V1000 RAF Transport.

‘The slaughter of that beautiful babe in the bulrushes was an act of defeatism that will come home to roost’

Aviation writer, Stanley H. Evans, on the termination of the Vickers V1000/VC7.

(Private correspondence to B.S. Shenstone in 1956)

‘One of the most disgraceful, most disheartening and most unfortunate decisions that has been taken in relation to the British aircraft industry in recent years …

‘From a national point of view that will be a tragedy when here, in almost completed form, we have a potential world-beater.’

Mr Paul Williams, MP (Sunderland South), the House of Commons. 8.51pm, 8 December 1955, speaking on the cancellation of V1000. (Hansard, Vol 547, cc665–670)

Despite the travails of the Second World War, British and American minds took time out from military strategy to consider the world in a more peaceful, post-war environment. Paramount amongst such considerations, were the expected airline transport needs of the world powers and their peoples, notably of the west. The Brabazon Committee, under John Moore-Brabazon, who had flown with Geoffrey de Havilland at the dawn of aviation, was the 1940s British body that performed the act of soothsaying to the future of British civil aviation; uppermost in its mind were the needs of the Empire, of mail, and of elite passengers travelling to their positions of colonial authority and importance. Mass travel was not what things were about.

The Americans had a wider vision of the new world order, and that vision served them well.

The Atlantic axis and the rising need for fast travel to Asia and Africa to serve old and new worlds, would be the key driving factors in years to come, yet there would be paradoxes and contradictions inherent within the debates and the application of the instrument of national policy via Britain’s airline – Imperial – and then its offshoot as the British Overseas Airways Corporation (BOAC). Some of the British failed to grasp that the war would end their Empire, they thought that there would be a return to flying boats and First Class travel. Such people, locked into their insular certainties, did not envisage mass travel, the tourist-class market, and an emerging world that would desire jet airliners and new airways.

While – circa 1943–1945 – the British toyed with their wartime Brabazon Committee looking at military and civil airframes for a post-war future, America developed, often-superior, military aircraft that could very easily be re-purposed as airliners for the new era and the new world market. Urgent wartime developments in airframe and powerplant technology soon gave us the DC4, DC6, DC7, Lockheed Constellation range, and Boeing’s bomber-derived airliner such as the Stratocruiser – all based upon wartime airframes. Military budgets had ‘free’ knock-on effects for civil airliner design and development, but the British were slower than the Americans to make the most of the opportunity. Converted British types like the Argonaut, Hermes, and Lancaster bombers were stumbling steps – ineffective anachronisms all.

However, a huge leap forwards in piston and turbine-engined, large, long-range airframe design did take place. Meanwhile, cash-strapped Britain was, despite the brilliant Viscount, still toying with elitist behemoths such as the Bristol Brabazon and the Saunders Roe Princess flying boat – ‘First Class’ affairs for the British and the very class system and empire mindset that would continue as a pre-war airliner psychology. While the troubled British four-engined Avro Tudor (surely a blot on Avro’s record?) seated less than twenty passengers, the four-engined American DC-4 could seat forty-five and a DC-6 over sixty. The economic arguments were obvious, yet ignored in London. But soon a prop-turbine Viscount and a fourjet Comet 1 that would seat thirty-six passengers in recumbent luxury, with no thought to the possibility of passengers who were not VIPs, was upon us. The British had woken up, a bright future hailed. Then came the Comet disasters, and the men of set minds wagged fingers and said; ‘I told you so’.

But was Comet really the answer? As an example, consider some other foreign airline chiefs and their airlines – such as Albert Plesman. He and his KLM did not rush to order Comet 1s, and there was a very sound reason why, and it was not about the Comet’s structure. Neither did TWA or American Airlines order the Comet 1, even if Pan Am were so enamoured of a Comet variant. Some people say that Comet 4 should have been sold by the hundreds; others understand why it was not.

Were these the circumstances of how aviation framed the moment the new world across the Atlantic realised that the old world in London, with all its blinkers, passed the baton to a quicker thinking society?

In Britain in 1949, realising the error of design psychology, certain, more internationalist British designers stunned the world with the propeller powered Vickers Viscount as a British design conceived not just for British airline needs, but one that met the new demands of airlines worldwide, who, ordered it by the hundreds. Then came that brilliant, but flawed, step into an uncertain future that was the de Havilland Comet 1 and a mistaken belief (perhaps even a delusion) that a decade later, a post-disaster, re-framed Comet 4 could compete in a world that had moved on.

Despite DC-7Cs and even larger L.1649s as prop-liners, jet airliner design concepts moved to 150 seat, six-abreast, swept-winged airliners with large underfloor cargo holds. Comet may have been brilliant in 1949, but by 1959 it was, despite a ‘stretch’, still small, relatively uneconomic, and was soon eclipsed. Indeed, de Havilland’s own advertisements for the Comet 4 stated in 1959–’60 that: ‘The Comet’s size fits the available traffic’ – surely an admission that it could not meet the size of future growth in traffic that lay inevitably just around the corner: change and changing of minds, was to be resisted in the ‘here and now’ school of ‘we know what we know’.

The British should, when bathed in patriotic fervour, always recall that their original Comet 1 used four, thirsty turbo-jets to transport just thirty-six luxuryseated passengers and a small amount of mail freight. Four jet engines for thirtysix passengers, looked at with detachment, was, in airline accounting terms, not exactly the triumph so often touted. But with no competition of any kind, the small cabin was a factor that was not argued over. It was a feature that became an acceptable abnormality, an invisible issue. This was the first jet airliner and, although under developed and small, that was that – it was all that mattered. Yet, even as an enlarged Comet 4 variant, the Comet remained small and narrow in the cabin, with about eighty, two-class passenger seats in mainline configuration; it also had limited freight capacity. After just a few years’ service, BOAC ‘dumped’ its still-fresh Comet 4s, which rather proved the point that Comet 4 was a hope too far as a 1960s premier airliner. After a brief BEA existence and few overseas operations, the upper crust Comet was relegated to a life of one-class tourist and charter life with Dan-Air’s clever Comet reincarnation.

A Defining Formula and Trident Tribulations

By the late 1950s, 130–150 seat, true ‘airliner’ generic design concept had eclipsed Britain’s thirty-six seat Comet 1, forty-four seat Comet 1A and sixty to eighty seat Comet 4/4C, or the ninety-two seat short/medium-haul 4B. A later four-engined jet airliner, the Convair CV-880, with its 105 seats and short, heavily loaded wings, would also be similarly eclipsed by the drive for seat per mile operating costs in an ever increasing airline accountants’ battle of the skies.

The vital calculation of an airliner’s ability to lift its weight, the weight of its passengers, cargo and fuel, and to fly a known distance – the ‘maximum-payload range’ – became the defining operational and sales formula; this coalesced on both sides of the Atlantic around an airframe that would lift 130–150 long-haul route sector seats, with four jet engines and a 3,000 mile range. But the issue of how long a take-off run – on a hot, high altitude or short-length runway – such an airliner might require, or its need to off-load weight to get safely airborne, seems to have been less visible in certain quarters.

Despite the Viscount’s international success, after it and the Comet 1, there came from Britain the cancelled V1000/VC7, the delayed Bristol Britannia, and, the prop-driven Vanguard for both BEA and Vickers favoured customer, Trans-Canada Airlines (TCA), the precursor to Air Canada. The Vanguard was strong and highly economical, but service introduction was delayed until 1960 due to problems with the Tyne engine; and designed to a narrow BEA specification. Vickers lost money – a lot of money (cited at £16million) – on the Vanguard, but the orders did keep the factory going at a difficult time.

The long-range, larger, prop-turbine Bristol Britannia 312, was a machine designed by other British minds that had not yet realised that the days of the prop were numbered, even if turbine-driven. It seems that the Bristol Company and many in British aviation seriously believed that the Britannia 312 could compete against the jet-engined 707 into the 1960s – an utterly bizarre managerial deployment of strategic irrationality that even the brilliant Peter Masefield (ex-BEA) stated to be ‘fact’. Meanwhile, Comet 1 carried a very few elite passengers in a series of very fast, short hops across the British Empire hued map, but such limitations were invisible to many observers. But Boeing and Douglas were investing nearly one billion US dollars between them in their late 1950s, true jet liners, as the 707 and DC-8 respectively.

So the clever, but myopic British school of airliner design, suffered from quickly dating appeal, delayed development and in the case of the Comet, tragic errors. Comet was brave, and in many ways clever; it cruised beautifully, but it was flawed nearer the ground, and structurally compromised at the hand of current knowledge and practice. But principally, and as so often overlooked, it was too small and too thirsty for its payload range and seat per mile figures and no amount of patriotic flag waving was ever going to alter those facts.

American designers at Boeing and French designers at Sud Aviation proved the point when they came up with different ideas – the 707 and the Caravelle respectively. At first, such designs were dismissed by the British as the wrong choice, or nationalistic flights of fancy. The British attitude to the daring Caravelle was hostile.

Yet the British, in an act of hypocrisy, would on one hand publicly criticise the Caravelle for being an exotic French design, by the French for the French (failing to realise that such a concept was a winner and a trend setter in a new world order), but then the British sold to the Caravelle’s manufacturer, complete Comet nose sections and Rolls-Royce engines to power it!

You cannot help but wonder why the British did not just order the Caravelle for BOAC and BEA and be done with pride? SAS, Iberia, Alitalia, Air France, Swissair, and a host of American and other airlines bought Caravelles and got on with the job, using the then ultimate short-medium haul jet tool.

Ah, but the antiquarian prop-driven, British, BEA-specific Vanguard was better old boy …

Then, realising that jets were the answer, the British would demand a four-engined jet and go and turn the original design for a capable short-medium-haul jetliner – the superbly proposed Rolls-Royce Medway-powered DH121 concept – into the cut-down and constrained Spey-powered Trident, a device useful only to the airline that demanded its original larger design be curtailed down to their revised and short-term edicts based on a small and temporary pothole in passenger traffic numbers circa 1959–60; it was the ‘available traffic’ argument again. Thus did BEA ignore world markets and growing demands for capacity, range, and take-off performance, and so hobble de Havilland and the Trident to BEA’s own blinkered mindset. The resulting cancellation of the Medway engine also impacted vital military airframe projects.

Ironically, BEA then spent the next ten years demanding that the Trident be made bigger – resulting in the addition of a (fourth) booster engine to the trijet; add in the auxiliary power unit, and arguably the Trident 3 was five engined, certainly it was four-engined for thrust purposes! Poor old de Havilland’s were stuck between a rock (BEA), and the proverbial hard place that was the mess that was British aviation amid the effects of the Sandys Report and the amalgamation of small independent aviation companies into larger manufacturing entities.

Via exchanges with de Havilland, Boeing had had sight of the original, much more competent, Rolls-Royce Medway engined Trident proposal, the DH121 with its new wing. The 727 was to ape that idea – not the smaller, stubbier airframe that de Havilland’s subsequently created for BEA as the Trident 1 – as BEA twisted de Havilland’s arm behind its back. BOAC’s actions meanwhile, killed off Vickers V1000 four-engined jet airliner project with no comment at all upon the fact that the 707s BOAC would subsequently quickly order within months, would not be runway and payload competent on BOAC’s key revenue earning routes of tropical, Empire and Commonwealth service. What a strange and paradoxical omission in management strategy.

Calamity and the Sclerosis of British Airline Attitude

So ended British internal design competition that might have produced a world beating tri-jet airframe, and a big long-haul four-engined jet before anyone else did it – both probably worth 2,000 orders in total. So began more single, airline-dictated demands, and to hell with wider, international sales appeal and financial viability for the airframe manufacturer. To make matters worse, the two dictating airlines concerned (BOAC and BEA) were tax-payer subsidised corporations. Vickers and other British aircraft manufacturers only became part of a nationalised, Statesupported ‘British Aircraft Corporation’ amalgam as BAC a decade later.

Even top British airline men were speaking out, and not at just procurement decisions, but at the poor quality of some British aircraft manufacturing practices. Beverley Shenstone, the ex-Supermarine Spitfire aerodynamicist, and BEA’s 1950s chief engineer, got himself into a lot of trouble, when just before Christmas in 1953, at an Institute of Engineers lecture in Southampton, he criticised what he thought were sloppy practices in aircraft factories – he said he had seen wings dragged across floors, poor workmanship, and metalwork damaged. American practices and build quality were better, said Shenstone. He woke up to find himself plastered all over The Times, Flight, and facing MPs and Trade Union leaders’ opprobrium. But some in the industry felt he had been making a point worthy of discussion. And were the workers under good or bad management?1

In 1955 the British airline and airframe procurement structure looked like something designed to go wrong. It was a political, corporate, and psychological sclerosis shielded by vast sums of public and private money and an arrogance of attitude. We might ask if it was a vignette of a strange period of post-war British social and political disorder shaded both blue and red.

Boeing meanwhile, never blinked and created the 707, and latterly the superbly capable 727 which aped the rear-engined design trend from Britain and Europe and was a viable future-proof airframe that would meet the demands of the new age that BEA had refused to consider. The BEA-optimised DH Trident would sell 117 examples – mostly to the State-sponsored carrier BEA and a few overseas operators. Boeing would sell 1,832 of its 727 around the world, simply because the 727 – the high-lift hot-rod – was better in every vital respect, even if once airborne, the ground-hugging Trident flew with true de Havilland panache; cracks in the wings latterly staining its reputation a touch.

Incredibly, despite the lessons of the Vickers Viscount’s international appeal and over 400 sales, the British airlines carried on with the view that a British airline could, and should, demand an airframe tailored to its own specific needs and that any export sales potential in the design was not that airline’s concern. Propellers were touted as the answer for the 1960s.

Of the past? Who could forget the wire, fabric and alloy concoction that was the Handley Page HP42/43 biplane airliner design – created for Imperial Airways at exactly the time others, such as Junkers, Boeing, Fokker, Lockheed, and Ford, were creating the world’s first monoplane, all-metal, true airliners. The HP42 seemed to be no more than an update of the HPW.8, which in 1920 became the world’s first ‘proper’ airliner in that it was not a conversion based upon a preexisting military bomber airframe (as the Vickers Vimy Commercial had been). As the latter HP42s were mooted, the Americans took to their metal Ford Tri-motors with the same alacrity as Germans did to their Junkers JU52s. The British decided to sail on upon the wings of their biplane behemoths – such as HP42. We might have expected Imperial, and the British, to have learned their lesson, but not a bit of it. The British airlines, locked into their views, could not face or accept the temerity of change or advance – unless of course they thought of it – now that would be different.

As we know, Viscount distanced Vickers from the herd. So the men of Vickers were not afflicted by British ‘Civil Service’ and corporate myopia and parochial arrogance, and thus created airframes like the Viscount and V1000/VC7 as machines with global performance attractions and sales potential, but which were then sadly swayed by the demands of a British airline and British Governments that ruled the financial roost.

Across the Atlantic, the likes of Boeing and Douglas had long since stopped designing airframes tied to the specific need on just one airline, however illustrious an airline’s history. Meanwhile, the Convair jetliners failed because they were too closely tied to one-specific operational theory and utterly bankrupted their manufacturer.

Empire Expectations

The British and their Empire had a lot to answer for – good and bad – and in 1946 the close-minded attitude still pervaded in aviation. How else could one explain the bomber conversions that were the Avro Lancastrian and Tudor, the HP Halton, and the Avro York, as opposed to the far more viable and capable Lockheed Constellation, or the Douglas DC-4 and its progeny?

Prior to the Second World War the British Empire had dictated its needs for transportation to its masters. Post-the Second World War, would not the British just carry on doing the same thing whatever the advances of aviation created by war? A self-serving design psychology ruled the British mind and mandate. Meanwhile, more open minds across the Atlantic had, pre-war, already created the revolutionary Douglas DC-2 and its DC-3 development, and then the DC-4, DC-6, DC-7, all were being designed and then sold, not just to national American carriers, but also to overseas airlines such as the likes of Koninklijke Luchtvaart Maatschappij (KLM) known globally as Royal Dutch Airlines, an airline which would make great strides using and promoting such equipment.

German Science and a Secret Legacy

In post-1945 global aviation design practice, a great change in knowledge took place at a fast pace and it informed a change in direction for military and civil aircraft design. The basis of the knowledge came from Germany and the legacy of that nation’s rapid development of glider wing design and technology in the 1920s and 1930s that stemmed directly from the post First World War Treaty of Versailles and its enforced limitation upon German powered aircraft design and development. From advanced German glider design, came advanced German swept-wing, all-wing, delta-wing, and jet engine technologies. All this, and rocket science too, was part of the great lode of aerodynamics science seized by the Allies from the spring of 1945 onwards as Germany collapsed.

In April 1945, before Hitler’s death, American experts were racing across Germany and seizing advanced aerodynamic research and the men that created that knowledge of future vision. By June 1945 the British were at it too – the Fedden Mission, under the lead of Sir Roy Fedden of the Bristol company, was scouring German research units for war-prize advances. The revered de Havilland Company managed to get an aerodynamics expert into Willy Messerschmitt’s Oberammergau design office and from there stemmed much knowledge of advanced, swept-wing design and high speed flight. Alongside the Fedden Mission, there could be found the other ‘F’ mission – the Farren Mission – that of William Farren (later Sir William) who, with various aviation and RAE experts, was also scouring Germany for advanced aeronautical knowledge. Inside the Farren Mission there could be found a man by the name of George Edwards (from 1957 Sir George Edwards). With Edwards was Captain A.J. Nannini, the Vickers weapons and armaments expert. Test pilot Captain Eric Brown was also present. After touring Germany, the Farren Mission men did, after visiting BMW in Bavaria, arrive at Messerschmitt’s Oberammergau design bureau. Of significance, Edwards also interviewed wing design expert W. Voigt. The similarly named, R. Vogt, the German aerodynamicist and swept-wing specialist, was also interviewed and both men were soon found to be working in the American aircraft industry, with Vogt at Boeing working on swept-wings. The Farren team recruited Dr Dieter Kuchemann – a man who would soon contribute to Vickers, RAE research and ultimately, the VC10 and Concorde wings. Also scooped up was Dr K. Doetsch. Both these men would contribute to the development of British supersonics, and George Edwards would work with them in the 1950s and 1960s, notably on Concorde.2

George Edwards would, like other British wartime investigators, wait many years before admitting that the point of the British presence in Germany was to gain as much knowledge as possible about high-speed wing design from the core of the most advanced collection of techniques then known in Germany. The Americans, so keen to secure German rocket experts, would take longer to either admit – or continue to deny – the contribution of German expertise to aerospace and aerodynamic developments under the American flag.

Indeed, in Germany, there could be found American experts sifting through the swept-wing and jet airframe research, including men from Boeing and the Bell Aircraft Corporation’s chief designer R. Woods. Even a certain C. Lindbergh pitched up; men from General Electric were also in Germany and T. von Karman of the California Institute of Technology (CALTECH) was also sniffing out research clues in Europe. Shorts and Avro also scooped up research into swept, delta, all-wing design and transonic technology. Indeed, Shorts chief designer, D. Keith-Lucas (a supporter of all-wing or ‘flying wing’ themes), was also in Germany. G. Lee at Handley Page was one of the most able British experts who had access in Germany to the practical details of sweep-back and sweep-forward effects in wing design.3

As we know, Vickers also had access to the German high speed aerodynamics research and it is safe to assert that the Allies secured an incredible cache of advanced German aerodynamic knowledge and feasted upon it. Britain’s new Labour Government seemed unbothered by the opportunity and let the Americans, French and Russians race ahead with State funding to develop such findings – notably in the transonic compressibility aerodynamic arenas. So it was private British industry, not the British State, that itself explored the knowledge for post-war British projects. The British Government also gave away to the USA the supersonic secrets of the Miles M.52, and to this date, no convincing explanation as to this act has ever been given.

Back in 1945–47, the swept-wing experts, the works of Prandtl, Lippisch, Horten brothers, Multhopp, Voigt, Vogt, Heinkel and many more, were absorbed into the Anglo-American academic base – and reinforced by Operation Paperclip, which, contrary to some perceptions, was not just about securing rocket propulsion knowledge. At the Royal Aircraft Establishment (RAE), Drs D. Kuchemann and J. Weber contributed great learning and much more from the 1930s pre-Nazi era Gottingen school of design. George Edwards had access to many of these people and under the Farren Mission interviewed them. Latterly, he agreed that the Germans had been far ahead in aerodynamic terms and how fortuitous it was that the RAE’s Morien Morgan had been on the Farren Mission to Germany in 1945 – from which had stemmed great strides in swept-wing, delta-wing and supersonic knowledge that finally manifested in Concorde itself.4

The Allies grabbed so much advanced aerospace science from Germany that the US Military Government of Germany, at the request of the Secretary of State for Occupied Areas, actually had to redraft the post-war peace treaty and invoke legislation protecting the USA from any claims by German designers who felt that their intellectual property had been stolen. Even later British commentators described Allied actions as a looting, or legalised seizure.

From tailless, delta, crescent wings and suction aerofoils, to jet design and rear mounted engines, from pylon engines, swept-wings (forward as well as rearward), T-tails, slats, flaps, ejection seats, composite structures, low-drag all-wing and variable sweep calculations and beyond, to the world’s only truly supersonic wind tunnel (Mach 5.5), which was quickly shipped to the United States of America: the German aircraft designers were decades ahead, just as were the rocket men of Peenemunde, soon to be the rocket men of Huntsville, Alabama, and then NASA and the Apollo projects.

From this cache of genius, America seized a re-branded future where such technology was remade and in many senses provided the underpinnings of the jets of the Cold War, and the airliners of the 1950s and 1960s. Inside the American aerospace industry were many German names who had, shall we say, ‘arrived’ in the United States soon after the summer of 1945. Until very recently the true nature of the knowledge transfer of Nazi funded and pre-Nazi German advanced aerospace science, has neither been admitted nor appreciated. By 1947, inside the American and British aviation establishments, were German experts who would go on to inform the design database of the major military and civil airframes of the next four decades, and to frame the aerial vehicles of the Cold War and the space race respectively.

The Americans (and the Russians) embraced the German knowledge and the designers, whereas much of the British political and academic establishment, so shocked to have discovered that they did not know it all, were slower to accept such advanced science into their thinking. However, belatedly, they would try to catch up, and the swept, delta-type, and all-wing research plundered by British experts in Germany circa spring 1945, gave rise to an Air Ministry specification for a large bomber – the Vulcan, Victor and Valiant were the resulting competing proposals to such ‘official’ specification. So German technology influenced the Vickers Valiant; and thus Vickers consequent Vanjet and VC10 ideas. One might argue that the DH Comet and the Avro Vulcan, to name just two examples, were proof of British brilliance and its golden era. That these aircraft contained German wing science, is rarely admitted, but to cite Avro’s exact words, the German delta-wing works of Alexander Lippisch, were, in the design of the mighty Vulcan, categorically stated as: ‘Of assistance’. A lovely euphemism from the British establishment.

Lippisch in London

We should recall that as early as 1930–1931, Alexander Lippisch flight tested unpowered and then powered, delta-winged airframes with great success at the Wasserkuppe, and publicly at Berlin Tempelhof. So revered was Lippisch (and his delta discoveries), that as late as December 1938, a few months before the Second World War became real, Lippisch was the invited guest lecturer at the Royal Aeronautical Society in London. There, assisted by his former research colleague, the engineer-aerodynamicist Beverley Shenstone (who spoke fluent German), Lippisch revealed his unique test findings and designs for his wing planforms. Lippisch was the only man in the world researching delta and swept-wing airflow using advanced German slow-motion camera (Zeiss Movikon) technology in smoke-lance equipped high-speed wind tunnels. The RAeS even published a translation of his findings at the time; the American NACA also re-published such German research as a series of ‘Memorandums’ in the late 1930s.

To this day, the British still insist that the delta-wing itself was Roy Chadwick’s actual invention as some kind of act of British genius. While not in any way wishing to offend him or his legacy, this is utter rubbish. Chadwick did indeed design the Avro Vulcan, Britain’s first true delta-winged jet, but he did not conceive the delta configuration and did not test or fly the first delta-wing aircraft. And as more knowledge was gained, the Vulcan’s straight, wing leading edge became curved. But it was Lippisch who flew the first Delta-type wing – in 1930–31 (Butler and Edwards had sketched such a thing decades previously and H. Junkers, and J. Dunne, may have been edging that way with their respective all-wing designs). However, even as late as 2015, experts appearing in the media and on the BBC were still claiming that the delta-wing was ‘invented’ by Chadwick and waving a sketch on a newspaper to apparently prove it. We can only excuse them upon the grounds of their ego, ignorance, or laziness.

Of significance, Richard Vogt the German aerodynamicist who had worked on wing sweep, including forwards sweep, and advanced wing design and airflows, had been scooped up under Operation Paperclip and taken to the USA. There, he would find employment at Boeing where he contributed to swept-wing research in the 1950s across Boeing’s output. Vogt knew all about the issue concerning applied degrees of wing sweep. Other 1930s German experts, men like Adolf Busemann, who under Operation Paperclip also soon found himself working for NACA and, by 1951, was a professor at the University of Colorado, had determined prior to 1945, that a 35º sweep angle provided the best trade-off between drag, lift, and attainable transonic Mach number. Boeing had grasped the importance of German research as early as 1946. And what of Rudiger Koisin and the cranked or aeroisoclinic wing? Would not the Handley Page Victor provide proof of concept?

Many people know that under Operation Paperclip, over 1,500 German experts were shipped off to the USA (notably the Peenemunde rocket men), but less well known is the fact American experts went the other way – into Germany. During 1946–48, teams of academics, scientists and designers toured Germany under Joint Intelligence Objectives Agency (JIOS) remit and under the remit of the Office of Strategic Studies (OSS) – the precursor to the Central Intelligence Agency (CIA) – and swept up a vital lode of science, inventions and expertise across numerous disciplines; notably aerodynamics and propulsion. A Technical Industrial Intelligence Committee (TIIC) was one of these search groups in Germany and had over 380 members, with translators, transport and accommodation laid on at US taxpayers expense.

A United Nations remit that phrased seizing science as, ‘the advancement and improvement of production and standards of living’, cited the ‘proper exploitation’ of German and Nazi technology. Therefore, private American companies (major industrial concerns) were allowed access to Germany and its industrial secrets under a Field Intelligence Agencies/Technical (FIAT) remit. Over 500 employees of US companies scoured the German research base. So, just as the British companies de Havilland and Vickers had managed to get experts into Willi Messerschmitt’s Oberammergau design office in the summer of 1945, Boeing too, soon had an expert touring German research institutions and aviation companies.5

Boeing’s Chief of Design, George Schairer, is officially said to have accompanied one of the American research teams into Germany and reviewed the aerodynamic research. There, he too realised that 35º was the ideal wing sweep angle. Four years later the Boeing B-47 deployed the new knowledge and five years from that date, the Boeing B-52 and then the 707 had 35º swept-wings. The reason why, lies in German research and the seizing of it for re-framing as the product of American brilliance: an American chorus of denial and shouts of ‘rubbish’ always follow such claims, however well evidenced, to which it is best to just respond with the names of ‘American’ citizens – like von Braun, Multhopp, Lippisch, Vogt, etc., etc.

The British, the French (and the Russians), were all part of this great scientific game. Soon, placed into British industry were expert German designers, many of whom, like some of those who went to America, had been deemed not to be Nazis, and some who had.

The names of German (but non-Nazi) experts also included the previously cited Dieter Kuchemann and another German, one closely associated with Kuchemann’s work, a Dr Johanna Weber, who also played a role in post-war British wing design development at the RAE and touched the Super VC10 wing design work. The fact that Dr Weber was a woman in an all-male preserve is often overlooked.

The first designs for the DH Comet 1, were also of a 35º swept ‘flying wing’ – more correctly an all-wing – this directly reflected German research findings. Few observers realise that the ‘advance’ of the production design Comet 1 was in fact a reverse-engineered step backwards from the original proposals for a high payload capacity, long-range, all-wing device of great futurism, which was refined from a tail-less all-wing into a highly swept, tail-equipped design that made even the later V1000 look tame. The all-wing Comet idea had speed, range, lift, payload and style, in fact it was simply too futuristic, it was too much for British minds, and Comet became the moderately swept, conventional planform shape that we are all so familiar with. Boeing’s first airliner thoughts of 1949 were also of delta and all-wing iterations.

However, swept-wings, delta-wings, high-lift devices and a rash of airframe developments, including of true significance, the T-tail and pylon mounted, and rear-mounted engines, were all pursued from seized wartime German research.

Significantly in the 707 story, and contrary to many claims made then and now, neither America nor Boeing pioneered wing-pylon mounted jet engines – German designers did so before any American wing-pyloned jet engine types. The 1944 dated Junkers Type 287, and the 1946 Type 140 of Professor Baade, and the Arado 234 of 1944, categorically evidenced that jet engines hung from pylons were a German idea, not a Boeing B-47 invention of 1949! The French did not ‘pioneer’ rear-mounted jets in their Caravelle either – they had the idea after the Focke-Wulf 294 Athodyd design by Hans Multhopp with its stub wing-mounted rear jet pods.

Military aviation advanced very quickly off the back of such works. Such findings soon percolated into civil aviation. At Boeing and at Vickers Armstrongs, there were swept-wing, jet age experts at work on advanced airframes, some of them had German names and had come from the ruins of Hitler’s nasty little experiment upon the world and its people. Those who wish to fulminate and deny these facts as ‘rubbish’, only serve to undermine their own so-called ‘expert’ credentials. History as written by the victors, is not always a reliable guide to factual reality, it takes time for the truth to come out.

Curiously, despite seizing so much knowledge, the Americans did not initially develop leading edge high-lift devices for their airframes. Lack of leading edge devices, allied to a lack of aerofoil development, also afflicted the Soviet airliners, this, despite a large number of German experts being seized by the Soviet Union in 1945. The British seem to have made more of the leading edge lift-enhancing qualities of the leading edge slat, or the drooped leading edge. Even Comet 1 had originally had small outboard slats (soon to be so unwisely deleted). In fact early British knowledge of leading edge lift devices came from the German emigré aerodynamicist and engineer Gustav Lachmann who worked for Handley Page Ltd in the 1930s and whom had patented such a device early on in his career.

The wartime science, seized and accrued post-1945, was a huge and vital reserve of knowledge that was developed between 1945 and 1955. It would not be wasted, notably in America.

Random Research

Reeling from the travails of war and near-bankruptcy, the British fired off research arrows into all sorts of aerospace arenas. A large cast of British aviation companies began to churn out all types of aircraft. And, it seemed, nobody could really decide whether to embrace the jet age or persevere with propeller powered flight. The new de Havilland Comet was one thing, but the Saunders Roe Princess was of another prop-persuasion, as was the new great hope the Britannia as a prop-turbine eggbeater-driven device. Even the behemoth that was Bristol’s Brabazon crept quietly away to a forgotten corner of design thinking.

The creation of the post-war operations of BOAC led to an airline that was not just an airline, but a nationalised, semi-State controlled, de facto national instrument of political will upon a new world still beset by old boundaries of the Empire. This situation created strategic management confusion and conflict for, and by, BOAC as a British airline transport entity: such themes would manifest in the VC10 story itself. Social change was afoot, and BOAC was initially too big and too encumbered to move at the pace of others such as the Americans, Boeing, and the airlines it served. BOAC supported the Comet 1, but showed only temporary interest in Vickers idea for a large long-haul jet airliner in that company’s studies for V1000/VC7 and then, finally, after procrastinations, went with the propellerdriven future of the Bristol Britannia in two bites – the original version and then a longer-range ‘312’ variant.

In America, the revived post-war Pan American Airways (PAA), would have a clearer commercial remit (as would Australia’s national airline Qantas), yet PAA, or ‘Pan Am’ too, would serve as a national flag carrier in more than the expected sense. The power of the American industrial and political lobby would secure a far less insular design direction than the confused and diffused British needs and aims of a declining power clinging to its pre-war psyche and geopolitical position.

Boeing’s brilliant big beast of a 707, and latterly the class-leading 727 (surely to all but the most clouded of minds, the best-designed, most proficient shortmedium-haul jet airliner ever created), would soon shatter the myths of those British beliefs. Boeing military jet transports and bombers – as B-52 and B-47 – were being designed, built, tested and made into successes in record time. Why reinvent the wheel creating some exotic airliner design when you could re-purpose and rebrand a tried and tested, part-part paid for piece of kit into a very fine airframe? It was obvious, and the ‘it’ in question had to be the superb Boeing ‘Dash 80’ – the 707.

The Comet’s failure re-opened the door to American opportunity, and the 707 story was born, but before that happened the men of Vickers Armstrongs had in fact, designed and nearly completed the build of a sensational, new long-range, four jet turbofan-engined airframe that could be used by the military and by airlines as a transport device par excellence, not just on the Empire routes but on transatlantic routes and global operations. This was the highly advanced V1000.

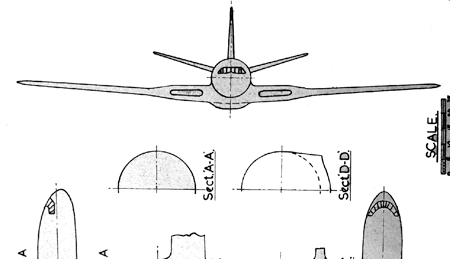

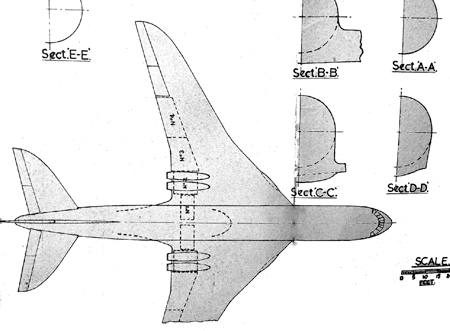

V1000 RAF Transport.

V1000: A Massive Loss

V1000 was far more than a Comet – even more than one in 4C guise could ever be. V1000 was in effect a second generation jet airliner before that era arrived. This aircraft represented a new, international outlook and design psychology, and it came from the genius and future vision of the men of Vickers led by George Edwards and the company’s Advanced Projects Office under Ernest Marshall’s design leadership – the men who had brought you the Viscount and its eventual 400 sales around the world. The new aircraft was the V1000, and with the first airframe eighty-five per cent complete, it was to be killed off by an insane decision taken by idiot politicians aided by BOAC’s stance. That decision must be proof that the British politicians ‘attitude’, and their inability to see beyond what they knew in the short-term, and that they did not want to know anything else, still pervaded. Paradoxically, it was British men, engineers and designers at Vickers, who threw off such conventions and saw into a brilliant internationalist future. Ironically, it was their own countrymen who killed off the chance to actually dominate the world’s airline fleets by merit for the next decade and beyond. As so often happens, the men of British heavy engineering and British industrial design were the victims of British politics, and poor State management.

The V1000 and its planned commercial, airline-specific derivative, the VC7, had it all – advanced design in structural and aerodynamic terms, a cranked sweptwing, four turbofan power plants, long-range, decent payload capacity, and a runway performance that made it usable not just on long straight runways near sea-level, but on shorter and more difficult fields on global airways. The V1000 was big, a real ‘heavy’ jet in its context.

Only in its ‘buried’ wing root engine installation was the V1000 in any sense structurally different from the similarly shaped airframes that followed from Boeing, Douglas, and ultimately Airbus. Burying the engines in the wing root was highly aerodynamically efficient (as was the cranked wing), and a fashionable design choice in the early jet age – doing so offered significant aerodynamic benefits in comparison to having the engines hanging off the wing as pyloned ‘barnacles’, where they tended to cause unwanted turbulence and loss of lift by affecting the aerofoil’s span lift distribution efficiency; not to mention the leading edge performance by interrupting the slats or droops and doing the same to trailing edge flaps. These factors created design issues for the pylon-wing behaviours. Low hanging, wing-pylon engines, also sucked up foreign objects from dirty runways and created a roll-angle limitation due to the risk of ground striking the pods if a wing was too low in a crosswind landing. Yet such pylon-mounted engines were said to be safer, kept fuel, fire, and noise away from the fuel tanks, main fuselage and cabin – according to theorists and many American designers.

This contentious theory was not proven in a number of accidents, including decades later in crash testing- using a retired 707. And if this theory was so true, how come Boeing built the rear-engined 727 or Douglas the DC-9? How come the wing-engine mounted Boeing 737 suffered so badly in accidents when the engines caught fire? But back in 1955, Boeing and other American design teams favoured the wing-pylon mounted engine theory. Wing-pylon engines were, however, certainly much easier to work on, to remove, and are easier to accommodate in the airframe, and have structural ‘relief ’ qualities. In the Vulcan, Valiant, Victor, and in the Comet, the British trend for wing root buried engines manifested – offering lower drag, and easier roll angles – against the complex, but solvable wing-box/ spar structural and safety issues extant, and which correct armour plating and designed-in reinforcement could address.

V1000 – Genesis and Cremation

Kicking off in 1951, and running through beyond 1954, George Edwards, Ernest Marshall, Basil Stephenson, Ken Lawson, Hugh Hemsley, John Hay, Maurice Wilmer, and others, as key figures of the Vickers engineering team, began studies for a post-war military and civil long-range jet type. They were requested to frame the V1000 project by the Ministry of Supply (MoS) under MoS Specification C.123D in 1952, as a new RAF type to replace the piston-powered post-war types such as the Handley Page Hastings. Post-war, post-Berlin airlift of 1948, and with a huge British military network to serve the world over in the yet-to-end British Empire, a fast new RAF transport was needed, in fact it was an urgent essential. Could the new transport type share features in common with the new Vickers Valiant bomber in order to ensure not just compatibility in operating regimes and schedules, but maybe in actual design and shape in order to provide ‘decoy’ capabilities in any ‘Cold War’, radar-related scenarios? Such strangeness had to be considered by airframe suppliers to Her Majesty’s Government and its Ministry of Supply (MoS).

Even at this stage BOAC were invited to contribute to the specifications, as an airline transport derivative was obvious – the VC7. The RAF’s V1000 could have been in service by 1958, a VC7 perhaps by late 1959. The then Minister of Supply, Reginald Maudling, was originally keen on both, and on Vickers as a company. After all, the V1000 was not (contrary to some latterly published claims) Vickers first big jet – it had already learned much with the Valiant.

The reason why the V1000/VC7 was so needed was also obvious – the old British Empire and Commonwealth airfields were often ‘hot’ in terms of local temperatures (30º-35ºC), and also ‘high’ in terms of altitude (5,000ft+), and sometimes both. Throw in an aircraft’s weight, and you had the ‘WAT’-formula of ‘Weight, Altitude and Temperature’ as one that defined if an airliner could get off the ground in the conditions and runway length available. Such routes had runways of 5,000ft or 6,000ft in length (as well as elevation), or rarely perhaps 8,000ft, and often dangerous local terrain. In contrast, New York and Los Angeles would soon offer 11,000ft-14,000ft runway lengths at near-sea level. London Heathrow offered 10,500ft.

Any machine required to service the shorter tropical runway airfields needed to be quick off the mark and able to climb properly – with decent payloads. And the same factors applied to the RAF’s end-of-Empire transport uplift airframe requirements. The conditions applied across BOAC’s route network, except for the North Atlantic routes, which were not then the principal focus of operations or earnings. Kano, Nairobi, Gan, Karachi, Singapore, Salisbury, Tripoli, Hong Kong and tropical points east, were the RAF and BOAC ‘Empire’ mindset. London Heathrow’s main 1960s runway, at low altitude, seemed innocuous compared to the narrow, short, hot runways at, for example, Lusaka, or the lift sapping tarmac at Salisbury (now Harare), Entebbe, Karachi, or some in Asia, or South America.

So a machine for serving the military on the Empire and commonwealth routes, could obviously serve the civilian airlines on the same medium-range routes. Here was a large sales opportunity for an aircraft maker.

Work on the project at Vickers Wisley base – as ‘V1000’ – started in October 1952, and as soon a December 1952, Vickers had forty-five draughtsmen working on the V1000 with planed basic weight of around 100,000lb. By 1953, sixty-three men were at work on a prototype – first a wooden mock-up, then an in-the-metal pathfinding airframe. Of note, much of the work already done for the Vickers Valiant bomber was transferable into the structure and design of the V1000. The military procured Valiant begat the V1000, just as the Boeing B-52 and B-47 military studies led to the B-362, B-367-80 for the USAF, and thus gave birth to a B-717 KC-135 military specification (with twenty-nine as initial order) that then delivered a civil derivative as the Boeing 707 itself. The RAF ordered six V1000s as a starting off point, so both nations were using military subsidies to underpin civil development, but on differing scales.

The Vickers modified Valiant idea was for a 90–100 seat, four-jet airframe, with a range of 2,100nm at a take-off weight of 126,500lbs, topped off with a 664kt high altitude cruising speed. From this early iteration came a longer range specification that would take-off at 155,700lbs weight, have a true North Atlantic, all-weather capable, 3,650nm range at a service ceiling way up at 40,000ft. Rolls-Royce Conway engines were proposed – with 13,500lbs to 15,500lbs thrust per engine being the early figures in 1952 – not dissimilar to the thrust ratings of the 1959 launched Boeing 707’s with Pratt and Whitney Turbojets. But Conway was an early pioneer of the ‘bypass’ turbofan design and clearly capable of massive development to over 20,000lbs thrust.

Yet Edwards and Marshall soon realised that this machine was, still, effectively a re-invented Valiant – despite seating double the number of passengers a Comet might accommodate, and possibly too small for the new world mass travel market that they knew would soon dawn – 150 two-class seats laid out six-abreast from a single central main aisle had to be the target. George Edwards and his team had avoided insular British design psychology and designed an airliner for the wider world market, not a tailored, British airline bespoke device. So was born the true V1000/VC7 airliner. With its clean swept-wing, and vital cruise-rated low-wing loading (under 80lbs/ft2), it had major aerodynamic advantages inherent within its operating performance (the later 707 and DC-8 would have planned wing loadings circa 100lbs.ft2). As things developed to a less Valiant-based V1000, a few delays crept in – latterly to be cited by critics.

The specifications had coalesced around a ‘Bluebook’ draft design agenda framed as B 97948, but throwing off the design constraints of the mid-fuselage or ‘shoulder’ mounted Valiant wing had given birth to a new, low-wing airframe that was framed as specification B 98545. Range was now 4,580nm, take-off weight was 175,000lbs and the payload 30,000lbs, but upgrading the design to a true, new status would put the costs up. However, the benefits would be huge in terms of performance and consequent international market sales appeal. By late 1953, BOAC’s lead engineer, Mr Dykes, and operations manager, Mr Jackson, were helping Vickers contribute to the airframe’s outcome. BOAC senior management, in the form of Whitney Straight and Campbell Orde, oversaw the potential BOAC specification angle to the project. The RAF and the Ministry of Supply were behind the military version, but asking the State to fund a developed variant – the airline VC7 – was going to be difficult. George Edwards decide that a ‘basic’ military specification V1000 would have to be ordered by the RAF – six examples were cited as the contractual point, and that these State-funded orders would also meet the baseline standards of civil need and could lead to the refinement that would create the ultimate, long-range world-beating VC7 development of that starting point. A step-by-step approach in post-war austerity Britain was understandable.

Vickers also noted that advancing the design early, for a future civil VC7 outcome, would allow the earlier baseline military transport version to be improved, and, if the RAF version would need a cargo door and strengthened floor, the VC7 pure airliner might not, so extra fuel tankage could be installed instead. Or could an airline derivative pure-cargo-only, or cargo/passenger ‘combi’ variant, be produced for world markets? Vickers thought of it all, in 1955! That was years before its competitors produced such machines.

With six-abreast seating as a design specification in 1953, the V1000 was also years ahead of the Boeing 707. In a great piece of cost saving, the Valiant’s mid and outer wing structures could still be used, so long as the mid-fuselage or ‘shoulder’ mounted wing configuration was discarded, and the noisy wing-root buried engines moved a bit further outboard from the cabin. In the Vickers design office, all sorts of permutations were toyed with before the defining V1000/VC7 layout and specifications were hardened up. One thing was for sure, here was a machine to lead the world, and it was British, and it was still not yet 1954 – a date well worth underlining in the context of other airframe developments.

The V1000 would have a low-set tailplane, swept fin, 32º main wing sweep, a higher sweep at the wing root to further reduce drag, solid milling of its metal structures and many structural reinforcements. Vickers would eschew de Havilland’s ultra-light, speed-related construction techniques and deploy thicker gauges of metal at the cost of increased weight.

Vickers had first built a pressurised hull in a Wellington V and V1 derivative, and despite not knowing details of the Comet’s inherent structural problems when they began designing the Valiant and the V1000, had put extra effort into refining a fail-safe, multi-load path pressure hull design. Experience with the Viscount fuselage also proved invaluable. Window and door apertures were ellipsoid and widely spaced, and metal panels were strong. Vickers pioneered airframe construction and in the V1000 used milled components from high-strength castings, and massive integral chassis reinforcing members or ‘spines’, as used in the Valiant’s wing-to-fuselage construction, were deployed; strengths and gauges around door openings were scaled up. The V1000 was almost ship-built in true Vickers Armstrongs Tyneside tradition!

Large ‘Fowler’ flaps and a ventral under-fuselage flap panel all contributed to a low landing speed. At this stage leading edge devices were being designed for the V1000. Testing of a V1000 model by Saunders Roe in a water tank, for hydrodynamic studies and ditching, showed that the aircraft, with its long forward fuselage, might nose-dip if it ditched, so the idea of using the front undercarriage doors as a sort of emergency ditching hydroplane was invented and drawn up.

Of significance, the V1000 cranked wing sweep aped the German research of Koisin, and was mirrored by that of Handley Page. The Valiant had established a production cranked, or aero-isoclinic wing, for Vickers, with its 47º sweep at root easing out to a 20º sweep at the tip, with a cleanly curved leading edge mating the planform neatly together. Perhaps it was not as radical as the Handley Page HP 80 Victor isoclinic iteration, but it did explore aerodynamic advantages. The Vickers wing delivered some level of reduced aerodynamic compressibility onset at the wing root, and gave low sweepback with safe stall and spin behaviours at the tip: so combined root and leading edge and root-to-tip overall drag reductions were achieved. Low drag high-speed cruising at Mach. 80 was first explored by the Vickers design team via the Valiant studies and all this knowledge permeated down into the V1000/VC7 wing design – itself having some degree of aero-isoclinic cranked shaping.

Further aerodynamics work went into the V1000, including an advanced underbody wing-to-fuselage fairing designed to reduce localised drag over the wing root and undercarriage areas – a device later deployed on the Airbus A380. Photographs of the V1000 (as opposed to models), clearly show a very modern looking airframe, far removed from the 1950s industrial design motifs of the Comet or even the 707. At the tail, advanced metal fairings that were flexible helped seal the tailplane-to-tailfin junction.

Apart from those wing root buried engines, the V1000 looks for all the world like a 1970s later generation Airbus or Boeing machine – minus the barnacled engines.

The V1000 had advanced flying controls and an all-moving variable incidence tailplane and fully powered electro-hydraulic flying surfaces with individual sections to ensure ‘fail safe’ redundancy. The main structural components, such as the crucial wing box/spar and frames, were machined from solid billets of the relevant metals that were of a new quality never before manufactured. Alloys, extrusions, and machining, were advanced arts for the Valiant and for the V1000 – ensuring great strides in structural safety and the doubled-up ‘fail-safe’ principal. Of interest, the V1000 wing had that cranked leading edge, giving advanced aerodynamic efficiencies – smoother flows and less likelihood of shockwave formation along the inboard leading edge, and, spanwise, thence easing through sweep to the less-swept outboard sweep angle of 32º.

Vickers learned a lot about wing design very quickly from the Valiant’s military design process. Meanwhile, de Havilland’s were suggesting a reverse-engineered military design for a bomber, using the civil Comet airliner’s wing and a new longer and deeper fuselage.

On 22 September 1954, the definitive framing of engineering frameworks for the V1000 took place – leading to the selection of structural specifications and more closely defined weights and performance expectations. By then, over 6,000 drawings had been produced and a mock-up of the shape considered. By January 1955, a first flight date of a sole, early prototype could be envisaged for late 1956, with a service entry for mid-1959 being perfectly rational.

By 1955, the V1000’s design was significantly more capable than the forthcoming Comet 4, had a wing over fifteen per cent bigger than the suggested new Boeing 707 airliner, and was of greater sweep than a Comet, and had more power (Rolls-Royce were upgrading the Conway engine and ideas of water injection and reheat were even considered). At this stage, Boeing had not yet widened the 707s fuselage to rival the V1000’s six-abreast layout. Later V1000 aerodynamic tweaks were to include aileron droop on take-off for more lift at hot and high airfields, and there was even some work on boundary layer control at the wing roots. The curved-top tail fin was replaced with a sharper styled fin design – with hints of later VC10 styling. The V1000 was set to become the largest, strongest, most technically advanced, longest range, airline transport airframe in the world. Airlines from all over the globe, even top American airlines, would have had to have ordered the V1000 as VC7 in order to remain competitive. National pride would soon have gone out of the window when the machine wiped the floor with future competing products – of which there were none – the 707 still being in military-to-civil airframe ‘Stratotanker-Stratoliner’ genesis at this time. And yet bizarrely, BOAC were to focus on the elegant, but ancient art of the prop-turbine Bristol Britannia, and to stick with Comet and its small cabin and freight capacity – even in redesigned the Comet 4 variant. The Comet 4 could not have competed, and the then to be launched Boeing 707 would not have matched the V1000/VC7 range and runway performance. Winter weather on the Atlantic ‘Blue Riband’ routes would have rarely caused a refuelling diversion into Gander, Shannon, or Prestwick for the V1000 and its variants – unlike the Comet or 707. Ultimately, V1000/VC7 was a truly oceanic, 3,500 miles-plus, winter capable machine.

V1000 Original Plans.

Offering 120–150 seats and true long-range, with reliable payload uplift that would not be heavily constrained by the need to offload cargo, fuel, or passengers at tropical airports, or to add a headwind-related transatlantic fuel stop, long before the 707 stole the world market, was all within the V1000’s max payload range grasp. And the V1000/VC7 could have been ‘stretched’ DC-8 style too, with 200 or 250 seats. The V1000/VC7 had a wing fifteen per cent bigger than the 707 – reducing wing loading, lowering landing speed and adding range and runway performance which would have swayed airlines towards it. Qantas could have had Pacific-capable VC7s before it asked Boeing to build it the unique ‘one-off ’ ultrashort bodied 707-138.

Airframe Reality

By late 1955, the first V1000 prototype airframe was eighty-five per cent complete ‘in the metal’, and Vickers had briefed numerous airline executives on the stunning performance capabilities of their offering. The V1000/VC7 was in the same position as Viscount had been, in that it was a world-beating design that was far ahead of any competition anywhere in the world. At the same time, the Bristol Britannia, Lockheed Electra, and Vickers Vanguard (all troubled by varying design issues), and the argument over whether jet, prop-jet, or piston-prop powered airframes would be required equipment across the world’s airline routes, were the focus of airline executives ruminations. It is recorded fact that Pan American Airways had shown close interest in the V1000/VC7. The old Vickers customer, Trans-Canada Airlines (forerunner of Air Canada), was a keen potential operator. BOAC should have been an ideal VC7 customer, yet said BOAC, the future lay with the exquisite Britannia; and if it did not, there was the Comet 4, whose limitations could, it seems, be ignored upon the mask of patriotism and past glories. Did BOAC really so naively believe that the Comet 4 could beat off the mighty 707? How could they – and did they not then quickly order 707s!

But massive changes were afoot in British aviation with the myriad small aviation companies all suffering, and a plethora of orders and types increasing costs notably for the RAF. Yet political considerations such as jobs in marginal constituencies and regional issues such as the economy of Northern Ireland would play hidden roles. Then would come the 1957 Sandys Report on British aviation and the nascent aerospace industries, from which came even more change and airframe confusion and forced collaborations.

Some people say that the VC10 was a natural progression of the V1000/VC7 story – via the Vanjet studies; others might argue that the VC10 was the bastard son of the V1000 and a post-Sandy’s era cut-and-shut idea, amid a mess of Stateinfluenced design, indecision and misdirection.

Meanwhile, in the 1950s, Super Constellations, DC-7s, and even the odd Stratocruiser, still strode the airways as queens of the skies. BOAC rushed out and bought second-hand DC-7Cs to meet its long-haul fleet shortage – spending huge sums to convert them to BOAC standards. Yet the V1000, as VC7, could and should have answered many questions, and perhaps sold one thousand airframes across a two decades life. The crazy policy decisions of successive British Governments, and the nation’s own corporation of BOAC, were the British reasons why not, and denial of such can in the face of overwhelming evidence, only indicate some kind of issue in the believer.

Funeral Pyre

The V1000 story was killed off by government decree on 24 October 1955 (announced by the Ministry of Supply in November) and the men of Vickers left to walk away, the tooling soon to be junked and the chapter closed. It was not the first or last time British design brilliance would be sold down the river; the Miles M.52, and the TSR2 being other key examples of how the fiddlings of, ‘here today and gone tomorrow’, idiot politicians of whatever ideology, can impact national history, global design and the employment of working men.

Britain’s Government had used (in great part, BOAC-framed) concerns over the V1000s engine power ratings and payload range contentions to end the programme for an RAF-based original V1000 contract, and thus the VC7 offshoot which Vickers had privately created. Vickers were less than twelve months behind schedule with the V1000 – which was nothing compared to the delays of other airliner airframes, then and latterly. Yet ‘delays’ were cited by enemies. But the RAF still needed a jet transport to keep up with its jet bombers and fighters – the problem was not going to go away; ironically and incredibly, five decades later the RAF would purchase ancient old Boeing 707 airframes re-manufactured for military surveillance duties! So, in a way, Boeing had the last laugh.

BOAC’s 1955 claims of a so-called Conway thrust inadequacy and concerns over its growth potential were utter rubbish – because the same Conway engines of such Civil Service and BOAC concerns, were soon to be found in the BOAC Boeing 707s that the government (via the Ministry of Transport and Civil Aviation) authorised BOAC to purchase just months later. And did not the Handley Page HP. Victor use Conways – buried in its wings? The fact that the Conway had the potential to be uprated during the V1000 development process was known, as was its possible use in a developed Valiant nuclear bomber. There was even talk of a Conway re-engined Comet 4 (three decades later a re-engined Comet derivative-Nimrod would prove a point). So any claim that powerplant was a problem, seems hollow indeed. Yes, the V1000’s weight went up as its abilities developed, but not to a degree thought unsolvable, and as weight went up, so too did the Conways thrust rating.

The V1000, near complete as a test airframe in 1955, was indeed the future.

We should never underestimate the effect of the death of the V1000 and its VC7 airline variant.

In the House of Commons, in November 1955, in an early V1000 cancellation related debate in Parliament, and imploring Minister Maudling to ‘save’ the V1000, Mr W. Robson Brown MP, stated that the V1000 was the only aircraft of its type in the world, and the only British machine, that could compete with American proposals. Mr John Peyton MP pointed out how much American competitors would relish the decision and the disadvantage to British aviation it would create. The Labour Party’s Deputy-Leader, George Brown MP, also weighed in to frame the loss to Britain and the gain to America.

In response, Minister Reginald Maudling MP added that the Government could not support an aircraft (V1000) that would not, or could not, be ordered by overseas airlines if the national airline (BOAC) would not order it in the first place.

Surely the only conclusion of the meaning of his statement was that ‘fault’ must lie with BOAC or Vickers? The debate in Parliament continued up to a further point on the evening of 8 December 1955, when Mr Paul Williams MP called the cancellation of the V1000 not just ‘disgraceful’, but one of the most unfortunate decisions that had ever been taken for the aircraft industry. Mr Williams noted that criticisms of the V1000 as VC7, by detractors, had referred to it as a ‘paper’ aeroplane – i.e. just a concept, which was being economical with the actualité. But was not the then proposed DC-8 a ‘paper’ aeroplane too – opined Mr Williams. Yet such ‘paper’ status was being given as a reason to cancel the near-complete V1000/VC7. Arguments about V1000’s weight increase had, said Mr Williams, utterly failed to note the increase in the thrust of the Conway engine, and confusion between basic weight and all-up maximum weights also existed in politicians comments.

Mr Williams noted that of the £2.3million already invested in the V1000, not one penny had been spent on the civil version (VC7) except by the firm (Vickers) itself. Mr Williams also noted that the V1000 had a lower wing loading than its American rivals – a key point in runway performance and in sales terms. Also noted were proposed British supersonic developments, how, if Britain could not deliver the V1000, would it deliver a competent supersonic airliner? And what would BOAC do if the V1000 died? ‘Buy American’, by the early sixties, said Mr Williams; little did he know that within months, not years, BOAC would do just that.6

V1000 advanced design.

As with George Edwards’ statement that this was a national decision that we would regret for many years, and one confirmed by external commentators such as Mr Williams MP, who framed for public view just what potential loss was being realised. We can only say it was indeed a tragedy.

The slaughtering of the V1000 and any potential civil variant was another seminal moment in British industrial history and British political farce. It cost the British billions in lost revenue, jobs, and global prestige. There is no doubt that an aspect of British history turned upon the V1000’s folded wings, yet few commentators outside aviation are aware of it.

The strangling in 1955, at near-birth of the V1000, did, as the great George Edwards (and others) observed at the time, hand the entire future world market for a large, four-engined, long-range airline transport, to America, on a plate. It was a madness that cost bankrupt Great Britain, so desperate for export earning commodities, great prestige and respect, as well as billions in lost income, earned yields, and global orders. In fact, in the cancellation of the V1000, we can see the beginning of the end for British civil jet aircraft manufacturing. It truly was a deliberate loss of historic proportions, and no fault lay with the men of Vickers at Weybridge for its occurrence. As with TSR-2, the original larger, Medwaypowered DH Trident, the Vickers V1000 could have been the future.

Sir George Edwards stated publicly and to the author, that in his view the V1000 cancellation, and the short-term political decisions that framed it, was, ‘the most serious setback that the British aircraft industry has suffered since the end of the Second World War’. He added the point that it occurred just as the great 1960s market for jet travel was to manifest on a global scale. Edwards might have been expected to blow Vickers trumpet, but he was right (he usually was), and he was right because of the sheer future vision that the V1000 represented – and MPs and others agreed with him. It was the Viscount all over again – only bigger, even better, and the world’s first serious, large four-engined turbofan airliner design. As suggested, the proof lay in the scenario that surrounded the Viscount when Vickers and Edwards had produced the right aircraft at the right time and it sold worldwide – even to American domestic carriers and European carriers – even the Douglas Company’s favourite customer, KLM!

The Viscount was, in the words of Gordon McGregor, ex-RCAF Battle of Britain and wartime fighter pilot and President of Trans-Canada Airlines: ‘By a very wide margin, the best commercial aircraft of its class that has ever been built.’7 The V1000/VC7 was the same thing – but a jet-age next-step and the biggest and best designed large airliner concept of its era and was well ahead of the early 707-120 concept. Indeed, it was McGregor who actually flew to London from Canada to try and save the V1000 with the promise of Canadian interest, alas to no avail, because, despite the urgings to BOAC of the Minister of Aviation, Reginald Maudling MP, the airline still refused to support, or save, the V1000/ VC7. Did Maudling or McGregor know that in under a year BOAC would go on to order Conway-powered 707s? It is unlikely.

The Minister expressed ‘regret’ at the V1000’s death and Geoffrey Ripon MP, the Parliamentary Secretary to the Ministry, called the cancellation a ‘terrible tragedy’. Aircraft designer and famous aviation writer, Stanley H. Evans, stated in correspondence to BEA’s Beverley Shenstone, that the V1000/VC7 was a worldbeater, and that: ‘The slaughter of that beautiful babe in the bulrushes was an act of defeatism that will come home to roost’.8

Evans was correct and the Americans must have been jumping for joy – as Brooklands wept.

As the V1000/VC7 died, BOAC quickly ordered those Conway jet-powered 707s – having ensured that no British jet competitor existed by ending the V1000 story! Yet then for BOAC’s State masters to seek a British jet to serve the long-haul routes of the tropical climes of the world. And did not BOAC’s own charter advise that it should seek British products to serve it? It was a management scenario that even the calmest of commentators might perceive as ill-conceived, if not astoundingly confused and utterly bizarre. What agendas were afoot? Did some conspiracy theory abound?

By avoiding the V1000/VC7 potential, notably as powered by advanced Rolls-Royce Conway turbofans and not Pratt and Whitney JTC3 turbojets, as found on the original 707s, BOAC had itself ensured that in 1956 Britain had no large four-engined jet airliner on its drawing boards. We should not blame BOAC for everything, but BOAC did essentially create the landscape that helped kill the V1000/VC7 within a political basis of claim.

BOAC would say that it had paid for and ‘lost’ its Comet 1s and Comet 2s; Comet 3, as Comet 4, was not ready, and that it had suffered the Britannia 312 delays and had had to pay out large sums on interim measures such as the DC-7C. Why, said BOAC, should it support yet another ‘on-paper’ project – the V1000/ VC7? The answer was, of course, that the V1000 and VC7 were very quickly ‘real’ and the V1000 was in the metal by 1955 and ideal for BOAC. Oh, but hang on, the prop-driven Britannia was at hand to answer it all!

Yet in October 1956, within months of the V1000’s end, BOAC had indeed gone jet-minded and ordered the Boeing 707, and then to rub salt into the wound by specifying that its 707s should be Conway turbofan powered, despite BOAC’s earlier citation of the Conway’s supposed thrust issue as a reason to deny the V1000/ VC7!

Were such outcomes accidents, or were they the result of the machinations of political and corporate games of smoke and mirrors? Or was it all just one great big foul-up by men paid very well indeed? And did BOAC, as alleged by some, seem to extend the delays surrounding the acceptance of the solving of the Britannia’s relatively innocuous engine intake icing problem that Bristol worked to solve? Was it just a coincidence that the delay was of massive assistance to Boeing in its rush to get the 707 into the air as a viable airliner for sale? We can only assume that all this was the circumstance of accident and not some underhand game of power.

BOAC’s Paradox of Internal Inconsistency

Why did BOAC effectively kill off the hope of a large four-engined British airliner in the V1000/VC7, but then say it ‘had’ to buy American Boeings because no British airliner existed! What of the statement that BOAC could not now wait for a British big jet to be designed – even though it had also said that the prop-turbine Britannia 312 would see it into 1960s competition with the 707.

There was more, and it was crucial: BOAC knew that the 707, either as a turbojet, or as turbofan, would not be capable in runway performance and maximumpayload range terms on BOAC’s vital revenue-earning tropical routes with the very demanding ‘hot and high’ runways and equatorial weather route sectors.

Let us make the point clear.

BOAC was, with public money, ordering a big jet, as the 707 (fifteen of them), that could not, repeat not, adequately serve BOAC’s main revenue vital (non-Atlantic) routes, and it was using £46million of precious British currency at a time of crippling national debt to do it!

BOAC was also, at the same time, expressing interest in the jet-powered de Havilland DH.118 four-engined large airliner proposal that was a sort of Comet 5, but with wing pylon-mounted engines! Paradoxically, BOAC also gave some encouragement to the Bristol 200 jet airliner proposal – that came in a suggested three and four rear-engined configuration. Not only was the V1000/VC7 killed off, but the 707’s seal of international use (by Britain) was officially stamped at British tax-payers expense via BOAC’s orders for it. BOAC’s Boeing order for a 1960s intercontinental variant was built on hope, and promises of a not then fully developed airframe. But the V1000s airframe had been nearly complete in late 1955!

However incredible it seems from today’s viewpoint, we should be clear that what happened was because the political and industrial consequences would have been so severe for cash-strapped Britain and for its workers.

Between BOAC and the British Government (which also needed to place jobs in Belfast at the Shorts factory in order to fend off economic crisis and political issues in Northern Ireland, and as orders for the Britannia failed to come in), Vickers and their V1000 would be sacrificed upon BOAC’s suggestions and the RAF’s forced withdrawal from a new Transport Command jet aircraft.

Here was BOAC screwing up its own future fleet and revenue earning choices!

The whole theatre seems like a farce, a psychiatric game, and open-season for conspiracy theorists to ask just what went on behind the scenes between BOAC’s board and Boeing? There is little proof of such conspiracies, yet the BOAC decisions do seem internally inconsistent in terms of behavioural psychology.

Yet perhaps we should not forget, behind the British flag-waving, just how poorly some parts of British civil aviation (in its now termed ‘golden age’) had performed for British airlines. The Comet 1 disasters, the delayed Comet 4, the Airspeed Ambassador, the appalling Avro Tudor, the brilliant, yet troubled propturbine Britannia, the delayed Vanguard Tyne engine, the soon-to-be emasculated Trident; all had missed their targets and failed on the international stage. Only the Vickers Viscount shone as a true, global success and one that the V1000 could have built upon – the Vickers customer-base existed.

The repeating of the Viscount’s story could, and should, have happened with the V1000/VC7 opportunity – as a jet age British success. Imagine if KLM, Lufthansa, Air France, Pan Am, TWA, Qantas and more, had used Viscounts at regional level to feed into their long-haul VC7 fleets. Imagine if they had then, for the 1960s, been offered a Vickers-built medium-route 120 seater twin-jet or tri-jet ‘Vanjet’ to complement their all-Vickers fleets and a V1000 on top! Vickers would surely have swept the airline order books in a manner beyond late 1950s comprehension. It was all there for the taking, yet it was all thrown away by others. Remember, the V1000 as a VC7, would, by 1957, have delivered the world’s first, true four-engined, turbofan, long-range airliner with six-abreast seating, a large passenger and freight capacity, and a high-lift ‘clean’ wing to deliver decent uplift and performance in difficult operating conditions all over the globe. Airlines would have flocked to order it in 1956 – before the 707 in its early range-limited turbojet versions became the only real option for 1959 launch.

All this was a near-reality – yet a dashed reality. Can we be surprised at the tears and the anger shed and vented inside Vickers over such a loss?