Agroindustrial Coproducts as Sources of Novel Functional Ingredients

Abstract

The disposal of agroindustrial coproducts derived from fruit and vegetable processing represents a serious contamination problem. Fruit and vegetable peels contain important bioactive ingredients like fiber and antioxidants. Different fiber sources contain high amounts of soluble and insoluble fiber. The peel fiber can be employed as a prebiotic ingredient. In vitro studies have demonstrated that the flour of these peels stimulates the growth of probiotic lactic acid bacteria, besides the production of an important amount of short chain fatty acids, mainly butyric. In same manner, these fibers as coating material improved the resistance of lactic acid bacteria against bile and acidic conditions. These fruit peels are low-cost potential food functional ingredients that develop novel functional foods that improve nutritional quality.

Keywords

1. Agroindustrial Coproducts

2. Dietary Fiber From Agroindustrial Coproducts

Table 8.1

| Sources | Total Dietary Fiber | References |

|---|---|---|

| Fig | 16.53 | Sánchez-Zapata et al. (2012) |

Banana Chía seeds |

32.9–51.9 a 37–40 |

|

| Lemon albedo | 22 | Fernández-Ginés et al. (2004) |

| Raspberry pomace | 77.5 | Górecka et al. (2010) |

Cactus pear peel Pineapple peel Guava powder Apple marc |

64.15 62.54 46.72 70.91 |

|

| Maguey leaf b | 41.44 | Castillejos-Gómez et al. (2015) |

| Orange peel | 38.11 | Pérez-Chabela et al. (2015a,b) |

a Depending of the varieties of banana.

b Residue from“barbacoa” elaboration. Barbacoa is a Mexican dish elaborated with lamb meat, where the maguey leaves are utilized to retain and transfer heat to meat.

2.1. Classification and Composition

- • Structural polysaccharides (cellulose, hemicellulose, and some pectin)

- • Structural nonpolysaccharides (lignin)

- • Nonstructural polysaccharides (gums and mucilage)

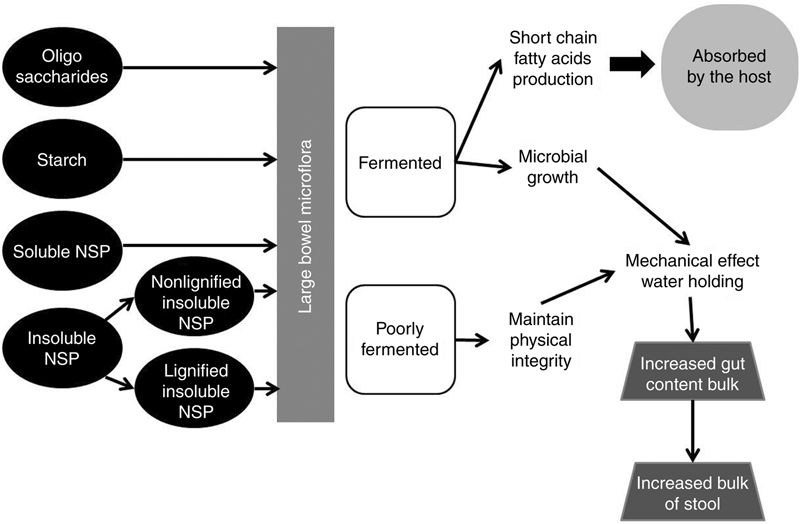

- • Insoluble DF (IDF)/less fermented fiber and soluble dietary fiber (SDF)/well-fermented fibers. Insoluble fiber consists of cellulose, part of hemicellulose and lignin

- • Soluble fiber consists of pectin, gums, and mucilage

2.1.1. Cellulose

2.1.2. Hemicellulose

2.1.3. Pectins

2.1.4. Lignin

2.1.5. Mucilage and gums

2.2. Physiological Effects From the DF

- • Reduced blood total and/or cholesterol levels

- • Attenuation of postprandial glycemia/insulinemia

- • Reduced blood pressure (BP)

- • Increased fecal bulk/laxation

- • Decreased transit time

- • Increased colonic fermentation/SCFA production

2.2.1. Lowering cholesterol levels

2.2.2. Postprandial plasma glucose and glycemic attenuation

2.2.3. Reduce blood pressure

2.2.4. Bulking ability

2.2.5. Fermentation on intestine (increase colonic fermentation)

2.3. Fiber Effect in Foods

2.3.1. Meat products

2.3.2. Dairy products

2.3.3. Cereal products

2.4. Fiber Effect In Vivo

2.5. Short History of the Methods of Analysis of Dietary Fiber

3. Phenolic Compounds in Agroindustrial Coproducts

Table 8.2

| Sources | Polyphenols (mg GAE/g) | References |

|---|---|---|

| Banana peel | 43.2 | Bezuneh and Kebede (2015) |

| Papaya peel | 26.6 | Bezuneh and Kebede (2015) |

| Fig | 5.72 | Sánchez-Zapata et al. (2012) |

| Guava powder | 44.04 | Verma et al. (2013) |

| Apple marc | 27.54 | Cerda-Tapia et al. (2015) |

| Orange | 12.30 | Al-Juhaimi (2014) |

| Lemon | 9.838 | Al-Juhaimi (2014) |

| Mandarin | 10.49 | Al-Juhaimi (2014) |

GAE, Gallic acid equivalent.

3.1. Classification and Composition

3.1.1. Flavonoids

3.1.2. Flavonols

3.1.3. Flavones

3.1.4. Flavanones

3.1.5. Isoflavones

3.1.6. Anthocyanidins

3.1.7. Flavanols

3.1.8. Phenolic acids

3.1.9. Hydroxybenzoic acids

3.1.10. Stilbenes

3.1.11. Phenolic alcohols

3.1.12. Lignans

3.1.13. Polyphenolic amides

3.2. Physiological Effect From Phenolic Compounds

3.2.1. Antioxidant activity and protection against oxidative stress

3.2.2. Hypoglycemic effects on diabetes risk

3.2.3. Cardiovascular protective effects

3.2.4. Neurodegenerative protective effects

3.2.5. Cancer protective effects

3.3. Phenolic Compounds in Foods

3.3.1. Meat products

3.3.2. Dairy products

3.3.3. Cereal products

3.4. Phenolic Compounds Effects In Vivo

3.5. Methods of Analysis of Phenolic Compounds

4. Prebiotics

- • Although all prebiotics are fiber, not all fiber is prebiotic. Classification of a food ingredient as a prebiotic requires scientific demonstration that the ingredient: resists gastric acidity, hydrolysis by mammalian enzymes, and absorption in the upper gastrointestinal tract.

- • It is fermented by the intestinal microflora.

- • It selectively stimulates the growth and/or activity of intestinal bacteria, potentially associated with health and well-being (Roberfroid, 2008).