Contrary to the opinion of several others who have written on the subject of smoked foods, I think that the smoking of natural cheese results in a product that tastes awful at best and inedible at worst.

I have tried to smoke many of the recommended varieties of natural cheese. They were smoked with light smoke for a short time as suggested, and the result was always bad. Invariably, the cheese seemed to absorb only the bad odors in the smoke. Therefore, I suggest that if you have some good-tasting natural cheese, count your blessings, and eat it as it is. Don’t smoke it! You will not likely be able to improve on the flavor resulting from 4,000 years of experience accumulated by cheese-makers.

What about the smoked cheeses sold in the grocery stores or those available by mail order? Some taste very good. If it is natural cheese being sold as smoked cheese, look at the small print where the ingredients are listed. “Natural smoke flavor” will most likely appear there. This means that the cheese was seasoned with something like liquid smoke. It was not smoked.

If the cheese was truly smoked, somewhere on the package it probably says something like “Smoked with real hickory!” In that case, if you look closely, you will most likely find that the cheese is processed, not natural. I have tasted many brands of smoked processed cheese, and most are excellent. They usually have a mellow natural smoke flavor, and the cheese, although it is processed, does not taste substandard in any way.

I have seen, on rare occasions, smoked cheese that appeared to be natural cheese. However, if they are using natural cheese, they most likely have a special processing technique. For example, I have heard of a company in Europe that produces excellent smoked, natural cheese by smoking the milk before it is made into cheese. Unfortunately, such technology is not available to us.

Nevertheless, the good news is that we can easily make smoked processed cheese, and it tastes great! But why is it that smoked processed cheese tastes so good and smoked natural cheese tastes so bad? Well, smoked natural cheese contains butterfat—a lot of butterfat, and butterfat absorbs foul odors readily. No doubt you have tasted butter that has absorbed odors from raw onions, and the like, while in the refrigerator. Natural cheese does the same thing, and it absorbs foul odors in the smoke chamber much faster than in the refrigerator.

Processed cheese is made from natural cheese that has been finely ground and blended with emulsifiers, conditioners, flavorings, and sometimes coloring and preservatives. The cheese is then melted and formed into blocks or some other shape. These additives attach themselves enthusiastically to the butterfat molecules in the cheese; consequently, the foul odor molecules in the smoke no longer have a place to attach. If there is no place for the foul odor molecules to attach, then they can’t be absorbed by the cheese. This is why processed cheese will not acquire an unpleasant taste when it is smoked. (A Japanese government agricultural researcher, Ms. Munekado, kindly explained this odor absorption and odor-blocking phenomenon to me.)

In Japan, I smoked about 88 pounds (40 kg) of processed cheese every winter. It was attractively packaged, and each package weighed a little less than ½ pound (200 g). About half of the smoked cheese was given to friends and acquaintances as year-end gifts. The rest I sold to local pubs and to acquaintances who wanted to give it away to their friends. The smoked processed cheese was so well received that I could have easily sold twice as much. I mention all of this only to encourage you to try it once, even if you are not fond of processed cheese.

To smoke processed cheese you will need the following:

The cheese should be cut into “sticks” about 1 inch by 1 inch by 5 inches (2.5 x 2.5 x 12 cm). The measurements are not critical, but there will be better smoke aroma penetration if the thickness does not exceed about an inch. If you are going to cut the large block of cheese yourself, you should first leave it at room temperature for about eight hours. Warmed blocks of cheese can be cut easily. Failure to warm the cheese to room temperature could result in unsightly broken pieces.

Place the cotton-net material on the racks, and then place the cheese on that material. There should be spacing of about 1 inch (2.5 cm) between the sticks of cheese. Cheese placed too closely together will not color properly. Let the uncovered sticks of cheese dry overnight in a cold room with no fan. This slight drying will aid coloration. (The golden color of the finished product results from both the smoke and the slight drying.) Excessive drying will cause the cheese to crack.

Cold smoke the cheese for three hours at a temperature of less than 80º F (27º C), remove the racks from the smoker, and inspect each stick. If there are moisture droplets on the tops and sides of the sticks, blot them with a paper towel, and then turn over each stick of cheese.

Return the racks to the smoker. If you are using several layers of racks, be sure to layer the racks in the reverse order: The top rack should now be placed on the bottom, et cetera. (Cheese on the bottom rack will dry faster than that on top because the rising hot air becomes more humid as it collects moisture from the cheese in the lower levels.)

Cold smoke the cheese for three more hours. At the end of the smoking period, the cheese should have taken on a beautiful golden color. Remove it from the smoker. Inspect each stick of cheese, and use the point of a paring knife to brush off any soot specks that may be present. Refrigerate in plastic bags or plastic containers.

If this cheese is refrigerated in sealed plastic bags, it will keep in perfect condition for many months; as a test, I kept a stick of this smoked cheese in the refrigerator for one year, and it still tasted great. It will not mold because the imparted smoke flavoring acts as a fungicide. (Some brands of American cheese have excessive salt, and this causes white salt deposits on the surface—this is not mold. To prevent this minor problem, buy cheese with reduced salt, if it is available.) Slice thinly, and eat at room temperature, preferably with your favorite wine.

There are several methods to smoke eggs. In all cases, the eggs are hard boiled before smoking. Extremely fresh eggs do not peel easily after boiling, so make sure that the eggs are at least three days old.

Boiling eggs is certainly a simple cooking operation, but the following method minimizes the problem of cracking:

Several books on food smoking mention the smoking of eggs. One method suggests placing the boiled, unpeeled eggs on a smoking rack or on a wire net, and then smoking them at 70º to 90º F (21º to 32º C) for many hours until they take on a rich amber color. If your smoker will not operate at such a low temperature, keep the temperature as low as possible. Actually, the eggs will color faster at higher temperatures, but they may become too dark. If these smoked eggs are refrigerated for a day or so in a plastic bag, the smoke aroma will mellow and penetrate the eggshells to some extent.

Another method suggests sprinkling boiled and peeled eggs with seasoned salt and then cold smoking them until they have absorbed enough smoke to suit your taste.

If you try these two methods, you may conclude, as I did, that the results are not dramatic enough to warrant the effort.

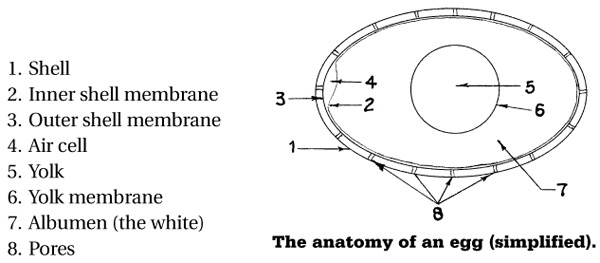

Because of my disappointment with the eggs that were smoked by using the methods described above, I have tried, over the years, to develop a process to make the perfect smoked egg. This quest has led me to study the “anatomy” of eggs and conduct many experiments. Much was learned from these experiments. In retrospect, however, a few of the many experiments were quite harebrained, and they resulted in nothing more than the destruction of perfectly good eggs!

The process explained below is the result of the more fruitful of my experiments mentioned above. Knowledge gained from those experiments helped me develop this improved process for smoking eggs. I cannot call the product “perfect,” but the smoked eggs produced by the following method are extraordinary and very good to eat. Smoked eggs supreme is an immeasurable improvement over either of the two simple methods of smoking eggs mentioned above.

Eggs with sturdy shells are desirable because the shells will undergo considerable stress. According to an acquaintance of mine, a veterinarian who specializes in chickens, small- or medium-sized eggs are apt to have stronger shells than large or extra-large eggs. One reason for this, he says, is that the smaller eggs are likely to come from young hens, and young hens produce stronger shells. All this assumes that the hens have been fed adequate eggshell-producing nutrients such as powdered oyster shells. But no matter what size eggs you use, try to use the same size every time so that the quality of your product will be consistent. Use white eggs. If brown eggs are used, the degree of coloration due to smoking is difficult to judge, and the degree of coloration on the outside of the egg is an indication of what is happening inside the egg.

Boil the eggs using the method previously explained. After cooling the eggs in cold water, remove them to a towel to drain and dry. Inspect each egg for cracks. If a crack is found, use the egg for some other purpose. Let them set at room temperature the rest of the day and overnight. Boiling, and then leaving the eggs at room temperature for one day and one night, will weaken the waterproof properties of the two layers of white, plastic-like membranes that lie just under the shell. By osmosis, these weakened membranes will allow salt to penetrate slowly into the interior of the egg. If the shell has a crack, the membranes will probably be damaged, and excessive salt will penetrate when the eggs are soaked in brine.

Use the brine table in appendix 3 to make sufficient 80 percent brine to cover the eggs. One quart (1 liter) of brine will cover about 10 to 12 eggs. Brine the eggs for 72 hours at room temperature. Use a plastic, glass, stainless-steel, or enameled container—not aluminum.

By this time, 72 hours will have elapsed, and sufficient salt will have penetrated the eggshells and the two membranes. Give them a quick rinse in fresh water, drain, and let them dry on a towel overnight, unrefrigerated.

Begin dehydrating the eggs in the smoke chamber by slowly bringing the temperature up to 140º F (60º C) over a 45-minute period (with no smoke). (When the entire process has been completed, the finished product will have become partially dehydrated—this is the first step in removing some of the moisture from within the eggs.) Hold at this temperature for about four hours. Then, over a period of one hour, slowly raise the temperature to 195º F (90º C). Look at the eggs; there may be tiny droplets of water on the shells. If there are no droplets, or only a few, begin smoking. The smoke will penetrate the microscopic holes in the shells, dissolving in the moisture escaping from those holes; the flavoring components of the smoke will pass through the weakened membranes by osmosis—similar to the way that smoke flavor passes through a sausage casing.

Smoke at about 195º F (90º C). The smoking will probably require seven hours. Sample one egg after five hours of smoking, and sample another every hour after that to determine when to stop smoking. When the first egg is sampled, use this opportunity to turn all the eggs over so that coloration will be even. The smoking is finished when the albumen (the white) has become a light tan color and the total edible part of the egg has shrunk about 20 percent. The egg, including the yolk, will have a mellow, smoky taste, and it will have just the right amount of salt. Because about 20 percent of the moisture will have been lost, the bite texture will be delightfully different from a common boiled egg.

If none of the eggs has exploded or imploded, then the process control has been very good, and you are blessed with good luck. Exploded eggs result when the processing temperature has exceeded 212º F (100º C), or the temperature has been raised too rapidly. Imploded eggs result when moisture loss has been too rapid. When the moisture loss has been too rapid, the atmospheric pressure is greater than the pressure inside the egg; the shell may break inward (implode).

Cool the eggs at room temperature. After they reach room temperature, rinse off the “freckles” with cold water (but don’t soak them in water). Refrigerate. (The freckles result from smoke dissolving in the salty moisture that escapes from the eggs during smoking.) The eggs will taste even better if they are allowed to set in the refrigerator for one day. Boiled eggs may be one of the least interesting of foods, but smoked eggs processed by this method are guaranteed to be an unforgettable delicacy.

Smoked salt is one of the easiest products to make, and it has numerous uses. Keep it in the kitchen, and use it in place of regular salt anytime you think a slightly smoky flavor might improve a dish you are preparing. Sprinkle it on eggs, salads, boiled foods, or baked foods.

The best time to make smoked salt is when you are smoking some other product and there is some unused space in the smoke chamber. The smoke chamber temperature is not critical, but it is best if the smoke chamber humidity is not too high. Any type of salt can be used, but the type that contains a free-flow agent is best.

Put about ⅜ inch (about 1 cm) of salt in a shallow, nonmetallic dish that is heat resistant. A chinaware dish is ideal. (The smoke could permanently stain the dish, so don’t use anything precious.) The humidity is always lowest in the lower levels of the smoke chamber, so place the dish on the lowest rack, if possible.

Stir the salt about once every hour while smoking. Stirring will allow all the salt crystals to get their share of smoke. The smoking is complete when the salt has become a uniform amber color.

Spread the nuts or seeds on a fine screen. If a fine screen is not available, put them in a shallow baking pan, and stir them from time to time while they are smoking. If possible, cold smoke at below 85º F (29º C). Smoke the nuts for about 30 minutes. Sample some of the nuts to determine if they have been sufficiently smoked. If 30 minutes does not provide enough smoky flavor, increase the smoking time to an hour or hour and a half. Note: Nuts and seeds will easily acquire a sooty taste if the smoking time is too long.

The proper smoking time varies according to the kind of nut or seed, so it is best to sample each variety as they are being processed. Record the smoking conditions that give the best results, according to your taste.

If the nuts are unsalted and you wish to impart a salt flavor, you can easily oil and salt them—before or after smoking. First, shake them in a plastic bag together with a piece of paper towel that has been moistened with peanut oil or olive oil. This will put a light coating of oil on the nuts. Next, remove the paper towel, sprinkle the desired amount of salt on the nuts, and shake them again. Because the nuts have been oiled, the salt will adhere to the nuts much better than if they were completely dry. Use smoked salt, if it is available.

My favorite smoked nut is the cashew, but other varieties are good, too. For me, a smoking time of one hour is just right for cashew nuts.