Don’t fight forces; use them.

—BUCKMINSTER FULLER

Shelter (1932)

Making two visits to one of our cold houses—one at dawn after a below-zero night, and the other a few hours later— provides a striking introduction to the winter harvest. During the dawn visit all the crops are frozen solid. Raising the inner covers, which is difficult because they too are frozen, reveals a spectacle of stiff, frost-coated leaves bleak enough to convince anyone that this idea is foolhardy. Yet a few hours later, after the sun (even the wan sunlight of a cloudy day) has warmed the greenhouses above freezing, the second visit presents a miraculous contrast. Under the inner covers are closely spaced rows of vigorous, healthy leaves that stretch the length of the greenhouse. The leaf colors in different shades of greens, reds, maroons, and yellows stand bright against the dark soil. It looks like a perpetual spring.

Over the course of devising, developing, and improving our winter-harvest practices, we have amassed a collection of technical studies on hardy crops and the effect of freezing temperatures. Copies of research papers on all aspects of greenhouse growing fill our file cabinets. Yet none of them offer as much information (or inspiration) as those two visits to the cold house.

Hardy Crops

In the natural world, hardy crops like spinach and chard inhabit niches where resistance to cold is a requirement for survival. Winter-annual crops, like mâche and claytonia, have found their space to grow by germinating in fall, growing over winter, and going to seed in spring. Whereas the outdoor winter climate here in Zone 5 Maine is too harsh for even the hardiest of these crops, the twice-tempered climate under the inner layer of our cold houses offers them conditions within the range to which they are adapted. See appendix B.

ACTA HORTICULTURAE

The Dutch journal Acta Horticulturae was very valuable when we were first researching the subject of greenhouses for unheated out-of-season production. Acta Horticulturae publishes papers on horticultural subjects delivered at research symposia throughout the world. Go to the Web site www.actahort.org and then to the list of volumes under the section “Commission Protected Cultivation.” You can read the abstracts online and then either join the International Society for Horticultural Science to read the full articles online or find the books themselves. They are most likely to be available in the library of your local land-grant university.

Even after working with this unheated system for many years, I continue to be amazed by the daily miracle. The same three words keep coming to my mind every winter day—unheated, uninsulated, unbelievable! When you enter the protection of one of our cold greenhouses, you can take off your parka because the microclimate you encounter is that of a location approximately one and one-half USDA zones to the south. When you reach your hand under the row covers you have moved another one and one-half zones south where the Maine winter definitely does not prevail. Outdoors the climate is Zone 5; under the inner layer, the climate is Zone 8.

We started using the phrase cold house to describe these structures because the word unheated made it sound as if we are not doing something—heating—that we should be doing. Furthermore, it may be clearer to use the descriptive phrase high tunnel or cold tunnel and avoid the word greenhouse altogether since many people assume that greenhouses, if unheated, are expensive superinsulated technological marvels or complicated heat-storage devices. Ours are neither. The best short statement to describe our approach is the epigraph to this chapter by Buckminster Fuller from his book Shelter (1932)—“Don’t fight forces; use them.” Instead of bemoaning the forces of winter and trying to fight them head on, we have limited our intervention to the climatic protection provided by two translucent layers. Instead of the usual thinking, which only sees greenhouses as a way to grow heat-loving crops during cold weather, we have said, “So it’s cold. Great! What vegetables thrive in the cold?” The answer is some thirty or so hardy vegetables.

Fighting force requires energy, and energy costs money. Our cold-house approach takes advantage of everything our two translucent protective layers can get for free from the sun as well as the residual heat of the soil mass and then works within those limits. The same applies in reverse during the summer. When the protected microclimate inside the houses turns warm, we don’t fight that warmth with motorized greenhouse cooling systems. We use it to grow heat-loving crops.

The Outer Covering

When we first started growing crops in cold houses, we covered all of the houses with just a single layer of plastic. We made that choice to maximize light input. Using two layers of plastic and blowing air into the space between them to inflate the plastic provides more protection from cold, but it also cuts out an additional 10 percent of available light. Also we prefer to work with systems that are inexpensive and simple. Thus, we decided to forgo the expense of the second layer and the electric blower required to inflate the layers.

We are interested in comparing greenhouse plastic from different manufacturers to find the type of cover that lets in the most light and keeps in the most heat. In our cold climate we want to increase daytime heat gain and light levels, so we favor covers that maximize those inputs. Plastic covers are available with an anti-drip coating that causes condensed moisture to form a thin film instead of droplets. Covers with this type of coating not only let in more light but the thin film of moisture also acts to reflect back the heat waves radiating from the soil at night thus helping to keep the air inside the house warmer. Growers in the southern states where cold is not as intense may want to use plastics designed to block infrared input and thus help to keep the greenhouse from overheating.

Using Double Covers

For experimental purposes, we trialed one small air-inflated house (17 feet by 36 feet) without heat. The temperature records we kept show that nighttime low temperatures averaged 4°C) warmer in the air-inflated house than in a cold house with a single-layer outer covering. For example, on a cold night, when the low temperature was –8°C) outside, the temperature dropped to 2°F (–7°C) under the inner layer of row cover. By comparison, in the air-inflated house, the low temperature was 7°C) and 24°F (–4°C) under the inner layer of row cover.

Our observations of crops during this trial showed some interesting comparisons between the two houses. Although we could detect no apparent difference in the quality of the crops of harvestable size, we did notice faster growth of new seedlings in the air-inflated house in winter. That house also warmed more quickly on cold mornings because the layer of sunlight-blocking frost that forms on the inside of the plastic melted off more slowly in the single-layer house. Based on this trial, we began double-covering the cold houses where we would be sowing new crops from December 15 to February 15. With the rest of the cold houses, such as one that protects leeks for midwinter harvest, we continue with our inclination in favor of simplicity and better light input and use only a single sheet of plastic to cover the house.

The Inner Layer

The success of our work with cold frames and then row covers convinced us of the benefits of the inner- and outer-layer concept. We wondered if we could do even more. We thought about placing smaller tunnel greenhouses inside the larger ones as some Japanese farmers were doing, but, on further consideration, we decided that the management and ventilation seemed complicated and the use of space seemed inefficient. We considered motorized night-curtain systems of reflective material, which are sometimes used in heated greenhouses, but they were very expensive. After exploring all of the above, we reverted, as we usually do, to the simplest, least expensive option—a floating row cover as the inner layer. If we had started our winter operation with more elaborate systems, we never would have known if they were really necessary.

Although we worried that floating row covers might be considerably less protective against cold than glass cold frames, the self-ventilating nature of the row covers and their availability in large sizes were overwhelming advantages. And, further, we did not know if we had yet pushed our crops to the lowest temperatures they would tolerate in a protected microclimate. Our opinion, after many years of practical experience with winter-harvest systems, is that the protected microclimate we have created is successful principally because it protects against wind (think of wind-chill readings and the desiccating effect of cold dry winds on winter vegetation) and, secondarily, because it protects against the fluctuating wet-dry, snow-ice conditions of the outside winter. In this microclimate, a few degrees of temperature one way or the other does not appear to be the crucial determinant of survival for most of our crops.

MORE ON EMMERT

One day, shortly after we began investigating these winter-harvest ideas, we stumbled across a journal article in the library referencing the early work with plastics in horticulture by a University of Kentucky professor, Emery Emmert. It was a fascinating find and reinforced my belief that every supposedly new idea in agriculture has been explored before by someone else. Dr. Emery Myers Emmert (1900–62) is acknowledged as the father of plastic greenhouses in this country, but his accomplishments went far beyond that. During the 1950s he pioneered row covers, plastic mulch, and inner layers in unheated winter houses as well. His field greenhouses and row covers were the models for today’s high tunnels and low tunnels. As you can tell from the following list of publications he was a tireless experimenter.

Emmert, E. M. Low-cost Plastic Greenhouses. Lexington, KY: Kentucky Agricultural Experiment Station Progress Report 28, 1955.

———. “Plastic Row Covering.” Market Growers Journal 85, no. 4 (1956): 40.

———. “Plastic Mulch for Vegetables.”

Kentucky Farm and Home Science 2, no. 1 (Winter 1956): 8, 9, 11.

———. “Black Polyethylene for Mulching Vegetables.” Proceedings of the American Society for Horticultural Science 69 (1957): 464–69.

———. “Earth Helps Heat Greenhouse: Lettuce Grows Unharmed in Below-Freezing Weather.” Kentucky Farm and Home Science 7, no. 2 (Spring 1961): 4–5.

Easy Handling

We plan to put the row covers over the crops just before the weather gets cold enough to freeze inside the greenhouse. One of the delights of using row covers inside a greenhouse is the ease of management. Since there is no wind, there is no need to bury or weigh down the edges. Even large pieces can be removed and replaced easily for harvest and other access needs without worrying about them being caught by a gust of wind.

For the large houses our interior covers are 20 feet wide by 50 feet long, large enough to cover one quadrant of a 30-by-96-foot greenhouse. The 48-foot houses are covered by two pieces each 15 feet wide. The covers are supported, 12 inches above the soil, by flat-topped wire wickets. We make the wickets from 76-inch-long straight lengths of number 9 wire. The flat top is 30 inches wide, the same width as the beds, and each leg is 23 inches long. Thus, when the wickets are in place, they do not block the access path between the beds.

We space the wickets every 4 feet along the length of a bed, which provides sufficient framework to support the row-cover fabric. When the fabric is in place, we pull it taut and clip it to the end wickets of the quadrant with clothespins. That prevents the fabric from sagging under the weight of condensed moisture, which can be quite substantial. We have noticed occasional frost damage at points where the fabric has drooped down and frozen to the leaves below, as opposed to no damage when the fabric does not touch the plants. The edges of the fabric drape down over the edge of the wickets and rest along the side of the greenhouse or in the pathway.

Some Revealing Comparisons

In order to learn how much protection we would sacrifice by shifting to fabric covers from our original cold frames, we conducted trials using two types of spun-bonded row-cover fabrics, one lightweight and one heavyweight. We compared them to one another, and we also compared the results of using them alone against using them in combination with an aluminized cloth cover, which is totally opaque to sunlight. This cloth is used as night-curtain material in heated greenhouses because it reflects back 100 percent of the long-wave radiation emitted by the soil at night, thus trapping the heat. Plastic-based materials such as the row-cover fabrics are transparent to long-wave radiation.

Clothespins hold fabric to wickets.

The results of the trial made it easy to decide against using the aluminized cloth. During the trial, we laid the aluminized cloth over the row-cover fabric every evening and removed it every morning. We expected the aluminized cloth to increase the temperature under the covers, and it did, averaging 3°F warmer nighttime minimums than the row cover alone. However, we detected no differences in crop quality as a result of the warmer minimums. Since the cost of the aluminized material is very high and the twice daily spreading and removing were a great deal of extra work (especially on mornings when it was frozen to the row cover material beneath it), all for no increase in crop quality, it clearly was not worth adding to our system.

The difference with and without the aluminized cloth would be greater without some help from the natural world. A film of moisture condenses on the floating row covers at night, and this film is nearly opaque to long-wave radiation and provides a reasonably reflective surface. Thus, it acts to prevent heat being radiated through the row covers as it would when the row covers are dry. There is usually plenty of humidity under the covers when they are covering crops of harvestable size. It is only when we have cleared a crop, worked in more compost, and reseeded that the soil surface can dry out and the air can be less moist. We find we can get around this to raise the night temperature a few degrees and benefit the young seedlings by moistening the surface soil if it looks dry. A buried water line with frost-proof hydrants makes water available inside our large houses and within 100 feet of all the others.

The comparison between a lightweight and a heavyweight spun-bonded fabric provided us with some intriguing insights. The heavyweight fabric we trialed is three times heavier than our standard lightweight fabric. It seemed logical that a heavier fabric would have more insulating value and keep the covered area warmer at night. At the start of the trial, the minimum nighttime temperatures under the heavy fabric were a degree or two warmer than under the lightweight. However, the heavy fabric only allows 50 percent of sunlight to pass through as opposed to 85 percent for the lightweight fabric. That meant the heavyweight fabric inhibited the crucial daily rewarming of the protected area under the fabric. The results, after a couple of days, were colder minimum temperatures and more soil freezing under the heavier fabric. This trial made clear that this is a sun-run system. The most important factor is the daily influx of sunlight. Not only does the light fuel plant growth, it also adds heat to the soil—heat that we can capture with the inner covering and thus raise nighttime temperatures. In this case less is more, and we now use only the lightweight fabric.

We have also compared the standard spun-bonded fabric with a Japanese row cover made of polyvinyl alcohol (PVA), which we were able to get from a California importer. This material had many pluses and some minuses. It is extremely durable and should last up to eight years under our protected conditions compared with only a year or two for the spun-bonded fabrics. PVA allows 90 to 92 percent light transmission. It has also averaged nighttime temperatures one degree warmer than the spun-bonded fabrics. Unfortunately the PVA cover cost about five times more per square foot than the spun-bonded fabric. Also, it was available only in a 78-inch width. We solved that problem by taking the fabric to a local sail maker who, for a reasonable price, sewed it into coverings wide enough to span our cold-house quadrants. In the end though, the fact that the PVA fabric was not locally available and required sewing made it seem more trouble than it was worth, and we decided to just use the spun-bonded fabrics.

Throughout our experimental investigations of greenhouse plastics and materials for the inner layer, our goal was to push the limits of the unheated system. We have opted for less expense, better light transmission, and simplicity over better temperature protection even though we farm in Maine. Those decisions may seem backwards for a winter-harvest system in our climate, but the crops have been surprisingly resilient. Nevertheless, we don’t think we have found the ultimate answer yet. We continue to search for ways to provide more adequate protection for crops while trying to determine the best balance between extra effort expended in management and labor and improved results in growth and quality.

The Role of Daytime Highs

We expect there may also be a cumulative effect from more substantial night protection. Warmer soil temperature resulting from more effective nighttime cover during the cold months should maintain both higher nighttime air temperature and a faster rate of plant regrowth. However, it may be possible to achieve a similar effect by allowing higher maximum daytime temperatures to occur. Normally we begin to vent our houses when the daytime temperature under the inner layer reaches 70°F. We have thought about venting at a lower temperature so the plants would experience a narrower range of temperatures, which intuitively seems as if it would make sense in the winter. But we have one small house with inadequate ventilation that gets much warmer (85° to 95°F) during sunny winter days. This house also experiences higher nighttime temperatures, which may be attributable to increased soil heat storage during the day. Thus far we have not detected any difference in crop quality (better or worse) as a result of the higher daytime temperatures.

Some studies of plant physiology suggest that rate of plant growth is not affected by the daily highs and lows but rather by the average temperature over twenty-four hours. If that is so, then, following a 20°F daytime temperature might be better than a 70°F average over twenty-four hours rather than a 45°F average. We have a lot of hunches but no hard opinions yet on any of these variables. We plan to investigate these ideas further in future years.

Another significant biological reality of growing cool-weather crops in winter greenhouses is that too warm is more damaging to these winter-harvest crops than too cold. On our farm the transition period to begin thinking more about too warm rather than too cold is late February. At this point, even though the row cover fabric that we use for the inner layer is self-venting, it may not vent the heat quickly enough. We heed the soothsayer’s caution to Caesar and “beware the ides of March” because by March 15, at the latest, we need to begin folding back the inner covers in the cold houses on sunny days to prevent overheating of the crops beneath. Growers in warmer climates will need to figure out their own critical date: one guideline is to begin monitoring overheating shortly after the end of the Persephone period in your region.

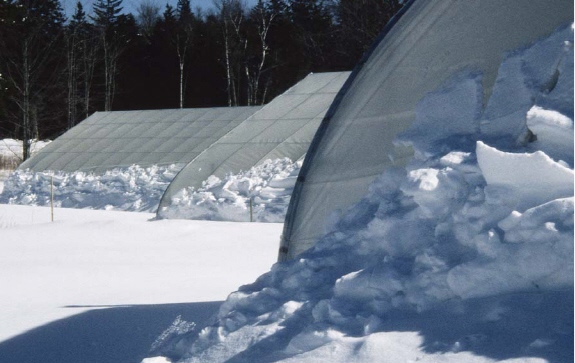

A typical winter farming scene.

March is also the month when we plan to start irrigating again, whereas, because of low evaporation and high water tables, we have had to provide little supplemental moisture during the winter months.

Summing Up

Obviously, growers in climates with less severe winter weather can grow a wider range of crops in cold houses than we can because the duration, depth, and frequency of temperature drops will be less. They can similarly create protected microclimates for the same winter crops we grow with fewer resources than we require. Growers in the warmer sections of Zone 8 and in Zone 9 (see map 2 in appendix A) could get by with row covers alone in areas with little snow. Based on our experience and the temperature records we have kept over the years, we think that growers in Zone 7 would find they could succeed perfectly well solely with unheated houses. Growers in the milder parts of Zone 7 might even find a double-covered, air-inflated high tunnel sufficient protection without the row-cover inner layer. However, they might want to have a small heater in reserve for spot protection on exceptionally cold nights (which is a reasonable option for any grower and achieves protection with minimal resource use).

For growers in Zones 3 through 6 we recommend trying everything from additional inner covers to specializing in spinach, mâche, leeks, claytonia, and Asian greens (the hardiest crops) in the coldest months of winter. The crops and the systems that work best will not be the same in all situations. The climate maps in appendix A provide a number of yardsticks by which to compare winter climates in other parts of the country. For comparison, we are located about two-thirds of the way up the Maine coast.

The eventual solution for an ideal winter-production system may come either through finding better inner- and outer-layer materials or through managing some greenhouses with minimal heat (see chapter 7) and some as cold houses. We still think increasing light transmission by a few percentage points is more important than raising nighttime low temperatures by a few degrees but, to be honest, we do not really know whether light level makes as much difference when temperatures are low in midwinter and the crops are basically hibernating. As other growers begin exploring these ideas it is our hope that there will be unrestrained exchange of ideas, techniques, and new information. The cold houses are the challenge that led us into this work in the first place, and we expect that they are where the most exciting new innovations will be developed.