References

Amsden BG, Goosen MFA. An examination of factors affecting the size, distribution, and release characteristics of polymer microbeads made using electrostatics. Control. Release. 1997;43:183–196.

Banks DP, Kaur K, Gazia R, Fardel R, Nagel M, Lippert T, Eason RW. Triazene photopolymer dynamic release layer-assisted femtosecond laser-induced forward transfer with an active carrier substrate. EPL (Europhysics Letter). 2008;83:38003.

Barron JA, Krizman DB, Ringeisen BR. Laser printing of single cells: statistical analysis, cell viability, and stress. Biomed. Eng. 2005;33:121–130.

Barron JA, Ringeisen BR, Kim H, Spargo BJ, Chrisey DB. Application of laser printing to mammalian cells. Thin Solid Films. 2004;453:383–387.

Barron JA, Wu P, Ladouceur HD, Ringeisen BR. Biological laser printing: a novel technique for creating heterogeneous 3-dimensional cell patterns. Biomed. Microdevices. 2004;6:139–147.

Bauwens CL, Peerani R, Niebruegge S, Woodhouse KA, Kumacheva E, Husain M, Zandstra PW. Control of human embryonic stem cell colony and aggregate size heterogeneity influences differentiation trajectories. Stem Cells. 2008;26:2300–2310.

Berrier A, Yamada K. Cell–matrix adhesion J. Cell. Physiol. 2007:565–573.

Boland T, Xu T, Damon B, Cui X. Application of inkjet printing to tissue engineering. Biotechnol. J. 2006;1:910–917.

Calvert P. Inkjet printing for materials and devices. Mater. 2001;13:3299–3305.

Catros S, Guillemot F, Nandakumar A, Ziane S, Moroni L, Habibovic P, van Blitterswijk C, Rosseau B, Chassande O, Amedee J, Fricain J-C. Layer-by-layer tissue microfabrication supports cell proliferation in vitro and in vivo. Tissue Eng Part C: Methods. 2011;18:62–70.

Chen C, Barron J, Ringeisen B. Cell patterning without chemical surface modification: cell-cell interactions between printed bovine aortic endothelial cells (BAEC) on a homogeneous cell-adherent hydrogel. Appl. Surface Sci. 2006;252:8641–8645.

Chen CS, Mrksich M, Huang S, Whitesides GM, Ingber DE. Micropatterned surfaces for control of cell shape, position, and function. Biotechnol. Prog. 1998;14:356–363.

Chrisey DB, Pique A, Fitz-Gerald J, Auyeung RCY, McGill RA, Wu HD, Duignan M. New approach to laser direct writing active and passive mesoscopic circuit elements. Appl. Surface Sci. 2000:154–155: .

Colina M, Serra P, Fernández-Pradas JM, Sevilla L, Morenza JL. DNA deposition through laser induced forward transfer. Biosens. Bioelectron. 2005;20:1638–1642.

Desmarais SM, Haagsman HP, Barron AE. Microfabricated devices for biomolecule encapsulation. Electrophoresis. 2012;33:2639–2649.

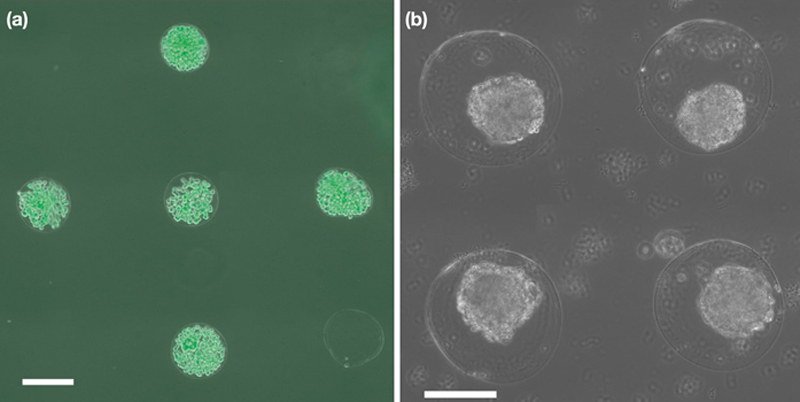

Dias AD, Unser AM, Xie Y, Chrisey DB, Corr DT. Generating size-controlled embryoid bodies using laser direct-write. Biofabrication. 2014;6:025007.

Dinca V, Farsari M, Kafetzopoulos D, Popescu A, Dinescu M, Fotakis C. Patterning parameters for biomolecules microarrays constructed with nanosecond and femtosecond UV lasers. Thin Solid Films. 2008;516:6504–6511.

Doraiswamy A, Narayan R, Lippert T, Urech L, Wokaun A, Nagel M, Hopp B, Dinescu M, Modi R, Auyeung R. Excimer laser forward transfer of mammalian cells using a novel triazene absorbing layer. Appl. Surface Sci. 2006;252:4743–4747.

Doraiswamy A, Narayan RJ, Harris ML, Qadri SB, Modi R, Chrisey DB, Hill C, Carolina N. Laser microfabrication of hydroxyapatite-osteoblast-like cell composites. Biomed. Mater. Res. Part A. 2006;80:635–643.

Engler A, Sen S, Sweeney H, Discher D. Matrix elasticity directs stem cell lineage specification. Cell. 2006;126:677–689.

Fernández-Pradas JM, Colina M, Serra P, Dom nguez J, Morenza JL. Laser-induced forward transfer of biomolecules. Thin Solid Films. 2004;453:27–30.

nguez J, Morenza JL. Laser-induced forward transfer of biomolecules. Thin Solid Films. 2004;453:27–30.

Freytes DO, Wan LQ, Vunjak-Novakovic G. Geometry and force control of cell function. J. Cell. Biochem. 2009;108:1047–1058.

Gaebel R, Ma N, Liu J, Guan J, Koch L, Klopsch C, Gruene M, Toelk A, Wang W, Mark P, Wang F, Chichkov B, Li W, Steinhoff G. Patterning human stem cells and endothelial cells with laser printing for cardiac regeneration. Biomaterials. 2011;32:9218–9230.

Godier AFG, Marolt D, Gerecht S, Tajnsek U, Martens TP, Vunjak-Novakovic G. Engineered microenvironments for human stem cells. Birth Defects Res. C. Embryo Today. 2008;84:335–347.

Gonzalez-Macia L, Morrin A, Smyth MR, Killard AJ. Advanced printing and deposition methodologies for the fabrication of biosensors and biodevices. Analyst. 2010;135:845–867.

Gruene M, Deiwick A, Koch L, Ph D, Schlie S, Unger C, Hofmann N, Bernemann I, Glasmacher B, Chichkov B. Laser printing of stem cells for biofabrication scaffold-free autologous grafts. Tissue Eng Part C: Methods. 2011;17:79–87.

Gruene M, Pflaum M, Deiwick A, Koch L, Schlie S, Unger C, Wilhelmi M, Haverich A, Chichkov B. Adipogenic differentiation of laser-printed 3D tissue grafts consisting of human adipose-derived stem cells. Biofabrication. 2011;3:015005.

Gruene M, Pflaum M, Hess C, Diamantouros S, Schlie S, Deiwick A, Koch L, Wilhelmi M, Jockenhoevel S, Haverich A, Chichkov B. Laser printing of three-dimensional multicellular arrays for studies of cell-cell and cell-environment interactions. Tissue Eng Part C: Methods. 2011;17:973–982.

Guillemot F, Souquet A, Catros S, Guillotin B, Lopez J, Faucon M, Pippenger B, Bareille R, Rémy M, Bellance S, Chabassier P, Fricain JC, Amédée J. High-throughput laser printing of cells and biomaterials for tissue engineering. Acta Biomater. 2010;6:2494–2500.

Hopp B, Smausz T, Kresz N, Barna N, Bor Z, Kolozsvári L, Chrisey DB, Szabó A, Nógrádi A. Survival and proliferative ability of various living cell types after laser-induced forward transfer. Tissue Eng. 2005;11:1817–1823.

Huebsch N, Arany PR, Mao AS, Shvartsman D, Ali OA, Bencherif SA, Rivera-Feliciano J, Mooney DJ. Harnessing traction-mediated manipulation of the cell/matrix interface to control stem-cell fate. Nat. Mater. 2010;9:518–526.

Hui E, Bhatia S. Micromechanical control of cell-cell interactions. Proceedings of the National Academy of Sciences. 2007;104:5722–5726.

Jackman RJ, Wilbur JL, Whitesides GM. Fabrication of submicrometer features on curved substrates by microcontact printing. Science. 1995;269:664–666.

Kaji H, Camci-Unal G, Langer R, Khademhosseini A. Engineering systems for the generation of patterned cocultures for controlling cell-cell interactions. Biochim. Biophys. Acta. 2011;1810:239–250.

Kattamis NT, Purnick PE, Weiss R, Arnold CB. Thick film laser induced forward transfer for deposition of thermally and mechanically sensitive materials. Appl Phys. Lett. 2007;91:171120.

Kingsley DM, Dias AD, Chrisey DB, Corr DT. Single-step laser-based fabrication and patterning of cell-encapsulated alginate microbeads. Biofabrication. 2013;5:045006.

Kleinman HK, Martin GR. Matrigel: basement membrane matrix with biological activity. Semin. Cancer Biol. 2005;15:378–386.

Kleinman HK, McGarvey ML, Hassell JR, Star VL, Cannon FB, Laurie GW, Martin GR. Basement membrane complexes with biological activity. Biochemistry. 1986;25:312–318.

Koch L, Deiwick A, Schlie S, Michael S, Gruene M, Coger V, Zychlinski D, Schambach A, Reimers K, Vogt PM, Chichkov B. Skin tissue generation by laser cell printing. Biotechnol. Bioeng. 2012;109:1855–1863.

Koch L, Kuhn S, Sorg H, Gruene M, Schlie S, Gaebel R, Polchow B, Reimers K, Stoelting S, Ma N, Vogt PM, Steinhoff G, Chichkov B. Laser printing of skin cells and human stem cells. Tissue Eng. Part C: Methods. 2010;16:847–854.

Lee LH, Peerani R, Ungrin M, Joshi C, Kumacheva E, Zandstra PW. Micropatterning of human embryonic stem cells dissects the mesoderm and endoderm lineages. Stem Cell Res. 2009;2:155–162.

Lee W, Debasitis JC, Lee VK, Lee J-H, Fischer K, Edminster K, Park J-K, Yoo S-S. Multi-layered culture of human skin fibroblasts and keratinocytes through three-dimensional freeform fabrication. Biomaterials. 2009;30:1587–1595.

Liu Y, Wang X, Kaufman DS, Shen W. A synthetic substrate to support early mesodermal differentiation of human embryonic stem cells. Biomaterials. 2011;32:8058–8066.

Lund AW, Yener B, Stegemann JP, Plopper GE. The natural and engineered 3D microenvironment as a regulatory cue during stem cell fate determination. Tissue Eng. Part B: Rev. 2009;15:371–380.

Massia SP, Hubbell JA. An RGD spacing of 440 nm is sufficient for integrin alpha V beta 3-mediated fibroblast spreading and 140 nm for focal contact and stress fiber formation. J. Cell Biol. 1991;114:1089–1100.

Meshel AS, Wei Q, Adelstein RS, Sheetz MP. Basic mechanism of three-dimensional collagen fibre transport by fibroblasts. Nat. Cell Biol. 2005;7:157–164.

Odde DJ, Renn MJ. Laser-guided direct writing of living cells. Biotechnol. Bioeng. 2000;67:312–318.

Orive G, Tam SK, Pedraz JL, Hallé J-P. Biocompatibility of alginate-poly-L-lysine microcapsules for cell therapy. Biomaterials. 2006;27:3691–3700.

Othon CM, Wu X, Anders JJ, Ringeisen BR. Single-cell printing to form three-dimensional lines of olfactory ensheathing cells. Biomed. Mater. 2008;3:034101.

Ovsianikov A, Gruene M, Pflaum M, Koch L, Maiorana F, Wilhelmi M, Haverich A, Chichkov B. Laser printing of cells into 3D scaffolds. Biofabrication. 2010;2:014104.

Pampaloni F, Reynaud EG, Stelzer EHK. The third dimension bridges the gap between cell culture and live tissue. Nat. Rev. Mol. Cell Biol. 2007;8:839–845.

Patz TM, Doraiswamy A, Narayan RJ, He W, Zhong Y, Bellamkonda R, Modi R, Chrisey DB. Three-dimensional direct writing of B35 neuronal cells. Biomed. Mater. Res. 2005;78:124–130.

Pedersen J, Swartz M. Mechanobiology in the third dimension. Ann Biomed. Eng. 2005;33:1469–1490.

Peerani R, Rao BM, Bauwens C, Yin T, Wood GA, Nagy A, Kumacheva E, Zandstra PW. Niche-mediated control of human embryonic stem cell self-renewal and differentiation. EMBO J. 2007;26:4744–4755.

Petrie TA, Capadona JR, Reyes CD, García AJ. Integrin specificity and enhanced cellular activities associated with surfaces presenting a recombinant fibronectin fragment compared to RGD supports. Biomaterials. 2006;27:5459–5470.

Pham QP, Sharma U, Mikos AG. Electrospinning of polymeric nanofibers for tissue engineering applications: a review. Tissue Eng. 2006;12:1197–1211.

Piner R, Zhu J, Xu F, Hong S, Mirkin C. “Dip-pen” nanolithography. Science. 1999;283:661–663.

Pirlo RK, Dean DMD, Knapp DR, Gao BZ. Cell deposition system based on laser guidance. Biotechnol. J. 2006;1:1007–1013.

Raof NA, Schiele NR, Xie Y, Chrisey DB, Corr DT. The maintenance of pluripotency following laser direct-write of mouse embryonic stem cells. Biomaterials. 2011;32:1802–1808.

Ringeisen B, Chrisey D, Krizman D, Kim H, Young P, Spargo B. Cell-by-cell construction of living tissue by ambient laser transfer. 2nd Annual International IEEE-EMBS Special Topic Conference on Microtechnologies in Medicine & Biology. 2002:120–125.

Ringeisen BR, Barron JA, Young D, Othon CM, Wu PK, Ladoucuer D, Spargo BJ. Laser Printing Cells. Virtual Prototyping & Bio Manufacturing in Medical Applications (Springer); 2008: .

Ringeisen BR, Kim H, Barron JA, Krizman DB, Chrisey DB, Jackman S, Auyeung RYC, Spargo BJ. Laser printing of pluripotent embryonal carcinoma cells. Tissue Eng. 2004;10:483–491.

Ringeisen BR, Wu PK, Kim H, Piqué A, Auyeung RYC, Young HD, Chrisey DB, Krizman DB. Picoliter-scale protein microarrays by laser direct write Chem. Biotechnol. Prog. 2002;18:1126–1129.

Roth EA, Xu T, Das M, Gregory C, Hickman JJ, Boland T. Inkjet printing for high-throughput cell patterning. Biomaterials. 2004;25:3707–3715.

Saunders RE, Gough JE, Derby B. Delivery of human fibroblast cells by piezoelectric drop-on-demand inkjet printing. Biomaterials. 2008;29:193–203.

Schaub NJ, Britton T, Rajachar R, Gilbert RJ. Engineered Nanotopography on Electrospun PLLA Micro fibers Modifies RAW 264. 7 Cell Response ACS Appl. Mater. Interfaces. 2013;5:10173–10184.

Schiele NR, Chrisey DB, Corr DT. Gelatin-based laser direct-write technique for the precise spatial patterning of cells. Tissue Eng Part C: Methods. 2011;17:289–298.

Schiele NR, Corr DT, Huang Y, Raof NA, Xie Y, Chrisey DB. Laser-based direct-write techniques for cell printing. Biofabrication. 2010;2:032001.

Schiele NR, Koppes RA, Corr DT, Ellison KS, Thompson DM, Ligon LA, Lippert TKM, Chrisey DB. Laser direct writing of combinatorial libraries of idealized cellular constructs: biomedical applications. Appl. Surface Sci. 2009;255:5444–5447.

Tasoglu S, Demirci U. Bioprinting for stem cell research. Trends Biotechnol. 2013;31:10–19.

Tien J, Nelson CM, Chen CS. Fabrication of aligned microstructures with a single elastomeric stamp. Proceedings of the National Academy of Sciences. 2002;99:1758–1762.

Wu PK, Ringeisen BR. Development of human umbilical vein endothelial cell (HUVEC) and human umbilical vein smooth muscle cell (HUVSMC) branch/stem structures on hydrogel layers via biological laser printing (BioLP). Biofabrication. 2010;2:014111.

Wu PK, Ringeisen BR, Callahan J, Brooks M, Bubb DM, Wu HD, Pique A, Spargo B, McGill RA, Chrisey DB. deposition, structure, pattern deposition, and activity of biomaterial thin-films by matrix-assisted pulsed-laser evaporation (MAPLE) and MAPLE direct write. Thin Solid Films. 2001:398–399: .

Wu PK, Ringeisen BR, Krizman DB, Frondoza CG, Brooks M, Bubb DM, Auyeung RCY, Piqué A, Spargo B, McGill RA, Chrisey DB. Laser transfer of biomaterials: matrix-assisted pulsed laser evaporation (MAPLE) and MAPLE direct write Rev. Sci. Instrum. 2003;74:2546.

Xie XN, Chung HJ, Sow CH, Wee ATS. Nanoscale materials patterning and engineering by atomic force microscopy nanolithography Mater. Sci. Eng. R Reports. 2006;54:1–48.

Xie Y, Castracane J. High-voltage, electric field-driven micro/nanofabrication for polymeric drug delivery systems. Eng Med. Biol. 2009:23–30.

Xu C, Inokuma MS, Denham J, Golds K, Kundu P, Gold JD, Carpenter MK. Feeder-free growth of undifferentiated human embryonic stem cells. Nat. Biotechnol. 2001;19:971–974.

Xu T, Jin J, Gregory C, Hickman JJ, Boland T. Inkjet printing of viable mammalian cells. Biomaterials. 2005;26:93–99.

Yamato M, Kwon O, Hirose M, Kikuchi A, Okano T. Novel patterned cell coculture utilizing thermally responsive grafted polymer surfaces J. Biomed. Mater. Res. 2001;55:137–140.

Yousaf MN, Houseman BT, Mrksich M. Using electroactive substrates to pattern the attachment of two different cell populations. Proceedings of the National Academy of Sciences. 2001;98:5992–5996.

Zhang C, Liu D, Mathews SA, Graves J, Schaefer TM, Gilbert BK, Modi R, Wu H, Chrisey DB. Laser direct-write and its application in low temperature Co-fired ceramic (LTCC) technology. Microelectron. Eng. 2003;70:41–49.