Chapter Seven

Time to Harvest

Like most farm operations, tree harvesting must be done at precisely the right time. Unlike crops such as strawberries, grapes, and asparagus, however, Christmas trees cannot be processed, stored, and sold at a later date.

In the north, trees should not be cut until their new growth has been hardened by a few days of freezing weather, and in the south not until the danger of prolonged periods of severely hot weather is over. For wholesale sellers, the harvest season may begin as early as mid-October in the northern mountains, but a month or more later in warmer regions. Anyone who tries to lengthen the harvest period by cutting a few weeks too early usually regrets it. Many growers have forfeited future sales by furnishing buyers dried-out trees. The later in the season that trees can be cut, the fresher they will be for customers. Wholesale buyers usually control when they want trees delivered or ready for pickup. Once trees have been harvested, every effort must be made to keep them in a cool, shaded area rather than sitting out in the sun and wind. Some farms sprinkle the cut trees with water to prevent them from drying out.

Selecting Harvesting Equipment

Because it will be several years after planting before you need harvesting equipment, this purchase can be delayed for a while, and this will give you time to select what is best for your operation. Even on small wholesale operations, chainsaws are necessary because they are faster and need less muscle power than bow saws.

Most choose-and-cut operations provide their customers with bow saws, rather than allowing use of chain saws. Bow saws are quieter, safer and lighter for customers to use out in the field.

One of the more muscular jobs in harvesting comes in getting the trees from the field to the loading area, and it may take several workers to keep up with one good cutter. Lightweight trees can be carried by hand and heavy ones can be safely dragged over snow-covered ground, but never pull large trees long distances over rough, bare ground. Such treatment is likely to scrub off bark and needles and ruin their appearance — another good reason for having plenty of access roads. Unless you are selling choose-and-cut, some combination of truck, tractor, and/or trailer will be needed.

Plan your operation so tree handling can be kept at a minimum. Handling costs money and can be hard on the trees, so the closer the truck or trailer can get to the growing area, the better. This is a consideration not only for wholesalers, but also choose-and-cut farms where the trees are a long distance from the parking area. Some farms in this situation offer wagon rides to get customers and trees back and forth.

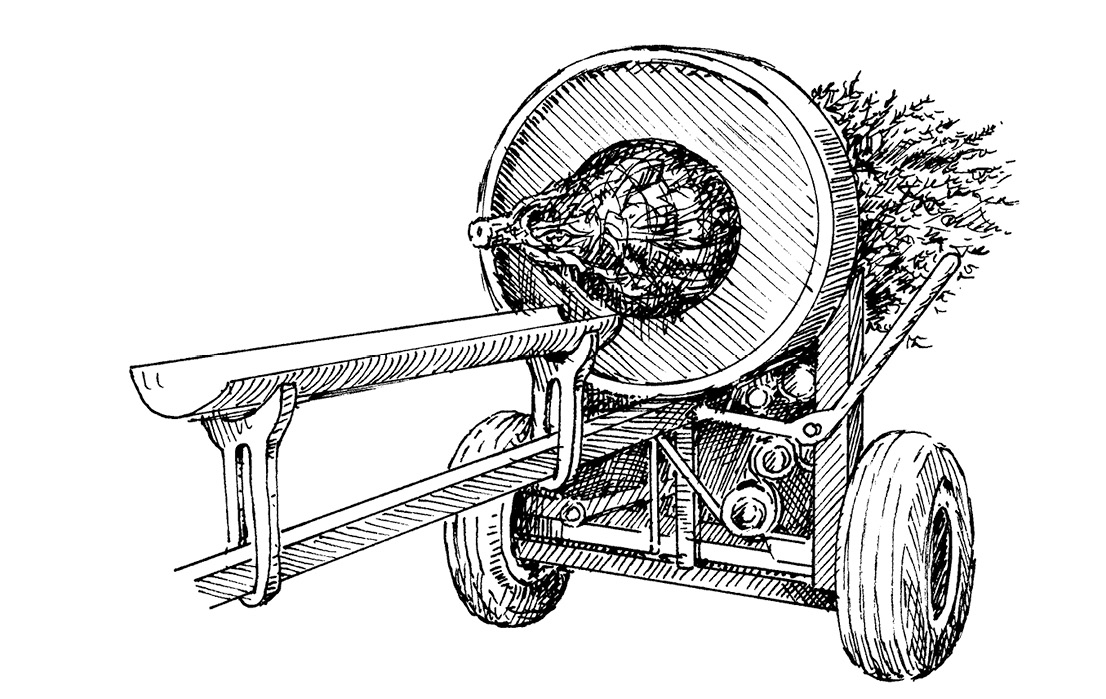

Larger operations — whether wholesale or retail — will need a motorized tree-tying machine; these devices can wrap trees in twine quickly and tightly, making them easier to handle and ship. Most wholesale buyers require that trees be wrapped because loose trees take up much more room on a truck and are more likely to be damaged in handling. (Wholesale sellers will also likely need a conveyer to pull the trees to the top of a large truck.)

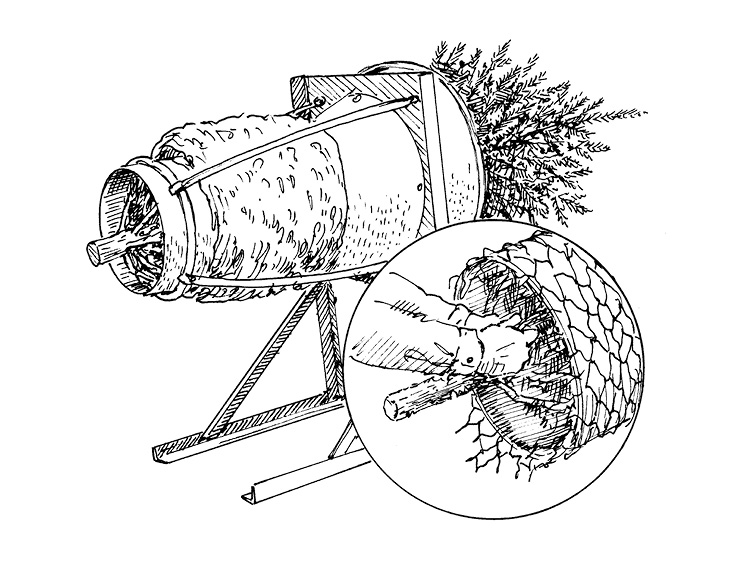

Retail customers may request that trees be wrapped to make them easier to transport home and bring inside. Smaller choose-and-cut farms might prefer a less-costly manual tree wrapper, most of which use plastic netting to package the trees. Each tree is slid, butt first, through a cone of the right size, picking up the plastic wrapping from a sleeve as it emerges from the cone. Before wrapping, some growers prefer to remove any dead needles (or leaves, grass, or other debris accumulated in the field) by placing them on a mechanical tree shaker, which resembles an oversized paint can shaker. The more needles that can be removed prior to ending up on a living room floor, the happier customers will be, and therefore more likely to be repeat customers.

Wrapping a Tree

Wrapping is an absolute necessity for wholesale sellers, and it's a popular touch with many customers in choose-and-cut and retail settings. There are three basic types of tree wrapping devices. The first is a motorized, mechanical type, such as the Howey baler, which pulls the tree through the unit, automatically compresses it, and wraps it tightly with twine.

The other two are manual wrappers, which offer less compression of the tree, and thus are less likely to be used by wholesalers interested in getting as many trees on a truck as possible. The first (less common) operates similar to the power baler mentioned above, but the operator must manually pull the tree and wrap the twine around it himself. The more common manual type involves a cone with plastic netting mounted on it. The operator manually pulls the tree through and it ends up encased in the netting (like a sausage).

Both the twine machines use a special plastic (manmade) twine rather than natural sisal baling twine for strength. With the netting, though maybe not as common, there are options that are marketed as recyclable or biodegradable.