To achieve the efficiency of symbiosis, different components must serve multiple purposes. In passive solar architecture, a wall is more than a wall – it may be part of an insulating envelope, a space divider, a solar collector, thermal mass, a light reflector or a director of breezes. Every component in the architectural whole must serve several functions at the same time.

A passive building must first be an energy conserving building. This prerequisite allows passive design to take the next step to on-site energy production. Energy conservation begins with the building envelope. Three aspects of an energy conserving envelope are insulation, reduction of air infiltration and energy efficient construction.

| Biome | Subtropical | Temperate | Cold | Very cold |

| Roofs | 3.3 [19] | 8 [45] | 10.5 [60] | 17.6 [100]6 |

| Walls | 7 [11] | 5.3 [30] | 7 [40] | 17.6 [100] |

The above nominal insulation value is typically much higher than the actual value of the wall because of conduction through framing and less than perfect installation. Added framing for openings, joints, fire breaks, or seismic resistance can reduce insulation values 10–25%. Insulation performance can also be degraded by moisture build-up, so placement of a vapor barrier is important and will vary depending on climate. Venting the cold surface of insulated walls or simplifying moisture control with a closed cell foam type insulation can minimize these losses. However, the production process, useful life, disposal and the potential for hazardous off-gassing in a fire are life cycle considerations for insulation. Certain insulation materials such as straw bales should be allowed to breathe water vapor, rather than seal in vapor with a barrier. In this case, providing weep screeds at the bottom of the wall is important.[73]

Infiltration losses can be just as great as conductive losses and may easily account for half of the winter heat loss in a well insulated, but poorly weatherized building. Weather stripping doors, windows, caulking and sealing building joints, access holes and other areas will reduce unwanted infiltration.

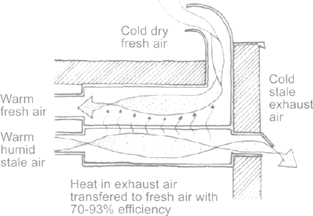

Recent improvements in insulation and glazing techniques have made air infiltration the prime contributor to winter heat loss; however, tight buildings are complicated by the need for fresh air to maintain the health of its occupants.

Afresh air intake should be provided for any fireplace, stove or furnace. Chemical properties of interior materials and their behavior will affect the fresh air needs of the occupants. Non-toxic materials, finishes and furnishings are preferable. Proximity to smoking areas, perfumes and other odors contribute to air quality and ventilation needs as well.

Air-to-Air Heat Exchanger [46]

| Insulation Type (Note: Value may very with installation method) |

RSI per cm thickness | R[US] per inch thickness | RSI per thickness indicated | R[US] per thickness indicated |

| Blanket or Batt mineral fiber | ||||

| 8.6 cm [3.5”] | 2.0 | 11 | ||

| 14 cm [5.6”] | 3.3 | 19 | ||

| 19 cm [7.51”] | 4.0 | 22 | ||

| 24 cm [9.51”] | 5.3 | 30 | ||

| 28 cm [11”] | 7.0 | 38 | ||

| 38 cm [15”] | 88 | 50 | ||

| Boards & Slabs | ||||

| Polystyrene (extruded) | 0.35 | 5.0 | ||

| Cellular Polyurethane | 0.40 | 6.0 | ||

| Cellular Polyisocyanurate | 0.49 | 7.0 | ||

| Cellular phenolic (closed cell) | 0.87 | 8.2 | ||

| Loose Fill | ||||

| Cellulosic Insulation | 0.23 | 3.4 | ||

| Perlite Expanded | 0.23 | 3.4 | ||

| Perlite Dense | 0.18 | 2.6 | ||

| Pumice | 0.14 | 2.0 | ||

| Rice Hulls | 0.14–0.20 | 2–3 | ||

| Vermiculite | 0.14 | 2.1 | ||

| Spray Applied | ||||

| Aircrete | 0.27 | 3.9 | ||

| Polyurethane Foam | 0.4 | 6.0 | ||

| Cellulosic Fiber | 0.22 | 3.8 | ||

| Glass Fiber | 0.26 | 3.8 | ||

| Reflective Insulation | ||||

| Reflective material in center of air cavity | 0.6 | 3.2 | ||

| Transparent Insulation | ||||

| Honeycomb Polycarbonate 50 mm | 0.5 | 2.8 | ||

| Honeycomb Polycarbonate 100 | 0.9 | 5.3 | ||

| Capillaries Polycarbonate 100 mm | 1.0 | 5.9 | ||

| Capillaries Acrylic Glass 100 mm | 1.1 | 5.9 | ||

| Aerogel between Dual Glazing 35 mm | 5.8 | 36.3 | ||

| Vacuum Panel 2.5cm [1”] | 3.4 | 50 | ||

| Recent concerns about indoor air quality in tight buildings has generated the increased use of non-toxic, natural products for insulation. | ||||

| Wool Fiber | 0.27 | 3.8 | ||

| Wool Felt | 0.23 | 3.3 | ||

| Hemp | 0.21 | 3.0 | ||

| Cotton | 2.5 | 3.5 | ||

| Flax | 0.21 | 3.0 | ||

| Cork | 0.22 | 3.2 | ||

| Straw bale 46 cm [18”] | 0.10–0.20 | 1.5–2.0 | 2.8 | 33 |

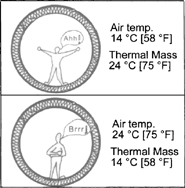

Large amounts of interior thermal mass are characteristic of passive solar architecture in temperate climate zones. The effectiveness of thermal mass is shown here, where the mean radiant temperature (MRT) is 40% more effective than air temperature in providing comfort. Humidity and air motion affect comfort, but MRT is the dominant factor in perceiving comfort.

Architectural thermal mass has two distinct categories: Concentrated and distributed.

Concentrated (C) thermal mass allows for the greatest amount of thermal mass radiatively coupled to the sun if it is an outside, equator facing wall with glazing. It usually consists of water or thick masonry although advances in phase change material offers additional opportunities.

Distributed (D) thermal mass is spread over a greater area of the building’s interior. It has a large surface area and although some may be radiatively coupled it is largely coupled to solar heat or cool air by convection.

1. Water has been successfully used as concentrated mass and has the following advantages:

• Highest heat capacity, short of phase change material

• Can distribute heat internally by convection

• Least expensive of all the materials listed on page 33

• Natural non-toxic material if kept free of algae

Applications of water as concentrated thermal mass are:

• Glazed steel tank behind windows

• Steel or plastic tubes of water

• Roof pond with movable insulation

• Thin shell structure with internal bladder

2. Uses of masonry as concentrated thermal mass include:

• Glazed masonry units below windows

• Glazed mass walls

• Floor, slab & structural walls

3. Distributed mass is relatively thin and can consist of walls, ceilings and partitions. Although less efficient for heating, it is superior for night vent cooling because of its large surface area for heat transfer to air. It can be used to supplement concentrated mass. Traditionally, distributed thermal mass has been a relatively expensive addition to standard construction; however, phase change materials that can be added to wallboard or plaster promises to change this drastically.

4. Thermal mass is usually the most expensive part of a passive system for a temperate climate. Therefore, dual use of other architectural elements such as floor slabs, structure and finished surfaces will reduce cost if kept uninsulated from the interior space. To inexpensively add distributed mass, gypsum wall board ceilings and walls may be doubled in thickness. Although not as effective as most other materials this is a relatively inexpensive way of adding more distributed mass.

5. Concentrated mass needs to be as absorptive as possible, even to the point of using selective surfaces on the areas facing the sun. In contrast, distributed mass needs to be somewhat reflective so that light and heat are spread over a greater area. Light colored interior surfaces including distributed mass, help with natural lighting and the prevention of glare.

As modern architecture matured most buildings became smooth seamless envelopes, sealed to allow thermal conditioning and lighting by mechanical and electrical equipment. The result of this highly differentiated approach was freedom from orientation, apertures and personal control; but this also created high energy demand and costs. In contrast, orientation is an integral aspect of passive solar architecture, providing lighting, heating, cooling, personal control and contact with the exterior environment.

Type of Aperture Listed by Single Function

U-Value (U): The measure of heat loss or gain through a material known as conduction and the inverse of the R-value; U = 1/R. Usually ranges from 0.1 (RSI 1.76 = [R = 10] to 1.20 (RSI 0.15 = [R = 0.83].

Solar Heat Gain Coefficient (SHGC): A measure of how much heat flows through the glass to the interior of the building, compared to amount that strikes it, usually ranging from 0.2–0.9. SHGC is especially important for passive heating.

Shading Coefficient (SC): The measure of a window’s ability to block solar heat relative to 3 mm [1/8”] clear glass.

Visible (Daylight) Transmittance (Tvis): A measure of the relative amount of sunlight passing through a glazing assembly, usually ranging from 0.3–0.8. A higher number yields more light for daylighting.

Air Leakage (ALR): The measure of how much infiltration (air leakage) exists around a window, door or skylight with a known specific pressure difference.

Condensation Resistance: Measured between 0 to 1 with a higher rating corresponding to better resistance against condensation or moisture due to thermal fluctuations.

| Glazing Type Typical window assemblies |

U-value | U-value | SHGC | Tvis |

| W/m2°C | BTU/ft2°F | |||

| Single-glazed Clear (Alum. frame) | 7.37 | 1.30 | 0.79 | 0.69 |

| Double-glazed Clear(Alum. frame) | 3.63 | 0.64 | 0.65 | 0.62 |

| Double-glazed Clear (wood or vinyl frame) | 2.78 | 0.49 | 0.58 | 0.57 |

| Double-glazed Bronze (Alum. frame) | 3.63 | 0.64 | 0.55 | 0.47 |

| Double-glazed Bronze (wood or vinyl frame) | 2.78 | 0.49 | 0.48 | 0.43 |

| Double-glazed Low-E (low-emissivity 0.20, wood or vinyl frame) | 1.87 | 0.33 | 0.55 | 0.52 |

| Triple-glazed Low-E 0.08 w/argon (wood or vinyl frame) | 1.70 | 0.30 | 0.44 | 0.56 |

| Double-glazed spectrally selective Low-E 0.04 w/ argon (wood or vinyl frame) | 1.65 | 0.29 | 0.31 | 0.51 |

| Double-glazed spectrally selective Low-E 0.01 w/ argon (wood or vinyl frame) | 1.76 | 0.31 | 0.26 | 0.31 |

| Triple-glazed Low-E 0.08 w/ krypton (insulated vinyl frame) | 0.85 | 0.15 | 0.37 | 0.48 |

| Triple-glazed Clear w/ air (wood I or vinyl frame) | 1.93 | 0.34 | 0.52 | 0.53 |