Wood finishing is a skill nobody truly masters. Even the pros make mistakes. But with some patience and attention to detail, beginners can do it right. Your best approach is to start on something small and simple before you take on more challenging projects.

There are a dozen ways to color and coat wood. But for most DIYers, stain followed by a clear coating of polyurethane is the best combination.

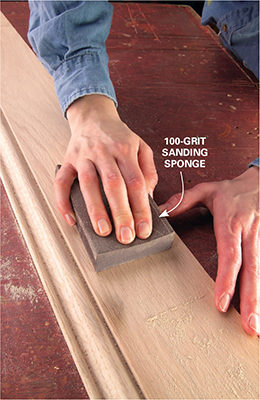

1. Sand it smooth

On coarse-grained wood like oak, start with 100-grit sandpaper, then go to 150-grit. On fine-grained woods like cherry, birch or maple, you need to end with a higher grit; 100-150-220 is a good combination.

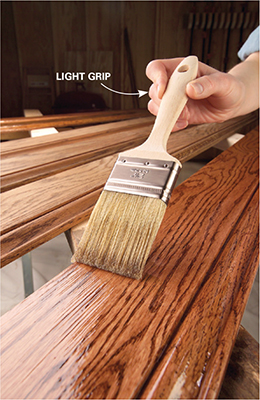

2. Add color

Apply stain with a brush or rag, then wipe off the excess with a rag. Spread out used rags to dry before putting them in the trash. Stain-soaked rags are a spontaneous-combustion hazard.

3. Apply polyurethane

This is the hard part; you have to work fast and apply the poly smoothly. Before the poly begins to dry, drag a brush lightly over it to smooth it. Apply two to four coats, lightly sanding between coats.

Water- and oil-based polyurethanes are equally tough, but there are some important differences:

• Water-based poly goes on milky and dries crystal clear. Oil has a warm amber tone.

• Oil-based poly dries much slower, which makes it easier to smooth out before it becomes gummy. This is a big advantage on large surfaces.

• Water-based poly cleans up with water. Oil requires mineral spirits. Oil also emits harmful fumes, so you need good ventilation.

Some woods absorb stain unevenly, which causes dark blotches to appear. Birch, maple, pine and cherry can all play this ugly trick on you. It’s hard to eliminate this effect, but you can limit it by applying a wood conditioner before staining. Conditioner also prevents wood’s end grain from absorbing more stain than the face grain. It’s available wherever stains and finishes are sold.

Voice of experience

In just 30 minutes, I once ruined a bookcase that took me 65 hours to build. The stain went on blotchy and the color was nothing like I expected. Every woodworker I know has a similar story (or several). I’ve learned that you can’t rely on the stain samples in stores. Actual color varies a lot, depending on the type of wood and how you prepared it for finishing. Now I always do several sample tests. Sometimes I mix stains to get the color I want.

David Radtke, The Family Handyman Contributing Editor

Even master finishers end up with a few imperfections in the clear coating. To remove them, lightly sand the entire surface with extra-fine sanding pads or paper. Be careful not to sand through the finish, especially along edges. Clean up the fine dust with a vacuum then a tack cloth before applying the next coat.

Multiple coats of satin or semigloss poly can obscure the wood’s grain. Ugly. That’s why experienced finishers often start out with gloss. Then, if they want less sheen, they add a final coat of satin.

Spend extra for a good-quality brush. Even if you spend $20 or more, you won’t regret it. Quality brushes hold more finish, lay it on smoothly and are less likely to leave lost bristles in your clear coat. If you clean your brush immediately after use, it’ll serve you well far into the future.

Polyurethane that’s formulated for application with a cloth has some important advantages over the brush-on stuff: It goes on thin, so it’s less likely to run, sag or pick up airborne dust. Smooth application with a cloth is also easier than brushing, especially on shaped surfaces. The big disadvantage of wipe-on is that it forms a very thin coating, so you have to apply lots of coats to equal one coat of brushed-on finish.

Brushing is a good way to build up a thick layer of poly, but it’s also difficult to apply smoothly. So woodworkers often brush on a few coats, then use spray or wipe-on poly for the final coat or two. Spraying and wiping are more likely to end in perfection.

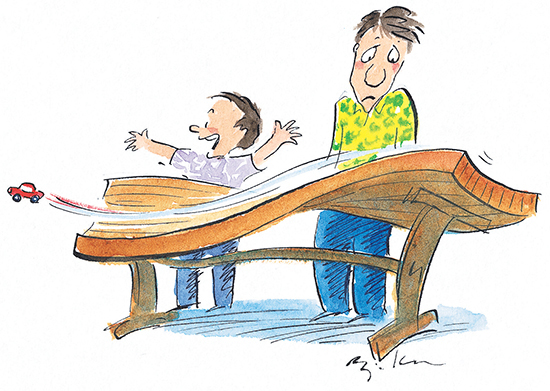

Voice of experience

Wood expands and contracts as the humidity changes. And if you finish just one side of wood, the unfinished side will shrink or swell differently from the finished. Years ago, I learned this the hard way when I finished only the top of a table. Over a few weeks, it went from perfectly flat to wild and wavy. The moral of the story is this: Whenever you finish the “show” side of a large piece of solid wood, slap a coat of poly on the hidden side too. That will equalize the effects of humidity changes.

Elisa Bernick, The Family Handyman Contributing Editor