6

PILLAR 2: ELECTRIFICATION

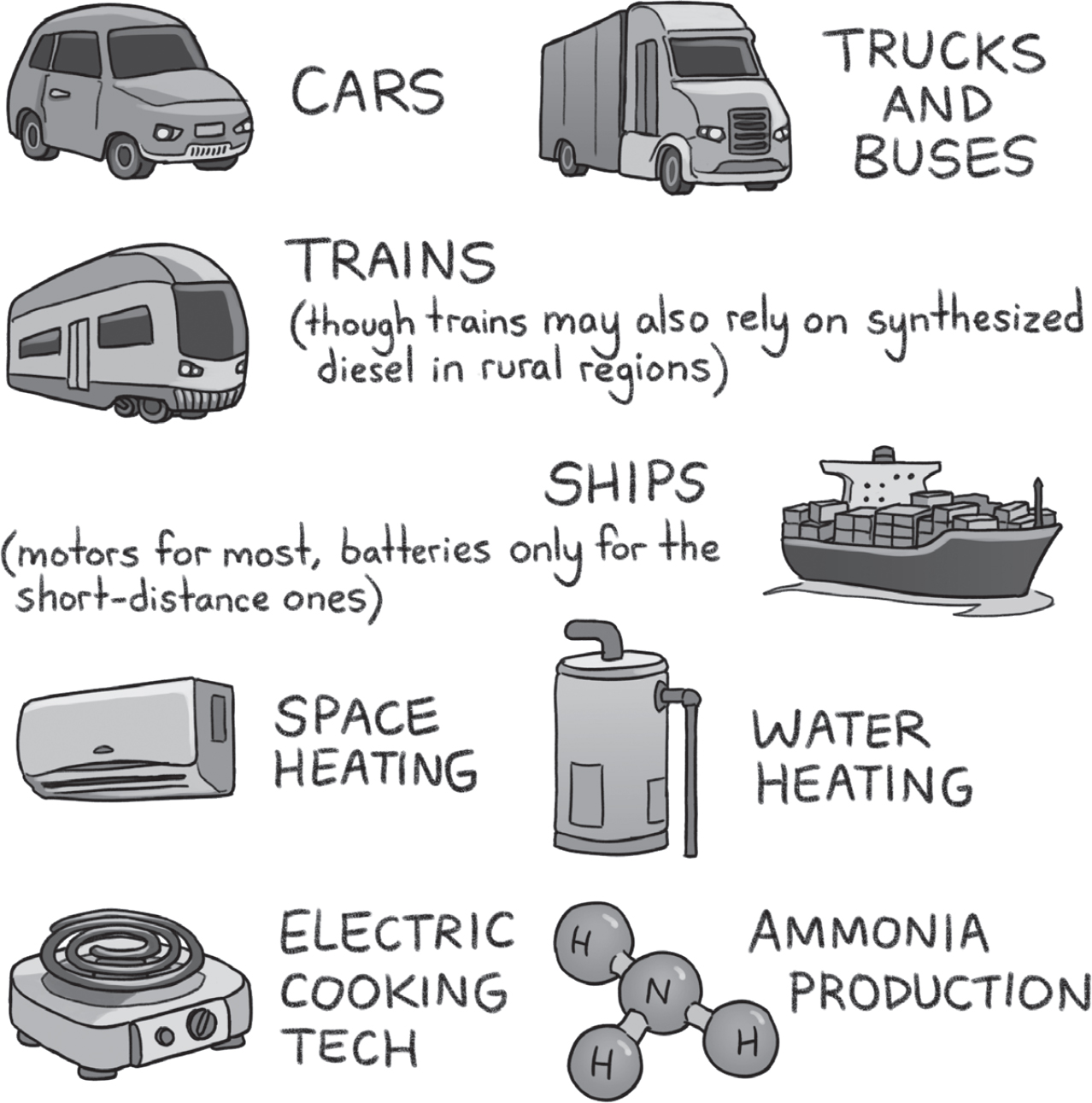

Most of the energy system could theoretically be decarbonized through electrification: converting equipment that currently runs on fossil fuels to equipment powered by electricity. We see this starting in our everyday lives with electric cars and electric home heating. The conversion will take place on a broader scale, too, in areas such as freight transportation and industrial processes.

VARIED EQUIPMENT

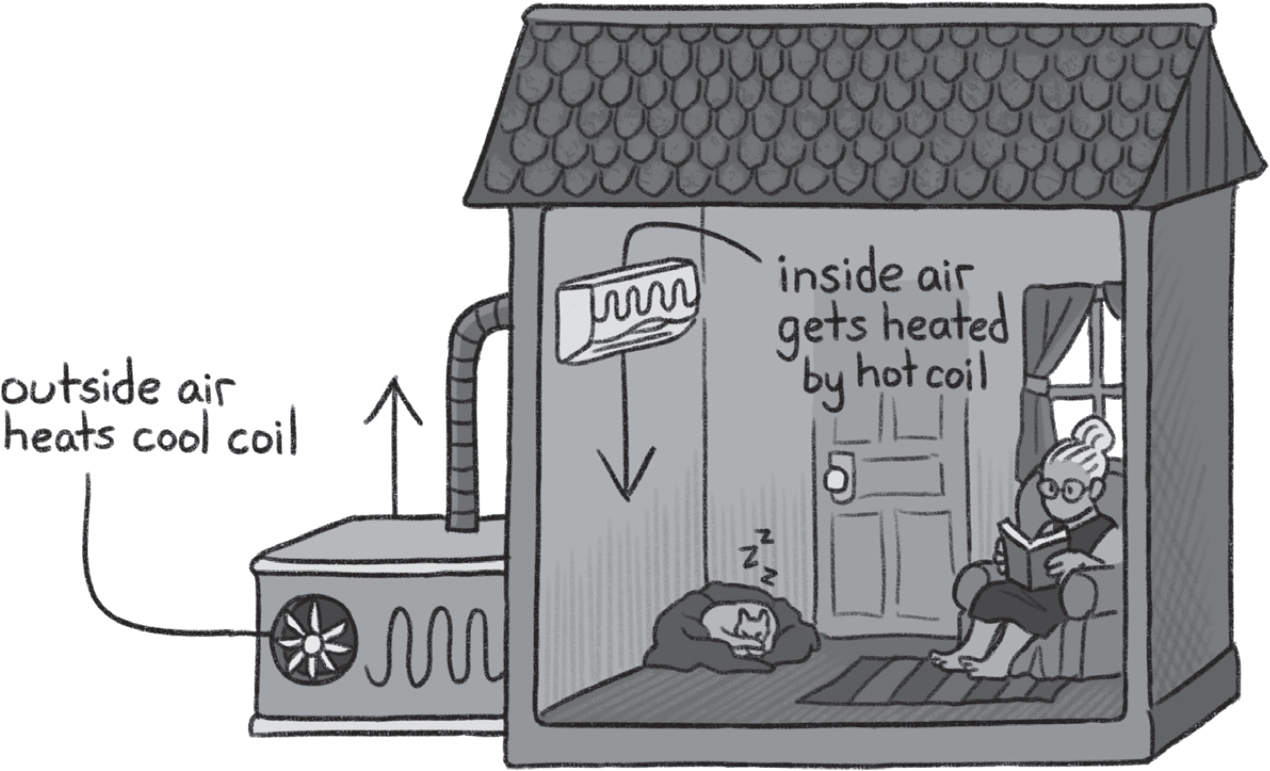

The technology required for electrification is different for every individual end use. To electrify personal transportation, an electric car motor and battery are both needed at capital costs that are lower than fossil fuel engines. An electric ship motor will call for a different design, and might run off the same or similar batteries, or off of a hydrogen or ammonia fuel cell (especially for longer-distance shipping). Electrification of trains requires building overhead power lines, a totally different challenge (those lines could also be used to extend and interconnect the grid). And heating for buildings requires improvement in the cost and cold-weather performance of heat pumps, which are like reverse refrigerators and bear no resemblance to engines or motors.

Government bodies should identify all the specific electric equipment that is either essential or would be highly useful, and convene researchers or industry players (depending how far along the given tech is) to ensure that at least one cost-competitive electrified option is available for each.

The good news here in Pillar 2 is that several electrified options are already close to becoming cheaper than their fossil competitors. Electric heat pumps are generally cheaper than oil heating and often competitive with other options depending on the climate, building’s insulation, and other factors.34

Electric heat pumps don’t work in extremely cold climates yet, but have improved to the point that they function in regions accounting for the vast majority of human population, and they can always be backed up by less efficient but equally non-polluting electric resistance heating (running electricity through lots of wire to heat up the wire and therefore the air around it). If clean electricity generation options outcompete fossil fuel electricity generation, the cost of electricity will by definition drop at least slightly, making heat pumps and other electrified equipment more competitive.

The main categories of equipment to focus electrification efforts on.

An air-source heat pump, with the compressor in the outside unit with the cold coil.

Electric cars have started to compete commercially, but their capital costs are still double those of equivalent gasoline cars, owing to the cost of the batteries.35 If lithium-ion batteries came down further in cost, or if new, cheaper batteries were developed to replace them, electric car manufacturing could be scaled up to the point that electric cars quickly outcompete gasoline cars.

Trends toward self-driving cars and fleet ownership of cars (a Lyft/Uber-type company of the near future might own thousands of cars and bring you where you need to go on demand, reducing the number of personally owned cars) may also help promote the adoption of electric cars, which have far lower maintenance costs compared to gas cars (this is key when cars are operating like taxis, driving a much higher percent of the time, rather than sitting in individual people’s driveways most of the time, as cars do now).36

The efforts required in this pillar span from basic engineering to mass-manufacturing scale-up. Government projects need to convene industry players to get certain key electric options designed. Policies and initiatives to scale up electrified equipment will help bring capital costs down to below or around those of fossil options. And improvement in technologies themselves, such as battery or heat pump chemistry, could help make electrified options definitively cheaper. Support for startups and existing companies that are conducting demonstration projects and bringing new designs to commercialization is key.

TIMELINE FACTORS

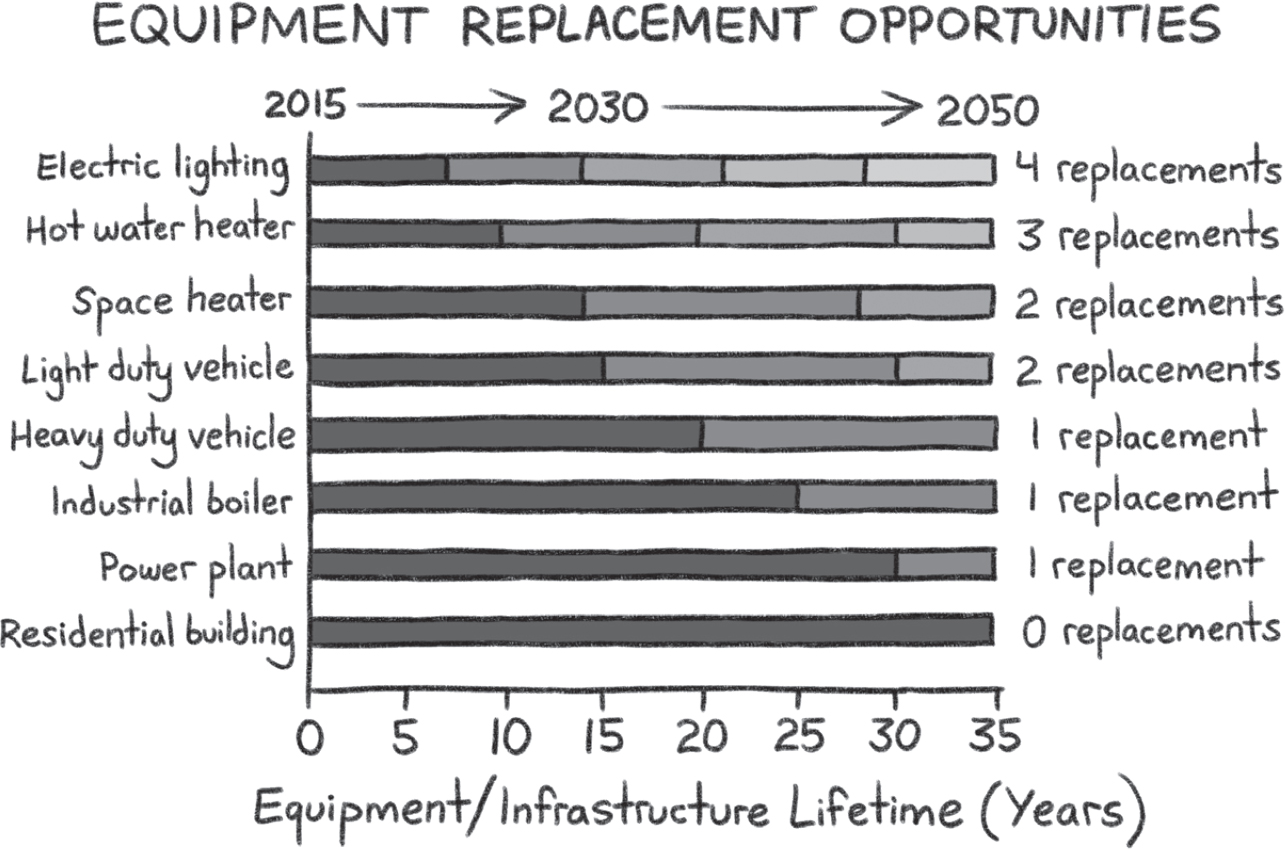

This pillar needs to be carried out relatively quickly. Electrified options may (easily, in some cases) become cheaper to install than installing a new fossil option for the same process. But it is much harder for these options to become so cheap that it makes economic sense to retire a still-functional piece of fossil equipment early and replace it with a new piece of electric equipment. Some options may get there, but for most, the deployment opportunity will be when each equivalent piece of fossil equipment is naturally retired. That turnover happens about every fifteen years for cars, but fifteen to twenty-five years (or longer) for home furnaces, and longer still for much industrial equipment. Therefore, electric options have to become definitively cheaper in the next ten years or so in order to be ready at the moments when most relevant fossil equipment is being retired. Even then, there will be some portion of fossil equipment that doesn’t get replaced naturally by 2050—so drop-in fuels (see Chapter 7), policy mandates or subsidies, or sequestration will be needed to fill in those gaps. Several recent reports estimated that 10–30% of equipment that could be electrified won’t happen to get converted by 2050.37

Electrified options may (easily, in some cases) become cheaper to install than installing a new fossil option for the same process. But it is much harder for these options to become so cheap that it makes economic sense to retire a still-functional piece of fossil equipment early and replace it with a new piece of electric equipment.

Most relevant equipment will only be naturally retired once or twice in the timeframe we have to achieve negative emissions.38

SCALING UP ELECTRIFICATION

This pillar is also one of the easiest to support with policy mandates or incentives. With several major electrified options nearly cost competitive, regions—even states and provinces in countries that aren’t yet ready to act nationally—can subsidize the adoption of electric cars or air-source heat pumps through tax credits or rebates. Government programs can educate individuals and convene companies to encourage adoption of these technologies. Policies can also incentivize large companies to spur deployment of electrified options. For example, states can enact performance-based regulation of electric utilities in which utility companies make more money if a target number of charging stations, or electric cars, or heat pumps, are deployed in their service area within a given timeframe. Under such a system, utilities might choose to build charging stations themselves, or they might engage in more widespread education and encourage companies and families to adopt electric heating or other clean technologies.

Government purchasing power can also be used to directly scale up emerging electrified equipment by providing the first guaranteed market for various technologies. Most public building projects or public purchases of vehicle fleets are put out for contractors or suppliers to bid on. The bidder with the cheapest option that meets quality criteria gets hired—and criteria could include that the product has to be carbon neutral. Government purchasing departments, for example, could consider bids to construct new government buildings only if the design included air-source heat pumps and advanced insulation. Or states could put out a request for bids to supply electric vehicles for the entire state fleet as it gets replaced over the following years. The US federal government recently helped a new industry get off the ground in this way, by purchasing satellite launches from SpaceX and thus creating the first market for private space equipment.39