To master any skill, it is imperative to have a solid foundation in the techniques. This section provides useful information for knitting.

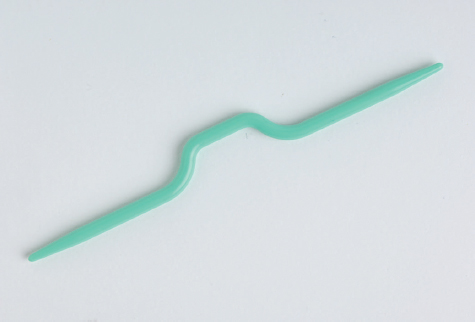

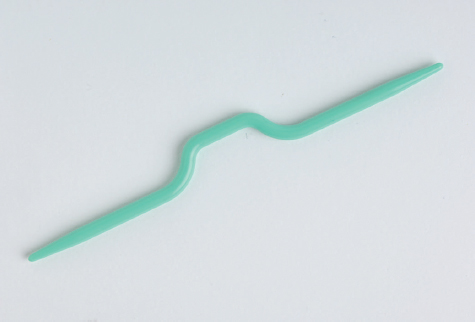

Cable needle

Knitting needles are used in pairs to produce a flat knitted fabric. They are pointed at one end to form the stitches and have a knob at the other to retain the stitches. They may be made in plastic, wood, steel or alloy and range in size from 2mm to 20mm in diameter. Needles are also made in different lengths that will comfortably hold the number of stitches required for each project. It is useful to have a range of sizes so that tension swatches can be knitted up and compared. Discard any needles that become bent. Points should be fairly sharp, as blunt needles reduce the speed and ease of working.

Circular and double-pointed needles are used to produce a tubular fabric or flat rounds. Many traditional fishermen’s sweaters are knitted in the round. Double-pointed needles are sold in sets of four or five. Circular needles consist of two needle points joined by a flexible length of plastic. The plastic varies in length. You can use the shorter lengths for knitting sleeves and neckbands and the longer lengths for larger pieces such as the bodies of sweaters.

Cable needles are short double-pointed needles with a kink in them that are used to hold the stitches of a cable to the back or front of the main body of knitting.

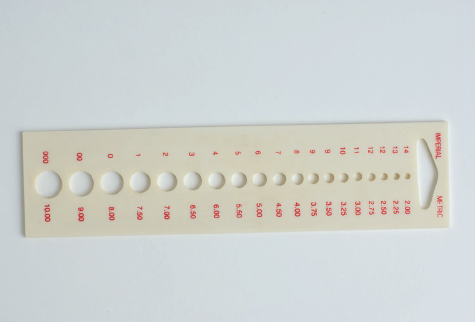

Needle gauge

Needle gauges are punched with holes corresponding to the needle sizes. They are usually marked with both US and metric sizing, so you can easily check the size of any needle.

Stitch holders resemble large safety pins and are used to hold stitches while they are not being worked – for example, around a neckline when the neckband stitches will be picked up and worked after the back and front have been joined. As an alternative, thread a blunt-pointed sewing needle with a generous length of contrast-coloured yarn, thread it through the stitches to be held while they are still on the needle, then slip the stitches off the needle and knot both ends of the contrast yarn to secure the stitches.

Wool sewing needles or tapestry needles are used to sew completed pieces of knitting together. They are large, with a broad eye for easy threading and a blunt point that will slip between the knitted stitches without splitting and fraying the yarn. Do not use sharp-pointed sewing needles to sew up knitting.

A row counter is a cylinder with a numbered dial that is used to count the number of rows that have been knitted. Push it onto the needle and turn the dial at the end of each row.

A tape measure is essential for checking tension swatches and for measuring the length and width of completed knitting. For an accurate result, always smooth the knitting (without stretching) on a firm flat surface before measuring it.

A crochet hook is useful for picking up dropped stitches.

Yarn is the term used for strands of spun fibre that are twisted together into a continuous length of the required thickness. Yarn can be of animal origin (wool, angora, mohair, silk, alpaca), of vegetable origin (cotton, linen), or man-made (nylon, acrylic, rayon). Knitting yarn may be made up from a combination of different fibres.

Each single strand of yarn is known as a ply. A number of plies are twisted together to form the yarn. The texture and characteristics of the yarn may be varied by the combination of fibres and by the way in which the yarn is spun. Wool and other natural fibres are often combined with man-made fibres to make a yarn that is more economical and hard-wearing. Wool can also be treated to make it machine-washable. The twist of the yarn is firm and smooth and knits up into a hard-wearing fabric. Loosely twisted yarn has a softer finish when knitted.

Yarn is most commonly sold wound into balls of specific weight measured in grams or ounces. Some yarn, particularly very thick yarn, is sold in a coiled hank or skein that must be wound into a ball before you can begin knitting.

Yarn manufacturers wrap each ball with a paper band on which is printed information such as the weight of the yarn and its composition. It will give instructions for washing and ironing and will state the ideal range of needle sizes to be used with the yarn. The ball band also carries the shade number and dye lot number. It is important that you use yarn of the same dye lot for an entire project. Different dye lots vary subtly in shading; this may not be apparent when you are holding the two balls, but it will show as a variation in shade on the finished piece of knitting.

Always keep the ball band as a reference. The best way is to pin it to the tension swatch and keep them together with any leftover yarn and spare buttons or other trimmings. That way, you can always check the washing instructions and also have materials for repairs.