving. But while this area is well known, there were once many small pockets of lowland fen scattered about in shallow valleys where drainage was poor and seasonal waterlogging was common. For example, Wallingfen, where the people of North Cave were cutting their turves in the sixteenth and seventeenth centuries, is now an area of flat agricultural development dotted with farmsteads as well as a completely new post-fen settlement called Newport. This township was built at the very end of the eighteenth century when, to provide transport and to drain the area, a canal was driven through the local wetlands. Natural England estimates that around three quarters of England’s former fenland is now farmland.

Peat was also once widely available upon the high moors. Acidic soils and high rainfall make upland plateaus and shallow valleys into the perfect habitat for sphagnum, the moss that is the primary vector of upland peat formation in areas where harsh climate and thin soils combine to make tree growth slow and unproductive. Many of the communities farming in the fertile valleys surrounding the moors utilized these reserves of peat for fuel. Eskdale in the Lake District, for example, boasts as testimony to this past a scattering of small, stone-built huts, known as ‘peat scales’, high on the valley slopes. Still discernible alongside the peat scales are carefully graded sledge tracks leading up to the peat-cutting zone. Pockets of peat-burning also occurred in parts of Devon (near Dartmoor and Exmoor), in the Yorkshire Moors, high up in the valleys of Cumbria and across large swathes of Scotland, Ireland and Wales.

But for all this, peat burners did not constitute the majority of the population, probably no more than 10 per cent of those who lived within the boundaries of what is now the UK. Everywhere else, they used wood.

The reasons for this were obvious to John Norden. In 1607 he worried about the use of ‘peats, turffe, heath, furze, broome and such like fuel for firing … yea and neats dung’ in those parts of Wiltshire where more conventional fuel was then in short supply. The dependence on such fuels spoke to him of severe poverty and, perhaps more crucially, of poor husbandry and inefficient land use. People who were using dung for fuel were clearly not using it to fertilize the fields, sacrificing future food crops for present warmth. Likewise the use of moors and heaths as sources of fuel discouraged people from ploughing up such areas and pressing them into food production. For Norden, wood represented the ideal of fuel efficacy and efficiency; nothing could be more perfect in terms of use or production cycle.