2

ELEMENT B: SHELL

INTRODUCTION

In the last analysis, everything turns as much on exactly how something is realized as on an overt manifestation of its form. This is not to deny spatial ingenuity but rather to heighten its character through its precise realization. Thus the presencing of a work is inseparable from the manner of its foundation in the ground and the ascendency of its structure through the interplay of support, span, seam, and joint—the rhythm of its revetment and the mod- ulation of its fenestration.

—Kenneth Frampton, Studies in Tectonic Culture: The Poetics of Construction in Nineteenth and Twentieth Century Architecture

This chapter on the shell of a building—the structure rising from the foundation; the exterior walls with doors, windows, louvers, and shading; the roof with openings and lights—describes what, arguably, are the most significant architectural form-givers and expressive elements. As Frampton points out in the epigraph here, the realization of the individual components and their interplay is as important as the overall spatial concept.

The information contained in this chapter is meant to serve as the starting point for an exploration of the poetic and tectonic expression of a building’s shell, in concert with its environment, rather than against it, to provide for human occupancy while elevating the emotional and spiritual experience.

In addition to the requirements to be warm and dry, humans need protection from a variety of natural and cultural vicissitudes. In 1963, in

Canadian Building Digest, Dr. Neil Hutcheon categorized the purposes of architectural enclosure, which are paraphrased as follows:

• Control heat flow.

• Control airflow.

• Control water vapor flow.

• Control rain penetration.

• Control light, solar, and other radiation.

• Control noise and vibration.

• Control fire.

• Provide strength and rigidity (resist gravity, snow, wind, seismic, blast, impact, and ballistic loads).

• Be durable.

• Be of economic value.

• Be of aesthetic value.

Satisfying the requirements to be warm, safe, and dry is only the beginning, however; without appealing to the human intellect and addressing sociocultural conditions, mere building results. For architecture to occur, poetics and art must be brought into the realization of the enclosure. Therefore, the last purpose listed is the key to the creation of architecture.

Frampton points out the other determinants with tectonics: the type and topos (or the function or commodity, and the site). The enclosure mediates two distinct environments: the interior and the exterior. The building type is a major determinant in the required interior environment, while the topos—the site and its distinct local climatic conditions—determines the exterior environment. The consideration of these two environments is essential to the architectural solution, and their impact is evident throughout the chapter.

Architecture is not a collection of standard details, but neither is it a maquette assembled without regard for the realities of service and function. Whether a building is expressive of its tectonics or tells a story based on other aesthetic and cultural aspirations, it must provide the basics of support and environmental control over time. Certainly, many details contained in this chapter represent tried-and-true solutions to common problems, but the underlying principles of their functionality have been given in hopes of expanding, modifying, and adapting their usage to inform and influence the overall design concept.

Contributor:

David Altenhofen, AIA, Hillier Archiecture, Philadelphia, Pennsylvania.

DESIGN CONSIDERATIONS

CLIMATE AND ENERGY

Of primary importance to the shell of a building is the mediation between the exterior and interior environment. Proper design and detailing of the building enclosure requires an understanding of the specific characteristics of both the desired interior environmental conditions and specific exterior environmental conditions, on both a macro and micro scale.

DEFINITIONS

When reading the content of this chapter, keep in mind the following definitions of concepts and principles:

• Air barriers: Materials or combinations of materials that form a continuous envelope around all sides of the conditioned space to resist the passage of air. Joints, seams, transitions, penetrations, and gaps must be sealed. The air barrier must be capable of withstanding combined positive and negative wind load and fan and stack pressure without damage or displacement. The air barrier must be at least as durable as the overlying construction and be detailed to accommodate anticipated building movement. An air barrier may or may not be a vapor retarder.

• Vapor barriers and retarders: Without industrywide consensus, materials with a perm rating less than 1 are interchangeably called vapor barriers or vapor retarders (IBC and IEC 2003 use “vapor retarder”). More important than the term is to understand a few basic principles:

• Vapor diffusion through materials with perm ratings less than 1 is nearly inconsequential, but even small gaps or holes can easily transport many times as much water vapor.

• All materials have some greater or lesser degree of resistance to diffusion, and their placement in an enclosure assembly, whether intended as a retarder or not, will affect wetting and, more importantly, drying of an assembly.

• Insulation: A material that slows the flow of heat through conduction.

• Radiant barriers: A material, usually metallic or shiny, that reflects radiant thermal energy.

• Weather barrier (water-resistant barrier): A material that is resistant to the penetration of water in the liquid state, or is waterproof. It may or may not be an air barrier or vapor retarder. The face of the weather barrier is sometimes called the drainage plane.

• Barrier wall: A wall assembly that resists moisture with a continuous waterproof membrane or with a plane of weather barrier material thick enough to prevent absorbed moisture from penetrating to the interior.

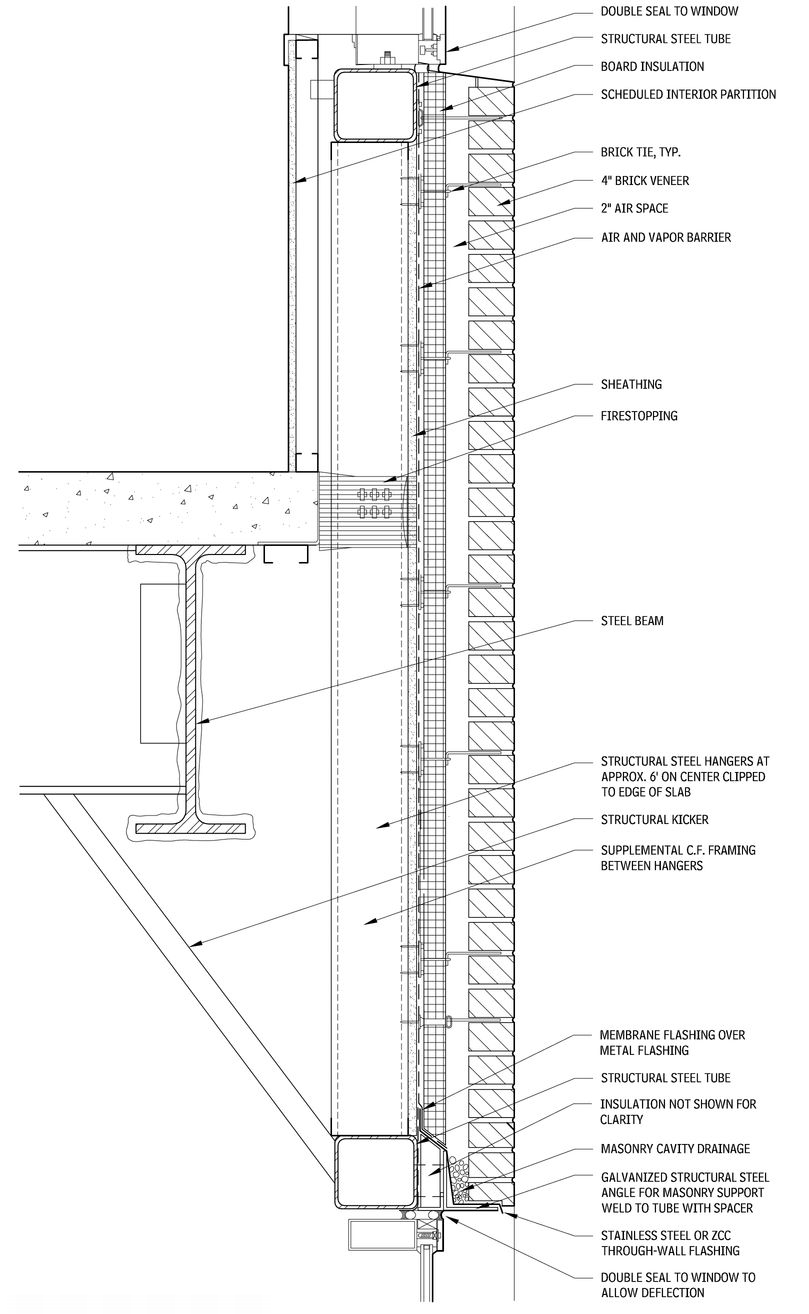

• Drained cavity wall: A wall assembly with an outer water-shedding layer over an air cavity, and with a weather barrier. The cavity is flashed and weeped to drain incidental water.

• Drainage plane wall: A wall assembly with a continuous water-resistant barrier under an outer water-shedding layer. The lack of a cavity limits the amount of water that can be quickly drained.

• Pressure-equalized rainscreen wall: A wall assembly that resists all the physical forces that can transport water across a joint in the outer or “rainscreen” layer. Kinetic energy forces are controlled by venting a cavity behind the rainscreen and, thus, allowing the pressure differential across the joint to be equalized. An air barrier and compartmentalization of the cavity are required to control the pressure equalization. The cavity is flashed and weeped to drain incidental moisture.

EXTERIOR CLIMATIC INFLUENCE

The United States has widely varying climates. More than the obvious extremes of Miami and Alaska are the subtler—and just as important variations—within the contingent states. The ANSI/ ASHRAE/IESNA Standard 90.1 Map of Climate Zones for the United States reproduced in Figure 2.1 dictates zones based on heating and cooling requirements. (Note: A simplified map of climatic zones can be found in the book, Moisture Control Handbook: Principles and Practices for Residential and Small Commercial Buildings, by Joseph W. Lstiburek and John Carmody, 1996.) There are six zones within the continental states and Hawaii, plus two more for Alaska. Within these zones are subzones for moist, dry, marine, and warmhumid.

CLIMATE ZONES FOR UNITED STATES LOCATIONS

2.1

Source: ANSI/ASHRAE/IESNA Standard 90.1

As this chapter will demonstrate, solutions appropriate for one zone may be totally unsuited for another. SEI/ASCE 7, “Minimum Design Loads for Buildings and Other Structures,” and other similar standards establish the wind, snow, and seismic structural loads on buildings. Again, there is wide variation in wind speed, snowfall, and ground movement. In addition to the base loads, localized conditions such as surrounding topography and adjacent buildings can cause wide variances in the environmental influences. Figure 2.2 shows the annual precipitation for North America. Suggested types of exterior enclosure systems that will meet the minimum level of service and reliability are correlated to the rainfall levels.

INTERIOR CLIMATIC INFLUENCE

Environmental conditions to be maintained within the building also influence the design of the shell. Buildings with requirements for high or low levels of humidity, tight temperature tolerances, pressure differentials to the exterior, high-reliability containment, acoustic isolation, protection from blast or forced entry, high indoor air quality, or other extraordinary requirements will require particular attention to system selection and detailing, in concert with consideration of the exterior climate.

ANNUAL PRECIPITATION IN NORTH AMERICA

2.2

Source: ASHRAE Journal, February 2002

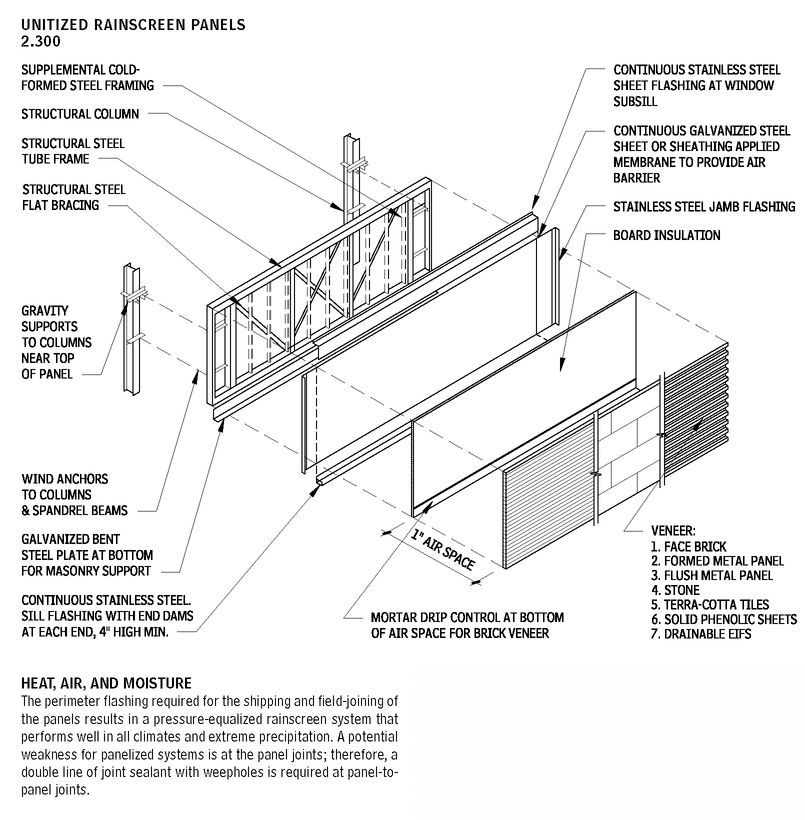

HEAT, AIR, AND MOISTURE

In addition to the obvious structural loads, the building enclosure must resist the transfer of heat, air, and moisture (HAM). The laws of physics dictate that heat always flows from hot to cold. Air moves through building enclosures by passing through porous materials, or through holes and gaps in nonporous materials, based on differential air pressures. Moisture, as water in the liquid state (such as rain, snow, and groundwater), moves through enclosures by four methods: capillary action, surface tension, gravity, and kinetic energy (e.g., wind-driven rain). Moisture in the vapor state moves through enclosures from zones of higher to lower vapor pressures, by diffusion through solid materials or by air transport through holes.

CONTROL OF HAM

Control of the flow of HAM across the building enclosure is an interrelated problem, in that air movement can create the kinetic energy that pulls water through joints, dramatically reduce thermal insulation effectiveness, or cause massive vapor transport. Improper thermal insulation can cause condensation on uncontrolled surfaces.

To control HAM, three components must be considered separately: heat, air, and moisture.

Heat is most commonly controlled by thermal insulation. Keep in mind the following:

• Air movement around thermal insulation can seriously degrade its effectiveness, so avoid systems that ventilate the conditioned side of the thermal insulation.

• Radiant barriers may be effective, particularly in hot climates, but they must have an airspace on the warm side. Generally speaking, radiant barriers have virtually no insulating value and should not replace but, instead, enhance typical thermal insulation and conductive losses.

• Thermal short circuits can dramatically reduce the U-value of thermal insulation. The most common example is metal studs, which may reduce the effective value of thermal insulation between the studs by half.

Air transfer is controlled by a coordinated and continuous system of air barriers for all six sides of the enclosure (i.e., the lowest grade level, foundation walls, exterior walls, and the roof).

• Common approaches to wall air barriers are continuous membranes applied to sheathing and sealed to windows, doors, and penetrations.

• Below-grade assemblies can utilize either the concrete walls and slabs or applied waterproofing membranes.

• Most typical low-slope roof membranes will provide an air barrier, except for mechanically fastened systems that may not be able to resist all of the required loads.

• It is possible to design the gypsum board as an air barrier, if all joints and cracks are sealed.

• Many air barrier systems require a combination of a membrane and a structural panel to resist loading, such as spun-bond polyolefin membranes stapled to sheathing or bituminous membranes adhered to CMU.

Moisture management consists of controlling moisture entry, moisture accumulation, and allowing for drying.

• Perfect barriers to moisture are virtually impossible to achieve; therefore, it is important that measures taken to keep out moisture do not also trap moisture—for example, waterproofing membranes that trap thermal insulation between a vapor retarder.

• It is essential to maintain a balance of the moisture that is able to accumulate in an assembly between drying cycles. Accumulation and drying are extremely dependent on the local climate. Some materials such as wood-framed walls and masonry have the capacity to absorb relatively large quantities of moisture and to then later dry out without damage or deterioration. Other systems such as gypsum board on metal studs have very little capacity for the storage of moisture.

• The source of water is primarily rain, which should be limited by a reasonably detailed assembly based on the expected amount of precipitation. The precipitation map in Figure 2.2 shows recommended enclosure types along with the required performance to minimize water entry.

• Below grade, the primary source of moisture is through capillary action that can be controlled through membranes and capillary breaks.

• Sources of vapor may be in the interior or exterior environment. Vapor retarders have been the traditional method used to control vapor movement, but their use in mixed heating and cooling climates must be carefully evaluated to allow drying.

• Moisture control in the solid state (i.e., ice) depends on not letting liquid water freeze; or, if it does, allowing room for expansion. For example, cold roof surfaces that eliminate thawing also prevent ice buildup, and air-entrained concrete provides room for ice crystals to expand.

Figures 2.3 and 2.4 show details of wall assemblies that can be used for analysis of drying under various climatic conditions. The various assemblies are somewhat independent of the cladding type. Other wall assemblies, including face-sealed or massive barrier assemblies, should receive similar analysis of HAM control. Two useful tools for this purpose are:

•

Computerized modeling of wetting and drying of walls: This is widely available and is very helpful to understanding moisture accumulation and drying. Analysis is recommended for large projects and any assembly that requires seasonal drying. Mixed climates may be the most difficult to predict by rule of thumb or empirical analysis. WUFI, developed by the Fraunhofer Institute for Building Physics in Germany with a North American version developed jointly with Oak Ridge National Laboratory (

www.ornl.gov) is widely recognized modeling tool. Similar software is available through

www.virtual-north.com/download/OrderForm.pdf and

www.architects.org/emplibrary/HAMtoolbox.pdf.

• Manual analysis of simple two-dimensional diagrams of wall sections: This involves using temperature gradients plotted against dew point temperature or vapor-pressure gradients plotted against saturation pressure. For instructions refer to “Design Tools,” by Anton TenWolde (Chapter 11 in the manual Moisture Control in Buildings [MNL18], Heinz R. Trechsel, editor, published by ASTM, 1994).

CONSIDERATIONS FOR CLIMATE ZONES

GENERAL

• Refer to specific information for each material for more information regarding selection criteria and proper detailing.

• Include only one vapor retarder in a wall assembly, and ensure that all other materials are increasingly permeable from the vapor retarder out.

• It is acceptable (and sometimes desirable) to provide more than one air barrier in a wall assembly.

• It is generally desirable to protect blanket insulation from airwashing with an air barrier on the cold side.

ALL CLIMATES

• Highly reliable enclosure system to control HAM in all climate zones, without relying on building mechanical systems to dry interior air.

• Thermal insulation located outside of structure and wall framing allows easy installation of continuous air barriers and vapor retarders.

• Thermal insulation must be continuous to prevent the vapor retarder from reaching the dew point.

• Excellent choice for masonry veneer over CMU or metal stud backup systems.

• If metal stud backup systems are used, do not place thermal insulation between the studs.

• Any paint or wall covering is allowed on interior finish.

COLD CLIMATES (Zones 5 to 8)

• Materials should be progressively more permeable, because they are located closer to exterior face.

• Any paint or wall covering is allowed on interior finish.

• Mechanical system is not required to dry interior air.

• Failure of the building paper may allow moisture accumulation that cannot be overcome by drying.

• Elements penetrating thermal insulation, (such as beams supporting a projecting canopy or the sump pan of roof drains) can cause condensation problems, unless they are insulated with closed-cell thermal insulation or a thermal insulation with a vapor retarder to keep moisture-laden air from getting to these surfaces. This is particularly true for occupancies with high humidity, (including residences, hospitals, museums, swimming pools,).

ALL CLIMATES AND COLD CLIMATES

2.3

HOT CLIMATES (Zones 1, 2, and 3)

• The mechanical system must provide dehumidification of interior air for drying.

• Avoid any vapor-impermeable interior finishes (e.g., a vinyl wall covering that will trap moisture).

• A radiant barrier may be incorporated into the cavity.

• Taped joints in sheathing, board insulation, or a combination may provide air barrier.

• An air barrier is crucial to limit moisture transport through imperfections in the vapor retarder.

MIXED CLIMATES (Zones 3 and 4)

• All materials must be relatively vapor-permeable to allow drying in both directions, because seasons change direction of heat flow and vapor drive.

• Detail system with interior and exterior side-permeable air barriers to limit moisture transport and infiltration/exfiltration.

• May be possible to use board insulation with taped joints as sheathing, which will form a vapor retarder if board and blanket insulation have approximately the same U-value.

SUSTAINABILITY AND ENERGY

The building shell should be a major part of the sustainable strategy. At a minimum, the shell should:

• Contribute to minimizing energy usage.

• Incorporate environmentally sensitive materials.

HOT, HUMID CLIMATES AND MIXED CLIMATES

2.4

• Ensure good indoor air quality and occupant comfort.

• Be durable.

For high-performance building projects, the enclosure could help generate energy, return nutrients to the environment, and filter pollutants.

One area of special concern for the building shell is durability, even though it currently is not included in LEED evaluations in the United States. (It is included in Canadian LEED programs). The building superstructure and enclosure are frequently portions of the building that should last the longest and are the most difficult to repair or replace. Buildings that perform well for many years slow or reduce the consumption of resources and the wastestream. Failures of the enclosure can lead not only to water-damaged materials needing repair or replacement but also to unnecessary long-term energy consumption, toxic mold, and sick buildings.

Buildings are major consumers of energy, so the enclosures should be part of a strategy to reduce energy consumption. In fact, creating a well-performing enclosure is considered to be the first step in reducing energy usage, ahead of other more sophisticated strategies, such as high-performance mechanical systems. A thorough understanding of the interior and exterior environments is paramount. For residential buildings in cold climates, heat loss through the enclosure may be the largest component of total energy consumption. For large commercial buildings in a moderate environment, daylighting schemes may save more energy, even as they may result in an enclosure with lower thermal resistance.

Most jurisdictions require compliance with an energy conservation code. ASHRAE 90.1 and the International Energy Code (in various editions) are common model codes. These minimum standards should be exceeded by 20 to 50 percent, if possible.

Consult the following references:

• Designing the Exterior Wall: An Architectural Guide to the Vertical Envelope by Linda Brock (John Wiley & Sons, Inc., 2005)

• Moisture Control Handbook: Principles and Practices for Residential and Small Commercial Buildings by Joseph W. Lstiburek and John Carmody (John Wiley & Sons, Inc. 1996)

• Water in Buildings: An Architect’s Guide to Moisture and Mold by William B. Rose (John Wiley & Sons, Inc., 2005)

NOTES

2.3 and 2.4 Provide an air barrier in the assembly at one or more of the locations noted by properly detailing either the inner layer of gypsum board, the sheathing layer, or the permeable weather barrier. The inner gypsum board can be made an air barrier by sealing the perimeter, penetrations, and transitions to adjacent air barrier assemblies. The sheathing can be made an air barrier through similar means of sealing all joints, penetrations, and transitions. Using a membrane over the sheathering (either fluid-applied or sheet material) that is vapor permeable, weather-resistant, anmd airtight is extremely effective for providing an air barries with the added benefits of simple installation and inspection.

SUPERSTRUCTURE

FLOOR CONSTRUCTION

This section of the chapter examines common floor construction assemblies. Consult literature from manufacturers and trade associations for more details on the information presented in the accompanying tables.

FLOOR STRUCTURAL FRAME

CONCRETE CONSTRUCTION

The information presented here is intended only as a preliminary design guide. All structural dimensions for slab thickness, beam and joint sizes, column sizes, should be calculated and analyzed for each project condition by a licensed professional engineer.

Spans shown in the accompanying figures and tables are approximate and are based on use of mild reinforcing steel. For spans greater than 40 ft, consider post-tensioning.

Consider embedded items such as conduits and penetrations for ducts and pipes when coordinating a structural system. Concrete floor construction may have less flexibility for locating large duct openings close to beam lines or small penetrations immediately adjacent to columns.

FLAT PLATE

2.5

FLAT SLAB

2.6

BANDED SLAB

2.7

JOIST SLAB

2.8

SKIP JOIST

2.9

WAFFLE SLAB

2.10

ONE-WAY SLAB

2.11

TWO-WAY SLAB

2.12

Contributor:

Russell S. Fling, PE, Columbus, Ohio.

FLOOR STRUCTURE ASSEMBLIES

2.13

Contributors:

Roger K. Lewis, FAIA, and Mehmet T. Ergene, architect, Roger K. Lewis & Associates, Washington, DC.

CONCRETE FLOOR SYSTEM COMPARISON

2.14

Contributors:

Russell S. Fling, PE, Columbus, Ohio; Roger K. Lewis, FAIA, and Mehmet T. Ergene, architect, Roger K. Lewis & Associates, Washington, DC.

PRESTRESSED AND POST-TENSIONED CONCRETE

Concrete by itself is inherently strong in tension and weak in compression. There are two procedures used for placing concrete in compression. Prestressing of the reinforcing steel occurs prior to placement of concrete and is used almost exclusively with precast concrete. Post-tensioning is the permanent tensioning of reinforcing steel for cast-in-place concrete.

• Concrete strength is usually 5000 psi at 28 days, and at least 3000 psi at the time of post-tensioning. Use hard-rock aggregate or lightweight concrete. Low-slump-controlled mix concrete is required to reduce shrinkage. Concrete shrinkage after post-tensioning decreases strength gains.

• Post-tensioning systems can be divided into three categories depending on whether the tendon is wire, strand, or bar. Wire systems use 0.25-in. diameter wires that have a minimum strength of 240,000 psi, and are usually cut to length in the shop. Strand systems use tendons (made of seven wires wrapped together) that have a minimum strength of 270,000 psi, and are cut in the field. Bar systems use bars ranging from 5/8- to 13/8-in. diameter, with a minimum strength of 145,000 psi, and may be smooth or deformed. The system used determines the type of anchorage used, which in turn affects the size of blockout required (in the edge of slab or beam) for the anchorage to be recessed.

• Grease and wrap tendons, or place in conduits, to reduce frictional losses during stressing operations. Limit the length of continuous tendons to about 10 ft if stressed from one end. Long tendons require simultaneous stressing from both ends to reduce friction loss. Tendons may be grouted after stressing, or left unbonded. Bonded tendons have structural advantages that are more important for beams and primary structural members.

• Minimum average post-tensioning (net force per area of concrete) equals 150 to 250 psi for flat plates and 200 to 500 psi for beams. Exceeding these values by much causes excessive posttension loss because of creep.

POST-TENSIONING ANCHOR

2.15

• Field inspection of post-tensioned concrete is critical to ensure proper size and location of tendons, and to monitor the tendon stress. Check tendon stress by measuring the elongation of the tendon and by monitoring gauge pressures on the stressing jack.

• Make provisions for the shortening of post-tensioned beams and slabs caused by elastic compression, shrinkage, and creep. After the post-tensioning is complete, build shear walls, curtain walls, or other stiff elements that adjoin post-tensioned members and isolate them with an expansion joint. Otherwise, additional post-tensioning force will be required to overcome the stiffness of the walls and prevent cracking.

• Fire tests have been conducted on prestressed beam and slab assemblies according to ASTM E 119, “Standard Test Methods for Fire Tests of Building Construction and Material,” test procedures. They compare favorably with reinforced cast-in-place concrete. There is little difference between beams using grouted tendons and those using ungrouted tendons.

PRESTRESSED OR POST-TENSIONED BEAM

2.16

Contributor:

Leo A. Daly, Planning/Architecture/Engineering/Interiors, Omaha, Nebraska.

Consult the following references:

• Post-Tensioning Institute, Post-Tensioning Manual.

• Precast/Prestressed Concrete Institute, PCI Design Handbook - Precast and Prestressed Concrete.

• Design of Prestressed Concrete Structures, 1981, T.Y. Lin and Ned H. Burns, Wiley

• American Concrete Institute, Building Code Requirements for Structural Concrete and Commentary (ACI-318)

When working with a prestressed or post-tensioned beam, keep the following in mind:

• Prestressing force compresses the entire cross section of the beam, thereby reducing unwanted tension cracks.

• Permanent tension is introduced into the tendon and “locked in” with the stressing anchorage in one of two ways, though the principle in both cases is the same. In prestressed concrete, the tendon is elongated in a stressing bed before the concrete is poured. In post-tensioned concrete, the tendon is elongated after concrete has been poured and allowed to cure by means of hydraulic jacks pushing against the beam itself. Post-tensioned beams permit casting at the site for members too large or heavy for transporting from the factory to the site.

• Internal vertical forces within the beam are created by applying tension on the tendon, making the tendon begin to “straighten out.” The tension reduces downward beam deflection and allows for shallower beams and longer spans than in conventionally reinforced beams.

• Auxiliary reinforcing steel provides additional strength, and controls cracking and produces more ductile behavior.

• Use stirrups to provide additional shear strength in the beam and to support the tendons and longitudinal reinforcing steel. Stirrups should be open at the top to allow the reinforcing to be placed before the tendon is installed. After the tendons are placed, “hairpins” that close the stirrups may be used, when required.

POST-TENSIONED CONCRETE BEAM AND SLAB

2.17

UNBONDED SINGLE-STRAND TENDON INSTALLATION AT SLAB

2.18

Contributor:

Leo A. Daly, Plan ning/Architecture/Engineering/Interiors, Omaha, Nebraska.

UNBONDED SINGLE STRAND TENDON ANCHORAGE

2.19

GROUTED THREAD BAR ANCHORAGE

2.20

PRECAST CONCRETE FRAME

Precast concrete frame systems are ideal for highly repetitive structural frames such as parking garages and hotel/apartment/dormitory buildings. Precast concrete members can be precast structural concrete or precast architectural concrete in exposed locations.

Detailing of connections for both aesthetics and to protect embedded steel members from corrosion is crucial. Typically, welded or bolted connections are grouted after final adjustment and anchorage.

Using shear walls in both directions is the most common method to resist lateral loads. Stair/elevator cores and dwelling unit separation may also serve as shear walls.

PRECAST CONCRETE COLUMN

2.21

PRECAST CONCRETE FRAME

2.22

PRECAST CONCRETE BEAM AND GIRDER

2.23

DOWELED BEAM-TO-COLUMN CONNECTION

2.24

BEAM-TO-HAUNCHED COLUMN CONNECTION

2.25

NOTES

2.24 The beam sits on the bearing pad, which provides uniform bearing and accommodates small movements caused by shrinkage, creep, and temperature changes.

2.25 Steel haunches are smaller than concrete bearing pads, which is important if headroom is critical.

Contributor:

Richard J. Vitullo, AIA, Oak Leaf Studio, Crownsville, Maryland.

SPANDREL CONNECTION

2.26

STRUCTURAL STEEL FRAMING

MOMENT-RESISTING FRAME

A moment-resisting frame’s lateral stability and resistance to wind and seismic forces depend on a fixed connection of beams and columns. A moment-resisting connection is achieved when the top and bottom flanges of each beam are welded to the flanges of the connecting columns with full-depth welds. By directly welding the beam web to the column flange, the beam’s horizontal reaction to wind forces is transferred to the column. (A connection using web angles and high-strength bolts is also permitted.) The building’s floors are designed to act as diaphragms that connect all of the columns and beams, enabling the building to react as a unit.

Moment-resisting frames are uneconomical in tall steel buildings because the larger lateral forces in such structures can be handled more efficiently by compression and tension diagonal members, as found in braced frames. To save costs, often the upper stories of a braced-frame building use moment-resisting beam-column connections to resist wind loads.

MOMENT-RESISTING FRAME

2.27

BRACED CORE

In the braced core system, walls around elevator shafts and stairwells are designed to act as vertical trusses that cantilever up from the foundation. The chords of each truss are building columns; the floor beams act as ties. Diagonals placed in a K pattern (occasionally, in an X pattern) complete the truss. A system employing knee braces is used in seismic areas because of its greater capability to dissipate earthquake energy.

Braced core systems can be used efficiently in single-story buildings, as well as in buildings over 50 stories.

BRACED CORE

2.28

BRACING DIAGRAM

2.29

Following are characteristics and principles to keep in mind when working with structural steel framing:

• The high strength of steel provides for economical construction of relatively large structural bays.

• Major framing elements are typically W-shaped sections, or round, square, and rectangular hollow structural sections. Angles or channels may be used for architectural expression.

• Building codes require protection of the steel from fire, except for small or low-rise structures in some low-hazard occupancies.

• Horizontal loads from wind and seismic events must be resisted, typically by diagonal bracing, moment connections, or shear walls.

• Moment frames allow maximum floor plan flexibility, but typically increase weight and cost of the structural steel framing.

• Braced frames are cost-effective, but disrupt the floor plan if not carefully located around typical core elements such as stairs, shafts, and toilet rooms. Bracing typically is provided by angles or W-shapes, as well as hollow structural shapes. Rods and cables may be used for architectural expression.

• Shear walls, typically around shafts for stairs, ducts, and elevators, can be an effective lateral load design option. Shear walls can be constructed of steel plate, concrete, or reinforced CMU. Minimize openings in shear walls for doors and services.

• It may be effective to mix different lateral restraint methods. For a long, narrow building, bracing in the short direction with moment frames in the long direction may be effective.

• The floor or roof deck typically is designed to act as a diaphragm to transmit loads to the lateral restraint elements. Structures without a deck capable of transmitting loads (such as bar grating or metal roofing) may require diagonal bracing in the floor or roof framing.

• Open-web steel joists may be used within a main frame of structural steel for economy.

For more information, refer to the AISC Manual of Steel Construction.

FABRICATED FIREPROOFED STEEL COLUMNS

Fabricated fireproofed steel columns, (lally columns) are structural units that consist of load-bearing steel columns filled with concrete. This creates a column with increased load-bearing capacity in a space no larger than a standard column. Lally columns have fire-resistant characteristics when a layer of fireproofing material encases the structural column. Fire ratings typically range from two to four hours.

NOTES

2.28 Bracing design to be determined by structural engineer based on specific loading configurations.

2.29 a. Knee bracing introduces bending into columns and beams and may increase their size, but allows largest openings.

b. Cross or diagonal bracing is very efficient but limits opening location and size.

Contributors:

Donald J. Neubauer, PE, Neubauer-Sohn Consulting Engineers, Potomac, Maryland; Richard J. Vitullo, AIA, Oak Leaf Studio, Crownsville, Maryland.

FABRICATED FIREPROOFED STEEL COLUMNS

2.30

ARCHITECTURALLY EXPOSED STRUCTURAL STEEL FRAMING

The characteristics and principles to keep in mind when working with architecturally-exposed structural steel (AESS) include the following:

• AESS is structural steel superstructure, supporting all or portions of a building, which is left exposed in the finished work. Through layout and detailing, AESS is meant to contribute to the architectural expression.

• The challenge to successful use of AESS is to clearly specify and detail the level of quality required, which is substantially beyond the requirements for normal structural steel. Primary areas of concern are the quality of finish of the individual members, the quality of the methods of joining members together (particularly of welds), and the tolerances of the finished work.

• AESS frequently incorporates a variety of tension members fabricated of stainless steel and proprietary fittings.

• AESS may need special fire protection, such as intumescent coating or deluge sprinkler systems.

• For economy, it is worthwhile to carefully identify which portions of the AESS will be viewed in close proximity versus those that are farther away. Locate defects, welds, and connections on the side of assembly away from view, for economy.

Refer to AESS Supplement to “Modern Steel Construction” (May 2003), for explanation of how to specify AESS.

AESS CONNECTION

2.31

AESS WELDS

2.32

NOTE

2.31 Locate HSS seam away from line of sight, or grind smooth.

Contributors:

Anthony Golebiewski, AIA, Kling, Philadelphia, Pennsylvania; Eric Gastier, Alexandria, Virginia.

STEEL JOIST FLOOR FRAMING

Design consideration of steel joist floor framing should include:

• Ceilings: Ceiling supports can be suspended from or mounted directly to the bottom chords of joists. Suspended systems are recommended, because of dimensional variations in actual joist depths.

• Floor construction: Joists are usually covered by 2-1/2 to 3 in. of concrete on steel decking. Concrete thickness may be increased to accommodate electrical conduit or electrical /communications raceways. Precast concrete, gypsum planks, or plywood can also be used for the floor system.

• Vibration: Objectionable vibrations can occur in open web joist and 2-1/2-in. concrete slab designs for open floor areas at spans between 20 and 40 ft, in particular at 28 ft. When a floor area cannot have partitions, objectionable vibrations can be prevented or reduced by increasing slab thickness or modifying the joist span. Attention should also be given to support for framing beams, which can magnify a vibration problem when unsupported.

• Openings in floor or roof systems: Small openings between joists are framed with angles or channels supported on the adjoining two joists. Larger openings necessitating interruption of joists are framed with steel angle or channel headers.

• Adaptability: It is more difficult to alter joists, add openings, or change loading than with structural steel framing.

• Fireproofing: Applying fireproofing to joists is more difficult and expensive than to structural steel.

SECTION-THROUGH OPEN WEB STEEL JOIST BEARING

2.33

SECTION-THROUGH OPEN WEB STEEL JOISTS

2.34

SECTION-THROUGH LONG SPAN STEEL JOIST BEARING

2.35

SECTION-THROUGH LONG-SPAN STEEL JOIST

2.36

BOTTOM CHORD BEARING AT SQUARE END

2.37

BOTTOM CHORD EXTENSION DETAIL

2.38

NOTE

2.35 Web-member type depends on span and load characteristics.

Contributors:

Kenneth D. Franch, PE, AIA, Aguirre, Inc., Dallas, Texas; Charles M. Ault, Setter, Leach, & Lindstrom, Architects & Engineers, Minneapolis, Minnesota.

COLD-FORMED METAL FLOOR JOIST FRAMING

Cold-formed steel (CFS) floor framing uses C-shaped members that are cold-rolled from a steel sheet. CFS framing is laid out similar to traditional wood joist floor framing. Finishes may be a hot-dipped galvanized coating or shop primed. Fastening is typically selfdrilling, self-tapping screws, or welded.

Final engineering of CFS framing is commonly provided by a structural engineer hired by the installing contractor, based on a performance specification prepared by the architect and project structural engineer. This delivery method, known as delegated design, allows an optimization of the design of the CFS system. CFS framing characteristic vary by manufacturer. Based on preliminary investigation and other project design requirements, the design professional may select certain characteristics of the joists, for example depth or minimum spacing. The installer’s engineer will then select specific joists that conform to the design characteristics that also meet the structural performance criteria, including yield strength (33 or 50 ksi), joist gauge and flange width. CFS rim joists, plates, and other framing may require continuous insulation outside of the CFS element, to reduce thermal bridging and to comply with energy code.

BRIDGING

2.39

Joists are subject to twisting under load. Bracing of the top and bottom flange is required at approximately 1/3 points or 6 to 8 ft on center, depending on final design. Bridging is, typically, continuous top and bottom straps with solid blocking at ends, and periodically spaced. Structural sheathing or decking may reduce some or all of the bridging.

WEB STIFFENERS

2.40

Point loads at bearing points or from applied loads may cause crushing of the flange or folding of the web. Stiffeners from short lengths of a vertical joist, a sistered joist, or angles attached to the rim track may be required, as determined by final engineering.

OPENINGS

2.41

Joists may come factory-punched, with openings of approximately 1-1/2 by 4 in. at 24 in. on center, though this will vary by manufacturer. Additional openings, generally not larger than half the joist depth, may be added if individually analyzed during final engineering. Reinforcing plates may be required.

COLD-FORMED METAL JOISTS

2.42

Common Depths: 6, 7-1/4, 8, 9-1/4, 10, 11-1/2, 12, 14, and 16 in., consult manufacturers for available sizes.

Lengths up to 60 ft.

| FLANGE (IN.) | RETURN (IN.) |

|---|

| 1-3/8 | 5/16 to 3/8 |

| 1-5/8 | 1/2 to 9/16 |

| 2 or 2-1/2 | 9/16 to 11/16 |

| 3 or 3-1/2 | 1 |

FRAMING OF FLOOR OPENING 2.43

FLOOR JOISTS AT CONTINUOUS WALLS

2.44

JOISTS OVER BEAM OR BEARING WALL (CONTINUOUS SPAN)

2.45

FLOOR FRAMING AT EXTERIOR WALL

2.46

Consult the following reference:

• “Product Technical Information,” the Steel Stud Manufacturers Association (

www.ssma.com)

NOTES

2.44 Provide solid blocking and bridging as required.

2.45 a. Continuous bridging is required between each joist above a beam. Solid blocking in other spaces may be used in lieu of bridging. b. When a bearing wall is above, the studs must align with the joists below.

c. Web stiffeners are not required when continuous solid blocking is used.

Contributor:

American Iron and Steel Institute, Washington, DC.

FLOOR JOISTS SUPPORTED BY BEAM OR BEARING WALL (OVERLAPPED)

2.47

FLOOR JOISTS BEARING ON FOUNDATION

2.48

WOOD FLOOR FRAMING

This section examines the use of wood in floor framing assemblies.

WOOD FLOOR FRAMING MEMBERS

2.49

FLOOR FRAMING WOOD BEAMS

2.50

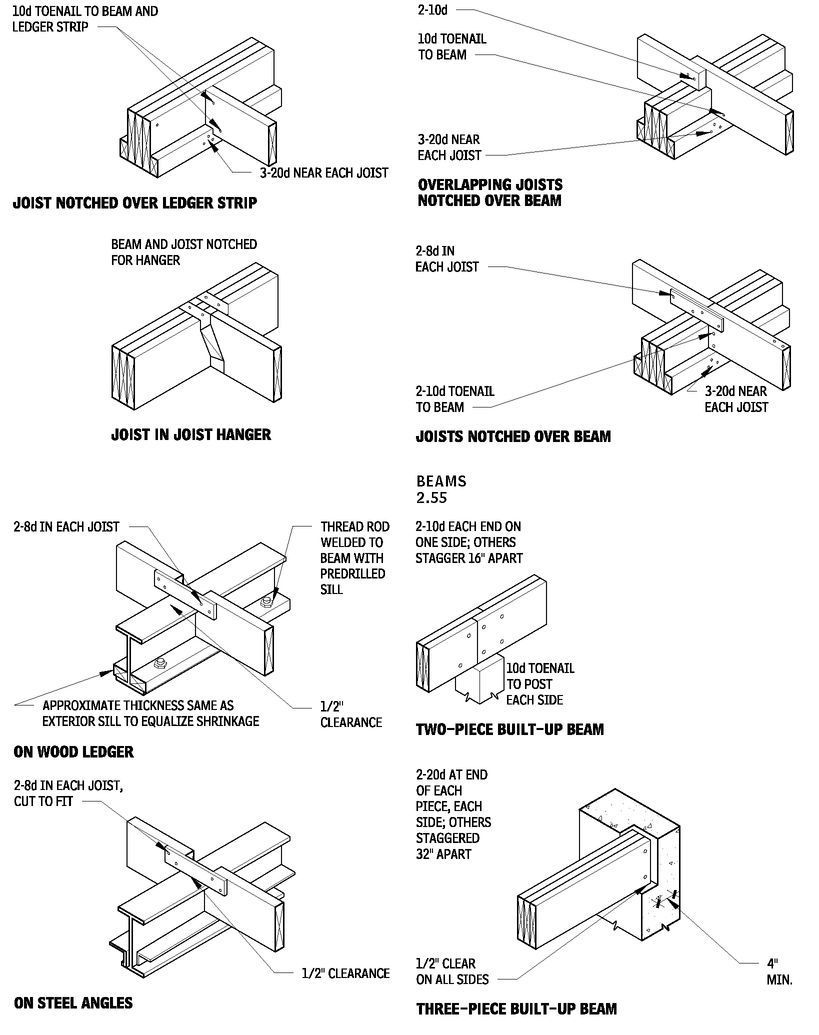

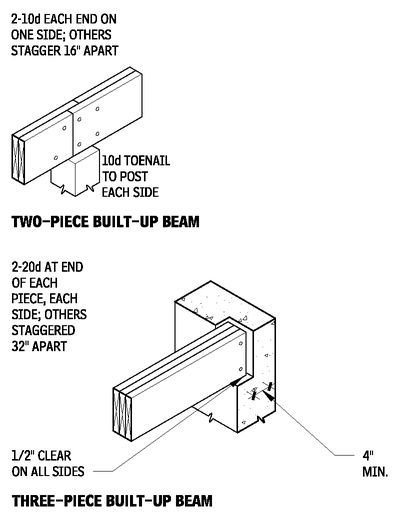

NOTES

2.47 a. Continuous bridging is required between each joist above a beam. Solid blocking in other space may be used in lieu of bridging.

b. When a bearing wall is above, studs must align with joists below. 2.50 a. Heavy timber beam: Timber beams are available in a variety of species and grades; Douglas fir is the strongest. Heavy timber uses rectangular solid-wood framing members that are a nominally a minimum of 5 in., in both dimensions.

b. Laminated veneer lumber (LVL) beam: Vertical factory-laminated sections are glued together. Actual widths are multiples of 1-3/4 in. (two pieces match thickness of 2 × 4 wall). Actual heights range from 5-1/2 to 18 in.

c. Parallel strand lumber (PSL) beam: Factory-glued composite beam made with long narrow strips of veneer, oriented along beam length. Actual widths are 3-1/2, 5-1/4, and 7 in. Heights range from 9-1/4 to 18 in.

d. Glue-laminated beam: Horizontal factory-glued laminations make a knot-free and very stable beam. Actual widths are 3-1/8, 5-1/8, 7-1/8 in., and so on. Heights are in multiples of 1-1/2 in.

e. Built-up beam: Dimension lumber is nailed together to form a single beam (four pieces maximum). Widths are multiples of 1-1/2 in. Height follows dimension lumber.

f. Flitch beam: A steel plate sandwiched between two pieces of lumber adds strength without substantially increasing the beam size. The lumber prevents buckling of the steel and provides a nailing surface. Widths are 3 to 3-1/2 in. Heights follow dimension lumber.

g. Box beam: 2 × 4 lumber is sandwiched between two plywood skins. Plywood is both nailed and glued to 2 × 4s and at all edges. Plywood joints must be offset.

WESTERN OR PLATFORM WOOD FRAMING

Before any of the superstructure is erected, the first-floor framing and subflooring is put down, making a platform on which the walls and partitions can be assembled and tilted into place. Because floor framing and wall frames do not interlock, adequate sheathing must act as bracing and provide the necessary lateral resistance. Where required for additional stiffness or bracing, metal strapping, or 1 × 4 may be let into the outer face of studs at 45° angles, secured at top, bottom, and to studs. The process is repeated for each story of the building.

Bridging may be omitted when flooring is nailed adequately to the joist. However, where nominal depth-to-thickness ratio of joists exceeds 6, bridging would be installed at 8-ft-0-in. intervals. Building codes may allow omission of bridging under certain conditions. Steel bridging is available. Some types do not require nails. For firestopping, all concealed spaces in framing, with the exception of areas around flues and chimneys, are to be fitted with 2-in. blocking arranged to prevent drafts between spaces.

Platform framing has essentially replaced balloon framing. Balloon framing with studs continuous from wood sill to top plate is rarely used, except in special locations (such as two-story spaces, at parapets, and similar situations where a structural cantilever of the wall is required).

PLATFORM FRAMING

2.51

NOTES

2.14 a. Roof framing may be level, I-joist, or trusses, shown in Figure 2.116.

b. Floor joists may be any of the framing members shown in Figure 2.50.

Contributor:

Timothy B. McDonald, Washington, DC.

PLATFORM FRAMING SECTION

2.52

FRAMING DETAILS FOR JOISTS AND SILLS

WOOD JOISTS SUPPORTED ON STEEL BEAM

2.53

WOOD JOISTS SUPPORTED ON WOOD BEAM

2.54

BEAMS

2.55

BRIDGING

2.56

SILL FOR PLATFORM FRAMING

2.57

Contributor:

Joseph A. Wilkes, Wilkes and Faulkner, Washington, DC.

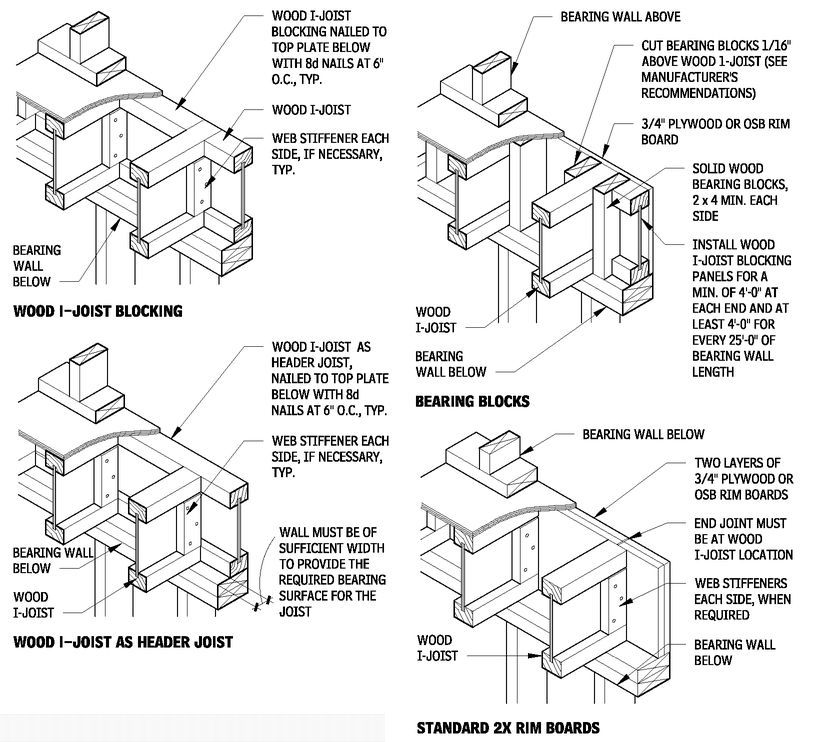

WOOD I-JOIST FLOOR FRAMING DETAILS

2.58

FLOOR DETAILS AT BEARING INTERIOR PARTITION

2.59

Contributors:

Joseph A. Wilkes, Wilkes and Faulkner, Washington, DC; John Ray Hoke, Jr., FAIA, Washington, DC.

FLOOR DETAILS AT NONBEARING INTERIOR PARTITIONS

2.60

FLOOR CANTILEVERS

2.61

NOTE

2.61 a. Any extension greater than 2 must be engineered.

Contributors:

Joseph A. Wilkes, Wilkes and Faulkner, Washington, DC; John Ray Hoke, Jr., FAIA, Washington, DC.

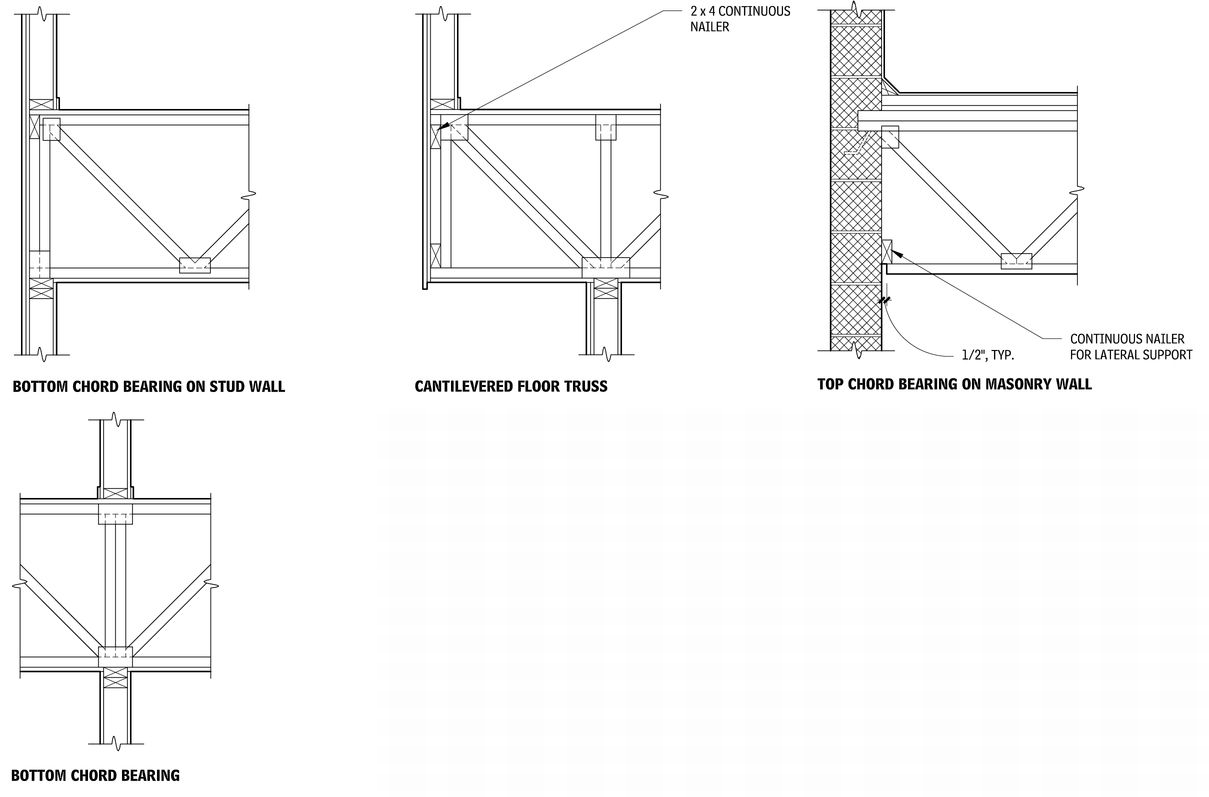

SHOP-FABRICATED WOOD TRUSSES

2.62

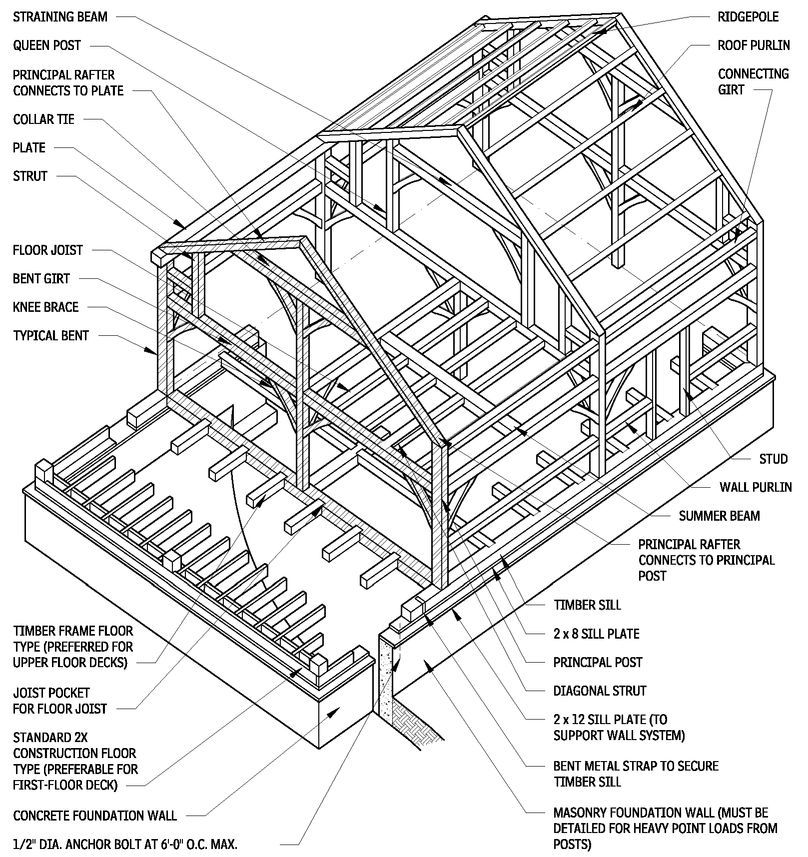

TYPICAL TIMBER FRAME (SHOWING TWO-ROOF AND FLOOR TYPES)

2.63

HEAVY TIMBER CONSTRUCTION

Heavy timber construction is characterized by large, exposed timber columns, beams, and other structural members, joined together by traditional pegged mortise-and-tenon or similar joints. Heavy timber uses rectangular solid-wood framing members that are a nominally a minimum of 5 in., in both dimensions. Heavy timber fabricated timber frame modules are called bents. Bents run perpendicular to the ridge, and include the primary columns, beams, girders, and rafters, and knee braces. Bents are typically spaced 10 to 16 ft on center. Note that alternate framing methods running parallel to the ridge, or utilizing systems similar in concept to platform framing, are available from some timber framers. Knee braces typically provide bracing against lateral loads.

Heavy timber structures are typically enclosed with stressed-skin insulated panels, leaving the frame totally exposed on the interior. Heavy timber construction is being updated with modern materials such as glulam members and proprietary concealed metal connections.

NOTE

2.63 Shaded members represent components of a typical bent.

Contributors:

Tedd Benson and Ben Brungraber, PhD, PE, Benson Woodworking Co., Inc., Alstead, New Hampshire; Timothy B. McDonald, Washington, DC; Richard J. Vitullo, AIA, Oak Leaf Studio, Corwnsville, Maryland.

SHOULDERED MORTISE-AND-TENON JOINT

2.64

A beveled shoulder or housed joint is used to connect all load-bearing beams (such as bent and connecting girts and summer beams) to posts. Angled variations can be used when principal rafters join to posts or for diagonal braces. The depth of the shoulder depends on loading, torsion, other joinery in the area, and wood species.

BASIC MORTISE-AND-TENON JOINT

2.65

The basic mortise-and-tenon joint can be very effective in resisting both tension and compression forces. To increase tensile strength, increase the depth and thickness of the tenon and use additional pegs if the width and length of the tenon allow.

TUSK AND SOFFIT TENON JOINT

2.66

OPEN MORTISE-AND-TENON JOINTS

2.67

LAP JOINTS

2.68

Contributors:

Tedd Benson and Ben Brungraber, PhD, PE, Benson Woodworking Co., Inc., Alstead, New Hampshire; Richard J. Vitullo, AIA, Oak Leaf Studio, Corwnsville, Maryland.

GLUED-LAMINATED CONSTRUCTION

The term glued-laminated construction refers to an engineered, stress-rated product made of wood laminations bonded with adhesives, with the grain approximately parallel lengthwise. Laminated pieces can be end-joined to form any length, be glued edge to edge to make wider pieces, or be of bent pieces curved during the laminating process.

STANDARD DEPTHS

Dimension lumber surfaced to 1-1/2 in. is used to laminate straight members and members that have a curvature within the bending radius limitations for the species. Boards surfaced to 3/4 in. are recommended for laminating curved members when the bending radius is too short to permit the use of dimension lumber, provided that the bending radius limitations for the species are observed. Other lamination thicknesses may be used to meet special requirements.

STANDARD WIDTHS

2.69

| NOMINAL WIDTH (IN.) | NET FINISHED WIDTH (IN.) |

|---|

| 3 | 2-1/8 |

| 4 | 3-1/8a |

| 6 | 5-1/8a |

| 8 | 6-3/4 |

| 10 | 8-3/4a |

| 12 | 10-3/4a |

| 14 | 12-1/4 |

| 16 | 14-1/4 |

CONNECTION DESIGN

The design of connections for glued-laminated construction is similar to the design of connections for dimension lumber. Since glued-laminated members often are much larger than dimension lumber, and the loads transferred are larger, the effect of increased size should be taken into account in the design of connections. In addition to being designed for strength to transfer loads, connections also should be designed to avoid splitting of the member, as well as to accommodate swelling and shrinking of the wood.

FIRE SAFETY

Similar in nature to those of heavy timber, the self-insulating qualities of glued-laminated construction cause the members to burn slowly. Good structural details, elimination of concealed spaces, and use of vertical fireblocking contribute to its fire resistance and ability to retains its strength longer than unprotected metals.

Therefore, building codes generally classify glued-laminated construction as heavy timber construction if certain minimum dimensional requirements are met. Codes also allow for calculation of one-hour fire ratings for exposed glue-laminated members.

It is not recommended that fire-retardant treatments be applied to glued-laminated members because they do not substantially increase the fire resistance. In considering fire-retardant treatments, it is essential to investigate the following: reduction of strength related to type and penetration of treatment, compatibility of treatment and adhesive, use of special gluing methods, difficulty of application, and effect on wood color and fabrication process.

PROPRIETARY CONNECTIONS

2.70

PURLIN-TO-BEAM CONNECTION

2.71

BEAM-TO-GIRDER CONNECTION

2.72

NOTES

2.69 a. Widths are 3, 5, 8-1/2, and 10-1/2 in. for southern pine.

2.70 a. Most typical connections can be accomplished with concealed or semiconcealed fasteners.

b. Final engineering is by manufacturer.

Contributor:

Timothy B. McDonald, Washington, DC.

FLOOR DECKS AND SLABS

PRECAST CONCRETE DECKS AND SLABS

Normal weight (150 pcf) or lightweight concrete (115 pcf) is used in standard precast concrete slab construction. Concrete topping is usually normal-weight concrete with a cylinder strength of 3000 psi. All units are prestressed with strand release once concrete strength is 3500 psi. Strands are available in various sizes, strengths, and placements, according to individual manufacturers.

Camber varies substantially depending on slab design, span, and loading. Nonstructural components attached to members may be affected by camber variations. Calculations of topping quantities should recognize camber variations. Safe superimposed surface loads include a dead load of 10 psf for untopped concrete and 15 psf for topped concrete. The remainder is live load.

FLAT DECK MEMBERS

2.73

SINGLE OR DOUBLE TEE MEMBERS

2.74

FLAT DECKS

2.75

TEE DECKS

2.76

TEE DECKS DAPPED

2.77

Contributor:

Timothy B. McDonald, Washington, DC.

FILIGREE SLABS

Filigree slabs combine desirable characteristics of cast-in-place and precast concrete. The precast filigree panels act as permanent forms for the field-placed reinforcing and cast-in-place (CIP) topping. Slabs can be used with CIP frame, precast frame, or steel frame or with bearing wall construction. The underside of the filigree panels is smooth enough to remain exposed.

METAL FLOOR DECKING

When designing with metal decking, two guidelines are important to follow:

• When lightweight concrete is used in the construction, use galvanized deck material.

• In a fire-resistant assembly, ensure that metal components are unprimed.

These are some advantages of metal floor decks:

• They provide a working platform, eliminating temporary wood planking in high-rise use.

• Composite decks provide positive reinforcement for concrete slabs.

• Both noncomposite and composite decks serve as forms for concrete, eliminating the need for forming and stripping.

• Acoustical treatment is possible.

• Electric raceways may be built into the floor slab.

• Metal floor decking provides economical floor assemblies.

Consult independent testing laboratory directories for specific firerating requirements.

FILIGREE FLAT PLATE

2.78

FILIGREE ON STEEL

2.79

COMPOSITE FLOOR DECK WITH CONCRETE FILL

2.80

NOTE

2.78 Required field placed reinforcing steel not shown for clarity.

Contributors:

Midstate Filigree Systems,

www.filigreein.com; Donald J. Neubauer, PE, Neubauer-Sohn, Consulting Engineers, Potomac, Maryland; Walter D. Shapiro, PE, Tor, Shapiro & Associates, New York City, New York.

NONCOMPOSITE FLOOR DECK WITH CONCRETE FILL

2.81

COMPOSITE AND NONCOMPOSITE CELLULAR FLOOR DECK WITH CONCRETE FILL

2.82

ELECTRICAL TRENCH DUCT

2.83

FLOOR DECK ACCESSORIES

2.84

WOOD DECKING

POST AND BEAM CONNECTIONS

2.85

NOTES

2.83 a. Electric raceways may be built into floor slabs by using cellular deck or special units that are blended with plain deck. Two-way distribution is achieved by using trench ducts that sit astride the cellular units at right angles.

b. Using trench ducts with composite floor deck may reduce or eliminate entirely the effectiveness of composite action at the trench duct. This is also true for composite action between steel floor beams and concrete fill. Trench duct locations must be taken into account in deciding whether composite action is possible.

2.84 A convenient, economical means of supporting lightweight acoustical ceilings is to attach a suspension system to hanger tabs at side laps, pierce tabs driven through the deck, or prepunch tabs in the roof deck. Do not use this tab-and-metal deck arrangement to support plaster ceilings, piping, ductwork, electrical equipment, or other heavy loads. Such elements must be suspended directly from structural members or supplementary subframing.

Contributors:

Donald Neubauer, PE, Neubauer Consulting Engineers, Potomac, Maryland; Walter D. Shapiro, PE, Tor, Shapiro & Associates, New York City, New York; The Bumgardner Architects, Seattle, Washington.

RAILINGS

2.86

CONNECTIONS AT BUILDING

2.87

DECKING APPLICATIONS

2.88

WOOD SELECTION

When it comes to selecting wood for decking, characteristics should include effective resistance to decay, nonsplintering, stiffness, strength, hardness, and warp resistance. Species selection will vary according to local climate and structure.

NOTE

2.88 Spacing of 1/4 in. is not recommended for walking surfaces where high heels are anticipated.

Contributor:

The Bumgardner Architects, Seattle, Washington.

RELATIVE COMPARISON OF VARIOUS QUALITIES OF WOOD USED IN DECK CONSTRUCTION

2.89

WALKWAYS AND RAMPS

2.90

POST BASES

2.91

DECK EDGES

2.92

STEPS AND STAIRS

2.93

NOTES

2.89 a. Includes West Coast and eastern hemlocks.

b. Includes western and northeastern pines.

c. Categories refer to semitransparent oil-base stain.

d. Use pressure-preservative-treated material only. All materials below deck surfaces should be pressure-treated.

e. Ipe used typically for decking only, not framing.

Contributors:

The Bumgardner Architects, Seattle, Washington; Mark J. Mazz, AIA, CEA, Inc., Hyattsville, Maryland.

POSTS AND FOOTINGS

2.94

FASTENERS

Guidelines for selecting fasteners include:

• Use hot-dipped galvanized fasteners to avoid corrosion and staining.

• Preservative treated wood requires stainless steel fasteners or special heavy galvanized coating recommended by the treatment manufacturer.

• To reduce board splitting by nailing, do the following: blunt nail points, predrill (3/4 of nail diameter), stagger nailing, and place nails no closer to the edge than one-half of board thickness.

• Avoid end-grain nailing and toenailing, if possible.

• Use flat washers under heads of lag screws and bolts, and under nuts.

In addition, note that hot-dipped galvanized casing nails or stainless steel deck screws are typically the best type of decking fasteners, and plated ring shank or spiral groove shank nails are suitable for arid climates.

PRESERVATIVE WOOD TREATMENT

To protect wood decking from moisture, follow these guidelines:

• Protect wood members from weather by preservative wood treatment.

• Treat wood in direct contact with soil or concrete with preservative.

• Ensure that the bottoms of posts on piers are 6 in. above grade.

• Sterilize or cover soil with membrane to keep plant growth away from wood members, to minimize moisture exchange.

• Treat ends, cuts, and holes, with preservative before placement.

• Kerf decking and flat-trim boards, 2 by 6 and wider, on the underside with 3/4-in.-deep saw cuts at 1 in. o.c., to prevent cupping.

• Avoid horizontal exposure of end grain, or provide adequate protection by flashing or sealing. Avoid or minimize joint conditions where moisture may be trapped by using spacers and/or flashing, caulking, sealant, or plastic roofing cement.

BRACING

On large decks or decks where post heights exceed 5 ft, lateral stability should be achieved with horizontal bracing (metal or wood diagonal ties on top or bottom of joists or diagonal application of decking), in combination with vertical bracing (rigid bolted or gusseted connections at tops of posts, knee bracing, or cross bracing between posts), and/or connection to a braced building wall. Lateral stability should be assessed by a structural engineer.

MACHINE-SHAPED DECKING TYPES

2.95

LAMINATED DECKING

2.96

WOOD DECKING JOINT PATTERNS

2.97

DECKING JOINTS

2.98

Contributors:

The Bumgardner Architects, Seattle, Washington; Mark J. Mazz, AIA, CEA, Inc., Hyattsville, Maryland; David S. Collins, FAIA, American Forest and Paper Association, Cincinnati, Ohio; Timothy B. McDonald, Washington, DC.

FLOOR CONSTRUCTION VAPOR RETARDERS, AIR BARRIERS, AND INSULATION

CRAWL SPACE INSULATION AND VENTILATION

The best understanding of the interrelated issues surrounding control of heat, air, and moisture (HAM) inside crawl spaces and the transfer of HAM to the building interior suggests that it is preferable to treat the crawl space as part of the interior conditioned environment.

Arguments against ventilating crawl spaces include:

• Venting of a crawl space is meant to keep moisture within acceptable levels, pulling hot, humid air into the space is counterproductive, especially when it is likely that the ground surface temperatures may be below the dew point temperature.

• Insulated floor assemblies are rarely constructed airtight and, allow air infiltration/exfiltration.

• Insulated floor assemblies are rarely as warm or as comfortable as floors with a conditioned environment on both sides.

• Conditioned spaces above hot, humid, ventilated crawl spaces create a vapor drive, which may result in excess load on the HVAC, uncontrolled condensation, and potentially rot and mold.

• Crawl spaces are frequently used for distribution of mechanical ductwork. The distribution ductwork is outside of the thermal envelope and, therefore, experiences greater loss than if interior to the thermal envelope. The penetrations required for the ductwork create more opportunities for air leakage between the conditioned and unconditioned space. In hot, humid conditions, there is a likelihood that the vapor retarder on the duct insulation will not be perfect, causing condensation on the ductwork to occur, thereby adding more moisture to an already damp environment.

• Sanitary sewer and domestic water supply lines likely pass through the unconditioned crawl space and may be susceptible to freezing and condensation.

Recommendations for crawl spaces include the following:

• Codes generally require ventilation of crawl spaces; however, they also provide exemptions for a variety of conditions, specifically: “where warranted by climatic conditions,” “where continuously operated mechanical ventilation is provided,” and “when the perimeter walls are insulated.” Most exemptions require the ground surface to be covered with a vapor retarder. Refer to the specific building codes in effect for all requirements.

• Cover the ground surface in the crawl space with a vapor retarder. Tape seams and seal penetrations. Consider protecting the vapor retarder with a rough concrete mud slab. Mechanically fasten the retarder to the foundation at the perimeter with a nailing strip. In cold climates, it may be desirable to insulate the entire ground surface.

• Insulate the crawl space walls as required by code. Follow recommendations for exterior walls regarding the permeability of insulation materials, air sealing, and the use of vapor retarders. Insulation may need to be fire-rated, especially board insulation; or use noncombustible-type insulation. If possible, locate insulation outside of the dampproofing on the foundation wall.

• Ventilate the crawl space, typically with a small supply duct at code-specified rate, normally 1 cfm for each 50 sq ft, and provide connection to the return air plenum, either directly or through the interior space above via transfer grilles. Locate the supply and return points to evenly mix and distribute the air.

• Alternative crawl space drying methods include a permanent dehumidifier or exhaust fans controlled by humidistats, with makeup air from the interior and ducted to the exterior. However, this solution may use a large amount of energy.

• Pay attention to exterior wall detailing and proper drainage to keep water away from the crawl space.

• Crawl spaces used as the supply plenum to the remainder of the house require special treatment to maintain air quality.

CRAWL SPACE VENTILATION MATERIALS

2.99

VENTILATED CRAWL SPACE

2.100

CONDITIONED CRAWL SPACE

2.101

WOOD FRAME OVER CRAWL SPACE (COLD CLIMATE)

2.102

Contributors:

Joe Lstriburek, Building Sciences Corporation, Richard J. Vitullo, AIA, Oak Leaf Studio, Crownsville, Maryland; Eric Gastier, Alexandria, Virginia.

WOOD FRAME OVER CRAWL SPACE (MIXED CLIMATE)

2.103

INSULATING UNDERSIDE OF STEEL AND CONCRETE FLOOR STRUCTURES

2.104

Two primary difficulties encountered with the insulation of floor assemblies are providing a continuous vapor retarder on the warm side, and keeping the floor warm, even with insulation. In cold climates, the floor will be uncomfortable for any long-term occupancy. If possible, it is best to avoid insulation applied directly to the bottom of floor assemblies; instead, use an insulated soffit. If direct application is unavoidable, consider the following two following methods:

• Board insulation is typically applied to the underside of the structure by impaling over adhesive-applied stickpins and crimped with large washers. Mineral wool insulation is a good choice because it is noncombustible and performs well even if it becomes slightly damp from condensation.

• Sprayed insulation can be cellulose-based, mineral-based, or foam. Closed-cell foam can eliminate the need for a separate vapor barrier.

ROOF CONSTRUCTION

This section examines common systems used in roof construction. Consult literature from manufacturers and trade associations for more details on the information presented in the accompanying tables.

Contributors:

Joe Lstriburek, Building Sciences Corporation, Richard J. Vitullo, AIA, Oak Leaf Studio, Crownsville, Maryland; Eric Gastier, Alexandria, Virginia.

ROOF STRUCTURE ASSEMBLIES

2.105

Contributors:

Roger K. Lewis, FAIA, and Mehmet T. Ergene, architect, Roger K. Lewis and Associates, Washington, DC.

Contributors:

Roger K. Lewis, FAIA, and Mehmet T. Ergene, architect, Roger K. Lewis and Associates, Washington, DC.

LONG-SPAN AND TENSILE STRUCTURES

DESIGN CONSIDERATION FACTORS

Examples of long-span structures shown in Table 2.126 are rated for their capability to address the following design factor conditions.

NATURAL CONDITIONS

A. Uneven or excessive snow and ice loads: Geometry, equipment, or surrounding structure may contribute to snow drifting or ice buildup.

B. Ponding: Provide positive drainage to remove water from the structure when roof drains clog.

C. Wind: Evaluate potential of wind-induced destructive vibration in members or connections.

D. Thermal: Daily and seasonal temperature cycles can cause significant changes in structural shape and member stresses, and may lead to fatigue failure.

E. Freeze/thaw cycles or corrosive atmosphere: Evaluate long-term effects on structural performance, particularly for exposed concrete structures.

PRIMARY STRESSES

F. Load paths: Two or more load paths for all loads should be provided wherever possible. The greater the area a single member supports, the greater should be its safety factor.

G. Compression failure: Resistance to lateral buckling of long members is crucial. Use members that ensure initial and verifiable alignment.

H. Tension failure: Dynamic stability under wind or other vibration loading should be carefully verified.

SECONDARY STRESSES

I. Deflection: Changes in orientation of members at joints can increase distructive stresses from loads.

J. Member interaction: Load flows through structures in such a way as to minimize strength. Check all possible load paths of complex geometric structures.

K. Nonstructural connections: Assemblies attached to a structure will influence structural load flow and even become part of the load flow if the attachment changes the deflected shape.

L. Scale: Most members have a span limit, beyond which weight of the member itself becomes a limiting factor.

M. Stress concentration: Check stresses at changes of cross sections, holes, and connections. High-strength materials are particularly sensitive.

TOLERANCES

N. Erection alignment: True member length and spatial position are crucial for proper alignment and load flow.

O. Creep: Length changes over time will influence both primary and secondary stresses.

P. Supports and foundations: Supports must accept movements due to deflections from primary and secondary stresses and differential foundation settlement.

QUALITY CONTROL

Q. Design: Engineering design must not be compromised by time, scheduling, design changes, or building codes.

R. Methods: Construction methods should be selected carefully to safely and accurately locate the structural components.

S. Site observation: Only when the structure is properly established in space should it be accepted. Changes in construction materials or methods should be carefully evaluated.

T. Structural building maintenance: Conditions and alignment of various members, especially crucial nonredundant members, should be verified on a regular schedule. Consider using equipment to detect excessive deflection.

U. Nonstructural building maintenance: The condition of building components should not adversely affect the structure (e.g., keep roof drains open, prevent excessive equipment vibration, and maintain expansion joints).

LONG-SPAN COMPONENTS

2.106

NOTES

2.106 a. Steel is A-36; wood is laminated, sometimes heavy timber; concrete is reinforced with steel; prestressed concrete is prestressed with steel.

b. Cable-stayed system can give auxiliary support to trusses, beams, or frames, greatly reducing span and member sizes, but providing additional tensional strength.

c. Lamella arches provide two-way arch structures and improve redundancy.

d. Domes may also be constructed of aluminum.

e. Pneumatics are fabric roofs, pressurized, and stabilized with steel cables.

f. For each system, the following notation applies: the bullet (•) indicates the typical configuration; the dash (—) indicates occasionally used.

Contributor:

William C. Bauman, Jr., University of Oklahoma, Norman, Oklahoma.

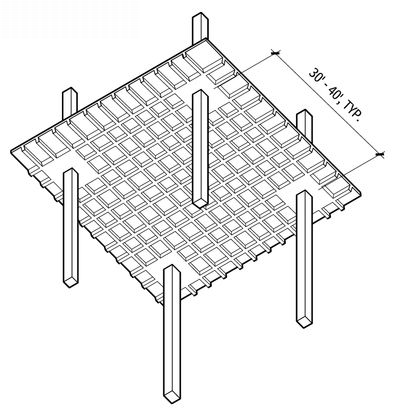

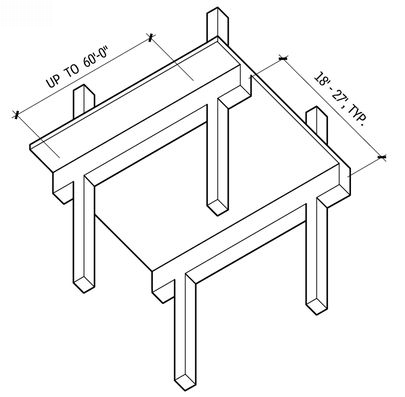

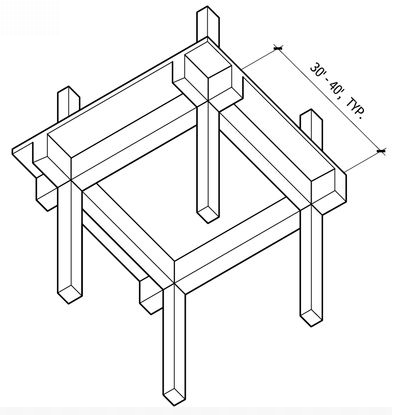

SPACE FRAMES

A space frame is a three-dimensional truss with linear members that form a series of triangulated polyhedrons. It can be seen as a plane of constant depth that can sustain fairly long spans and varied configurations of shape.

Space frames prime attributes include:

• Light weight

• Inherent rigidity

• Wide variety of form, size, and span

• Compatible interaction with services, primarily HVAC

Most space frames are designed for specific applications, and a structural engineer with specific experience should be consulted. Manufacturers can provide the full range of capabilities (loading, spans, shapes, specific details) for their products. Standardized structural assemblies in 4- and 5-ft modules are available.

Metal space frames are classified as noncombustible construction, and can usually be exposed when 20 ft above the floor. However, a fire suppression or a rated ceiling assembly may be required. Consult codes.

Common finishes include paint, thermoset polyester, galvanized, stainless steel, and metal plating.

SUPPORT TYPES

2.107

COMMON PATTERNS

2.108

MODULE SELECTION AND CHARACTERISTICS

2.109

Select a space frame module that is compatible with the structural module in shape (e.g., a square module with orthogonal plan) and size (a multiple of the structural module), is consistent with the limitations of the interfacing systems (e.g., the maximum span of the roof deck or mullion spacing of the glazing system), and satisfies the spatial and aesthetic effects in scale and form.

MEMBER SHAPES

2.110

SLOPED GLAZING

2.112

NOTES

2.108 Many proprietary node systems are available for specific applications and budgets. Keep field connections to a minimum; welded connections often eliminate joint pieces.

2.110 Square tubes or angles within their span range are often the most economical.

2.111 Space frame supports are at joints only, not along members.

Contributor:

Severud Associates, New York City, New York.

GRID SHAPES

2.113

SPACE FRAME FORM TYPES

2.114

ROOF AND FLOOR CONNECTIONS

2.115

COLD-FORMED METAL ROOF FRAMING

Cold-formed steel (CFS) framing members can be used to frame roofs in essentially the same manner as wood rafters or trusses. Note that thermal bridging can be a problem in cold climates when CFS members are not covered by continuous insulation.

Similarly cold-formed metal floor joist framing, including the use of delegated design, the following considerations should be considered when utilizing CFS for roof framing:

• Cold-formed metal roof framing uses C-shaped members, in sizes approximating wood framing, with special details for sloped bearing conditions.

• CFS framing is laid out similar to traditional wood joist framing.

• CFS roof trusses are available in virtually all of the configurations available for wood trusses.

• Proprietary roof truss systems use various shapes for chords and webs designed to allow higher productivity in fabrication and optimization of structural performance. It is generally not advisable to design around any single system, but instead to provide a general shape that many fabricators can provide.

For more information, consult the reference “Product Technical Information,” Steel Stud Manufacturers Association,

www.ssma.com.

COLD-FORMED METAL ROOF FRAMING DETAILS

COLD-FORMED STEEL ROOF TRUSSES

2.116

WEB MEMBERS

2.117

RIDGE BOARD

2.118

NOTES

2.116 a. Chords and webs can be typical CFS C-shapes or a variety of proprietary special shapes.

b. Bracing is typically channel or track.

c. Gusset plates from flat plate or section of large C-shape.

Contributors:

American Iron and Steel Institute, Washington, DC; Severud Associates, New York City, New York.

ROOF EAVE AT CATHEDRAL CEILING

2.119

ROOF TRUSS EAVE DETAIL

2.120

ROOF EAVE DETAIL

2.121

ROOF END DETAILS

2.122

COLLAR TIE DETAIL

2.123

FRAMING DETAILS FOR WOODROOFS

These figures illustrate details of common types of roof framing.

GABLE ROOF

2.124

GAMBREL ROOF

2.125

HIP ROOF

2.126

NOTE

2.122 Provide bridging at ceiling joists and roof rafters, and continuous bridging between rafters at the wall.

Contributors:

American Iron and Steel Institute, Washington, DC.; Timothy B. McDonald, Washington, DC.

MANSARD ROOF

2.127

SHED ROOF

2.128

FLAT ROOF

2.129

JACK RAFTERS

2.130

ROOF PEAK

2.131

RAFTER TAILS

2.132

INTERSECTING ROOF

2.133

RAFTERS AND CEILING JOISTS RESTING ON WALL PLATES

2.134

NOTCHED OR BEVELED RAFTERS RESTING ON PLATE

2.135

Contributors:

Timothy B. McDonald, Washington, DC.; Joseph A. Wilkes, FAIA, Wilkes and Associates, Washington, DC.

CURB FOR SKYLIGHT

2.136

WOOD I-JOIST CONSTRUCTION DETAILS

WOOD I-JOIST RAFTER AT RIDGE BEAM DETAIL

2.137

WOOD I-JOIST RAFTER AT RIDGE BEAM DETAIL

2.138

WOOD I-JOIST RAFTER AT RIDGE BEAM DETAIL

2.139

LAPPED WOOD I-JOIST RAFTER AT RIDGE BEAM

2.140

WOOD I-JOIST RAFTER AT OVERHANG

2.141

WOOD I-JOIST RAFTER AT OVERHANG

2.142

WOOD I-JOIST RAFTER AT OVERHANG

2.143

TYPICAL BIRD’S MOUTH I-JOIST CUT DETAIL

2.144

NOTES

2.137 Uplift connections may be required.

2.138 Uplift connections may be required.

2.139 Uplift connections may be required.

2.140 Uplift connections may be required.

2.141 Uplift connections may be required.

2.142 Uplift connections may be required.

2.143 a. Uplift connections may be required.

b. Special sloped seat-bearing metal connectors can be used in lieu of beveled wood plate in some sloped applications. See manufacturer’s recommendations.

2.144 Uplift connections may be required.

Contributor:

Richard J., Vitullo, AIA, Oak Leaf Studio, Crownsville, Maryland.

WOOD I-JOIST RAFTER WITH OUTRIGGER

2.145

WOOD I-JOIST RAFTER AT OUTRIGGER

2.146

FLY RAFTER DETAIL

2.147

WOOD I-JOIST SKYLIGHT FRAMING DETAIL

2.148

SHOP-FABRICATED WOOD TRUSSES

Shop-fabricated wood trusses have been used in building construction since 1953, when the metal connector plate was invented. Metal plates are available in a range of styles and tooth orientations. The metal plates are punched with barbs that grab onto the wood truss, thus reducing the hand-nailing required to fabricate a structure. Plate size for a given truss is based on a combination of the tooth withdrawal strength of the plate, the tensile and shear strength of the steel, and the net sectional area of the lumber.

PITCHED CHORD TRUSSES

2.149

This system is primarily used for roofs with either pitched or parallel chord trusses. It is occasionally employed for floors with parallel chord trusses. Individual trusses are cut from 2-by-4-in. or 2-by-6-in. dimension lumber and can be spaced 24 in. or 48 in. o.c. For typical residential construction, 24 in. o.c. is used. Exceptionally long spans are possible with shop-fabricated wood trusses, allowing the large, unencumbered interior spaces often required in commercial, agricultural, and other nonresidential building types.

Camber is designed for dead load only: Camber (in.) = Length (ft)/60

BRACING

Providing adequate bracing for trusses is essential, both during installation and as a component of the overall roof design. Truss members must be held in place with supports that meet them at right angles. Truss chords and web members are placed in a vertical, plumb position, and maintain that position, resisting applied design loads throughout the life of the structure. Permanent bracing and anchorage are expected to be an integral part of construction, and strongbacks are often used for this purpose.

Movement by crane can damage trusses. Crane spreader bars are used to avoid this “out-of-plane” buckling. Special stiffening may be applied to trusses during erection.

NOTES