In the early 1980s, the American military took into service the 4 × 4 High Mobility Multipurpose Wheeled Vehicle (HMMWV) designed and built by the AM General Corporation. The HMMWV was originally named the ‘Hummer’ by the builder, later replaced by the name ‘Humvee’. Both names are registered trademarks of AM General. The Hummer name was later used by AM General for its civilian models of the vehicle.

The HMMWV was the replacement for a number of vehicles, including the 4 × 4 M151 MUTT (Military Unit Tactical Truck) series, the 6 × 6 M561 Gamma Goat and the 4 × 4 Commercial Utility Cargo Trucks (CUCVs). The latter, while more affordable than specialized military trucks, lacked the durability the services sought.

The bulk of the HMMWVs ordered for the American military were non-armoured, weaponless transport trucks. A smaller number were referred to as armament carriers, and could be fitted with a variety of weapons ranging from machine guns to an anti-tank missile launcher known as the TOW (tube-launched optically-tracked wire-guided).

Those armament carriers in US Army and US Air Force service that were armed with a machine gun or grenade launcher were referred to as the M1025, and when fitted with a winch they became the M1026. US Army armament carriers fitted with the TOW were labelled as the M966. Those with TOW and fitted with a winch were referred to as the M1036.

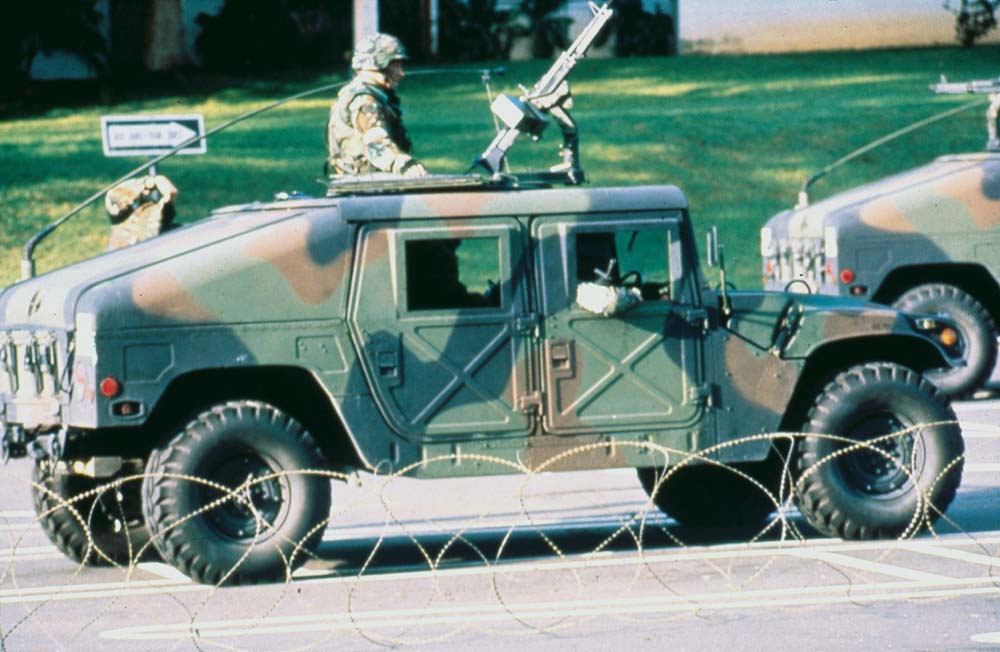

Armament carriers taken into service by the US Army and US Air Force had bullet-resistant windows and doors, which were intended to stop small bullet fragments. This armour arrangement is referred to as ‘basic armour’ and can be identified by an X-shaped stamping on the four doors of US Army and US Air Force armament carriers.

Armament carriers acquired by the USMC came with an armour arrangement referred to as ‘supplemental armour’. It consisted of flat steel armour plates attached to various portions of the vehicles, including over the existing basic armour X-shaped stamped doors. The supplemental armour add-on kit provided protection from larger bullet fragments than the basic armour kit.

Due to their supplemental armour kit, USMC armament carriers were assigned different designations than the same vehicle employed by the other services. Those fitted with either a machine gun or grenade launcher where labelled the M1043, while the same vehicle with a winch became the M1044. The TOW armament carrier employed by the USMC without a winch was designated the M1045, and with a winch as the M1046.

AM General tried to anticipate future US Army requirements in 1991 and, using their newest version of the HMMWV, referred to as the M1097 Heavy Humvee Variant (HHV), they created an up-armoured armament carrier. It was not ordered by the US Army, although some were sold to friendly foreign governments.

A large number of US Army and USMC HMMWV armament carriers participated in the ground war portion of Operation Desert Storm in 1991. However, such was the brevity of that land-based conflict that little or no insight was gained on their combat utility, or lack thereof.

In 1993, US Army units were deployed to Somalia in support of United Nations peacekeeping duties. In a country in which almost every male citizen was armed with a high-powered assault rifle, it was soon clear to the US Army that the limited armour protection found on its various versions of the HMMWV armament carrier (protected by the basic armour kit) left its soldiers highly vulnerable.

In a quick-fix approach, the US Army had AM General team up with the O’Gara-Hess & Eisenhardt Armoring Company, a long-time builder of armoured vehicles for the commercial market. They took an M1097 HHV Shelter Carrier chassis and armoured it to new US Army specifications. This mating produced the XM1109 Up-Armored HMMWV (UAH) in 1993. After a brief test period, the vehicle was standardized by the US Army in 1994 as the M1109 UAH.

Positive results with the M1109 UAH resulted in the US Army going back to AM General and the O’Gara-Hess & Eisenhardt Armoring Company and asking for an improved version based on the newest model of the HMMWV being built. That vehicle was named the Expanded Capacity Humvee (ECH) by AM General. Employing the ECH baseline chassis, the two firms came up with the XM1114 UAH for field testing in 1995.

In an article by First Lieutenant Jonathan C. Byrom that appeared in the January– February 1998 issue of Armor magazine titled ‘Up-armored HMMWVs: Answer for Peacekeeping Operations’, he describes the usefulness of the XM1114 UAH during operations in Bosnia-Herzegovina, located in the Balkans:

The XM1114 uses significantly less fuel than both [M2/M3] Bradleys and M1A1 [Abrams] tanks. My platoon was able to patrol for an entire day and use less than 30 gallons of fuel per vehicle compared to the hundreds of gallons needed by Bradleys and tanks during the same patrol duration . . . Another strength of the up-armoured Humvee is its mobility. It can traverse some terrain that a tank or Bradley cannot, particularly tight spaces in villages and wooded terrain . . . The XM1114 equipped platoon is also effective because it preserves the roads, unlike tracked vehicles . . . The XM1114 HMMWV is also equipped with combat locks on each door, which allows it to function effectively in the riot situations that soldiers often encounter in tense peacekeeping or peace-enforcing operations.

The XM1114 UAH entered into series production for the US Army in 1996 as the M1114 UAH. The US Air Force (USAF) was impressed enough with the new M1114 UAH for it to order a modified version, designated the M1116 UAH; it entered into the USAF inventory in 1998. The USAF also employs an unarmed version of the M1114 UAH, designated as the M1145 UAH, for its forward air controllers (FACs).

In 1994, the US Army began receiving the newest model of the HMMWV referred to as the A1 series, all of which were based on the Heavy Hummer Variant (HHV) chassis. At that point, all the initial series production models of the HMMWV were assigned the A0 suffix to their original vehicle designation codes. For example, the M966 TOW missile carrier without a winch, and fitted with the basic armor kit, became the M966A0.

With the introduction of the A2 series model of the HMMWV in 1995, the US Army did away with the separate designation for those armament carriers with basic armor and equipped with winches, and those fitted with TOW. The only armament carrier designation for the US Army became the M1025A2 and the M1121A2 armament/TOW carrier with basic armor.

The USMC decided that its version of the armament/TOW carrier with the supplemental armor kit would retain not only a separate designation, but would also retain different designations for those fitted with and without winches. This resulted in the M1043A2 armament/TOW carrier and the M1045A2 armament/TOW carrier with the supplemental armor kit.

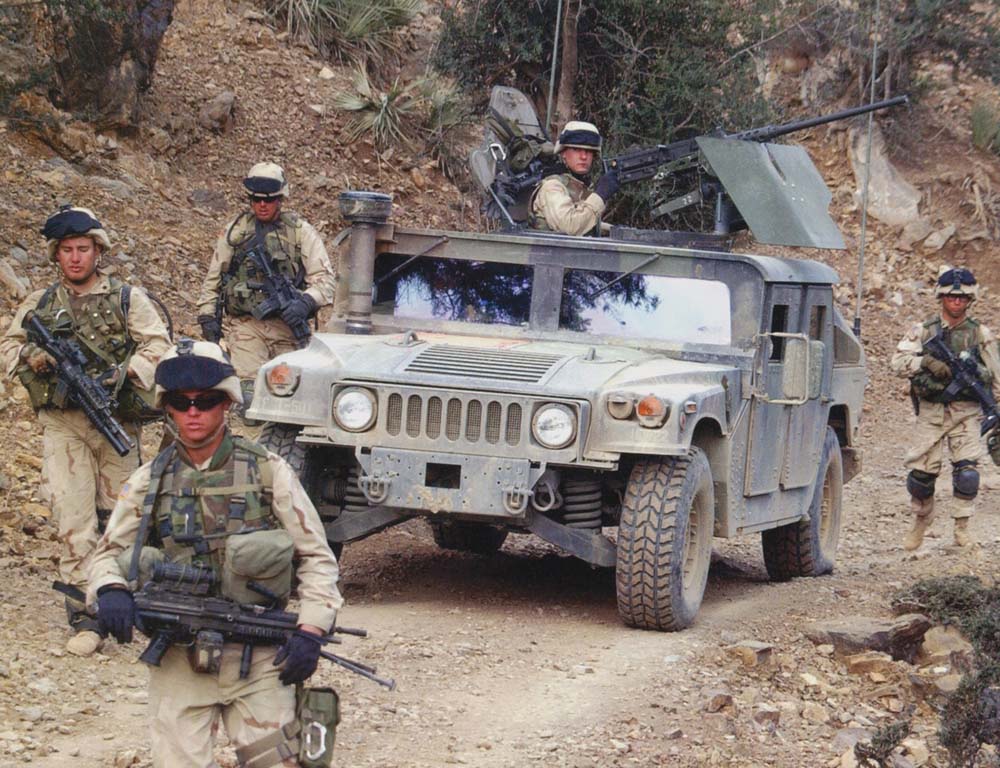

In response to a Taliban Insurgency that began in 2003, a large number of US Army and USMC combat units deployed to Afghanistan, all of which brought their various models of the HMMWVs, both armoured and non-armoured. US Army Special Forces member Eric Evans relates a story about his M1114 UAH encountering a large IED in Afghanistan in January 2003:

The explosion that hit us picked our vehicle up and tossed it more than 10 feet in the air. My teammates found pieces of the vehicle more than 150 metres away from the explosion. I ended up at the hospital and received 48 stitches and 9 staples in my head, and the driver ended up with a few stitches in his leg and a nice cut on his head. Amazingly, we all walked away . . . I then saw the vehicle [his unrepaired M1114 UAH] at the Association of the United States Army conference in Washington DC, and it was awe-inspiring to see how much damage the explosion had done to my vehicle, yet how little damage was done to the interior of the vehicle.

In an interview conducted in Afghanistan in June 2004 by a Marine Corps public affairs member with Marines from the 22nd Marines Expeditionary Unit (Special Operations Capable), every Marine present stated that the one vehicle that had been involved in every operation since they had arrived in the country in April 2004, from vehicular reconnaissance patrols to combat offensives, was an M1114 UAH, affectionately nicknamed ‘Alone and Unafraid’.

As the US Army planned for its part in Operation Iraqi Freedom in early 2003, it could not envision any requirement for the M1114 UAH. The unforeseen Iraqi Insurgency that began in the summer of 2003 resulted in a quick change of opinion about the usefulness of the vehicle. By April of the following year, there were approximately 2,500 units of the M1114 UAH in Iraq.

To fulfill the demand in Iraq for even more M1114 UAHs, the US Army placed a rush order in April 2004 for an additional 2,000 units of the vehicle. All were delivered before the end of 2004. Yet there were still not enough of them to meet the needs of the soldiers in Iraq. It was envisioned by the US Army in 2004 that it would need at least 8,000 units of the M1114 UAH to deal with the rising tempo of the insurgency.

In a 2004 US Army public affairs article, Gary Motsek, deputy director of Support Operations for the US Army Material Command, stated that the requirement for 8,000 M1114 UAHs in Iraq was once considered unthinkable. However, because it was easier to manoeuvre in some of the tight urban spaces within Iraq, the M1114 UAH became by default, in Motsek’s words, ‘the platform of choice’. Motsek went on to say, ‘If anybody would have told me a Humvee would be the platform of choice in war, I would have told them they’re crazy.’ By 2007, there were approximately 20,000 UAH in service overseas with the American military.

The M1114 UAH was a big improvement over early HMMWV armament carriers, but despite all the extra armour added to the vehicles, there were limits to what it could protect against, as there are with all AFVs. In early March 2005, General Michael Hagee, then commandant of the USMC, told reporters a fully armoured HMMWV had been, as he described it, ‘ripped apart, just torn apart’ by an Iraqi insurgent IED consisting of three 155mm artillery shells linked together to go off all at the same time.

Brigadier General William Cato of Marine Corps Systems Command described the evolving threats in Iraq to a Congressional House Armed Services Meeting in May 2005: ‘Insurgent IED threats once chiefly consisted of 60mm, 81mm mortar kinds of rounds.’ He then pointed out that the insurgents had begun using 122mm and 155mm artillery shells, as well as 500-pound bombs and double-stacked anti-tank mines to provide more explosive power for their IEDs. ‘As we’ve added armour they’ve added greater explosives,’ Cato told the Congressmen.

When the US Army ordered the non-armoured cargo/troop carrier models of the HMMWV in the early 1980s, they were considered rear-area non-combat vehicles. However, with the Iraqi Insurgency it soon became apparent that there were no non-combat rear areas, as is typical for asymmetric warfare. All American military vehicles and personnel were considered targets of opportunity by the Iraqi insurgents wherever they might be found.

Like the Vietnam War, the soldiers and the Marines on the ground in Iraq quickly developed a wide variety of improvised add-on armour kits for all of their nonarmoured wheeled vehicles, especially the HMMWV as it was one of the most common wheeled vehicles in Iraq in 2003. An impression of these improvised armour kits, sometimes nicknamed ‘Hillbilly Armor’ due to their make-shift appearance, comes from US Army Captain Jerry Diamond:

The quality of design and construction varies very dramatically, from fairly well manufactured to rolling death traps. As a rule, most of the steel is local carbon steel, about 4mm thick. It offers little protection from anything short of a thrown rock. Worse, when struck by a high-velocity round, not only will the round penetrate the thin steel plates, the steel itself will spall [break up into small fragments], adding to the danger for the soldiers inside the vehicles.

The US Army Research Development and Engineering Command (RDECOM) soon came up with its own version of an add-on armour kit for all the various HMMWVs, including armament carriers. They would refer to it as the Armor Survivability Kit (ASK), the first example of which showed up in Iraq in October 2003.

Major Dan Rusin, leader of the ASK team at Aberdeen Proving Ground, talked about the construction of the up-armour package in a US Army Public Affairs released article in 2004: ‘We tried an assortment of products from aluminum composites, a lot of fancy stuff. But we came back to the same armoured steel that you make tanks from.’

The downside of encasing the two-door and four-door unarmoured HMMWVs in the ASK was heat build-up, which soon became a serious issue in Iraq; it was solved by adding Red-Dot air-conditioning units to the vehicles.

In addition to its own in-house ASK, the US Army contracted with Armor Holdings, which had acquired the O’Gara-Hess & Eisenhardt Armoring Company in 1996, to provide an add-on armour kit for some versions of the unarmoured HMMWV cargo/troop carriers. The company referred to their product as the ‘lightweight HMMWV armoured demountable (HArD) kit’. It provided a superior level of protection than that offered by the US Army’s in-house developed ASK.

The HArD kit was also ordered by the USMC in late 2003 for some versions of its unarmoured HMMWV cargo/troop carriers. In addition, Armor Holdings added, at the service’s request, new ballistic windshields for their vehicles. Despite the addition of the HArD kits, it was not uncommon for Marines to add additional improvised armour to their vehicles.

In 2005, the USMC began the fielding of a new in-house developed add-on armour kit they named the Marine Armor Kit (MAK). The MAK started as a collaborative effort between the USMC and US Army, but the latter dropped out of the programme.

Unlike the HArD kits, the MAK was adaptable to all the various versions of the HMMWV. Major James Washburn, a Marine Corps System Command project officer who worked on the MAK programme describes the difficulties of developing it:

It’s a huge task to match armour protection against the evolving threat while staying within the carrying capacity of the wheeled vehicle fleet. You simply can’t retrofit a HMMWV to match the armour protection of a main battle tank. Our main objective is to make sure the Marines get the best possible protection in the time frame they need it.

Like the US Army’s in-house ASK, the MAK, when applied to the USMC HMMWV fleet in Iraq, created a serious problem for the crews with heat build-up inside their vehicles. This resulted in the quick addition of air-conditioning units to all HMMWVs that had the MAK.

Besides the HArD kits and their in-house MAK programme, the USMC had showed no interest in the M1114 UAH prior to the Iraqi Insurgency. Its outbreak pushed the senior leadership of the USMC to change their mind, and in 2004 they ordered 498 units of the vehicle from AM General. They were also provided additional M1114 UAHs from the US Army inventory and M1116 UAHs from the US Air Force inventory.

In a June 2004 interview conducted by USMC public affairs in Iraq, Gunnery Sergeant Paul L. Jones, a motor transportation chief with the 2nd Battalion, 4th Marine Regiment, stated the following: ‘Right now the battalion has seventeen M1116 uparmoured Humvees and ten M1114 heavy variant Humvees.’ His shop chief, Sergeant Jay C. Asland, stated that they had been very pleased with the performance of both types of Humvees: ‘These things are covered in armour. The doors, the under panels, and the side panels all are protected by thick steel.’ Asland went on to say: ‘The windows are made of glass that’s almost four inches thick.’

One of the most popular features the Marines found with being issued the M1114 or M1116 UAHs was their built-in air-conditioning. The biggest drawback to the new vehicles appears in a quote by Lance Corporal Philip E. Truman, who stated: ‘With all the communications equipment and the AC [air-conditioning] unit that take up so much space, they’re not very comfortable to ride in.’ While the ride might not be much fun in an M1151 or M1116 UAH, Truman went on to comment: ‘I’d rather be safer than comfortable.’

With the insurgents in both Iraq and Afghanistan constantly improving upon their anti-vehicle weapons, the US Army developed another quick-fix approach to better protecting their fleet of M1114 UAHs: Fragmentation Armor Field Kits (FRAGs).

The initial FRAG was labelled 1A. It was followed by FRAGs two through four. All were developed to counter under-vehicle explosions. None of them were easily identifiable on the M1114 UAH without close inspection – not until the advent of the interim FRAG 5 and then the standard FRAG 5, both of which can be identified by a set of thickly armoured doors.

Combat experience gained with the M1114 UAH during the early part of the Iraqi and Afghanistan Insurgencies was incorporated into a next generation HMMWV armament carrier designated the M1151 UAH. It entered into series production in 2005 and is based on the chassis of the newest version of the HMMWV built by AM General. It is known as the Reliability Enhanced M1100 Series HMMWV.

A sub-variant of the M1151 UAH is designated the M1167 TOW ITAS Carrier. Both were later upgraded to an A1 standard in 2009.

The factory-installed armour packages fitted to the M1114 UAHs were not capable of accepting add-on armour kits. The Reliability Enhanced M1100 Series M1151 and M1167 UAHs were originally designed to be fitted with mounting hardware able to accept various add-on armour kits. The American military refers to this as an ‘armour capable’ vehicle. Add-on armour kits are also classified by the American military as ‘scalable armour’.

The US Army eventually decided that it preferred the M1151 and M1167 series UAHs to come off the production line with a factory affixed base armour package, which AM General labels as the A Kit. It was designed to accept an additional add-on armour kit that AM General refers to as a B1 Kit.

According to AM General marketing literature, the B1 Kit can be either factory installed or field installed, and when combined with the A Kit provides both under-body mine and upper-body ballistic protection to the M1151A1 series UAHs. If the threat level decreases, the B1 Kit can be removed from the vehicles. There is also a B3 kit for the M1151A1 series UAHs consisting of perimeter armour, overhead armour and a rear ballistic bulkhead.

Other vehicles based on the Reliability Enhanced M1100 Series HMMWV include the M1165/M1165A1 and the M1152/M1152A1. The four-door M1165/M1165A1 is a command and control vehicle and the M1152/M1152A1 a multi-purpose platform that can be configured as a troop carrier, cargo carrier, or shelter carrier. The A through to B3 Kits were also designed to be mountable on the M1165A1 and M1152A1 if required.

Besides the A through to B3 Kits developed for the M1151 series UAH, there were also two FRAGs developed that could be fitted to the M1151 and M1167 UAH series, as well as the older generation M1114 UAH. These were labelled FRAG 6 and 7.

FRAG 6 could be identified by extremely large external boxes fitted to a vehicle’s doors. They were intended to protect the occupants of the vehicles from explosively formed penetrators (EFPs). However, it proved a failure in service because the external boxes did not prove durable enough in the field. Another problem was the extra width FRAG 6 added to the vehicles so fitted, thereby reducing their manoeuvrability in urban areas.

Due to the various design shortcomings of FRAG 6 it was replaced by FRAG 7 in 2009. The latter lacked the large boxes seen on the doors of vehicles fitted with FRAG 6. A key external identifying feature of those vehicles fitted with FRAG 7 was a removable overhead armour protection on existing OGP-K turrets. FRAG 7 overhead cover could not be installed on GPK turrets.

From a US Army public affairs article dated 9 April 2009 appears this extract regarding what the new turret design, which formed part of FRAG 7, brought to the M1114 and M1151 series UAHs:

FRAG 7 introduces the ARDEC [Armament Research, Development and Engineering Center] developed and Army Depot produced Overhead Cover (OHC), which provides the capability of the gunner to view the battlefield without compromising safety. Fitted with transparent glass, the OHC provides protection from the sun, while still allowing the gunner to maintain situational awareness.

In addition to the OHC, FRAG 7 also consisted of new more-durable tyres and wheel assemblies for the M1114 and M1151 series UAHs. Together these provided increased reliability compared to the tyre and wheel assemblies found on earlier models of the HMMWV series UAHs, which sometimes failed under hard usage.

The addition of ever more armour to the HMMWV design, despite the continuous upgrades and improvement to the vehicle’s chassis, has not been without problems, as can be found in a report issued by the US Army Program Manager: Light Tactical Vehicles, on 7 October 2011. In that report are a number of quotes from unnamed US Army soldiers on their impressions of the M1151A1 series UAHs:

1. The weight is too much for the engine. Engine parts are breaking because of the extra weight added.

2. The vehicle moves slower. The acceleration, ventilation and air conditioning is not good.

3. ‘The vehicle lacks power. It would stall or lose all power (pedal to the floor) and the truck goes nowhere during missions.

4. The vehicle’s acceleration is much worse and the brakes are not holding up. The vehicle is too heavy, and needs upgraded brakes.

For use by American military Special Operation Forces (SOFs) there is an armoured version of the M1165A1 command and control vehicle referred to as Ground Mobility Vehicle (GMV). The builder labels it as the ‘Special Operation HMMW2V’. As with the M1151A1 series UAHs, it came with the base A Kit and can be upgraded to the B1 or B3 Kit.

Depending on the user, the GMV has a number of slightly different designations. The US Navy SEAL variant is labelled as the GMV-Navy (GMV-N). Those employed by the US Army Rangers are referred to as the GMV-R, while those used by the US Army Special Operations Command for its Special Operation Forces (SOF) go by the designation GMV-S SOF. The UMSC has a version designated the GMV-M.

The US Army was well aware of the design shortcoming of the M1151 UAH series, as well as all the other variants that made up the aging HMMWV series. It had therefore long planned on acquiring a new series of 4 × 4 vehicles, which they went ahead and labelled as the Joint Light Tactical Vehicle (JLTV), the ‘joint’ in the title meaning that it is also intended for use by the other services, in particular the USMC.

Testing JLTV prototypes submitted by companies interested in winning a contract began in 2013. After extensive review, the US Army chose the JLTV submitted by the Oshkosh Corporation in August 2015. Plans call for the building of 55,000 units of the JLTV at an estimated cost of $30 billion. Production is scheduled to begin in 2018, with operational capability being attained the following year.

The JLTV series is comprised of two variants. A two-seat model referred to as the Combat Support Vehicle (CSV) is fitted with an armoured cab that has a rear platform able to accept a variety of loads, labelled ‘mission packages’ by the US military. The second is a four-seat weapon-armed model referred to as a Combat Tactical Vehicle (CTV). Both variants are able to be fitted with various up-armouring kits if required.

This prototype of the AM General Humvee armament carrier variant is armed with an automatic grenade launcher. External features that identify it as a prototype include the four windshield wipers and the horizontal engine grille work. Notice that AM General has stencilled the name ‘Hummer’ on the front bumper of the vehicle, a registered trademark of the firm. (AM General)

The vehicle pictured is the AM General prototype of their proposed Humvee TOW Missile Carrier variant. The engine grille work is now vertical, which is seen on all the different production versions of the HMMWV, both armoured and non-armoured. Not seen on this prototype are the three holes in the bumpers of production nonwinch-equipped vehicles. (AM General)

A photograph of a US Army M1025A0 Armament Carrier in Panama during Operation Urgent Fury in 1989, fitted with the basic armour package that can be identified by the X-shaped stampings on the doors. A key external spotting feature of all Humvee armament carriers is the thin armoured hatchback-like enclosure at the rear of the vehicle. (DOD)

In this posed picture taken during Operation Desert Storm in 1991 is a US Army M966A0 TOW Missile Carrier. The 5 foot 6 inch long 50lb TOW anti-tank missile is stored within a disposable launch tube that is manually inserted into the launcher unit tube seen in this picture prior to firing. The gunner on the vehicle is aiming the anti-tank missile with a 13-power daylight telescopic sight. (DOD)

In this dramatically-composed company marketing photograph is an M1026A1 Armament Carrier armed with a small-calibre machine gun. Unlike the non-ballistic front windshields on the A0 series of non-armoured HMMWVs, their armoured counterparts had ballistic windshields that consisted of a 2-inch-thick polycarbonate material that could stop bullet fragments. (AM General)

This picture taken during Operation Iraqi Freedom in 2003 shows a US Army M1025A1 Armament Carrier armed with a large-calibre machine gun. The A1 version of the HMMWV series was introduced into service with the American military in 1993, and the A2 version in 1995. The A2 models have a rear bumper added, which provides increased towing capacity. There were nineteen different variants of the A0 HMMWV series, thirteen with the A1 model and only nine with the A2 model. (DOD)

The USMC desired a slightly higher level of protection from bullet fragments for its armoured HMMWVs than the US Army. Therefore the doors on their A0 through A2 armoured variants were fitted with additional thin armoured plates that covered the X-shaped stampings, as seen on this M1045 or M1046 TOW Missile Carrier. (Michael Green)

This overhead view of a USMC M1043A2 Armament/TOW Missile Carrier shows the vehicle’s armament mounting kit featuring a 32-inch weapon ring with a pedestal mount and quick release cradle. This was the same armament mounting kit found on the A0 and A1 series of armoured HMMWVs employed by all the services. (DOD)

Shown during a training exercise is an M1043A0 or M1043A1 Armament Carrier in the foreground armed with a large-calibre machine gun. The vertical engine air intake tube located at the left-hand front side of the vehicle, and the engine exhaust extension coming out of the rear bottom of the vehicle on the right side, form part of the vehicle’s deep water fording kit and are only seen on USMC HMMWVs. (Michael Green)

Based on the chassis of the discontinued M1035 Shelter Carrier without a winch is this USMC anti-aircraft version of the HMMWV named the ‘Avenger’. Also employed by the US Army, the Avenger consists of a one-man, electrically powered turret armed with tow pods, each containing four heat-seeking surface-to-air missiles, and a large-calibre machine gun. (Michael Green)

Racing into action is this M1045 or M1046 TOW Missile Carrier with its crew at the ready during Operation Iraqi Freedom in 2003. The HMMWV is approximately 15 feet long, 7 feet wide and 6 feet tall. With its supplemental armour kit, the A2 model of the USMC armament/TOW carrier weighs in at about 10,300lbs. Maximum speed is listed at 60mph. (DOD)

The supplemental armour kit visible on this Humvee would mark it as belonging to the USMC at first glance. However, it lacks the deep water kit extensions seen on all USMC HMMWVs, making it a US Army M1025A2 Armament/TOW Missile Carrier. Where it acquired its supplemental armour kit is unknown. The strange-looking attachment fitted to the vehicle’s large-calibre machine gun is a blank-firing adapter employed during a training exercise. (Michael Green)

The up-armoured M1097 HHV (Heavy Hummer Variant) pictured was a private developmental venture by AM General in the early 1990s but not adopted by the American military. It was based on the chassis of the unarmoured M1097 HHV Cargo/Troop Carrier introduced into American military service in 1992. The following year, the improved M1097A1 version was introduced. (AM General)

A US Army M1114 UAH on patrol in Afghanistan. Protection for the machine-gunner is provided by the Gunner’s Shield Kit (GSK). The M1114 UAH came about because the US Army believed that the M1109 UAH was overloaded. To resolve this issue, the US Army asked for a similarly armoured version built upon AM General’s new more powerful M1113 ECH (Expanded Capacity Humvee). (DOD)

The M1114 UAH armour package was intended to provide protection from 7.62mm armour-piercing ammunition fired from ranges in excess of 100 yards. An under-armour plate, located under the front tyres of the vehicle, was supposed to protect against a 12lb mine blast. Here we see an M1114 subjected to a mine blast of unknown size at the US Army testing facility. (O’Gara-Hess & Eisenhardt)

Taking part in a driver’s training course is an M1114 UAH in the markings of the American-trained and equipped Iraqi Army. Prominent in this picture is the protruding engine grille, an identifying feature of all the HMMWV series vehicles, which are based on the chassis of the ECH (Expanded Capacity Humvee). The engine on the ECH series produces 190hp. (DOD)

On display at a museum is this near mint example of the M1114 UAH. Due to the high losses of machine-gunners on the M1114 UAHs fitted only with the forward-facing Gunner’s Shield Kit (GSK), a new open-topped turret kit, seen on the vehicle pictured, provided some armour protection for the machine-gunner’s sides and rear. It was referred to as the Gunner’s Protection Kit (GPK). (Brent Sauer)

An overhead photograph of the forward-facing Gunner’s Shield Kit (GSK) and the Gunner’s Protection Kit (GPK) on the turret of an M1114 UAH in Iraq. The vehicle’s weapon operator is manning an M240 machine gun, which fires a 7.62mm bullet. In theory, the M240 can fire 750 rounds per minute. The realistic rate of fire of the weapon is approximately 100 rounds per minute, to prevent it from overheating. (DOD)

Having been unloaded in Kuwait, a number of US Army M1114 UAHs are prepped for their journey to Iraq. Visible are the two rows of vents for the vehicle’s builtin air-conditioning unit located on the left-hand side of the vehicle’s hatchback enclosure, which are open in this photograph. The M1114 UAH is listed as having the ability to accelerate from 0 to 50mph in 26.1 seconds. (DOD)

The US Air Force adopted a slightly modified version of the US Army’s M1114 UAH they labelled as the M1116 UAH. An example is shown being decontaminated during a Nuclear, Biological and Chemical (NBC) training exercise. The turret seen in this photograph was unique to the M1116 UAH and consisted of an upper and lower portion. Pictorial evidence indicates that the upper portion of the turret was not always fitted. (DOD)

On duty at an air base in Iraq is a US Air Force M1116 UAH. They are employed by US Air Force Security Force units. Unlike the hatchback rear enclosure of the M1114, that of the M1116 is a square-back enclosure as seen in this photograph. The turret on the vehicle is improvised and was named the ‘Chavis Turret’ after an airman weapon operator on an M1116 was killed by a sniper during the Iraq Insurgency. (DOD)

Patrolling an urban area in Iraq is a trio of US Air Force M1116 UAHs, as is evident by the square-back enclosure barely visible on the vehicle in the foreground. The vehicles are fitted with the Objective Gunner’s Protection Kit (O-GPK) with the Overhead Cover (OHC) installed. The device projecting out of the front of the vehicle is a Rhino Convoy Protection Device. (DOD)

Another US Air Force Humvee variant is the M1145 UAH, which provides both the mobility and protection needed by the US Air Force Enlisted Terminal Attack Controllers (ETACs). Besides supporting battlefield commanders with close-air-support guidance, they also have a level of expertise in both artillery and naval gunfire support. (DOD)

An example of the improvised armour arrangements that cropped up on many American military non-armoured and armoured HMMWVs with the beginning of the Iraqi Insurgency in 2003. Visible are locally obtained steel armoured plates mounted on either side of the rear compartment of a HMMWV cargo/troop carrier, as well as locally built steel armoured doors. (DOD)

The US Army’s short-term solution to the need for better-protected HMMWVs in Iraq was the application of something referred to as the Armor Survivability Kit (ASK), seen here on an M1025 Armament Carrier. The four-door ASK added 1,300lbs to a HMMWV armament carrier, such as the M1025 or M1026. Besides new armoured doors, the ASK included under-body protection. (Brent Sauer)

With the encasing of the occupants of HMMWVs in Iraq with the Armor Survivability Kit (ASK) came the need to provide them with air-conditioning. To address this issue, the US Army purchased commercial truck air-conditioning units from the Red Dot Corporation. An example of the Red Dot air-conditioning system is shown mounted on the rear hatchback enclosure of an M1025 Armament Carrier. (Brent Sauer)

This US Army M1025 or M1026 HMMWV armament carrier in Iraq is fitted with the Armor Survivability Kit (ASK). Notice the thickness of the ballistic glass in the foreground that forms part of the armoured door, an external spotting feature of the ASK. The ASK was designed to provide protection for vehicle occupants from both 7.62mm ammunition and improvised explosive devices. (DOD)

Taken during the Iraqi Insurgency is this picture of a US Army HUMMWV two-door cargo/troop carrier fitted with ASK. On either side of the rear compartment of the vehicle are what appear to be locally acquired scrap steel plates held in place by brackets. For additional protection, the soldiers have placed Kevlar blankets on the outside and inside of the rear compartment. (DOD)

Rolling down an Iraqi road is a two-door USMC cargo/troop carrier fitted with the Marine Corps Armor Kit (MAK). The protection provided by the MAK comes from a combination of different types of steel armours and thick ballistic glass all around the cab. Instead of the single thick ballistic glass vision port seen in the doors of US Army ASK-equipped HMMWVs, the MAK-supplied armoured doors each have two ballistic glass vision ports. (DOD)

An overhead photograph of a two-door USMC cargo/troop carrier fitted with the Marine Corps Armor Kit (MAK). Notice the Red Dot air-conditioning unit on the cab roof of the vehicle. The MAK was designed to be modular in design and could provide a minimum level of protection, with 1,800lbs of extra armour protection for cargo/troop carriers. (DOD)

Marines with guns drawn dismounting from an M1043A2 Armament Carrier fitted with the Marine Armor Kit (MAK). The tall vertical turret design was unique to the USMC armament carriers fitted with the MAK. Full protection for armament carriers fitted with the MAK came at the price of an extra 3,400lbs. (DOD)

A young Marine crouched in front of a USMC M1114 in Iraq. The elaborate turret on the roof of the vehicle is referred to as the Marine Corps Transparent Armored Gun Shield (MCTAGS), which replaced the rather crude turret design that came with the MAK. The two thick ballistic glass vision ports seen on each of the two armoured doors identify it as being fitted with the MAK. (DOD)

The replacement for the M1114 UAH was the M1151 series UAH, seen here during a US Army training exercise. It was intended to be built with the basic armour package seen on this vehicle, labelled as the ‘A Kit’. Notice it is fitted with the original bullet-resistant (not bullet-proof) doors of the A0 through A2 legacy HMMWV series armament/TOW carriers. (DOD)

At a staging area are a number of US Army National Guard M1151 series UAHs. They are fitted with the up-armour ‘B3 Kit’, as indicated by the single thick horizontal oriented ballistic glass vision port in each armoured door. In comparison, the ballistic glass vision ports that came with the US Army ASK or the UMSC MAK were both smaller and vertically-oriented. (DOD)

This USMC M1151A1 UAH is fitted with the up-armour B3 Kit. An identifying feature of the entire M1151 series UAHs is the wire-mesh covering for the horizontally-oriented air-conditioning intake located at the rear of the cargo bay just above the rear tyre. There is another one in the same location on the other side of the vehicle. (DOD)

In this picture taken during a training exercise is a USMC M1151A1 UAH in the foreground. It is fitted with the up-armour B3 Kit that allowed for the ballistic glass windows to be opened by being slid out sideways on an upper and lower track. The vehicle is fitted with the Marine Corps Transparent Armored Gun Shield (MCTAGS). (DOD)

Moving through a field during a training exercise is an M1167A1 UAH in the foreground, fitted with the up-armour B3 Kit. The M1167A1 UAH is a sub-variant of the M1151 UAH series. It is armed with the TOW Improved Target Acquisition System (ITAS). Prior to firing the missile, the operator lowers the rear armour panel of his open-topped turret to vent the back-blast from the weapon. (DOD)

Despite the outstanding mobility capabilities of the entire HMMWV series it is possible to render them immobile, as is evident with this picture of a US Army M1151A1 UAH in Afghanistan, fitted with an up-armour B3 kit. Located at the rear of the vehicle is a Counter Remote Controlled Improvised Explosive Device (RCIED). On the roof of the vehicle is the open-topped Objective Gunners Protective Kit (O-GPK). (DOD)

Driving off a US Navy landing craft is a USMC M1151A1 UAH fitted with the Marine Corps Transparent Armored Gun Shield (MCTAGS). The vehicle is fitted with the up-armour B3 kit. To facilitate the driving of its HMMWV fleet on and off the steep ramps of US Navy landing craft, the USMC had all of them constructed without the rear bumpers which appear on the other services, HMMWV inventories. (DOD)

This photograph taken at a US Army reclamation yard in Iraq shows the door of a badly-damaged M1151A1 UAH being torn-off by a steel cable during a training exercise. What is interesting in this picture is the improvised transparent armour cover fitted over the standard Gunner’s Protection Kit (GPK). The improvised turret roof was made from the ballistic windshields of destroyed M1114 series UAHs. (DOD)

Having just arrived at its designation by ship, this M1151A1 UAH has not yet been issued to its unit. The vehicle is fitted with the up-armour B3 Kit and features a factory-designed and built FRAG 7 turret arrangement. This consists of the open-topped Objective Gunner’s Protection Kit (O-GPK) fitted with a new overhead armour component labelled as the Overhead Cover (OHC). (DOD)

Other than developing ever-more elaborately constructed turrets for the weapon operators on armoured HMMWVs such as the M1114 and M1151 UAHs, the US Army adopted for some of its UAH inventory a device pictured here known as the Common Remotely Operated Weapons Station (CROWS). It can be fitted with a variety of weapons. (DOD)

As seen in this picture, the Common Remotely Operated Weapons Station (CROWS) mounted on the M1114 UAH is operated by a gunner located in a rear passenger seat of the vehicle. The weapon mount is stabilized and provides a fire-on-the-move capability. The mount includes a thermal camera as well as a laser rangefinder. (DOD)

Because the insurgents in Iraq never stopped developing ever-more powerful roadside IEDs, a call came to up-armour the doors of the M1114 UAHs. This prompted the development of an interim FRAG 5, seen here on the door of a M1114 UAH pictured somewhere in Iraq. The turret on this vehicle is the standard open-topped Gunner Protection Kit (GPK) fitted with a non-standard transparent gun shield. (DOD)

This picture taken in Iraq is of an M1114 UAH in UMSC service. It can be readily identified as an M1114 UAH rather than the M1151 series UAH by the air-conditioning vents on the right side of the vehicle’s rear hatchback enclosure. The vehicle is fitted with the standard FRAG 5, identified by the thick armoured doors, which allowed room for the ballistic glass windows to be rolled down. (DOD)

An Iraqi Army Special Operation Forces (SOF) modified M1114 UAH with FRAG 5 that may have been passed down to them by an American SOF unit. The standard rear hatchback enclosure has been removed, and in its place is an open-topped armour-protected seating area with steps at the rear of the vehicle. The vertical door latches on the FRAG 5 are unique and are a spotting feature. (DOD)

A USMC training exercise in Iraq during the insurgency; notice the lack of a magazine in the Marine’s M4 rifle seen in the foreground of the picture. In the background is an M1114 UAH fitted with FRAG 5. On the roof of the vehicle is the Objective Gunner’s Protection Kit (O-GPK), with an improved sun shield that also made it harder for enemy snipers to identify the weapon operator. (DOD)

Two USMC HMMWVs being readied for loading upon a US Navy transport ship. One is a four-door M1165A1 and the other a two-door M1152A1. Both are fitted with the maximum up-armour ‘B-3 Kits’. The M1165A1 is classified as a command and control vehicle by the American military. The M1152A1 is suitable for being employed as a troop carrier, cargo carrier or shelter carrier. (DOD)

The widespread use of IEDs by the enemy in both Iraq and Afghanistan pushed American Special Operation Forces (SOFs) to take into service an armoured HMMWV based on the M1165A1. It is designated the Ground Mobility Vehicle (GMV). The example pictured belongs to the US Navy SEALs and is labelled as the GMV-N (Navy). (DOD)

The American military’s replacement for its HMMWV legacy fleet is referred to as the Joint Light Tactical Vehicle (JLTV). Pictured are three different versions of the same vehicle that were submitted by Lockheed Martin for US Army consideration as the JLTV. The JLTV contract calls for as many as 55,000 units of the vehicle to be built in two different models. (DOD)

Undergoing US Army testing is the Oshkosh Corporation vehicle that was chosen by the US Army in late August 2015 as the future Joint Light Tactical Vehicle (JLTV). In the configuration shown it is labelled as a Combat Tactical Vehicle (CTV). Based on the same chassis would be another variant referred to as the Combat Support Vehicle (CSV). (DOD)