References

Aguera E, Bes M, Roy A, Camarasa C, Sablayrolles JM. Partial removal of ethanol during fermentation to obtain reduced-alcohol wines. Am. J. Enol. Viticult.. 2010;61:53–60.

Alkhatib A. As good as it gets: low/non-alcoholic beer in mature markets. Euromonitor. 2013; .

Alston JM, Fuller KB, Lapsley JT, Soleas G, Tumber KP. Splendide mendax: false label claims about high and rising alcohol content of wine. J. Wine Econ.. 2015;10(3):275–313.

Balda P, Martínez de Toda F. Decreasing the alcohol level and pH in wines by the “double harvest” technique. Ciência e Técnica Vitivinícola. 2013; 899–903: .

Bamforth C. Beer - Tap into the Art and Science of Brewing. 2nd ed Oxford, United Kingdom: Oxford University Press; 2003.

Bamforth CW. Beer Health and Nutrition. Oxford, United Kingdom: Blackwell Science Ltd.; 2004.

Belisario-Sánchez YY, Taboada-Rodríguez A, Marín-Iniesta F, López-Gómez A. Dealcoholized wines by spinning cone column distillation: phenolic compounds and antioxidant activity measured by the 1,1-diphenyl-2-picrylhydrazyl method. J. Agric. Food Chem.. 2009;57(15):6770–6778.

Bindon K, Varela C, Kennedy J, Holt H, Herderich M. Relationships between harvest time and wine composition in Vitis vinifera L. cv. Cabernet Sauvignon 1. Grape and wine chemistry. Food Chem.. 2013;138:1696–1705.

Bindon K, Holt H, Williamson PO, Varela C, Herderich M, Francis IL. Relationships between harvest time and wine composition in Vitis vinifera L. cv. Cabernet Sauvignon 2. Wine sensory properties and consumer preference. Food Chem.. 2014;154:90–101.

Biyela BNE, du Toit WJ, Divol B, Malherbe DF, van Rensburg P. The production of reduced-alcohol wines using Gluzyme Mono 10.000 BG-treated grape juice. S. Afr. J. Enol. Vitic.. 2009;30:124–132.

Blanco CA, Andrés-Iglesias C, Montero O. Low alcohol beers: Flavour compounds, defects and improvement strategies. Crit. Rev. Food Sci. Nutr.. 2016;56(8):1379–1388.

Bottcher C, Harvey K, Forde CG, Boss PK, Davies C. Auxin treatment of pre-veraison grape (Vitis vinifera L) berries both delays ripening and increases the synchronicity of sugar accumulation. Aust. J. Grape Wine Res.. 2011;17:1–8.

Brányik T, Silva DP, Baszczyňski M, Lehnert R, Almeida e Silva JB. A review of methods of low alcohol and alcohol-free beer production. J. Food Eng.. 2012;108(4):493–506.

Briggs DE, Boulton CA, Brookes PA, Stevens R. Brewing Science and Practice. Cambridge, United Kingdom: Woodhead Publishing; 2004.

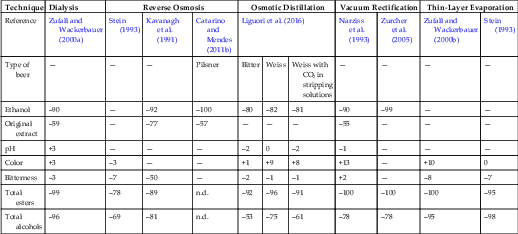

Catarino M, Mendes A, Madeira LM. Alcohol removal from beer by reverse osmosis. Sep. Sci. Technol.. 2007;42:3011–3027.

Catarino M, Mendes A. Dealcoholizing wine by membrane separation processes. Innov. Food Sci. Emerg.Technol.. 2011;12:330–337.

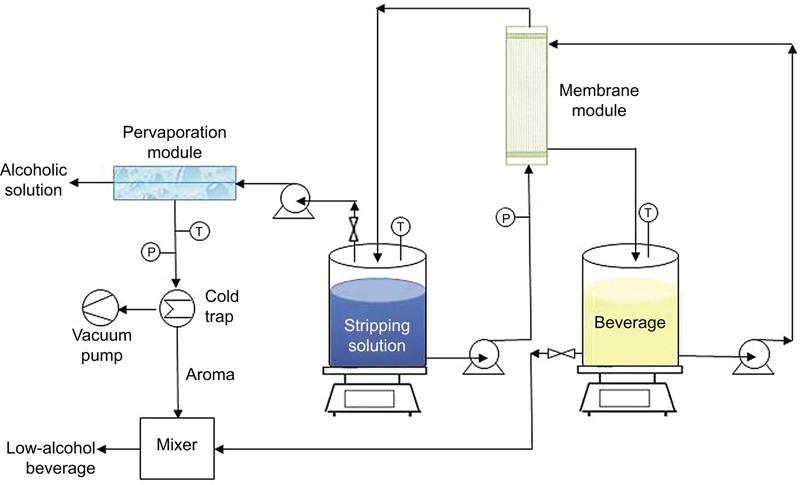

Catarino M, Mendes A. Non-alcoholic beer—a new industrial process. Sep. Purif. Technol.. 2011;79(3):342–351.

Commission Regulation, (EC) No. 606/2009 of 10 July 2009 laying down certain detailed rules for implementing Council Regulation (EC) No. 479/2008 as regards the categories of grapevine products, oenological practices and the applicable restrictions. Offi. J. Eur. Union, L 193/59.

Conibear, H., 2010. European drinking trends—the way we drink now. Available from: http://www.aim-digest.com/digest/members%20%20yr/thewaywedrink.pdfover%.

Contreras A, Curtin C, Varela C. Yeast population dynamics reveal a potential “collaboration” between Metschnikowia pulcherrima and Saccharomyces uvarum for the production of reduced alcohol wines during Shiraz fermentation. Appl. Microbiol. Biotechnol.. 2015;99(4):1885–1895.

Corbet-Milward J, Loftus S. When is a wine not a wine? Bringing a low alcohol product to market. Presentation at OIV meeting. 2011.

Council Regulation (EC) No. 479/2008 of April 29, 2008 on the common organisation of the market in wine, amending Regulations (EC) No. 1493/1999, (EC) No. 1782/2003, (EC) No. 1290/2005, (EC) No. 3/2008 and repealing Regulations (EEC) No. 2392/86 and (EC) No. 1493/1999.

De Francesco G, Freeman G, Lee E, Marconi O, Perretti G. Effects of operating conditions during low-alcohol beer production by osmotic distillation. J. Agric. Food Chem.. 2014;62(14):3279–3286.

del Olmo A, Blanco CA, Palacio L, Prádanos P, Hernández A. Pervaporation methodology for improving alcohol-free beer quality through aroma recovery. J. Food Eng.. 2014;133:1–8.

Diban N, Arruti A, Barcelo A, Puxeu M, Urtiaga A, Ortiz I. Membrane dealcoholization of different wine varieties reducing aroma losses: modeling and experimental validation. Innov. Food Sci. Emerg. Technol.. 2013;20:259–268.

Filippetti I, Movahed N, Allegro G, Valentini G, Pastore C, Colucci E, Intrieri C. Effect of post-veraison source limitation on the accumulation of sugar, anthocyanins and seed tannins in Vitis vinifera cv Sangiovese berries. Aust. J. Grape Wine Res.. 2015;21:90–100.

Fornari T, Hernández EJ, Ruiz-Rodriguez A, Seňorans FJ, Reglero G. Phase equilibria for the removal of ethanol from alcoholic beverages using supercritical carbon dioxide. J. Supercrit. Fluids. 2009;50:91–96.

Fsanz, 2011. Application A1026—Minimum alcohol content for wine assessment report. Food Standards Australia New Zealand.

Gambuti A, Rinaldi A, Lisanti MT, Pessina R, Moio L. Partial dealcoholisation of red wines by membrane contactor technique: influence on colour, phenolic compounds and saliva precipitation index. Eur. Food Res. Technol.. 2011;233:647–655.

Garcia-Martin N, Perez-Magarino S, Ortega-Heras M, Gonzalez-Huerta C, Mihnea M, Gonzalez-Sanjose ML, Palacio L, Pradanos P, Hernandez A. Sugar reduction in musts with nanofiltration membranes to obtain low alcohol-content wines. Sep. Purif. Technol.. 2010;76:158–170.

Gil M, Estevez S, Kontoudakis N, Fort F, Canals JM, Zamora F. Influence of partial dealcoholization by reverse osmosis on red wine composition and sensory characteristics. Eur. Food Res. Technol.. 2013;237:481–488.

Global Health Observatory (GHO), 2016. Available From: http://www.who.int/gho/alcohol/en/.

Gómez-Plaza E, López-Nicolás JM, López-Roca JM, Martinez-Cutillas A. Dealcoholization of wine behaviour of the aroma components during the process. Lebensm. Wissens. Technol.. 1999;32:384–386.

Guilford JM, Pezzuto JM. Wine and health: a review. Am. J. Enol. Vitic.. 2011;62:4.

Harbertson JF, Mireles MS, Harwood ED, Weller KM, Ross CF. Chemical and sensory effects of saignee, water addition, and extended maceration on high Brix must. Am. J. Enol. Vitic.. 2009;60:450–460.

Heymann H, LiCalzi M, Conversano MR, Bauer A, Skogerson K, Matthews M. Effects of extended grape ripening with or without must and wine alcohol manipulations on Cabernet Sauvignon wine sensory characteristics. S. Afr. J. Enol. Vitic.. 2013;34:86–99.

International code of Oenological Practices, 2016. International Organisation of Vine and Wine, Paris, France.

Jordão AM, Vilela A, Cosme F. From sugar of grape to alcohol of wine: sensorial impact of alcohol in wine. Beverages. 2015;1:292–310.

Kavanagh TE, Clarke BJ, Gee PS, Miles M, Nicholson BN. Volatile flavor compounds in low alcohol beers. Tech. Q. Master Brew Assoc. Am.. 1991;28(3):111–118.

Kontoudakis N, Esteruelas M, Fort F, Canals JM, Zamora F. Use of unripe grapes harvested during cluster thinning as a method for reducing alcohol content and pH of wine. Aust. J. Grape Wine Res.. 2011;17:230–238.

Labanda J, Vichi S, Llorens J, Lopez-Tamames E. Membrane separation technology for the reduction of alcoholic degree of a white model wine. Food Sci. Technol.. 2009;42:1390–1395.

Liguori L, Attanasio G, Albanese D, Di Matteo M. Aglianico wine dealcoholization tests. Computer Aided Chem. Eng.. 2010;28:325–330.

Liguori L, Russo P, Albanese D, Di Matteo M. Effect of process parameters on partial dealcoholization of wine by osmotic distillation. Food Bioprocess Technol.. 2013;6(9):2514–2524.

Liguori L, Russo P, Albanese D, Di Matteo M. Evolution of quality parameters during red wine dealcoholization by osmotic distillation. Food Chem.. 2013;140(1–2):68–75.

Liguori L, De Francesco G, Russo P, Albanese D, Perretti G, Di Matteo M. Quality improvement of low craft beer produced by evaporative pertraction. Chem. Eng. Trans.. 2015;43:13–18.

Liguori L, De Francesco G, Russo P, Perretti G, Albanese D, Di Matteo M. Production and characterization of alcohol-free beer by membrane process. Food Bioprod. Process. 2015;94(1):158–168.

Liguori L, De Francesco G, Russo P, Perretti G, Albanese D, Di Matteo M. Quality attributes of low-alcohol top-fermented beers produced by membrane contactor. Food Bioprocess Technol.. 2016;9(1):191–200.

Lisanti MT, Gambuti A, Genovese A, Piombino P, Moio L. Partial dealcoholization of red wines by membrane contactor technique: Effect on sensory characteristics and volatile composition. Food Bioprocess Technol.. 2013;6(9):2289–2305.

Loira I, Morata A, Comuzzo P, Callejo MJ, González C, Calderón F, Suárez-Lepe JA. Use of Schizosaccharomyces pombe and Torulaspora delbrueckii strains in mixed and sequential fermentations to improve red wine sensory quality. Food Res. Int.. 2015;76:325–333.

Margallo M, Aldaco R, Barceló A, Diban N, Ortiz I, Irabien A. Life cycle assessment of technologies for partial dealcoholisation of wines. Sustain. Product. Consump.. 2015;2:29–39.

Martinez de Toda F, Sancha JC, Balda P. Reducing the sugar and pH of the grape Vitis vinifera L. cvs “Grenache” and “Tempranillo” through a single shoot trimming. S. Afr. J. Enol. Vitic.. 2013;34:246–251.

McDonnell, C., 2011. The effect of crop load and extended ripening on wine quality and vine balance in Vitis vinifera cv Cabernet Sauvignon. PhD thesis, University of Adelaide, Adelaide, Australia.

Meillon S, Viala D, Medel M, Urbano C, Guillo G, Schlich P. Impact of partial alcohol reduction in Syrah wine on perceived complexity and temporality of sensations and link with preference. Food Qual. Prefer.. 2010;21:732–740.

Meillon S, Dugas V, Urbano C, Schlich P. Preference and acceptability of partially dealcoholized white and red wines by consumers and professionals. Am. J. Enol. Vitic.. 2010;61:1.

Mendez-Costabel, M., 2007. Impact of irrigation levels during the latter stages of fruit ripening on the yield components, physiology and berry and wine composition of Vitis vinifera L. MS thesis, University of California, Davis, CA, United States.

Mihnea M, González-SanJosé ML, Ortega-Heras M, Pérez-Magariño S, García-Martin S, Palacio NL, Prádanos P, Hernández A. Impact of must sugar reduction by membrane applications on volatile composition of Verdejo wines. J. Agric. Food Chem.. 2012;60:7050–7063.

Mintel, 2016. Available from: http://reports.mintel.com.

Montanari L, Marconi O, Mayer H, Fantozzi P. Production of alcohol-free beer. In: Preedy VR, ed. Beer in Health and Disease Prevention. Cambridge, MA, United States: Acdemic Press; 2009:61–75.

Narziss L, Back W, Stich S. Alcohol removal from beer by countercurrent distillation in combination with rectification. Brauwelt Int.. 1993;133(38):1806–1820.

Nascimento Moreira, C., 2015. Light Wine—Technological and Legal Aspects of Alcohol Reduced Wine. Master's thesis in Viticulture and Winemaking. Available from: https://www.repository.utl.pt/bitstream/10400.5/11041/1/Tese_CM2015.pdf.

Rehn N, Room R, Edwards G. Alcohol in the European Region – Consumption Harm and Policies. Copenhagen, Denmark: World Health Organization Regional Office for Europe; 2001.

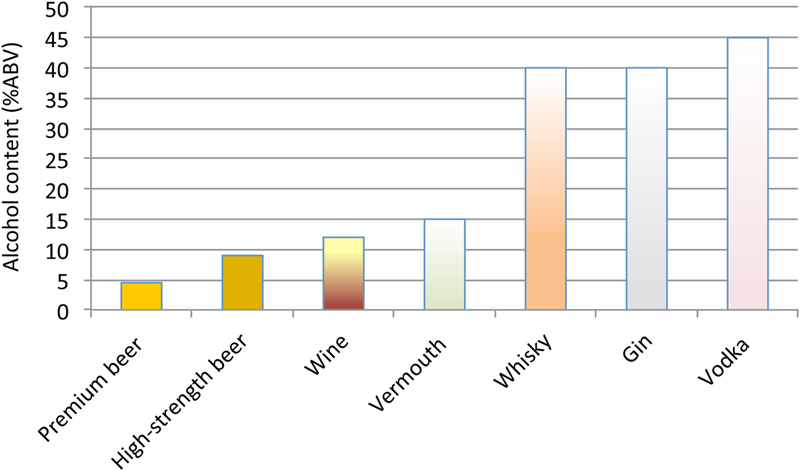

NutrientsReview, 2016. Alcoholic beverages: beers, wines, spirits, liqueurs. Available from: http://www.nutrientsreview.com/alcohol/alcoholic-beverages-abv-calories.html.

Ozturk B, Anli E. Different techniques for reducing alcohol levels in wine: a review. Bio. Web Conf.. 2014;3.

Palliotti A, Poni S, Berrios JG, Bernizzoni F. Vine performance and grape composition as affected by early-season source limitation induced with antitranspirants in two red Vitis Vinifera L. cultivars. Austr. J. Grape Wine Res.. 2010;16:426–433.

Palliotti A, Silvestroni O, Leoni F, Cini R, Poni S. Effect of late mechanized leaf removal to delay grape ripening on Sangiovese vines. Acta Hort.. 2013;978:301–307.

Palliotti A, Panara F, Silvestroni O, Lanari V, Sabbatini P, Howell GS, Gatti M, Poni S. Influence of mechanical postveraison leaf removal apical to the cluster zone on delay of fruit ripening in Sangiovese (Vitis vinifera L) grapevines. Aust. J. Grape Wine Res.. 2013;19:369–377.

Pickering GJ. Low- and reduced-alcohol wine: a review. J. Wine Res.. 2000;11(2):29–144.

Poni S, Gatti M, Bernizzoni F, Civardi S, Bobeica N, Magnanini E, Palliotti A. Late leaf removal aimed at delaying ripening in cv Sangiovese: physiological assessment and vine performance. Aust. J. Grape Wine Res.. 2013;19:378–387.

Pretorius IS. Tailoring wine yeast for the new millennium: novel approaches to the ancient art of winemaking. Yeast. 2000;16:675–729.

Purwasasmita M, Kurnia D, Mandias FC, Khoiruddin, Wenten IG. Beer dealcoholization using non-porousmembrane distillation. Food Bioprod. Process. 2015;94:180–186.

Resolution OIV-OENO 373B/2010. Application of membrane techniques. Oenology Resolutions. International Organisation of Vine and Wine, Paris, France.

Resolution OIV-ECO 432-2012. Beverage obtained by dealcoholisation of wine. In: International Code of Oenological Practices, 2016. Chapter 6, Part I. International Organisation of Vine and Wine, Paris, France.

Resolution OIV-ECO 433-2012. Beverage obtained by partial dealcoholisation of wine. In: International Code of Oenological Practices, 2016. Chapter 6, Part I. International Organisation of Vine and Wine, Paris, France.

Resolution OIV-OENO 394A-2012. Dealcoholisation of wines. In: International Code of Oenological Practices, Chapter 3, Part I, par. 3.5.16.

Resolution OIV-OENO 394B-2012. Correction of the alcohol content in wines. In: International Code of Oenological Practices, Chapter 3, Part II, par. 3.5.13.

Russo P, Liguori L, Albanese D, Crescitelli A, Di Matteo M. Investigation of osmotic distillation technique for beer dealcoholization. Chem. Eng. Trans.. 2013;32:1735–1740.

Russo P, Liguori L, Albanese D, Crescitelli A, De Francesco G, Perretti G, Di Matteo M. Investigation of osmotic distillation technique for beer dealcoholization. AIDIC Conf. Series. 2013;11:311–320.

Salamon, A., 2006. Techniques to achieve moderate alcohol levels in South African wine. Assignment submitted in partial requirement for the Cape Wine Master Diploma.

Salgado MC, Fernández-Fernández E, Palacio L, Hernández A, Prádanos P. Alcohol reduction in red and white wines by nanofiltration of musts before fermentation. Food Bioprod. Process.. 2015;96:285–295.

Sanchez, L.A., Mendez, M.P., Dokoozlian, N., 2006. Irrigation levels during the latter stages of ripening influence vine yield components and physiology but have little impact on fruit and wine composition in Merlot (Vitis vinifera L.) grapevines. Proceedings of the 15th International GiESCO Symposium; June 20–23, pp.758–766.

Schmidtke LM, Blackman JW, Agboola SO. Production technologies for reduced alcoholic wines. J. Food Sci.. 2012;71(1):25–41.

Seidlitz, H., Lack., E., Lackner, H., 1991. Process for the reduction of the alcohol content of alcoholic beverages. United States Patent, no. 5034238.

Sohrabvandi S, Mousavi S, Razavi S, Mortazavian A, Rezaei K. Alcohol-free beer: methods of production, sensorial defects and healthful effects. Food Rev. Int.. 2010;26(4):335–352.

Stasi A, Bimbo F, Viscecchia R, Seccia A. Italian consumers’ preferences regarding dealcoholized wine, information and price. Wine Econ. Policy. 2014;3:54–61.

Stein W. Dealcoholization of beer. Tech. Q. Master Brew. Assoc. Am.. 1993;30(2):54–57.

Stoll M, Scheidweiler M, Lafontaine M, Schultz HR. Possibilities to reduce the velocity of berry maturation through various leaf area to fruit ratio modifications in Vitis vinifera L Riesling. Progres Agricole Viticole. 2010;7(3):68–71.

Sun SY, Gong HS, Jiang XM, Zhao YP. Selected non-Saccharomyces wine yeasts in controlled multistarter fermentations with Saccharomyces cerevisiae on alcoholic fermentation behaviour and wine aroma of cherry wines. Food Microbiol.. 2014;44:15–23.

Takács L, Vataia G, Korány K. Production of alcohol free wine by pervaporation. J. Food Eng.. 2007;78:118–125.

Tittmann S, Stöber V, Bischoff-Schaefer M, Stoll M. Application of anti-transpirant under greenhouse conditions of grapevines (Vitis vinifera cv. Riesling and cv. Müller-Thurgau) reduce photosynthesis. Ciência e Técnica Vitivinícola. 2013;28:276–282: .

Varavuth S, Jiraratananon R, Atchariyawut S. Experimental study on dealcoholization of wine by osmotic distillation process. Sep. Purif. Technol.. 2009;66:313–321.

Varela C, Dry PR, Kutyna1 DR, Francis IL, Henschke PA, Curtin CD, Chambers PJ. Strategies for reducing alcohol concentration in wine. Aust. J. Grape Wine Res.. 2015;21:670–679.

Varela C, Sengler F, Solomon M, Curtin C. Volatile flavour profile of reduced alcohol wines fermented with the non-conventional yeast species Metschnikowia pulcherrima and Saccharomyces uvarum. Food Chem.. 2016;209:57–64.

Whiting J. Regulating winegrape sugar accumulation through leaf removal. Aust. New Zeal. Grapegrower Winemaker. 2010;555:18–20.

World Health Organization (WHO), 2010. Global strategy to reduce the harmful use of alcohol. Available from: http://www.who.int/substance_abuse/activities/gsrhua/en/.

World Health Organization (WHO), 2014. Global Status Report on Alcohol and Health. WHO, Geneva, Switzerland.

YouGov Omnibus Panel, 2011 (August). WDR analysis. Base size: 1,693 British adult drinkers.

Zufall C, Wackerbauer K. The dealcoholization of beer bydialysis—influencing beer quality by process engineering (written in German). Monatsschr. Brauwiss.. 2000;53(9/10):164–179.

Zufall C, Wackerbauer K. Process engineering parameters for the dealcoholization of beer by means offalling film evaporation and its influence on beer quality (written in German). Monatsschr. Brauwiss.. 2000;53(7/8):124–137.

Zurcher A, Jakob M, Back W. In: Proceedings of the 30th EBC Congress; 2005Prague, Czech Republic. 240–248.