|

8

Introducing Project Quality Management

|

CERTIFICATION OBJECTIVES

What is quality? According to the PMBOK Guide, quality is the “totality of characteristics of an entity that bear on its ability

to satisfy stated or implied needs.” Every project has an anticipated level of quality

for the project deliverables. Project quality management is the process of ensuring

that the project fulfills its obligations to satisfy the project needs. As projects

vary, so, too, will the anticipated level of quality.

Picture this: It’s late on a hot summer night and you’re hungry. You pull onto a gravel

road and see a diner with a neon “Open” sign. The sign, you notice, really says “Ope”

since the “n” is burned out. Inside the diner, stale smoke drifts around like fog.

Grease, onions, and garlic seep into your clothes. You opt for a booth only to find

the table smeared with catsup, a little gravy, and, guessing by the stickiness, a

glob of maple syrup.

Now picture this: You step off the elevator on the 43rd floor. A maitre d’ welcomes

you and guides you to a table next to a window offering a sweeping view of the city.

A piano player massages a song into the evening. The waiter snaps open a napkin and

drapes it across your lap. Another waiter pours you a glass of cold, crisp water and

presents the menu. By the soft candlelight, everything looks, and feels, grand.

With these two contrasting scenarios, which one do you think will have the better

quality? Or can they both have an acceptable level of quality? For the first scenario—the diner—you expect a certain level of

quality when it comes to service, food, and atmosphere. With the second scenario—the

fancy restaurant—you also have an expected level of quality regarding service, food,

and atmosphere. Both experiences are measured by that expected level of quality.

In the diner, you might get one of the best bacon cheeseburger/milkshake combos you

can find late at night in the middle of nowhere. Just what you’d expect from this

kind of place. And the fancy downtown restaurant? A fancy meal cooked to perfection—also

what you’d expect. The difference between the two restaurants is in their grade. The

expected level of service, food, and atmosphere is the quality of the experience.

CERTIFICATION OBJECTIVE 8.01

Looking at the Big Quality Picture

Before we hop into the three different facets of project quality management, let’s

establish a few “PMI-isms” on quality. Because quality means so many different things

to so many different people, it’s important to confirm we’re working with a common

understanding of what quality is and what quality management hopes to accomplish from

the PMI’s point of view.

Accepting the Quality Management Approach

The details and specifications set out by the customer determine the expected level

of quality. Project quality management, as far as your exam goes, is compatible with

ISO 9000 and ISO 10000 quality standards and guidelines.

Project quality management also is concerned with both the management of the project

and the product of the project. It’s easy to focus on the product (the thing or service

the project creates), but project managers must also provide quality for the project

management activities. Aspects of the downside of focusing too much on the product

include the following:

Overworking the project team in order to complete the project. This may result in

unacceptable work, a decline in team morale, and the slow, steady destruction of the

project team’s willingness to work.

Overworking the project team in order to complete the project. This may result in

unacceptable work, a decline in team morale, and the slow, steady destruction of the

project team’s willingness to work. A hurry to complete the project work by speeding through quality inspections. This

can result in unacceptable deliverables.

A hurry to complete the project work by speeding through quality inspections. This

can result in unacceptable deliverables.

ISO 9000 is an international standard that helps organizations follow their own quality

procedures. It is not a quality system, but a method of following procedures created

internally in an organization. And for the curious, ISO means uniform in Greek and

it’s from the International Organization for Standardization.

See the video “Project Quality Management.”

See the video “Project Quality Management.”Quality vs. Grade

Quality and grade are not the same.

Quality is the sum of the characteristics of a product that allow it to meet the demands

or expectations of the project. Quality is all about fulfilling requirements.

Know that low quality is always a problem, but low grade may not be. Depending on

the requirements of the customer, low grade may be completely acceptable, but low

quality never is.

Grade, according to the PMBOK, “is a category or rank given to entities having the

same functional use but different technical characteristics.” For example, there are

different grades of paint, different grades of metal, and even different grades of

travel.

Implementing Quality Project Management

Quality management and project management have similar characteristics:

Customer satisfaction The project must satisfy the customer requirements by delivering what it promised

in order to satisfy the needs of the customer. The PMBOK states it as “conformance

to requirements” and “fitness for use.”

Customer satisfaction The project must satisfy the customer requirements by delivering what it promised

in order to satisfy the needs of the customer. The PMBOK states it as “conformance

to requirements” and “fitness for use.” Prevention Quality is planned into a project, not inspected in. It is always more cost-effective

to prevent mistakes than to correct them.

Prevention Quality is planned into a project, not inspected in. It is always more cost-effective

to prevent mistakes than to correct them. Management responsibility The project team must work toward the quality goal, but management must provide

the needed resources to deliver on the quality promises.

Management responsibility The project team must work toward the quality goal, but management must provide

the needed resources to deliver on the quality promises. Plan-do-check-act Dr. W. Edwards Deming, arguably the world’s leader in quality management theory

thanks to his management methods implemented in Japan after World War II, set the

bar with his “plan-do-check-act” approach to quality management. This approach is

similar to the project management processes that every project passes through.

Plan-do-check-act Dr. W. Edwards Deming, arguably the world’s leader in quality management theory

thanks to his management methods implemented in Japan after World War II, set the

bar with his “plan-do-check-act” approach to quality management. This approach is

similar to the project management processes that every project passes through. Kaizen technology Kaizen is a quality management philosophy of applying continuous small improvements

to reduce costs and ensure consistency or project performance.

Kaizen technology Kaizen is a quality management philosophy of applying continuous small improvements

to reduce costs and ensure consistency or project performance. Quality improvement programs One of the goals of any organization is to improve quality, reduce errors, and

effectively become more efficient and more productive. Two quality improvements the

PMBOK Guide mentions directly are Total Quality Management and Lean Six Sigma. Both programs

aim to reduce waste, eliminate non-value-added efforts, and help the organization

become more efficient and achieve quality goals.

Quality improvement programs One of the goals of any organization is to improve quality, reduce errors, and

effectively become more efficient and more productive. Two quality improvements the

PMBOK Guide mentions directly are Total Quality Management and Lean Six Sigma. Both programs

aim to reduce waste, eliminate non-value-added efforts, and help the organization

become more efficient and achieve quality goals.CERTIFICATION OBJECTIVE 8.02

Preparing for Quality

Before a project manager can plan for quality, he must know what the quality expectations

are. Specifically, what are the quality standards of the performing organization and

which quality standards are applicable to the project? As part of the planning processes,

the project manager and the project team must identify the requirements of planning,

determine how the requirements may be met, and identify the costs and time demands

to meet the identified requirements.

One of the key principles of project quality management is that quality is planned

in, not inspected in. Planning for quality is more cost-effective than inspecting

work results and doing the work over or correcting problems to adhere to quality demands.

The project manager must consider the cost of achieving the expected level of quality

in contrast to the cost of nonconformance. The cost of quality includes training,

safety measures, and action to prevent poor quality. The cost of nonconformance can

far outweigh the cost of quality with its possible loss of customers, the rework needed,

lost time, lost materials, and the danger to workers.

As part of planning, the project manager must be wary of gold plating. Gold plating

happens when the project manager sees there’s money left in the budget so she adds

features and extras to the project scope only to consume the budget. The customer

does not need or want more than what was requested. Gold plating can be considered

unethical.

Determining the Quality Policy

Top management should define the quality policy; this is part of the organizational

process assets. The quality policy of the organization may follow a formal approach,

such as ISO 9000, Six Sigma, or quality function deployment, or it may have its own

direction and approach to satisfying the demand for quality. There are loads of proprietary

quality management methodologies, and you won’t need to know much about any of them

for your PMP exam. Out in the real world, however, you’ll need to be familiar with

the rules, policies, and procedures of whatever quality management methodology your

organization subscribes to. Lucky you.

The project team should adapt the quality policy of the organization to guide the

project implementation. This ensures that the management of the project and the deliverables

of the project are in alignment with the performing organization’s quality policy.

In addition, the project manager should document how the project will fulfill the

quality policy both in management and in the project deliverable.

But what if the performing organization doesn’t have a quality policy? Or what if

two different entities are working together on a project and they use differing quality

policies? In these circumstances, the project management team should create the quality

policy for the project. The quality policy, in these instances, will accomplish the

same goals as a company’s quality policy: to define quality requirements and determine

how to adhere to them.

Regardless of where the quality policy comes from—management or the project team—the

project stakeholders must be aware of the policy. This is important because the quality

policy and associated quality methodology may require actions that could lengthen

the project schedule—for example, quality audits, peer reviews, and other quality-centric

activities. In addition to the required time to fulfill the quality requirements,

other costs may be incurred.

Reviewing the Scope Baseline

Just as project quality management is focused on fulfilling the needs of the project,

the project scope baseline is a key input to the quality planning process. I know

you know that the scope baseline comprises the project scope statement, the WBS, and

the WBS dictionary. Recall that the scope statement defines what will and will not

be delivered as part of the project, as well as objectives regarding cost, schedule,

and scope. The deliverables, and the expectations of the customers, will help guide

the quality planning session to ensure that the customer requirements are met with

regard to quality.

While the project scope will define the initial product description, the product description

may have supporting detail that the project manager and project team will need to

review. Consider a project to create an apartment building. The requirements, specifications,

and details of the building will need to be evaluated and reviewed since this information

will, no doubt, affect the quality planning.

The WBS and WBS dictionary are needed during quality planning because they define

the specific things that will satisfy the project requirements for deliverables. The

WBS is like a catalog of expectations the customer has of you. When you and your project

team fulfill the elements of the WBS, you’re meeting customer satisfaction, which

maps to quality. The WBS dictionary tags along because it has the specific details

of what each element of the WBS requires.

So what is quality in project management? Quality is the accurate completion of the

project scope and the satisfaction of the stated and implied project needs. In your

quest for your PMP certification, do you have quality? What is the scope of your certification

goal and how will you reach it? Focus on quality as you’re studying, in your preparation,

and in your mental mindset, and you’ll find quality in the execution of your PMP test-taking.

So what is quality in project management? Quality is the accurate completion of the

project scope and the satisfaction of the stated and implied project needs. In your

quest for your PMP certification, do you have quality? What is the scope of your certification

goal and how will you reach it? Focus on quality as you’re studying, in your preparation,

and in your mental mindset, and you’ll find quality in the execution of your PMP test-taking.Consider Schedule and Costs

From the project management plan you will also need to consider the schedule and costs

baselines. Recall that quality is affected by the balance of the schedule, costs,

and scope, so it stands to reason that you’ll need the baselines of these components

of the project management plan as part of quality planning. The balance of time, cost,

and scope are the Iron Triangle of project management. If your organization has high

demands for quality, but the project is rushed or insufficient funds are available

to achieve the quality demanded in the project scope, then there is a risk that the

project will not be successful because quality could not be achieved.

The schedule of the project does affect quality. Consider a schedule that is perfect

only for the project activities and doesn’t consider time for the quality inspections.

If the quality inspections are rushed, or worse, skipped entirely, there will probably

be errors in the project work. The project schedule should include time for the project

management work, including the quality control activities discussed in this chapter,

in order for the quality expectations to be met.

Costs can also influence the ability of the project to meet quality. If the costs

are not adequate to meet the demands of the project scope—such as purchasing the correct

materials, tools, and equipment—then quality is likely to suffer as well. Costs affect

the elements of the project quality because to achieve the expected quality, you’ll

have to pay for the correct tools, equipment, material, and resources to ascertain

quality. If there are errors and mistakes in the project execution, quality can be

adversely affected by costs again. Consider a project that wastes materials due to

an error. If the organization can’t afford to replace the materials, the quality of

the project suffers because of the error and ultimately because of the cost of the

wasted materials.

Reviewing the Standards and Regulations

The standards and regulations of each industry should be reviewed to determine that

both the project plan and the plan for quality are acceptable. For example, a project

to wire a building for electricity will have certain regulations to which it must

adhere. The relevance of the regulations must be understood and planned into the project

to ensure conformance with regulatory requirements. Standards and regulations are

considered part of the enterprise environmental factors that affect the project planning

and execution.

CERTIFICATION OBJECTIVE 8.03

Planning for Quality

Once the project manager has assembled the needed inputs and evaluated the product

description and project scope, she can get to work creating a plan regarding how to

satisfy the quality demands. She’ll need to rely on the documentation created to date,

her project team, and the project’s key stakeholders for much of the input. In addition,

the project manager will use several different techniques to plan on meeting quality.

As planning is an iterative process, so, too, is quality planning. As events happen

within the project, the project manager should evaluate the events and then apply

corrective actions. This is a common PMI theme: plan, implement, measure, react—and

document! Throughout the project implementation, things will go awry, team members

may complete less-than-acceptable work, stakeholders will demand changes, and so on;

all of these variables must be evaluated for their impact on project quality. What

good is a project if it’s “completed” on time, but the quality of the deliverable

is unacceptable? Technically, if the product is unacceptable, the project is not finished,

because it failed to meet the project scope. Let’s look at some tools and techniques

the project manager will use to plan for quality.

Using a Benefit/Cost Analysis

Benefits should outweigh costs.

A benefit/cost analysis is a process of determining the pros and cons of any process,

product, or activity. The straightforward approach when it comes to project management

is concerned with the benefits of quality management activities versus the costs of

the quality management activities. There are two major considerations with the benefit/cost

analysis in quality management:

Benefit Completing quality work increases productivity because shoddy work does not have

to be redone. When work is completed correctly the first time as expected, the project

does not have to spend additional funds to redo the work.

Benefit Completing quality work increases productivity because shoddy work does not have

to be redone. When work is completed correctly the first time as expected, the project

does not have to spend additional funds to redo the work. Costs Completing quality work may cost more than the work is worth. To deliver a level

of quality beyond what is demanded costs the project additional funds. The types of

quality management activities that guarantee quality may not be needed for every project.

Costs Completing quality work may cost more than the work is worth. To deliver a level

of quality beyond what is demanded costs the project additional funds. The types of

quality management activities that guarantee quality may not be needed for every project.Although quality is required on every project, not every project has the same quality

expenses based on the demands. For example, consider a project to create a temporary

drainage ditch for a field. Specifications are set for the ditch, but the project

may not require the expense of a landscape architect to evaluate the slant and descent

of the temporary ditch.

Another project, to create and secure an information technology department, may require

the expense of a security consulting firm to evaluate, test, and certify the security

of the software code, the network servers, and the physical security of the department.

The cost of the quality requirements is in alignment with the demands of the project.

Applying Benchmarking Practices

Benchmarking, when it comes to quality project management, is all about comparing

one project to another. This technique considers what the project manager has planned

or experienced regarding quality and compares it to another project to see how things

measure up. The current project can be measured against any other project—not just

projects within the performing organization or within the same industry.

The goal of benchmarking is to evaluate the differences between the two projects and

then to make corrective actions to the current project if necessary. For example,

Project A may have better quality performance than Project B. When the project manager

compares the two projects, she’ll want to determine the differences between them.

She’ll look for what’s missing in Project B or what activities the folks in Project

A are doing that she’s not.

If used improperly, benchmarking can create some false goals and internal competition.

If the projects that are being compared are active, truth in reporting is mandatory;

otherwise, the results of the benchmarking will be skewed. Just imagine what could

happen if you compared your cost variances to another project that was hiding cost

variances. By comparison, your project would seem to be performing worse, although

that might not actually be the case. Ideally, benchmarking compares similar, completed

projects early in the quality planning, rather than late in the process.

Benchmarking allows the project manager and the project team to see what’s possible

and then strive toward that goal. Benchmarking can also be used as a measurement against

industry standards, competitors’ pricing, or competitors’ level of performance.

Design of Experiments

The design of experiments approach relies on statistical “what-if” scenarios to determine

which variables within a project will result in the best outcome. This type of approach

is most often used on the product of the project rather than on the project itself.

For example, a project team creating a new bicycle may experiment with the width of

the tires, the weight of the frame, and the position of the handlebars in relation

to the bike seat to determine the most comfortable ride at an acceptable cost to the

consumer.

Although design of experiments is most often associated with product design, it can

be applied to project management activities. For example, a project manager may evaluate

the activities within a project and determine the time and cost of activities, depending

on which employees are assigned to complete the work. A more experienced worker may

cost the project more money on an hourly basis, but this individual is expected to

complete the work in a third of the time that a less experienced worker would. This

is design of experiments: experimenting with different variables to find the best

solution at the best cost.

Design of experiments is also used as a method to identify which variables within

a project or product are causing failures or unacceptable results. The goal of design

of experiments is to isolate the root cause of an effect and then make adjustments

to that cause to eliminate the unacceptable results.

Considering the Cost of Quality

The cost of quality considers the expense of all the activities within a project that

are undertaken to ensure its quality. The cost of quality is divided into two major

categories:

Cost of conformance to requirements This approach is the cost of completing the project work to satisfy the project

scope and the expected level of quality. Examples of this cost include training, safety

measures, measurement, and quality management activities to ensure that quality is

met.

Cost of conformance to requirements This approach is the cost of completing the project work to satisfy the project

scope and the expected level of quality. Examples of this cost include training, safety

measures, measurement, and quality management activities to ensure that quality is

met. Cost of nonconformance This approach is the cost of completing the project work without quality. The biggest

issue here is the money lost by having to redo the project work; it’s always more

cost-effective to do the work right the first time. Other nonconformance costs include

loss of sales, loss of customers, downtime, and corrective actions to fix problems

caused by incorrect work.

Cost of nonconformance This approach is the cost of completing the project work without quality. The biggest

issue here is the money lost by having to redo the project work; it’s always more

cost-effective to do the work right the first time. Other nonconformance costs include

loss of sales, loss of customers, downtime, and corrective actions to fix problems

caused by incorrect work.

You might use some additional quality management planning tools, such as the affinity

diagram, brainstorming, nominal group techniques, or—here’s a new one—force field

analysis. It sounds like something out of Star Wars, but it’s actually a collection

of diagrams that capture the forces that are for or against a particular change. The

forces could be people, policies, or other constraints in the organization. When you

think about “may the force be with you,” it could mean you want the people, policies,

and other factors on your side as you move toward project execution.

Creating the Quality Management Plan

The end result of quality planning is to find a method for implementing the quality

policy. Because planning is iterative, the quality planning sessions often require

several revisits to the quality planning processes. Longer projects may include scheduled

quality planning sessions to compare the performance of the project in relation to

the quality that was planned.

One of the major outputs of quality planning is the quality management plan. This

document describes how the project manager and the project team will fulfill the quality

policy. In an ISO 9000 environment, the quality management plan is referred to as

the “project quality system.” The quality management plan addresses the following

three things about the project and the project work:

Quality control Work results are monitored to see if they meet relevant quality standards. If the

results do not meet the quality standards, the project manager applies root-cause

analysis to determine the cause of the poor performance and then eliminates the cause.

Quality control is inspection-oriented.

Quality control Work results are monitored to see if they meet relevant quality standards. If the

results do not meet the quality standards, the project manager applies root-cause

analysis to determine the cause of the poor performance and then eliminates the cause.

Quality control is inspection-oriented. Quality assurance The overall performance is evaluated to ensure that the project meets the relevant

quality standards. Quality assurance maps to an organization’s quality policy and

is typically a managerial process. Quality assurance is generally considered the work

of applying the quality plan.

Quality assurance The overall performance is evaluated to ensure that the project meets the relevant

quality standards. Quality assurance maps to an organization’s quality policy and

is typically a managerial process. Quality assurance is generally considered the work

of applying the quality plan. Quality improvement The project performance is measured and evaluated, and corrective actions are applied

to improve the product and the project. The improvements can be large or small, depending

on the condition and the quality philosophy of the performing organization.

Quality improvement The project performance is measured and evaluated, and corrective actions are applied

to improve the product and the project. The improvements can be large or small, depending

on the condition and the quality philosophy of the performing organization.Identifying the Operational Definitions

Operational definitions, also known as metrics, are the quantifiable terms and values

used to measure a process, activity, or work result. An example of an operational

definition could be an expected value for the required torque to tighten a bolt on

a piece of equipment. By testing and measuring the torque, the operational definition

would prove or disprove the quality of the product. Other examples can include hours

of labor to complete a work package, required safety measures, cost per unit, and

so on.

Operational definitions are clear, concise measurements. Designating that 95 percent

of all customer service calls should be answered by a live person within 30 seconds

is a metric; a statement that all calls should be answered in a timely manner is not.

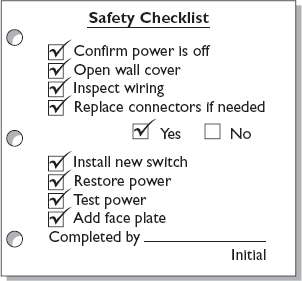

Applying Checklists

Checklists are simple approaches to ensure that work is completed according to the

quality policy. It’s usually a list of activities that workers will check off to make

sure that each task has been completed. Checklists can be quick instructions of what

needs to be done to clean a piece of equipment or questions that remind the employee

to complete a task: “Did you turn off the printer before opening the cover?”

Creating the Process Improvement Plan

One of the goals of quality project management is continuous process improvement.

The process improvement plan looks to improve the project, not just the end result

of the project. Its aim is to identify and eliminate waste and non-value-added activity.

Specifically, this plan aims to accomplish the following:

Increase customer value by eliminating waste within the project.

Increase customer value by eliminating waste within the project. Establish process boundaries.

Establish process boundaries. Determine process configuration through a flowchart for evaluation and analysis

in order to improve the project as a whole.

Determine process configuration through a flowchart for evaluation and analysis

in order to improve the project as a whole. Create and manage process metrics within the project.

Create and manage process metrics within the project. Establish targets for performance improvement.

Establish targets for performance improvement.CERTIFICATION OBJECTIVE 8.04

Executing Quality Assurance

Quality assurance (QA) is an executing process. It is the sum of the planning and

the implementations of the plans the project manager, the project team, and management

apply to ensure the project meets the demands of quality. QA is not something that

is done only at the end of the project, but it should occur before and during the

project as well. Because QA is an executing process, you should link it to continuous

process improvement because its aim is to make the project better.

In some organizations, the QA department or another entity will complete the QA activities.

QA is interested in finding the defects and then fixing the problems. There are many

different approaches to QA, depending on the quality system the organization or project

team has adopted. There are two general types of QA activities:

Internal QA Assurance provided to management and the project team

Internal QA Assurance provided to management and the project team External QA Assurance provided to the external customers of the project

External QA Assurance provided to the external customers of the projectPreparing for Quality Assurance

The project manager and the project team will need to prepare several inputs for QA:

The quality management plan This plan defines how the project team will implement and fulfill the quality policy

of the performing organization.

The quality management plan This plan defines how the project team will implement and fulfill the quality policy

of the performing organization. The process improvement plan This plan aims to improve the project, not just the project’s product.

The process improvement plan This plan aims to improve the project, not just the project’s product. Quality metrics Quality control tests will provide these measurements. The values must be quantifiable

so results may be measured, compared, and analyzed. In other words, “pretty close

to on track” is not adequate; “95-percent pass rate” is more acceptable.

Quality metrics Quality control tests will provide these measurements. The values must be quantifiable

so results may be measured, compared, and analyzed. In other words, “pretty close

to on track” is not adequate; “95-percent pass rate” is more acceptable. Results of quality control The measurements taken by the project manager and the project team to inspect the

project deliverables’ quality are fed back into the QA process.

Results of quality control The measurements taken by the project manager and the project team to inspect the

project deliverables’ quality are fed back into the QA process. Project documents The technical performance measures, project status, information on what the project

has created to date, corrective actions, and performance reports can all be inputs

to help the iterative process of quality assurance.

Project documents The technical performance measures, project status, information on what the project

has created to date, corrective actions, and performance reports can all be inputs

to help the iterative process of quality assurance.Applying Quality Assurance

The QA department, management, or in some instances even the project manager can complete

the requirements for QA. QA can be accomplished using the following tools, and the

same tools can be used during quality planning:

Affinity diagrams These diagrams group similar ideas, deliverables, or concepts together. The WBS

could be considered an example of an affinity diagram.

Affinity diagrams These diagrams group similar ideas, deliverables, or concepts together. The WBS

could be considered an example of an affinity diagram. Process decision program charts These charts help the project team identify all of the steps that are required

to achieve the project goal.

Process decision program charts These charts help the project team identify all of the steps that are required

to achieve the project goal. Interrelationship diagraphs Also called interrelationship diagrams, these diagrams help connect the logical

relationships of a project or system. They can be used to illustrate the relationships

of up to 50 elements to assist in problem-solving and quality improvement.

Interrelationship diagraphs Also called interrelationship diagrams, these diagrams help connect the logical

relationships of a project or system. They can be used to illustrate the relationships

of up to 50 elements to assist in problem-solving and quality improvement. Tree diagrams These diagrams represent a tree, or parent-child relationships. The WBS is an example

of a tree diagram, as is a risk breakdown structure and an organizational chart.

Tree diagrams These diagrams represent a tree, or parent-child relationships. The WBS is an example

of a tree diagram, as is a risk breakdown structure and an organizational chart. Prioritization matrices These evaluate and prioritize the elements of the issue. Each element is prioritized,

weighed, and then plotted in the matrix to achieve a score that will determine the

actions the project manager and project team should take.

Prioritization matrices These evaluate and prioritize the elements of the issue. Each element is prioritized,

weighed, and then plotted in the matrix to achieve a score that will determine the

actions the project manager and project team should take. Activity network diagrams These diagrams illustrate the flow of the project work, as do the critical path

and the critical chain method. The most common activity network diagram is the activity-on-the-node,

though the activity-on-the-arrow approach may still be utilized in some industries.

Activity network diagrams These diagrams illustrate the flow of the project work, as do the critical path

and the critical chain method. The most common activity network diagram is the activity-on-the-node,

though the activity-on-the-arrow approach may still be utilized in some industries.Completing a Quality Audit

Quality audits are about learning. A quality audit identifies the lessons learned

on the current project to determine how to make things better for this project and

other projects within the organization. The idea, for example, is that project manager

Susan can learn from the implementations of project manager Bob, and vice versa.

Quality audits are formal reviews of what’s been completed within a project, what

worked, and what didn’t work. The end result of the audit is to improve performance

for the current project, other projects, or the entire organization. Quality audits

aim to do the following:

Document the best practices the project is using.

Document the best practices the project is using. Document any variances in the project quality approach.

Document any variances in the project quality approach. Recommend best practices that should be implemented in the current project.

Recommend best practices that should be implemented in the current project. Assist the project manager and project team in implementing recommendations for

quality improvement.

Assist the project manager and project team in implementing recommendations for

quality improvement. Document the outcomes of the quality audit in the project’s lessons-learned documentation.

Document the outcomes of the quality audit in the project’s lessons-learned documentation.Quality audits can be scheduled at key intervals within a project, or—surprise!—they

can occur without warning. The audit process can vary, depending on who is completing

the audit: internal auditors or hired, third-party experts. The goal of a quality

audit is to ensure that the project is adhering to the requirements of QA, and the

goal of QA is to reduce the overall cost of quality. As you probably know from your

experience, it’s usually more cost-effective to do something right the first time

than to do it right the second time. That’s QA—do the work according to plan, and

you’ll save time and money.

Improving the Project

The primary output of QA? Quality improvement. But it’s not just the quality of the

project’s deliverables, but also of the process to complete the project work. This

is process analysis, and it follows the guidelines of the process improvement plan.

Process analysis is completed through any or all of the following measures:

An examination of problems and constraints

An examination of problems and constraints An analysis of the project for non-value-added activities

An analysis of the project for non-value-added activities Root-cause analysis

Root-cause analysis The creation of preventive actions for identified problems

The creation of preventive actions for identified problemsQuality improvement requires action to improve the project’s effectiveness. The actions

to improve the effectiveness may have to be routed through the change control system,

which means change requests, analysis of the costs and risks, and involvement from

the change control board.

CERTIFICATION OBJECTIVE 8.05

Implementing Quality Control

Quality control (QC) requires the project manager, or another qualified party, to

monitor and measure project results to determine that the results are up to the demands

of the quality standards. If the results are unsatisfactory, root-cause analysis follows

the quality control processes. Root-cause analysis allows the project manager to determine

the cause and apply corrective actions. QC occurs throughout the life of a project,

not just at its end.

QC is also not only concerned with the product the project is creating, but with the

project management processes. QC measures performance, scheduling, and cost variances.

The experience of the project should be of quality—not just the product the project

creates. Consider a project manager who demands the project team work extreme hours

to meet an unrealistic deadline; team morale suffers and likely so does the project

work the team is completing.

The project team should do the following to ensure competency in quality control:

Conduct statistical quality control, such as sampling and probability.

Conduct statistical quality control, such as sampling and probability. Inspect the product to keep errors away from the customer.

Inspect the product to keep errors away from the customer. Perform attribute sampling to measure conformance to quality on a per-unit basis.

Perform attribute sampling to measure conformance to quality on a per-unit basis. Conduct variable sampling to measure the degree of conformance.

Conduct variable sampling to measure the degree of conformance. Study special causes to determine anomalies to quality.

Study special causes to determine anomalies to quality. Research random causes to determine expected variances of quality.

Research random causes to determine expected variances of quality. Check the tolerance range to determine whether the results are within or without

an acceptable level of quality.

Check the tolerance range to determine whether the results are within or without

an acceptable level of quality. Observe control limits to determine whether the results are in or out of quality

control.

Observe control limits to determine whether the results are in or out of quality

control.Preparing for Quality Control

Quality control relies on several inputs, such as the following:

The quality management plan The quality management plan defines how QA will be applied to the project, the

expectations of QC, and the organization’s approach for continuous process improvement.

The quality management plan The quality management plan defines how QA will be applied to the project, the

expectations of QC, and the organization’s approach for continuous process improvement. Quality metrics The operational definitions that define the metrics for the project are needed

so QC can measure and react to the results of project performance.

Quality metrics The operational definitions that define the metrics for the project are needed

so QC can measure and react to the results of project performance. Quality checklists If the project is using checklists to ensure that project work is completed, a

copy of the checklists will be needed as part of QC. The checklists can then serve

as an indicator of completed work and expected results.

Quality checklists If the project is using checklists to ensure that project work is completed, a

copy of the checklists will be needed as part of QC. The checklists can then serve

as an indicator of completed work and expected results. Work performance data The key performance metrics about the work the project team has performed are needed.

The project manager will need to inspect the variances between what was planned and

what was actually implemented for schedule, costs, and scope.

Work performance data The key performance metrics about the work the project team has performed are needed.

The project manager will need to inspect the variances between what was planned and

what was actually implemented for schedule, costs, and scope. Approved change requests Approved change requests have an effect on how the project work is scheduled and

performed, which may affect the project’s overall quality.

Approved change requests Approved change requests have an effect on how the project work is scheduled and

performed, which may affect the project’s overall quality. Work results Execution brings about deliverables. The results of both the project processes

and the product results are needed to measure the results of the project team’s work

and compare it to the quality standards. The expected results of the product and the

project can be measured from the project plan.

Work results Execution brings about deliverables. The results of both the project processes

and the product results are needed to measure the results of the project team’s work

and compare it to the quality standards. The expected results of the product and the

project can be measured from the project plan. Project documents This documentation, such as contracts and technical specifications, can assist

the project manager and the project team inspecting the work to determine whether

the work results are in synch with the promised level of quality.

Project documents This documentation, such as contracts and technical specifications, can assist

the project manager and the project team inspecting the work to determine whether

the work results are in synch with the promised level of quality. Organizational process assets The organization’s quality policy, standards for quality control techniques, and

communication requirements based on the outcomes of quality control inspections are

all needed for the quality control process.

Organizational process assets The organization’s quality policy, standards for quality control techniques, and

communication requirements based on the outcomes of quality control inspections are

all needed for the quality control process.Inspecting Results

Although quality is planned into a project, not inspected in, inspections are needed

to prove conformance to requirements. An inspection can be done on the project as

a whole, on a portion of the project work, on the project deliverable, or even on

an individual activity. Inspections are also known as the following:

Reviews

Reviews Product reviews

Product reviews Audits

Audits Walkthroughs

WalkthroughsCreating a Flowchart

Technically, a flowchart is a diagram illustrating how components within a system

are related. An organizational flowchart shows the bottom crew of operations up to

the “little squirt” on top. Flowcharts show the relationships between components and

help the project team determine where quality issues may be present; once the project

work is done and any errors have been identified, the project team to can plan accordingly

for defect repair.

You’ll need to be concerned with two types of flowcharts for this exam:

Cause-and-effect diagrams These diagrams show the relationships between the variables within a process and

how those relationships may contribute to inadequate quality. They can help organize

both the process and team opinions, as well as generate discussion on finding a solution

to ensure quality. Figure 8-1 shows an example of a cause-and-effect diagram. To create a diagram, start with the

effect—the problem you want to solve—and then fill out the diagram with possible causes

that contribute to the effect. These diagrams are also known as Ishikawa diagrams

and fishbone diagrams.

Cause-and-effect diagrams These diagrams show the relationships between the variables within a process and

how those relationships may contribute to inadequate quality. They can help organize

both the process and team opinions, as well as generate discussion on finding a solution

to ensure quality. Figure 8-1 shows an example of a cause-and-effect diagram. To create a diagram, start with the

effect—the problem you want to solve—and then fill out the diagram with possible causes

that contribute to the effect. These diagrams are also known as Ishikawa diagrams

and fishbone diagrams.

FIGURE 8-1 Cause-and-effect diagrams show the relationship of variables to a problem.

System or process flowcharts These flowcharts illustrate the flow of a process through a system, such as a project

change request through the change control system or work authorization through a quality

control process. A process flowchart does not have to be limited to the project management

activities. It could instead demonstrate how a manufacturer creates, packages, and

ships the product to the customer, as shown in Figure 8-2.

System or process flowcharts These flowcharts illustrate the flow of a process through a system, such as a project

change request through the change control system or work authorization through a quality

control process. A process flowchart does not have to be limited to the project management

activities. It could instead demonstrate how a manufacturer creates, packages, and

ships the product to the customer, as shown in Figure 8-2.

FIGURE 8-2 Flowcharts demonstrate how processes within a system are related.

A cause-and-effect diagram is also called an Ishikawa diagram and a fishbone diagram—all

of these terms refer to the same thing.

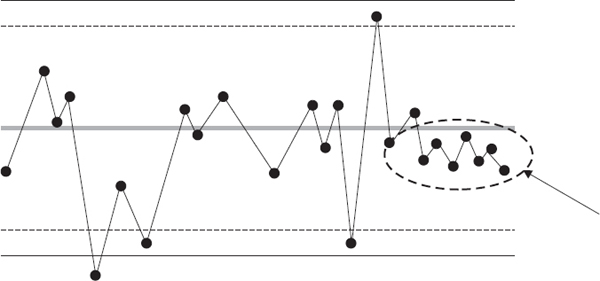

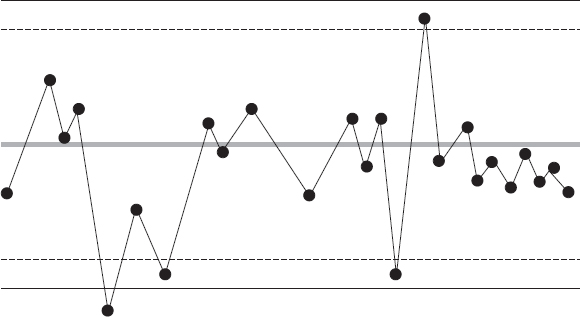

Creating a Control Chart

Ever feel like your project is out of control? A control chart can prove it. Control

charts illustrate the performance of a project over time. They map the results of

inspections against a chart, as shown in Figure 8-3. Control charts are typically used in projects or operations that involve repetitive

activities—such as projects for manufacturing, a testing series, or help desks.

FIGURE 8-3 Control charts demonstrate the results of inspections.

The outer limits of a control chart are established by customer requirements. Within

the customer requirements are the upper control limits (UCLs) and the lower control

limits (LCLs). The UCL is typically set at +3 or +6 sigma, while the LCL is set at

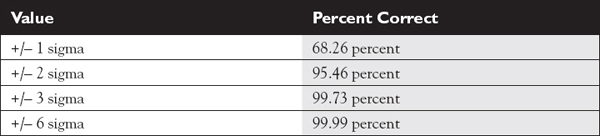

–3 or –6 sigma. Sigma results show the degree of correctness. Table 8-1 outlines the four sigma values representing normal distribution. You’ll need to know

these for the PMP exam.

TABLE 8-1 The Four Sigma Values Representing Normal Distribution

So what happened to sigma 4 and sigma 5? Nothing. They’re still there; it’s just that

the difference between 3 sigma at 99.73 and 6 sigma at 99.99 is so small that statisticians

just jump to 6 sigma. The mean in a control chart represents the expected result,

while the sigma values represent the expected spread of results based on the inspection.

A true Six Sigma allows only two defects per million opportunities, and the percentage

to represent that value is 99.99985%. For the exam, you can go with 99.99%.

For example, if a manufacturer creates 1000 units per hour and expects an average

of 50 units each hour to be defective, the mean would be 950 units. Of course, a better

approach would be to create a mean based on a history of what’s been produced, but

for now let’s assume that the expectation is 50 units defective per hour out of 1000

units created. If the control limits were set at +/− 3 sigma, the results of testing

would actually expect up to 953 correct units and down to 947 correct units.

Over time, the results of testing are plotted in the control chart. Whenever a result

of testing is plotted beyond the UCL or LCL values, it is considered to be “out of

control.” When a value is out of control, there is a reason why—it’s called an assignable

cause. Something caused the results to change for better or for worse, and the result

must be investigated to understand the why behind the occurrence.

Another assignable cause is The Rule of Seven, which states that whenever seven consecutive

results are all on one side of the mean, this is an assignable cause. Thus, some change

has caused the results to shift to one side of the expected mean. Again, the cause

must be investigated to determine why the change happened.

Although control charts are easily associated with recurring activities, such as manufacturing,

they can also be applied to project management. Consider the number of expected change

requests, delays within a project, and other recurring activities. A control chart

can plot out these activities to measure performance, evaluate positive and negative

results, and track corrective actions.

Some project managers may believe that there should be no variance at all in the results

of testing—they expect it to be 100-percent correct all the time. In some instances,

this is valid; consider hospitals, military scenarios, and other situations dealing

with life and death. When a project manager demands 100-percent perfection, the cost

of quality issues needs to be revisited. What is the cost of obtaining perfection

versus the cost of obtaining 98-percent correctness?

Some project managers may believe that there should be no variance at all in the results

of testing—they expect it to be 100-percent correct all the time. In some instances,

this is valid; consider hospitals, military scenarios, and other situations dealing

with life and death. When a project manager demands 100-percent perfection, the cost

of quality issues needs to be revisited. What is the cost of obtaining perfection

versus the cost of obtaining 98-percent correctness?Creating Pareto Diagrams

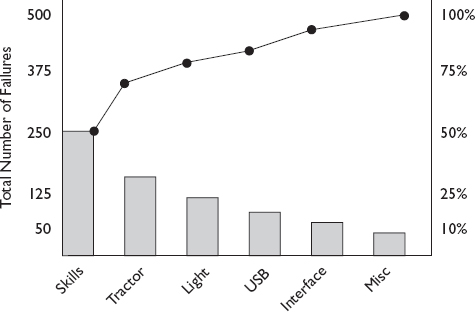

A Pareto diagram is somewhat related to Pareto’s Law: 80 percent of the problems come

from 20 percent of the issues. This is also known as the 80/20 rule. A Pareto diagram illustrates the problems by assigned cause from smallest to largest,

as Figure 8-4 shows. The project team should first work on the largest problems and then move on

to the smaller problems.

FIGURE 8-4 A Pareto diagram is a histogram that ranks the issues from largest to smallest.

Creating a Histogram

A histogram is a bar chart showing the frequency of variables within a project. For

example, a histogram could show which states have the most customers. Within project

management, a common histogram is a resource histogram, which shows the frequency

of resources used on project work. It’s nothing more than a bar chart.

The seven basic quality management tools are scatter diagrams, control charts, histograms,

Pareto diagrams, checksheets, flowcharts, and cause-and-effect diagrams.

Creating a Scatter Diagram

A scatter diagram is similar to a run chart, but it instead tracks the relationship

between two variables. The two variables are considered related the closer they track

against a diagonal line. For example, a project manager could track the performance

of two team members, the time and cost, or even changes between functional managers

and the project’s schedule.

Creating a Run Chart

A run chart, as Figure 8-5 shows, is a line graph that shows the results of inspections in the order in which

they’ve occurred. The goals of a run chart are first to demonstrate the results of

a process over time and then use trend analysis to predict when certain trends may

reemerge. It is similar to a control chart, but it tracks the outcomes of measurements

against when the outcome happened and the time between the measurements. This gives

insight into the measurements that’s different from what the control chart offers.

Based on this information, an organization can work to prevent the negative trend

or work to capitalize on an identified opportunity.

FIGURE 8-5 Run charts track the results of inspections over time.

Completing a Statistical Sampling

Statistical sampling is the process of choosing a percentage of results at random.

For example, a project creating a medical device may have 20 percent of all units

randomly selected to check quality. This process must be completed on a consistent

basis throughout the project, rather than on a sporadic schedule.

Statistical sampling can reduce the costs of quality control, but mixed results can

follow if an adequate testing plan and schedule are not followed. The science of statistical

sampling (and its requirements to be effective) is an involved process. Many books,

seminars, and professionals are devoted to the process. For the PMP exam, know that

statistical sampling uses a percentage of the results to test for quality. This process

can reduce quality control cost.

Revisiting Flowcharting

Flowcharting uses charts to illustrate how the different parts of a system operate.

Flowcharting is valuable in quality control because the process can be evaluated and

tested to determine where in the process quality begins to break down. Corrective

actions can then be applied to the system to ensure that quality continues as planned—and

as expected.

Applying Trend Analysis

Trend analysis is the science of taking past results to predict future performance.

Sports announcers use trend analysis all the time: “The Cubs have never won in St.

Louis, on a Tuesday night, in the month of July, when the temperature at the top of

the third inning was above 80 degrees.”

The results of trend analysis allow the project manager to apply corrective action

to intervene and prevent unacceptable outcomes. Trend analysis on a project requires

adequate records to predict results and set current expectations. Trend analysis can

monitor the following:

Technical performance Trend analysis can ask, “How many errors have been experienced up to this point

in the project schedule, and how many additional errors were encountered since the

last testing of the technical performance?”

Technical performance Trend analysis can ask, “How many errors have been experienced up to this point

in the project schedule, and how many additional errors were encountered since the

last testing of the technical performance?” Cost and schedule performance Trend analysis can ask, “How many activities were completed incorrectly, came in

late, or had significant cost variances?”

Cost and schedule performance Trend analysis can ask, “How many activities were completed incorrectly, came in

late, or had significant cost variances?”The Results of Quality Control

Quality control should, first and foremost, result in quality improvement. Based on

the results of the tools and techniques to implement quality control, the project

manager and project team apply corrective actions to prevent unacceptable quality

and improve the overall quality of the project management processes.

The corrective actions and the defect repairs that the project manager and the project

team want to incorporate into the project may require change requests and management

approval. The value and importance of the change should be evident so the improvement

to quality is approved and folded into the project. In addition to quality improvement,

there are other results of quality control:

Validated deliverables and changes The work results are either accepted or rejected. Rejected items typically mean

rework. When changes are approved and executed, these changes also need to be validated,

as they’re now part of the project scope baseline.

Validated deliverables and changes The work results are either accepted or rejected. Rejected items typically mean

rework. When changes are approved and executed, these changes also need to be validated,

as they’re now part of the project scope baseline. Rework Nonconformance to quality results in change requests for corrective action. Rework

costs time and money, and it contributes to projects being late, over budget, or both.

It is always more cost-effective to do the work right the first time than to do it

correctly the second time.

Rework Nonconformance to quality results in change requests for corrective action. Rework

costs time and money, and it contributes to projects being late, over budget, or both.

It is always more cost-effective to do the work right the first time than to do it

correctly the second time. Completed checklists If the project is using checklists to confirm the completion of work, the completed

checklists should become part of the project records. Some project managers require

the project team member completing the checklist to initial it as whole and complete.

Completed checklists If the project is using checklists to confirm the completion of work, the completed

checklists should become part of the project records. Some project managers require

the project team member completing the checklist to initial it as whole and complete. Process adjustments When results of inspections indicate quality is out of control, process adjustments

may be needed to make immediate corrective actions or planned preventative actions

to ensure that quality improves. Process adjustments, depending on the nature of the

adjustment, may qualify for a change request and be funneled through the change control

system as part of integration management.

Process adjustments When results of inspections indicate quality is out of control, process adjustments

may be needed to make immediate corrective actions or planned preventative actions

to ensure that quality improves. Process adjustments, depending on the nature of the

adjustment, may qualify for a change request and be funneled through the change control

system as part of integration management. Recommendations The project manager and the project team can also make recommendations for additional

defect repairs, preventative actions, corrective actions, and even additional change

requests.

Recommendations The project manager and the project team can also make recommendations for additional

defect repairs, preventative actions, corrective actions, and even additional change

requests.

INSIDE THE EXAM

Quality, in project management, has many different meanings. For the PMP exam, you

should know the following four key facts:

Customer satisfaction is the conformance of the requirements and fitness for use.

Customer satisfaction is the conformance of the requirements and fitness for use. Quality is distinct from grade.

Quality is distinct from grade. Quality is obtained by the project team doing what was promised at the start of

the project.

Quality is obtained by the project team doing what was promised at the start of

the project. Quality is concerned with prevention over inspection.

Quality is concerned with prevention over inspection.Don’t get flustered over the difference between QC and QA. QC focuses on monitoring

the specific results of project work, while QA focuses on monitoring overall performance.

If it helps for the exam, think of QC as being project-wide and QA as being organization-wide.

Another aspect of QC is that the project team must be empowered to stop project work

if quality is outside of the control limits set by the quality management plan.

The quality management plan spans all areas of project quality—not just the product

the project is creating. The experience of the project as led by the project manager

should be of quality as well. There is a direct relationship between the project deliverables

and the quality of project management.

Another area of quality is scheduling. A project manager must examine resources and

how they are allocated, and pay attention to the cost of quality for the assigned

resources. One scheduling technique, just-in-time (JIT) scheduling, demands higher

quality. JIT scheduling means, for example, that you do not order inventory, such

as supplies and materials, until they are needed. This improves cash flow and reduces

the cost of inventory not in use. However, a lack of quality in the project may cause

defects. Because of the defects, the material in use is thus wasted and downtime occurs.

This downtime results because no additional materials are on hand and the project

is waiting for new materials to arrive.

Finally, spend some time learning the values for the four sigmas shown in Table 8-1. You’ll need to know them.

CERTIFICATION SUMMARY

What good is a project deliverable if it doesn’t work, is unacceptable, or is faulty?

Project quality management ensures that the deliverables that project teams create

meet the expectations of the stakeholders. For your PMP examination, quality means

delivering the project at the exact level of the design specifications and the project

scope. No more, no less.

Quality and grade are two different things. Grade is the ranking assigned to different

components that have the same functional purpose. For example, sheet metal may come

in different grades based on what it is needed for. Another example is the grade of

paper based on its thickness, ability to retain ink, and so on. Low quality is always

a problem; low grade may not be.

Quality planning happens before project work begins, but also as work is completed.

Quality planning can confirm the preexistence of quality or the need for quality improvements.

Quality is planned into a project, not inspected in. However, quality control uses

inspections to prove the existence of quality within a project deliverable.

There is a distinct difference between quality assurance and quality control. Quality

assurance is a prevention-driven process. Management wants the project manager and

the project team to do the work right the first time. Quality control, however, is

an inspection-driven process—the project team, the project manager, and sometimes

third-party inspectors examine the work to confirm that it is correct and of quality.

Quality assurance is usually a program for the entire organization, or at least a

line of business or department. In project management, quality control is specific

to the actual project work.

The cost of quality is concerned with the monies invested in the project to ascertain

the expected level of quality. Examples of this cost include training, safety measures,

and quality management activities. The cost of nonconformance centers on the monies

lost by not completing the project work correctly the first time. In addition, this

cost includes the loss of sales, loss of customers, and downtime within the project.

Optimal quality is reached when the cost of the improvements equals the incremental

costs to achieve quality. Marginal analysis is the study of when optimal quality is

reached. The PMP candidate should know what marginal analysis is and why management

is concerned with it. Ideally, the cost of quality is earned back because the deliverables

of the project are better and more profitable than if the quality of deliverables

were lacking.

KEY TERMS

If you’re serious about passing the PMP exam, memorize these terms and their definitions.

For maximum value, create your own flashcards based on these definitions and review

daily.

activity network diagram Illustrates the flow of the project work, as does the critical path and the critical

chain method. The most common activity network diagram is the activity-on-node, although

the activity-on-arrow approach may still be utilized in some industries.

affinity diagram Groups similar ideas, deliverables, or concepts together. The WBS could be considered

an example of an affinity diagram.

benchmarking The process of using prior projects internal or external to the performing organization

to compare and set quality standards for processes and results.

benefit/cost analysis The process of determining the pros and cons of any project, process, product,

or activity.

checklist A listing of activities that workers check to ensure the work has been completed

consistently; used in quality control.

continuous process improvement A goal of quality assurance to improve the project’s processes and deliverables;

it meshes with the project’s process improvement plan, which is to improve the processes

of the project.

control chart Illustrates the performance of a project over time. It maps the results of inspections

against a chart. Control charts are typically used in projects or operations that

have repetitive activities, such as manufacturing, testing series, or help desk functions.

Upper and lower control limits indicate whether values are in control or out of control.

cost of conformance The cost of completing the project work to satisfy the project scope and the expected

level of quality. Examples include training, safety measures, and quality management

activities. Also known as the cost of quality.

cost of nonconformance The cost of not completing the project with quality, including wasted time for

corrective actions, rework, and wasted materials. Could also mean loss of business,

loss of sales, and lawsuits. Also known as the cost of poor quality.

design of experiments approach Relies on statistical “what-if” scenarios to determine which variables within a

project will result in the best outcome; can also be used to eliminate a defect. This

approach is most often used on the product of the project, rather than on the project

itself.

flowchart A chart that illustrates how the parts of a system occur in sequence.

histogram A bar chart, such as a Pareto diagram.

interrelationship digraph A diagram that helps connect the logical relationships of a project or system.

It illustrates the relationships of up to 50 elements to assist in problem solving

and quality improvement.

ISO 9000 An international standard that helps organizations follow their own quality procedures.

ISO 9000 is not a quality system, but a method of following procedures created by

an organization.

operational definition The quantifiable terms and values used to measure a process, activity, or work

result. Operational definitions are also known as metrics.

Pareto diagram A Pareto diagram is related to Pareto’s Law: 80 percent of the problems come from

20 percent of the issues (this is also known as the 80/20 rule). A Pareto diagram

illustrates problems by assigned cause, from smallest to largest.

prioritization matrix Evaluates and prioritizes the elements of the issue. Each element is prioritized,

weighed, and then plotted in the matrix to achieve a score that will determine the

activities the project manager and project team should take.

process adjustments When quality is lacking, process adjustments are needed for immediate corrective

actions or for future preventive actions to ensure that quality improves. Process

adjustments may qualify for a change request and be funneled through the change control

system as part of integration management.

process decision program chart This chart helps the project team identify all of the needed steps that are required

to achieve the project goal.

quality assurance (QA) An executing process to ensure that the project is adhering to the quality expectations

of the project customer and organization. QA is a prevention-driven process to perform

the project work with quality to avoid errors, waste, and delays.

quality audit A process to confirm that the quality processes are performing correctly on the

current project. The quality audit determines how to make things better for the project

and other projects within the organization and measures the project’s ability to maintain

the expected level of quality.

quality control (QC) A process in which the work results are monitored to see if they meet relevant

quality standards.

quality management plan A document that describes how the project manager and the project team will fulfill

the quality policy. In an ISO 9000 environment, the quality management plan is referred

to as the project quality system.

quality policy The formal policy an organization follows to achieve a preset standard of quality.

The project team should either adapt the quality policy of the organization to guide

the project implementation or create its own policy if one does not exist within the

performing organization.

run chart Similar to a control chart, a run chart tracks trends over time and displays those

trends in a graph with the plotted data mapped to a specific date.

scatter diagram Tracks the relationship between two or more variables to determine whether one

variable affects the other. It allows the project team, quality control team, or project

manager to make adjustments to improve the overall results of the project.

statistical sampling A process of choosing a percentage of results at random for inspection. Statistical

sampling can reduce the costs of quality control.

tree diagram Any diagram that represents a tree in a parent-child relationship. The WBS is an

example of a tree diagram, as are a risk breakdown structure and an organizational

chart.

trend analysis Analyzes past results to predict future performance.

TWO-MINUTE DRILL

TWO-MINUTE DRILLLooking at the Big Quality Picture

The project manager is responsible for the overall quality management of the project

and must set quality expectations based on the requirements of the customers and stakeholders.

The project manager is responsible for the overall quality management of the project

and must set quality expectations based on the requirements of the customers and stakeholders. The project manager must integrate the quality control of the project with the quality

assurance program of the performing organization.

The project manager must integrate the quality control of the project with the quality

assurance program of the performing organization. Quality is planned into a project, not inspected in.

Quality is planned into a project, not inspected in.Preparing for Quality

Quality doesn’t happen by accident. Quality is satisfying the expectations of the

project scope baseline.

Quality doesn’t happen by accident. Quality is satisfying the expectations of the

project scope baseline. The project team members (the people actually completing the project work) are responsible

for the quality of the deliverables.

The project team members (the people actually completing the project work) are responsible

for the quality of the deliverables. The project team, as guided by the project manager and the quality management plan,

should be empowered to stop the project work when preset quality thresholds are exceeded.

The project team, as guided by the project manager and the quality management plan,

should be empowered to stop the project work when preset quality thresholds are exceeded.Planning for Quality

Quality planning is an iterative process. As quality concerns creep into the project,

the planning processes are revisited to ensure that actions—both preventive and corrective—are

taken to ensure quality.

Quality planning is an iterative process. As quality concerns creep into the project,

the planning processes are revisited to ensure that actions—both preventive and corrective—are

taken to ensure quality. The quality management plan is a subsidiary plan of the overall project management

plan. It defines how the project will accomplish the quality expectations of the organization

and how the project will adhere to the quality policy of the organization.

The quality management plan is a subsidiary plan of the overall project management

plan. It defines how the project will accomplish the quality expectations of the organization

and how the project will adhere to the quality policy of the organization. The process improvement plan is a subsidiary plan of the overall project management

plan. It defines how project processes will be analyzed and improved upon. The goal

of this plan is to improve the value of the project by removing non-value-added activities.

The process improvement plan is a subsidiary plan of the overall project management

plan. It defines how project processes will be analyzed and improved upon. The goal

of this plan is to improve the value of the project by removing non-value-added activities. The cost of quality is the amount of monies the performing organization must spend